Drying Ovens vs. Incubators: Functional Differences and Applications

Two metal boxes, same steel doors, same digital displays but completely different jobs. One quietly dries glassware and materials, the other carefully protects cells, cultures and sensitive samples. Choosing the wrong one can cost you time, money and valuable data.The right choice and the right partner can keep your lab running smoother every day.

Understanding Drying Ovens and Incubators

Drying ovens are made for non-living samples. They are used to remove moisture, cure coatings or heat-treat items like glassware, metal parts, powders, filters and other solid samples. They usually run at medium to high temperatures, often above 100 °C, and push warm air through the chamber so everything dries quickly and evenly. Instead of protecting water or biological activity, a drying oven does the opposite; it is designed to drive moisture out on purpose.

Incubators are designed for living or delicate samples. Their main job is to keep the temperature very steady in a narrow range and in various models,it also controls humidity and gases so that cells, microbes or reactions can continue safely over time. You'll find incubators in microbiology, cell culture, food testing, diagnostics and anywhere else that needs gentle, stable warmth rather than strong drying. Instead of removing moisture, an incubator helps keep it in, so samples stay comfortable and are not stressed.

Core Functional Differences

The main difference between drying ovens and incubators is what they are trying to do inside the chamber. A drying oven is made to blow hot, dry air over non-living materials so moisture is removed quickly. An incubator, on the other hand, is made to keep the temperature and conditions gentle and stable so living cells, microbes or sensitive reactions can grow and stay active.

Aspect | Drying Oven | Incubator |

Main purpose | Drying, curing and heat-treating non-living materials | Supporting growth or reactions in living or sensitive samples |

Typical temperature range | Medium to high, often above 100 °C | Ambient to moderate, usually up to around 60 °C |

Airflow style | Stronger airflow, especially in forced-air designs | Gentle airflow to avoid drying and stress |

Moisture behaviour | Actively removes moisture and dries samples | Tries to preserve moisture; often maintains humidity |

Sample type focus | Glassware, metal, filters, powders, components | Cells, bacteria, yeast, tissue, media, biochemical assays |

Extra controls | Usually time and temperature only | May include humidity, CO₂, shaking or refrigeration |

Effect on living systems | Damaging or destructive | Designed to keep them alive and active |

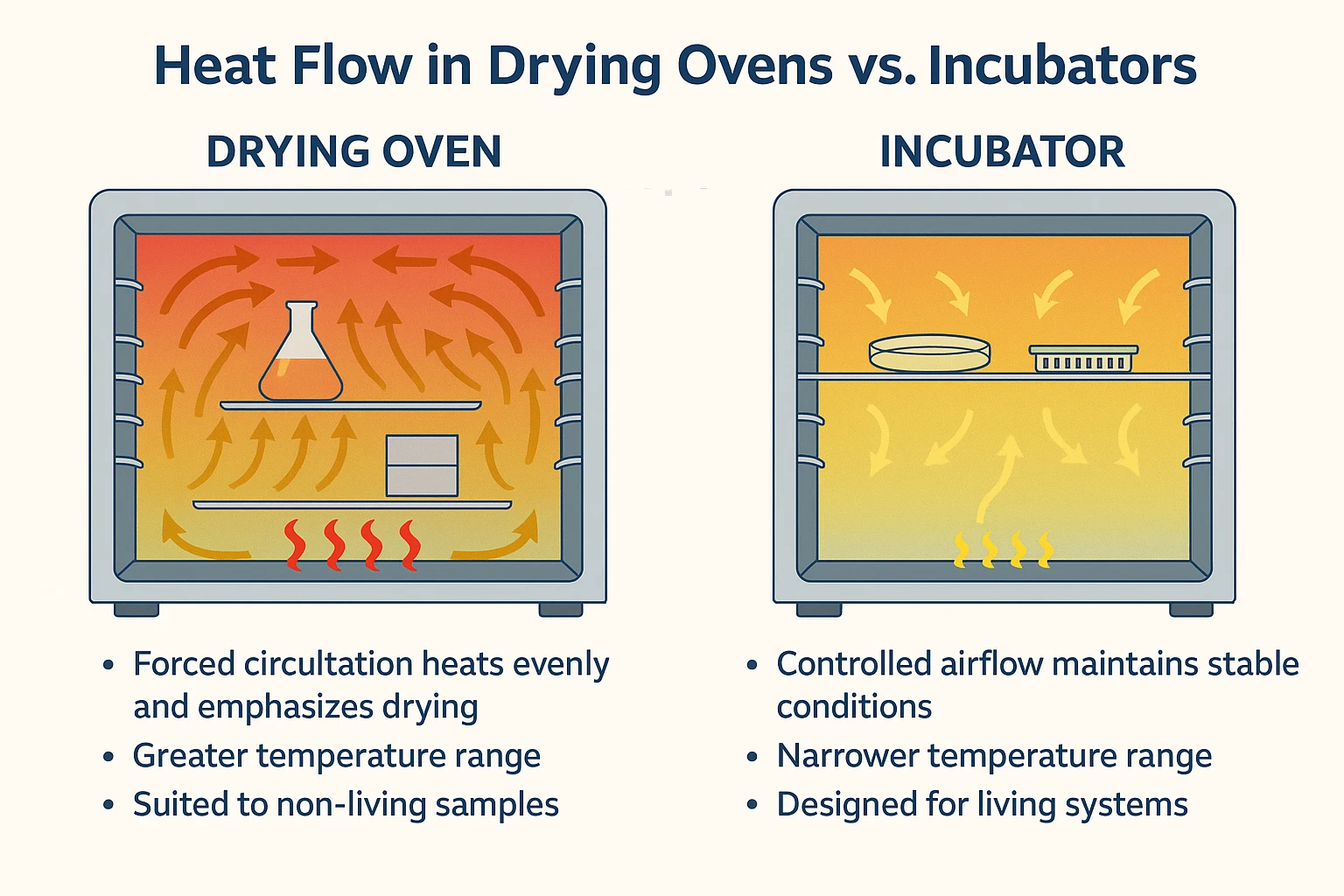

How They Work: Heat and Air in Each System

Inside a drying oven, the main job is to heat everything well and push moist air out. Heating elements warm the chamber and, in forced-air models with a fan, hot air is circulated around so it reaches all corners quickly. This strong airflow helps water or solvents evaporate faster, so glassware, filters and solid samples become fully dry in a reasonable time. The focus is on strong heating and fast drying, not on keeping the environment gentle.

In an incubator, it's almost the opposite.The heating system is designed to reach the set temperature and hold it steady without creating strong drafts or big temperature swings. Air moves softly and in a controlled way, so plates, flasks and culture vessels warm up evenly but do not dry out. Many incubators use water pans or humidity control to reduce evaporation, and CO₂ control in cell culture models to keep the media pH stable. Here the focus is on stability, even conditions and cleanliness, not on speed.

Heat Flow Comparison

Drying Ovens and Incubators in Everyday Use

In everyday lab work, drying ovens are the quiet helpers in the background. After washing, glassware is often placed in the oven so any remaining water can fully evaporate before the next experiment. Filters with solid material are dried before weighing, so the results are accurate. Materials labs use ovens to cure coatings, test how things react to heat and mimic storage at higher temperatures. Environmental, food and industrial labs use them to dry soils, powders and product samples so they can be tested in a stable, dry condition. In all these situations, the samples are non-living, and the main goal is fast, complete drying, not gentle treatment.

Drying Oven

Incubators are at the heart of any work that depends on living things or sensitive reactions. In microbiology labs, inoculated plates and broths are placed in incubators so bacteria or fungi can grow at a set temperature. In cell culture labs, CO₂ incubators keep mammalian cells at body temperature with the right humidity and gas levels to keep them healthy.In food, water and pharmaceutical testing, incubators are used for microbial limit tests and stability studies where it's important to see how things change over time. Research labs also use incubators for enzyme tests and other reactions that need a steady temperature but would be damaged by strong heat or drying. In all these cases, the incubator acts as a safe, controlled home where delicate systems can grow and develop properly.

Incubator

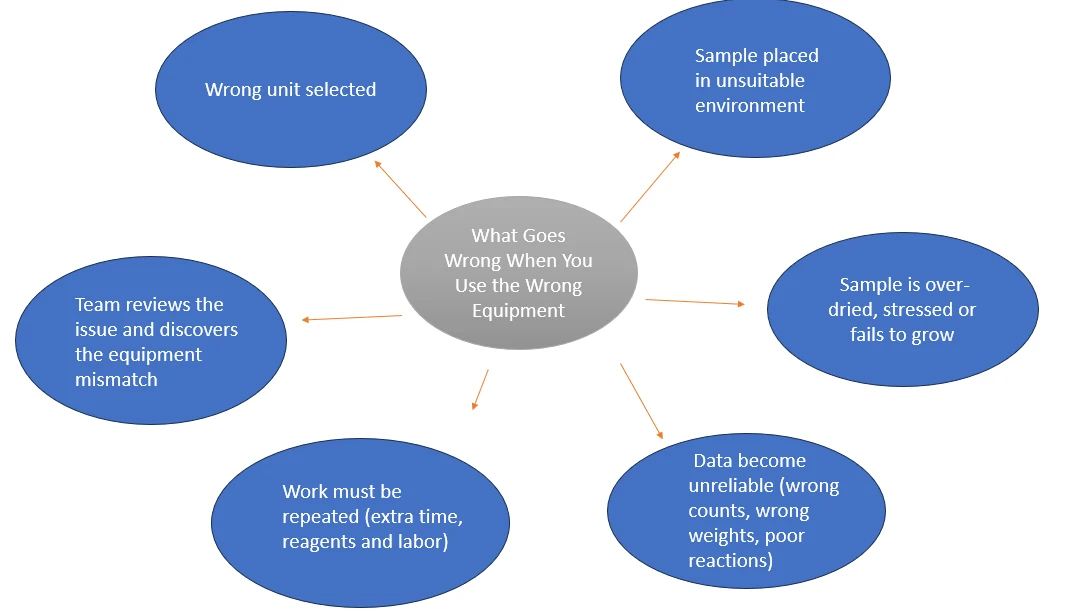

What Goes Wrong When You Use the Wrong Equipment

One wrong decision at the start triggers a chain of problems that loops back to wasted time and cost:Putting cultures into a drying oven dries plates and kills or damages cells, so growth either doesn't appear or no longer reflects the real microbial load. Trying to dry glassware or filters in an incubator can leave them slightly damp, increasing contamination risk and giving unstable weights. Each step delays and frustrates until the lab adjusts and matches the task to the right piece of equipment.

Real Lab Scenarios

In a microbiology lab, an incubator is used to grow colonies on agar plates at a set temperature, while a drying oven is used in the background to dry washed glassware and metal instruments. If someone accidentally puts inoculated plates in the oven, they may come back to find them cracked, dried out and useless, and will have to repeat sampling and plating. Using plates in the incubator and glassware in the oven keeps both microbiology work and basic prep running smoothly.

Agar Plates In An Incubator

In a food or pharmaceutical quality control lab, the tasks are a bit different. Filters with product or environmental samples are dried in a drying oven so they can be weighed accurately, while incubators are used to grow any microorganisms present for safety testing. If filters are dried in an incubator, they may not dry fully and the weight can drift over time. If microbial tests are done in an oven , the organisms are killed instead of grown. Using each chamber correctly helps protect product quality and meet regulatory standards.

In a cell culture lab, researchers depend on Co₂ Incubators to keep mammalian cells alive at 37 °C, with the right humidity and gas levels. At the same time, they may use a drying oven to cure materials, dry scaffolds or test parts that will later be used with those cells. Mixing up these roles can mean putting cells in a hot, dry oven and destroying them, or trying to gently dry materials in an incubator that is not meant for that job. Clear lab rules and good labelling help make sure every sample goes into the environment it was designed for.

Co₂ Incubators

Choosing the Right Chamber

Drying ovens and incubators may look similar, but they do very different jobs: ovens use stronger heat and airflow to dry non-living materials, while incubators create gentle, stable conditions that support living cells and sensitive reactions. Choosing the right one protects your samples, saves time and keeps your daily work predictable. Make your next equipment decision with confidence. Contact us to learn more about reliable drying ovens and incubators, review clear comparisons, and identify the right match for your lab's real, everyday needs.

You May Also Like