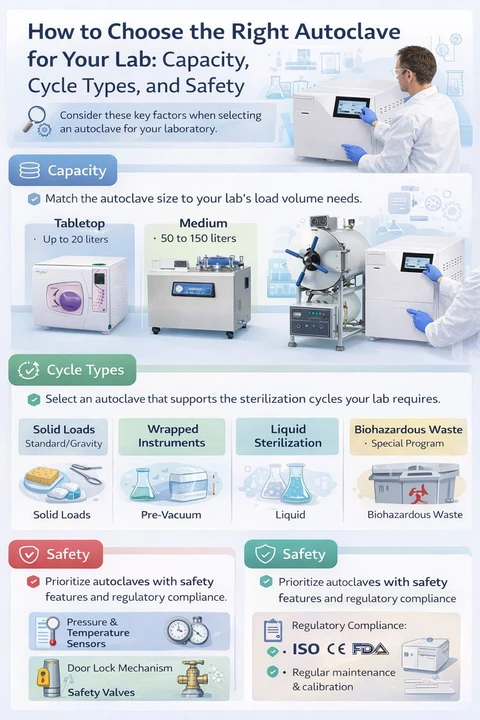

How to Choose the Right Autoclave for Your Lab: Capacity, Cycle Types, and Safety.

An Autoclave is not just a hot metal box, it's the final safety gate of your lab. If it's the wrong type, the wrong size, or missing the right cycles, the result isn't just a failed run.It can mean contaminated waste leaving the lab labelled as safe, instruments going into use without true sterilization, failed audits, shutdown benches and expensive repeat work. One weak Autoclave choice can quietly undermine good SOPs, skilled staff and high-quality science, which is why selecting the right unit isn't a minor purchase decision; it's a core decision about safety, reliability and trust in your results.

Autoclave Selection: Capacity, Cycles & Safety

Start With the Load: What Are You Really Sterilizing?

Before you look at model names or chamber size, start with one simple point: what will you sterilize most often?

Different loads need different cycles and settings, so knowing your main load types helps you choose the right Autoclave faster and avoid the wrong option.

Common load types and what they need

Main load type | Typical examples | What the Autoclave must handle |

Solid instruments & glassware | Flasks, beakers, metal tools, pipette tips, trays | Reliable steam penetration and good drying |

Liquids & media | Media bottles, buffers, reagents, saline, water | Gentle heating/cooling, liquid cycles, slow exhaust |

Biohazard waste | Contaminated plates, tubes, tips in bags | Robust sterilization, safe steam/air handling |

Wrapped / porous loads | Wrapped sets, textiles, filters, porous materials | Pre-/post-vacuum cycles for air removal and strong drying |

Take a week and simply note what goes into your Autoclave and how often. That load map becomes your first filter when you compare models.

Common Autoclave Loads

Capacity Planning That Actually Works

Capacity is not just the number of litres. It's about how many properly loaded, fully finished cycles you can complete on your busiest day without creating a waiting line. A chamber may look big on paper, but it can still feel small if your loads are bulky, wrapped, or need extra drying time. The right capacity keeps sterilization running smoothly in the background, no delays, no rushing, and fewer repeat cycles.

Think about your real workload: how many loads do you run on a normal day and on a peak day? Do people end up waiting because the Autoclave is full again? Do you ever pack items too tightly just to make them fit? Also consider growth will your work increase in the next 3-5 years? These points quickly show whether you truly need more capacity, better scheduling, or a cycle/load mismatch.

Verifying Loads Before Sterilization

A simple rule of thumb: Peak daily loads x 1.3-1.5 = practical chamber capacity you should plan for.That 30-50% buffer covers peak-day traffic, re-runs, longer liquid cycles, and time lost to cooling and safe unloading.

If you're always playing Autoclave Tetris, your chamber is probably too small or your load mix is not efficient. Overpacking blocks steam circulation and often causes wet loads or uneven results. On the other hand, if you run one small load a day in a very large chamber, you may be paying more than needed in purchase cost, power use, and maintenance. The best choice is the one that fits your peak workload, cycle time, and future growth, while still allowing correct loading and reliable sterilization every day.

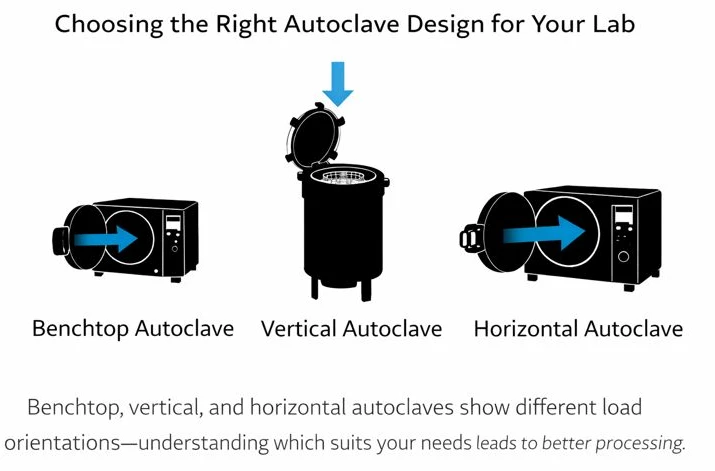

Choose the Right Autoclave Format

Once you know what you sterilize and roughly how much, the next step is to format how the Autoclave sits in your space and how you load it.

Autoclave design matters just as much as capacity because it affects how well the unit fits your space, how safely staff can load and unload it, and how quickly you can finish your daily cycles.

Benchtop (tabletop) Autoclaves are ideal for small clinics, dental practices, and compact labs where floor space is limited. They are mainly used for wrapped instruments, small tool kits, and small glassware.

Laboratory Vertical (top-loading) Autoclaves are a good fit for labs that often sterilize bottles, media, and waste bags. They are also useful when floor space is limited, but you have enough height to load from the top.

Laboratory Horizontal (front-loading) Autoclaves are ideal for busy labs because shelves and trays make loading easier and safer, keep loads better organized, and reduce the time spent handling items when you run many cycles each day.

Medical and Dental Autoclaves , especially Class B pre and post-vacuum models, are best when you need to sterilize wrapped or porous items, because they remove air properly and dry the load well for reliable, consistent sterilization.

Hot Air Sterilizers support specific cases where dry heat sterilization is preferred or required, and they are typically used as a complement rather than a replacement for steam sterilization.

Different Types Of Autocalves

The best format is the one your team can use consistently every day, with comfortable loading height, easy tray handling, and the right cycle capability for your most common loads.

Pick a format that makes daily work easier for your staff: loading height, tray handling and access matter just as much as the spec sheet.

Autoclave Types and Loading

Cycle Types

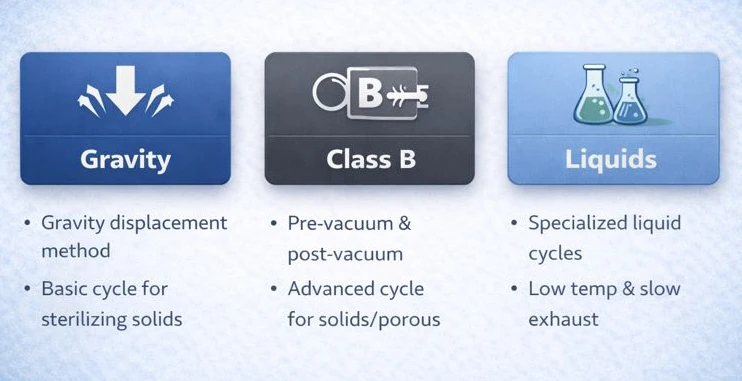

Autoclaves don't all sterilize in the same way because the cycle type decides how air is removed, how well steam gets into the load, and how pressure is released at the end. Choosing the right cycle makes sterilization more dependable, keeps loads safer, and helps avoid common issues like wet packs or liquids boiling over.

Gravity cycles

Gravity (displacement) cycles work by letting incoming steam push the air out through the drain. They are simple and reliable, and they usually work well for unwrapped metal tools, basic lab items, and unwrapped glassware where steam can reach all surfaces easily.

Pre-Vacuum / Post-Vacuum (Class B) cycles

Pre-Vacuum / Post-Vacuum (Class B) cycles use vacuum pulses to remove trapped air before steam enters, and they often include vacuum drying. They are important for wrapped instruments, textiles, porous loads, and surgical sets where trapped air can stop steam from reaching all areas.

Liquid cycles

Liquid cycles are made for media, buffers, and other liquids in bottles. They use gentle heating and a slow exhaust to reduce boil-over, prevent broken glass, and avoid loss of liquid volume.

Cycles Type

Quick mental guide:

Mostly unwrapped solids - gravity cycles are often enough.

Wrapped/porous loads - you'll want Pre-Vacuum Class B capability.

Lots of media and liquids - you must have reliable liquid cycles.

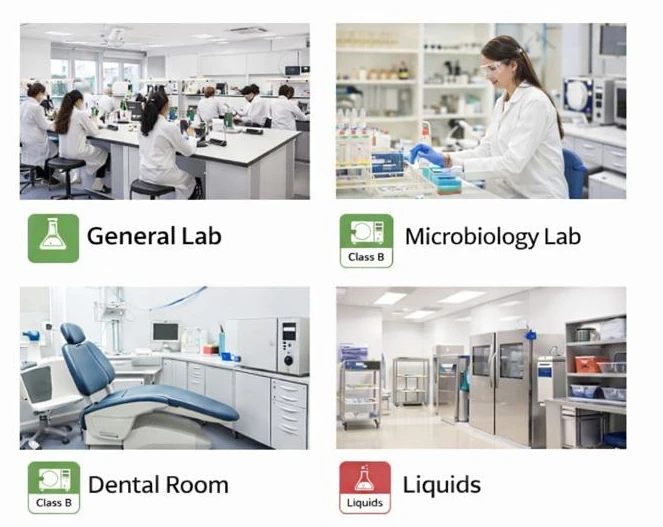

Matching Autoclave Style to Your Lab

Now combine load, capacity, format and cycles into something practical. Different labs naturally match different Autoclave styles.

Typical lab scenarios and good matches

Lab scenario | Main loads | Recommended Autoclave style |

Teaching / small research lab | Glassware, small media batches, light waste | Benchtop or small vertical with gravity + liquid cycles |

Microbiology / analytical lab | Regular media, glassware, biohazard waste | Medium Vertical or horizontal lab Autoclave |

Dental / small medical practice | Wrapped instruments and small packs | Class B benchtop with strong Pre-Vacuum + drying |

Hospital CSSD / central sterilization | High-volume wrapped sets, textiles, instruments | Large Horizontal / Medical Autoclave with advanced Pre-/Post-Vacuum cycles |

If you read down this table and think that sounds like us, you already have a strong hint about which family of Autoclaves to focus on.

Applications Of Autoclaves

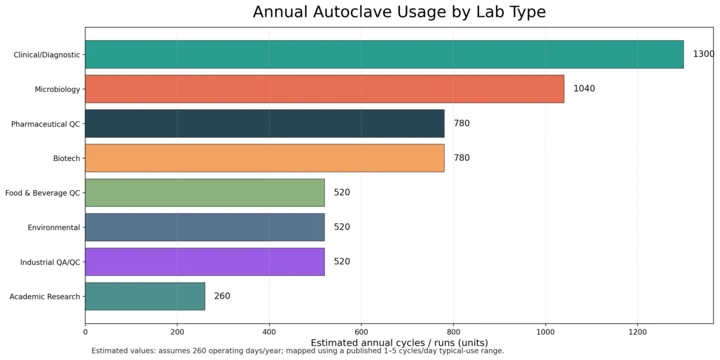

Annual Autoclave Runs By Lab

Performance Specs That Matter

Specification sheets can be overwhelming, but a few performance specs really make a difference in daily use:

Temperature & pressure range

Make sure the Autoclave can reach the temperatures your lab really needs 121°C for most routine loads and 134°C for faster, higher-assurance cycles. Having the correct range helps you follow your protocols exactly and avoids using almost right settings that can weaken sterilization results.

Autoclave Cycle Monitor

Warm-up and total cycle time

Don't look only at the sterilization time. Check the full cycle time warm-up, holding/exposure, exhaust, and cooling. A faster, well-designed full cycle means less waiting, more loads completed in a day, and fewer bottlenecks in busy labs.

Drying performance

Drying is very important for wrapped instruments and porous loads. If items come out damp, you can get wet packs and unsafe storage. A strong Post-Vacuum drying step helps loads finish clean and dry, ready to store or use right away without extra drying on the bench.

Chamber material and build quality

A stainless-steel chamber lasts longer and resists rust better, especially when the Autoclave runs often and is exposed to heat and steam every day. Also check practical build points like strong hinges, proper door/lid alignment, and a secure locking system; these directly impact safety and long-term reliability.

Control system and programmability

A clear screen and easy controls make the Autoclave simpler to use every day and help reduce mistakes. A good unit lets you save common programs, quickly choose the right cycle (gravity, pre-vac, liquid), and clearly show alarms and error messages so problems are easier to fix and downtime stays low.

Focus on what affects waiting time, failure rate and result reliability, not just every technical number.

Safety Features

Autoclaves combine heat, pressure and potentially infectious material. Safety for users and the environment is essential.

Safety Feature | Why It Matters |

Pressure-activated door lock | Prevents opening under pressure |

Over-pressure protection / safety relief valve | Protects from dangerous pressure rise |

Over-temperature protection | Prevents overheating and damage |

Low-water protection | Protects heaters and avoids unsafe dry heating |

Audio-visual alarms | Alerts users before failure escalates |

Controlled exhaust for liquids | Prevents boil-over and burns |

A safe Autoclave protects your staff, your building and your reputation.

Choose With Confidence

Your Autoclave is more than a hot chamber; it plays a big role in how safely and smoothly your lab runs. The best option is not always the biggest or the most advanced model, but the one that matches your load types, daily workload, lab space, and safety needs so well that it fits naturally into your routine.

When you start by listing what you sterilize, plan the right capacity, choose the right Autoclave type and cycle options, and confirm safety and installation needs early, you can avoid daily delays and sudden breakdowns.Instead, your Autoclave becomes a dependable workhorse that keeps instruments, media, and waste moving on time.

If you want practical help choosing the right Autoclave for your workload, Get in touch through our website for clear guidance on the best Benchtop, Vertical, Horizontal, Class B, or Medical A

Autoclave options for your lab.

You May Also Like