Better Viewing Starts With Right Microscope Design

Great microscopy comes from choosing a microscope that suits the job. Different samples need different viewing conditions, some require sharp detail, some need a stronger sense of depth, and some must be handled gently because they're alive. When the microscope design fits the task, you get clearer images, smoother workflow, and more dependable results in everyday lab work.

Once you define what you need to observe (transparent or opaque, flat or 3D, fixed or live, handling required or not), choosing becomes much easier. That's why many labs keep more than one type on hand, so each sample can be viewed using the microscope that shows it at its best.

Biological Microscope Working, Features & Applications

Why One Microscope Can't Do Everything

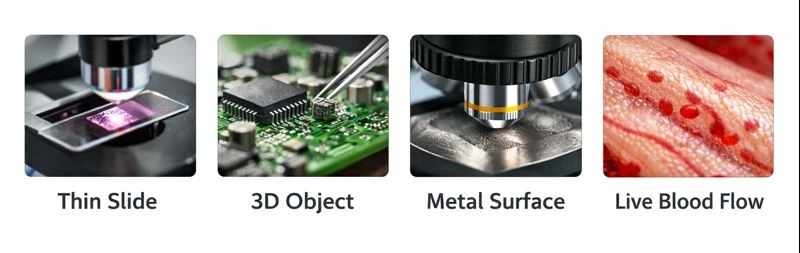

A single microscope can't handle every task because different samples need very different optics and lighting.

Thin, stained tissue sections need bright light from below, high magnification, and precise focusing to reveal tiny internal details.

Thick 3D samples like insects or circuit boards need a wider view, real depth perception, and enough working space under the lens to use tools comfortably.

Metals and polished coatings are opaque, so they require light from above that reflects back, instead of light passing through the sample like a slide.

Live capillaries and moving blood cells add another challenge: the microscope must handle motion clearly, often record video, and be comfortable to use near a patient.

Because these problems are so different, the optics, illumination, mechanics, and user comfort features must be designed differently.

Trying to use one universal microscope usually leads to compromises, lower contrast, awkward working distance, and images that don't show what you really need.

Different Samples For Different Microscopes Design

Types Of Microscopes Designs

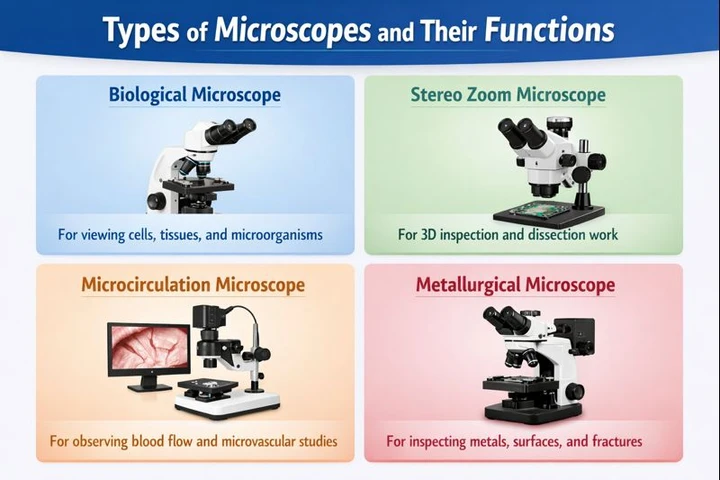

Biological Microscopes

A biological microscope is made for one clear purpose helping you see what's happening inside thin biological samples. When you're examining blood smears, tissue sections, cell cultures, or microorganisms on slides, this is the microscope that does the real work.

How it works

A biological microscope uses light that passes through the sample:

Light comes from the lamp under the stage (usually an LED).

The condenser focuses that light into a clean, bright beam.

The light travels through the slide and specimen.

The objective lens creates the main magnified image with fine detail.

The image is then viewed through the eyepieces or sent to a camera.

The sample is thin and light can pass through it, you can clearly see internal details like nuclei, cell structure, tissue layers, bacteria, and parasite forms.

Key features that make this possible

Objective lenses:commonly 4x, 10x, 40x, and 100x oil immersion for higher magnification

Condenser:improves contrast and sharpness by controlling the light

Coarse + fine focus knobs:smooth focusing at both low and high magnification

Mechanical stage:precise slide movement so you can scan the sample easily

Binocular or trinocular head:comfortable viewing, with camera support in trinocular models

Optional advanced options

Phase contrast: for viewing live, unstained cells.

Fluorescence : for detecting tagged DNA, proteins, or specific cell markers.

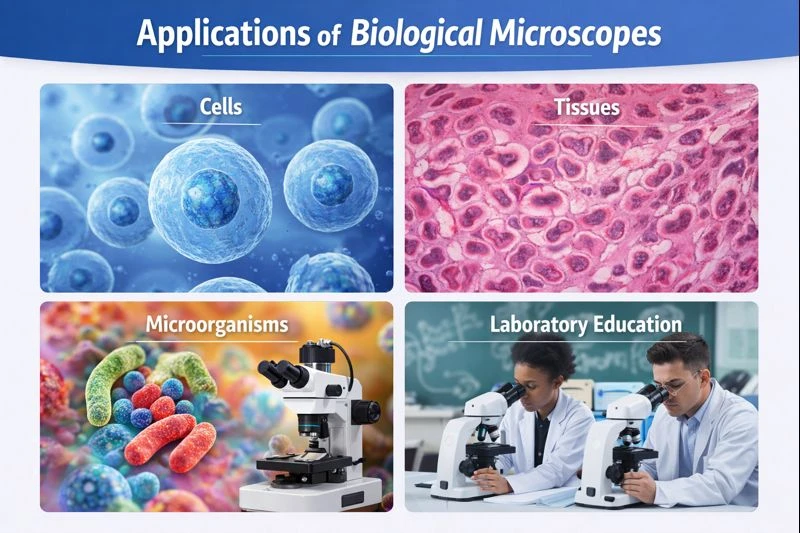

Applications:

Examining blood smears for cell morphology and blood parasites.

Evaluating tissue sections from biopsies for disease diagnosis.

Identifying bacteria, fungi and parasites in stained clinical samples.

Screening Pap smears and other cytology slides for abnormal cells.

Monitoring cell cultures for confluence, morphology and contamination.

Teaching students basic cell, tissue and microorganism structure.

Checking food, water and environmental samples for microbial contamination.

Inspecting pharmaceutical and cosmetic samples for particulates and microbes.

Applications For Biological Microscopes

Stereo Zoom Microscopes

Stereo zoom microscopes are made for jobs where you need a clear 3D view and also need to work on the sample with your hands. Unlike biological microscopes that focus on thin slides, stereo microscopes are best for solid, uneven objects like circuit boards, insects, seeds, small parts, tissues, wires, and tools. Anything you want to inspect, hold, cut, solder, glue, assemble, or sort under the lens.

They use light from above and create a true stereo image, meaning each eye sees a slightly different angle. Your brain combines these views, giving you natural depth perception, so it's much easier to judge height, distance, and position. They also have a long working distance, which leaves plenty of space for tweezers, scalpels, probes, or soldering tools. And with the zoom function, you can change magnification smoothly without constantly swapping lenses.

Because they give both depth and workspace Stereo zoom microscopes are ideal for hands-on tasks like dissection, electronics inspection and repair, small-parts quality checks, sample sorting, and preparation for any work where your eyes and hands need to work together accurately on a small object.

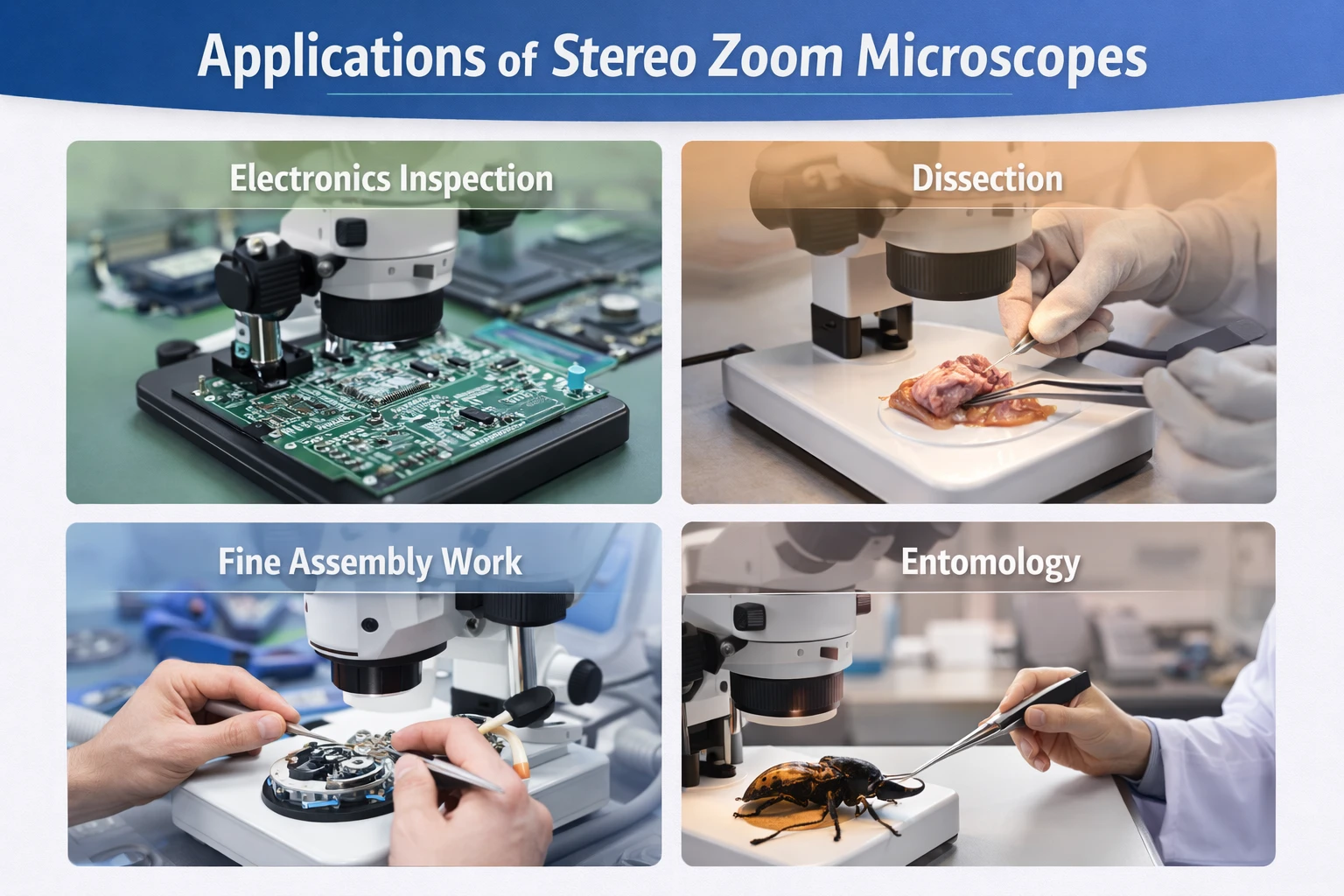

Applications:

Dissection and micro-surgery on small animals, plants, insects and tissues.

Inspection and rework of Printed Circuit Boards, electronic components and solder joints.

Sorting, picking and preparing small samples (seeds, crystals, insects, particles).

Quality control of mechanical parts, plastics, medical devices and assemblies.

Viewing and manipulating micro-tools, catheters, implants and fine instruments.

Examination of textiles, fibers, papers and surface textures in R&D or forensics.

Assisting with microscale assembly and repair in watchmaking, jewelry and precision engineering.

Teaching gross anatomy, dissection and basic microscopy where a 3D view is important.

Applications For Stereo Zoom Microscopes

Metallurgical Microscopes

Metallurgical microscopes are made to solve one simple problem: light can't pass through metal. While biological microscopes shine light up through thin slides, metallurgical microscopes use reflected light from above to show fine details on the surface of opaque materials.

The samples are usually mounted and polished, and sometimes etched, so surface features become easy to see like grain boundaries, different phases, inclusions, cracks, weld patterns, and coating layers. The stage and stand are built to hold solid, sometimes heavy pieces steady and flat, and the optics are designed to give sharp, high-contrast images at medium to high magnification.Because they are focused on viewing flat, reflective surfaces, metallurgical microscopes are widely used in materials science, metallurgy, quality control, and failure analysis where seeing the true condition of metals and coatings helps improve safety, performance, and product lifespan.

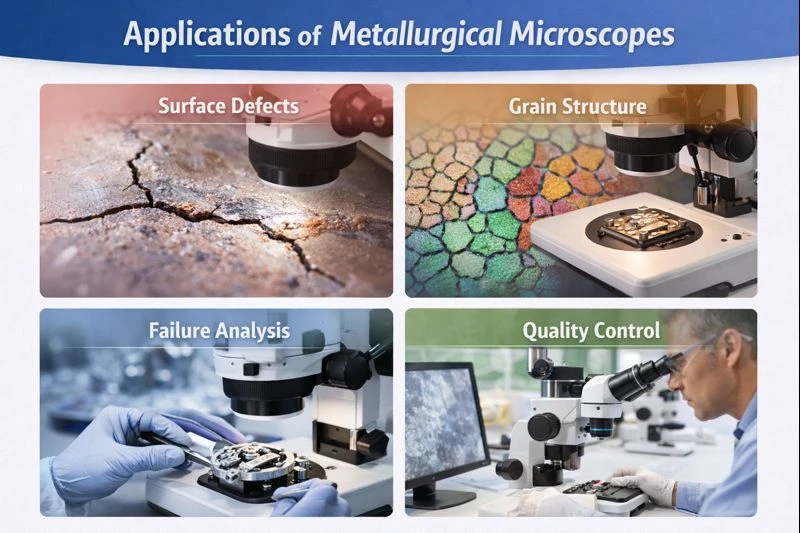

Applications:

Examining grain structure and phases in metals and alloys after polishing.

Inspecting welds, joints and heat-affected zones for cracks, porosity and defects.

Evaluating coatings, platings and surface treatments for thickness, adhesion and uniformity.

Studying fracture surfaces and failure points as part of failure analysis.

Checking inclusions, segregation and impurities in steel and other engineering materials.

Documenting corrosion, pitting and surface wear over time or after testing.

Quality control in automotive, aerospace, machining, casting and metal fabrication industries.

Applications for Metallurgical Microscopes

Microcirculation Microscopes

Microcirculation microscopes are designed for one very specific job: watching tiny blood vessels and live blood flow in real time. Instead of looking at fixed slides, these systems are used directly on or very close to the skin or tissue surface, so you can see capillaries, red blood cells and microvessels actually moving. The optics and illumination are tuned to pick up fine vessels just below the surface, while a built-in digital camera and display make it easy to observe, record and analyze flow patterns without needing a separate imaging setup. Ergonomic, often handheld or probe-style designs mean the device can be positioned comfortably on fingers, nailfolds, mucosa or other target areas, making it suitable for bedside use, clinics or research labs. Where a biological microscope answers "What do these cells look like on a slide?", a microcirculation microscope answers "How well is blood really flowing through these small vessels right now?"

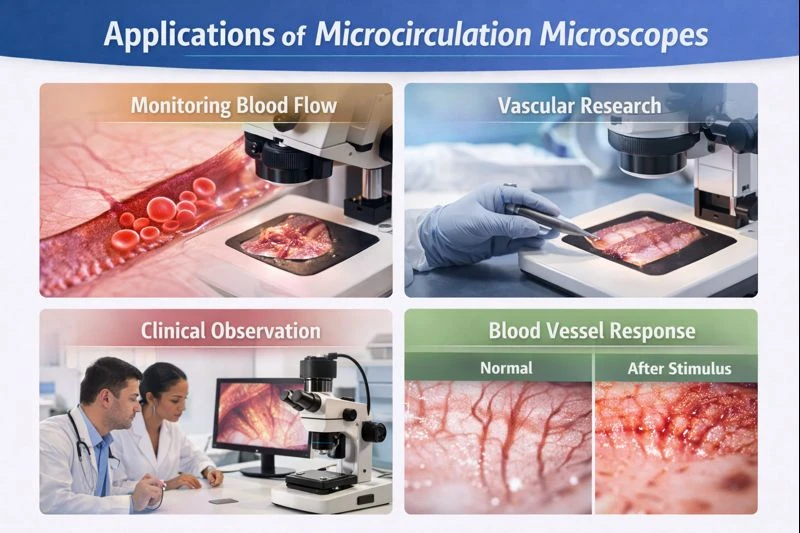

Applications:

Assessing capillary density and morphology in nailfold or skin microcirculation.

Monitoring microvascular perfusion before and after treatment or surgery.

Studying microcirculation changes in diabetes, rheumatic diseases and other systemic conditions.

Evaluating response to drugs, fluids or therapies that affect blood flow.

Research on shock, sepsis, ischemia-reperfusion and critical care microcirculation.

Teaching and demonstration of real-time blood flow and capillary function.

Applications For Microcirculation Microscopes

When Does Your Microscope Really Need a Camera?

A microscope doesn't always need a camera, but in many labs digital imaging makes daily work easier and more professional. The main point is simple: decide if the microscope is only for your own quick viewing, or if the images need to be shared with other students, teammates, clients, or reports.

Digital microscope with zoom camera module

A camera-ready (trinocular) microscope is a smart choice when you often need to:

Save images for reports, emails, audits, or lab records

Display live viewing on a monitor or projector for teaching and training

Document before-and-after changes in QC, R&D, or materials work

Build a library of reference images for future comparison

In these cases, having a proper camera port from the start is much more convenient than trying to take pictures through the eyepiece with a phone. It also keeps the setup stable, which helps you get clear, repeatable images.

If the microscope is mostly used for quick personal checks like fast looks at culture flasks, simple routine viewing, or small-group teaching an eyepiece-only model can be enough. Many labs keep one or two camera-equipped microscopes for shared use, instead of adding cameras to every unit.The best approach is to match the microscope to the level of documentation your lab actually needs. For some teams, a camera is just a useful extra. For others, it becomes essential for teaching, collaboration, and proving results. Thinking about this early helps you avoid paying for features you won't use, while still being ready for real imaging needs later.

How to Choose the Right Design for Your Lab

Choosing the right microscope for your lab starts with a simple reality check: think about what you work on every day. Are you mostly viewing stained slides, handling 3D samples, inspecting metals and coatings, or observing live blood flow? Once you're clear about your main sample types and how you need to handle them, it becomes much easier to choose the right design biological, stereo zoom, metallurgical, or microcirculation or even a mix that fits your workflow best.

Lab type | Typical work | Recommended microscope combination | Why this works well |

Clinical / Hospital Lab | Blood smears, Pap smears, biopsies, microbial smears | Biological + (optional) Microcirculation | Biological covers all slide work; microcirculation adds real-time capillary flow for specialist use. |

Materials / Engineering / QC Lab | Metals, welds, coatings, fracture surfaces, polished cross-sections | Metallurgical + Stereo Zoom | Metallurgical for microstructure; stereo zoom for 3D parts, surfaces and sample prep. |

Teaching / Academic Lab | Basic cell/tissue slides, microorganisms, insects, dissections, 3D samples | Biological + Stereo Zoom | Biological for theory and slides; stereo zoom for 3D specimens and hands-on demonstrations. |

Small Private / Multi-Purpose Lab | Mixed slide work, small parts inspection, sample prep | Biological + compact Stereo Zoom | Two versatile instruments cover most routine and client-facing tasks without over-investing. |

Electronics / Repair / Assembly Lab | PCB inspection, solder joint checking, rework and small component handling | Stereo Zoom (with good working distance) | 3D view and space under the lens make inspection and rework comfortable and precise. |

Microvascular / Therapy / Research Unit | Monitoring microcirculation, therapy response, capillary changes | Microcirculation + Biological | Microcirculation for live flow; biological for related slide-based investigations and documentation. |

Industrial Training / Vocational Center | Teaching basic inspection, assembly, simple materials and slide observation | Stereo Zoom + a few Biological units | Stereo zoom for hands-on skills; biological for basic microscopy and sample understanding. |

The Right Tool for the View

When your microscope design matches the real viewing task in your lab, everything feels smoother, images look sharper, users feel more confident, and results support better decisions. Biological microscopes, stereo zoom systems, metallurgical microscopes, and microcirculation microscopes are each built to solve a different seeing challenge, and using the right one for the right job saves time, reduces frustration, and avoids repeat work. If you're reviewing your current setup or setting up a new lab, list your main sample types and match them to the right microscope style, contact us through our website for suitable model options and a best-fit recommendation for your workflow and budget.

You May Also Like