From Manual to Semi-Auto to Fully Auto: How Far Should Your Lab Go?

Automation is a big topic in labs today. Everywhere you look, there are systems that promise faster results, fewer mistakes, and less manual work. But choosing automation isn't about buying the most advanced machine you can find. It's about picking the right level of automation that matches your lab's daily workload, budget, and future plans.

Some processes really benefit from being automated, while others work just fine staying manual. Not every lab needs a fully automatic setup. The real question is how much automation makes sense for your lab and where should you stop so that technology helps, instead of becoming an expensive burden?

Understanding the Automation Spectrum

Laboratory automation isn't just one big jump it's more like a range of options. On one side, you have manual systems, where people do most of the work and the instrument is just a tool. In the middle, there are semi-automatic systems that help with repetitive or time-consuming steps. On the other side, you have fully automatic systems that can run most of the process on their own with very little human involvement.

All three levels can be useful, depending on the type of lab and the amount of work you do. Choosing the right level of automation can make a big difference to how fast you work, how reliable your results are, and how much it costs to run your lab day-to-day.

Manual To Fully Automatic

Comparison Table For Manual vs Semi-Automated vs Fully Automated

When you're deciding how much to automate, it helps to see manual, semi-automated and fully automated systems side by side. Each level changes how much the operator is involved, how fast you can work, how consistent your results are, and how much you spend on equipment and maintenance. The goal isn't to always move to the highest level, but to find the point where automation actually supports your workload, staff and budget instead of complicating them. The comparison below gives a quick overview of how the three options differ in day-to-day lab use.

Aspect | Manual Systems | Semi-Automated Systems | Fully Automated Systems |

Operator involvement | High | Moderate | Minimal |

Flexibility | Very high | High | Limited |

Throughput | Low to moderate | Moderate to high | Very high |

Consistency | Operator-dependent | Improved consistency | Highly consistent |

Cost (initial) | Low | Medium | High |

Maintenance complexity | Low | Moderate | High |

Ideal for | Research, teaching, low volume labs | Growing labs, QC, routine testing | High-volume clinical and industrial labs |

Manual Systems for Maximum Control and Flexibility

Manual equipment remains the backbone of many laboratories, especially in research, education, and low-volume testing environments. These systems give operators full control over every step, making them ideal for method development, variable workflows, and experimental work. When you are still fine-tuning a protocol, testing new reagents, or handling unusual samples, it's often easier to adjust settings, timing, and technique on a manual system than to constantly reprogram an automated one. Because they have fewer electronic and mechanical parts, manual systems are typically more affordable, easier to install, and simpler to maintain. A basic centrifuge , spectrophotometer, microscope , or manual pipette can often be kept in service for many years with minimal downtime. They also support training and skill development: students and junior staff learn the underlying technique instead of pressing a button and trusting the result. This hands-on understanding is valuable when something goes wrong or when results look suspicious and need to be checked.

At the same time, manual workflows have natural limits. As sample volumes increase, they become time-consuming and physically demanding, and the quality of results depends heavily on the person doing the work. Fatigue, distraction, or differences in technique between staff can lead to variability in timing, pipetting and reading, which shows up as inconsistent data. For this reason, even labs that value flexibility often keep manual systems for special tasks, backups and teaching, while gradually moving high-volume, repetitive tests to semi-automated or fully automated platforms.

Manual Testing

Semi-Automated Systems for Smart, Balanced Workflows

Semi-automated systems are often the most practical choice for growing laboratories. These instruments take over the steps that are repetitive, time-sensitive or calculation heavy, while the operator still handles sample preparation, loading and overall supervision. This makes them ideal for labs that have outgrown purely manual methods but are not yet ready financially or operationally for a fully automated platform.

In day-to-day work, semi-automated systems might have time reactions, control incubation , measure signals (like absorbance or clotting time) and automatically calculate final results based on stored methods and calibrations. The user still decides which test to run, checks samples, and reviews results, but no longer has to watch a stopwatch or do calculations on a calculator or in Excel. This reduces fatigue, cuts down on common errors and makes it easier to train new staff, because the instrument guides much of the process.

Semi-Automatic Analyzer

For many quality control, clinical, and applied research labs, this level of automation strikes the right balance between efficiency, cost and control. Instruments are usually more affordable and simpler to maintain than fully automatic systems, yet they offer a big improvement in consistency and throughput over manual workflows. The main limitation is that some manual steps remain, especially pipetting and sample loading, so there is still a ceiling on how far you can push volume. When those instruments are running near full capacity every day, it's often a sign that your lab may be ready to consider selective upgrades to fully automated systems in the most heavily used areas.

Fully Automated Systems That Keep Your Lab Running Smoothly

Fully automated systems are designed for laboratories with high, stable and time-sensitive workloads. Once samples and reagents are loaded and the worklist is set, instruments such as a fully automatic biochemistry analyzer, automated coagulation analyzer or walk-away hematology analyzer can run large batches or even continuous streams of tests with minimal human intervention. They handle sampling, dilution, mixing, incubation, measurement, result calculation and often quality control checks according to pre-validated protocols. This takes much of the day-to-day routine work off your staff and turns the analyzer into a true workhorse that can operate for long stretches with only occasional user input.

In clinical diagnostics, industrial testing and large centralized labs, this level of automation is especially valuable. Fully automated systems like auto chemistry analyzers, automated solid phase extraction systems and automatic glassware washers provide high throughput, strong repeatability and built-in traceability. Many connect directly to LIS/LIMS, use barcodes for sample identification, track reagent usage, and store audit trails for every run. This makes it easier to meet accreditation standards, respond to audits, and compare historical data. With integrated QC, automatic flagging of abnormal results and standardized workflows, they also reduce the risk of human error in repetitive routine testing.

Fully Automated Analyzer

However, full automation comes with trade-offs. These systems require higher upfront investment, stable power and environmental conditions, and enough space for the instrument, consumables and service access. They also need trained personnel for daily maintenance, troubleshooting, calibrations and software management whether it's for a fully automatic biochemistry analyzer, an automated blood culture system or a high-capacity auto glassware washer . Method changes are usually more structured and take longer to validate than on manual or semi-automatic setups. For labs with low or highly variable volumes, a fully automated system can be underused and expensive to keep running. For high-volume, routine environments, though, a well-chosen fully automated system can transform operations shortening turnaround times, freeing staff for higher-value tasks, and delivering a more consistent quality of results day after day.

Example 1: Clinical Chemistry / Biochemistry

Manual chemistry (basic spectrophotometer)

A technician pipettes samples and reagents into cuvettes, mixes by hand, incubates with a stopwatch and then reads absorbance on a simple spectrophotometer . Calculations (factor, standard curve, dilution) are done on a calculator or in Excel, and results are written or typed into the LIS.

Best for: very small labs, teaching labs, method development.

Semi-automatic chemistry analyzer

The user still pipettes samples and reagents, but into the analyzer cuvette or flow cell. They select the test on the screen; the instrument controls timing, measures absorbance at the right wavelength, applies the stored calibration, and directly displays or prints the concentration. Many common methods are stored as programs, so staff don't recalculate each time.

Best for: growing labs and small/medium hospitals that want consistent results without full automation cost.

Fully automatic biochemistry analyzer

Technicians place barcoded tubes into racks, ensure reagents, controls and calibrators are loaded, and start the run. The analyzer identifies each sample, aspirates and dilutes it, mixes reagents, incubates, measures, checks QC rules and sends results straight to the LIS. Staff mainly load, unload, respond to flags and maintain the system instead of running each test step by step.

Best for: high-volume hospital or reference labs where throughput and standardization are critical.

Example 2: Solid Phase Extraction / Sample Preparation

Manual SPE cartridges

For manual solid phase extraction, the operator conditions each cartridge with solvents, loads samples by pipette, controls flow with a stopcock or gentle vacuum, washes and elutes manually into tubes. Every step's timing and flow rate depend on the person doing it, which can affect recovery and reproducibility.

Best for: low-volume labs, flexible method development and occasional special samples.

Manual Solid Phase Extraction System

Semi-automatic vacuum manifold.

Here, the cartridges are still loaded by hand, but a controlled vacuum or pressure system sets a more constant flow rate and timing. Some manifolds include timers or flow control so each step is more reproducible, even though the operator still adds solvents and samples manually.

Best for: labs with moderate volume that want better consistency but still need flexibility to change methods.

Fully automatic SPE system

An automated SPE workstation uses a robotic arm or multi-channel head to condition cartridges, load samples, perform washes, elute into specific wells or tubes and sometimes evaporate and reconstitute. Methods are stored as programs and run with very little intervention once samples are loaded.

Best for: clinical tox, environmental and pharma labs with high sample numbers and strict reproducibility requirements.

Automated Solid Phase Extraction System

Example 3: Coagulation Testing

Manual coagulation (tilt-tube method)

The technician mixes plasma and reagent in a tube, starts a stopwatch, gently tilts the tube and stops timing when they see a visible clot. The clotting time is then converted to a result by hand or simple chart.

Best for: low-resource settings, teaching and rare backup situations.

Semi-automatic coagulation analyzer

The operator loads plasma and reagent into the cuvette, selects the assay and lets the analyzer detect clot formation electronically. The system measures clotting time, applies calibration and displays PT, APTT or other results automatically. Some models print results and basic QC.

Best for: small and mid-size labs that run regular coagulation tests but don't have the volume or budget for a large fully auto system.

Fully automatic coagulation analyzer

Samples are loaded in racks or carousels; reagents and controls are onboard. The analyzer aspirates samples, performs multiple tests in parallel, applies QC and sends validated results straight to the LIS. Multiple channels allow continuous loading and high throughput.

Best for: busy hospital and reference labs where coagulation is a core, high-volume service.

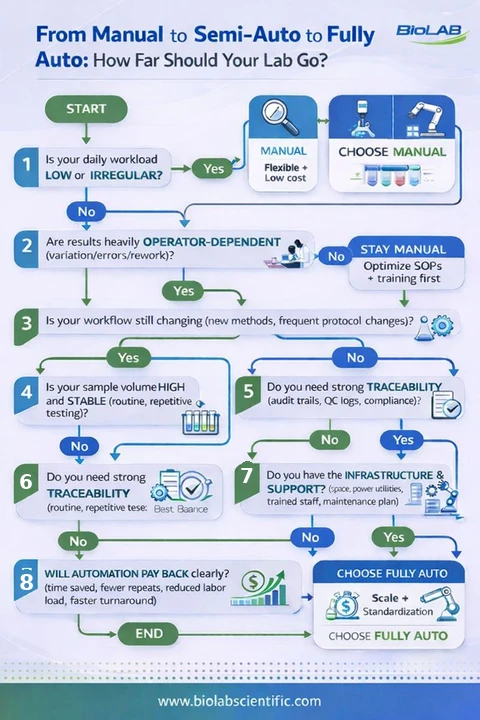

Upgrading in Steps Instead of Jumping Straight to Full Auto

Jumping straight from fully manual work to a big, fully automated system can look exciting, but for many labs it's a big risk in terms of money, technology and how people work day to day. A safer and smarter way is to upgrade in small steps, using your own lab's data to decide when it really makes sense to move to the next level. Instead of asking, Can we afford a fully automatic analyzer,start by asking, Where are we struggling the most right now, time, errors, or staff workload? and focus on automating that problem first.

Lab Automation Decision Map

A good first step is to find your main bottleneck. It might be endless pipetting in chemistry, timing clots by hand in coagulation , or doing the same sample prep over and over. Once you know the weak point, move that area from manual to semi-automatic first. This alone can remove a lot of timing and calculation errors, make turnaround times more stable, and reduce pressure on your team. Over the next 6-12 months, keep an eye on a few simple things: how many samples you run per day, how often you repeat tests, how much overtime staff do, and how often you still fall behind.

If, after that, your workload keeps growing and your semi-automatic instruments are always running at or near full capacity, you now have real proof that a fully automatic system is the next sensible step, not just a fancy upgrade. You'll know roughly how many hours you could save, how many errors you could avoid, and how much extra capacity you need. In the end, many labs end up with a mix of manual tools for special or low-volume tests, semi-automatic analyzers as everyday workhorses, and a few carefully chosen fully automatic systems for the highest-volume routine work.

Automation Progression

Pros and Cons

Laboratories don't have to choose between all manual or fully automatic. Most teams work somewhere in between, and each level of automation has its own strengths and weaknesses. Manual systems are highly flexible and low-cost but depend heavily on skilled staff. Semi-automatic systems share the work between people and instruments, improving speed and consistency without losing too much control. Fully automatic systems are designed for high, stable workloads where maximum throughput, standardization and connectivity matter most. The table below summarizes the main pros and cons of each level.

System type | Pros | Cons |

Manual | • Lowest purchase cost • Very flexible for different methods and small changes • Easy to install and maintain • Ideal for teaching and method development | • Slow and labour-intensive at higher volume • Strongly operator-dependent (skills, fatigue, technique) • Higher risk of pipetting , timing and transcription errors |

Semi-automatic | • Better consistency than manual (timing, reading and calculations automated) • Faster for routine work • Still relatively affordable compared to full automation • Keeps human control and flexibility for special or changing tests | • Sample prep and loading are still manual • Still uses staff time and attention during busy periods • Can become a bottleneck if daily volume keeps increasing |

Fully automatic | • Highest throughput and efficiency • Very consistent, standardized results with built-in QC • Less manual handling, fewer routine errors • Often integrates with LIS/LIMS for automatic result transfer and traceability | • Highest purchase and service cost • More complex installation, validation and maintenance • Requires trained staff and stable workload to be cost-effective • Less flexible for niche, low-volume or frequently changing methods |

The Bottom Line: How Far Should Your Lab Go?

There is no single perfect level of automation that works for every lab. What really matters is finding the right level for how your lab actually works. Manual instruments are great when you need flexibility and want to keep costs low, but they depend a lot on skilled staff and can become slow and tiring as sample numbers increase. Semi-automatic systems are often the best middle step; they help with routine work, cut down timing and calculation mistakes, and are usually easier to afford for small and medium labs. Fully automatic analyzers make sense when you handle many samples every day, run the same tests repeatedly, and need everything to be standardized and connected to your software systems.

In real life, most well-run labs don't rely on just one setup; they use a mix. Manual tools are kept for special tests, backup and training. Semi-automatic analyzers handle most of the everyday routine work. Fully automatic systems are used only for the highest-volume, very routine tests where they clearly save time and reduce risk. If you're not sure how far to go, start by listing your main tests, how many you run each day, and where your team feels the most pressure or repeat work. Then ask yourself If this step moved from manual to semi-auto or fully auto, would it remove a lot of stress and rework? The answer will usually show you the level of automation your lab really needs, nothing more, nothing less.If you'd like help turning that insight into the right mix of equipment, You can contact us through our website for practical advice on suitable manual, semi-automatic and fully automatic lab equipment.

You May Also Like