Shakers or Mixers - What’s best for my Lab?

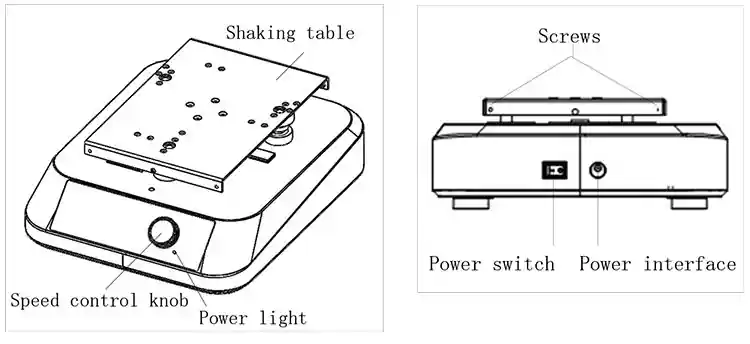

Laboratory shakers do just that - shake the mixture that is placed on them. The plates vibrate back and forth or in circulatory motion to homogenise the mixture. Some plates additionally tilt up and down or side by side for proper mixing.

Laboratory shaker

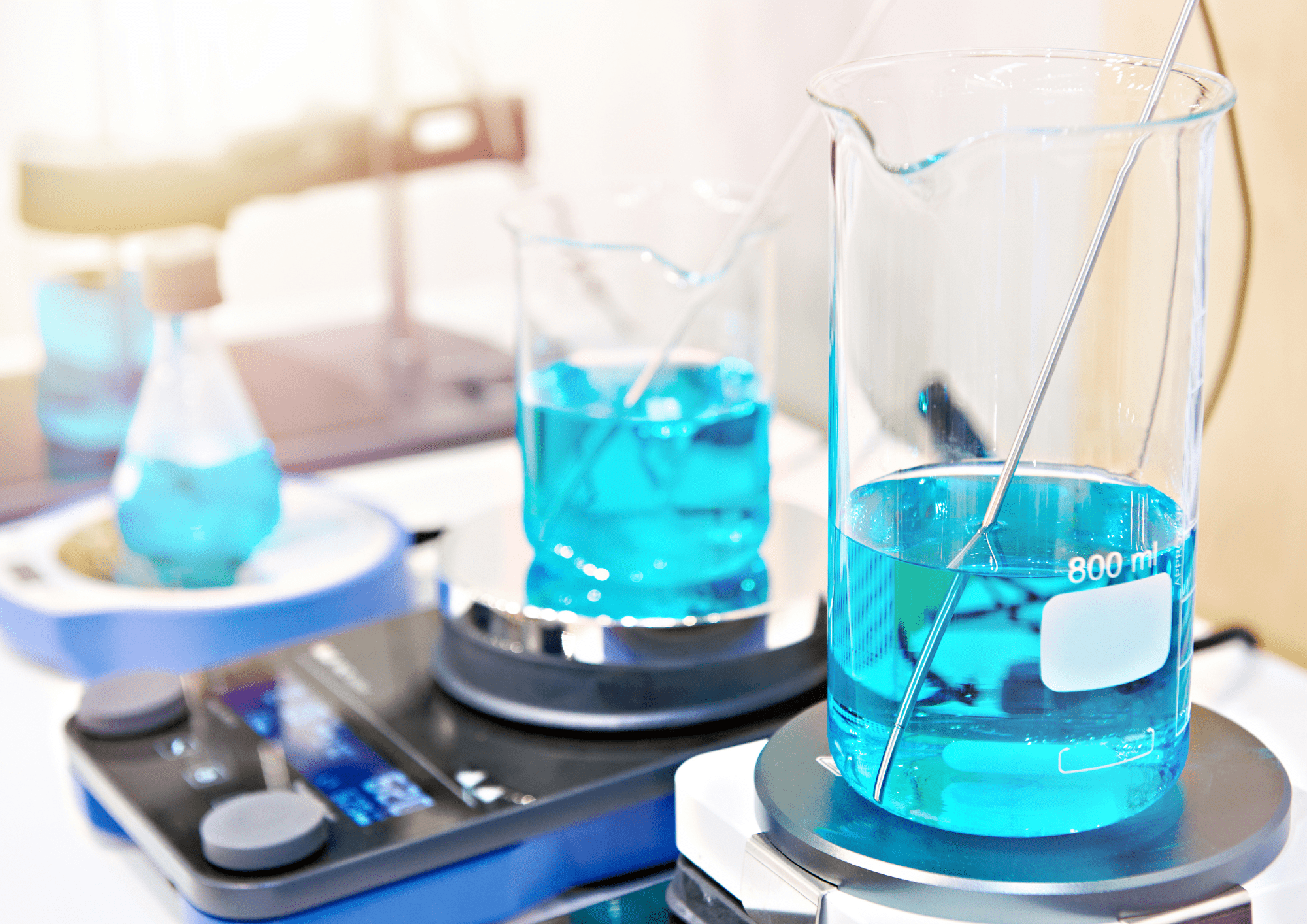

Vortex mixers creates a whirlpool-like motion in liquid by rapidly spinning the small platform causing he rotational movement of the liquid. This creates a downward force in the centre thereby pulling the liquid down and then up along the sides of the container ensuring thoroughly mixing it.

Vortex mixer

Top 10 differences between shakers and mixers to keep you moving

1.Structure design

| Shakers | Mixers |

| Base: It is the lower part which is placed on the laboratory bench. | Main switch: Controls the power supply to the vortex mixer, allowing it to be turned on or off. |

| Platform: Upper part of the shaker where the samples are placed. | Speed controller knob: Enables the adjustment of the rotational speed of the vortex mixer. |

| Clamps: Gripping devices to hold the sample vessels in place to the platform while mixing. These are usually adjustable to hold vessels of different sizes. | Operation controller button: Offers the programming capabilities to the users. It allows the user to choose between direct rotation or rotation when the vials are in contact with the cup head. |

| Motor: Electric devices located underneath the platform and connected to it via a drive mechanism. They provide the motion to the platform. | Motor: Positioned directly beneath the cup head. It rotates in the circular motion which creates a vortex effect in the sample for proper homogenization. |

| Controller: Part of the shaker that allows the user to control the speed and the intensity of the shaker. | Cup head: Designed to hold the sample tubes securely in place during mixing. They are usually made to rubber and available in different sizes to accommodate vessels of different sizes. |

components of shaker

components of mixer

2.Capacity & load

Capacity of the instrument is necessary depending on the number and quantity of samples to be processed.

Shakers can be found in wide variety of sizes with varying capacity. Hence, bulk quantity of multiple samples can be processed. The maximum limit of shakers capacity can range till two litres. However, shakers do have weight concerns. One should consider a triple eccentric drive mechanism shaker if a heavy workload is placed on the shaker. While single eccentric drive mechanism is best suited for light weight load

Capacity of laboratory shaker

Vortex mixers are designed with 2 or 4-plate formats or rubber cup head. They can usually mix small volumes of liquid samples at a time. Plate format mixer can place at least 6-8 tubes in each plate while the rubber cup head can hold only one sample at a time. The maximum volume of liquid that can be mixed using a benchtop vortex mixer is 10-15 ml in each tube.

Capacity of vortex mixer

Capacity of mixer

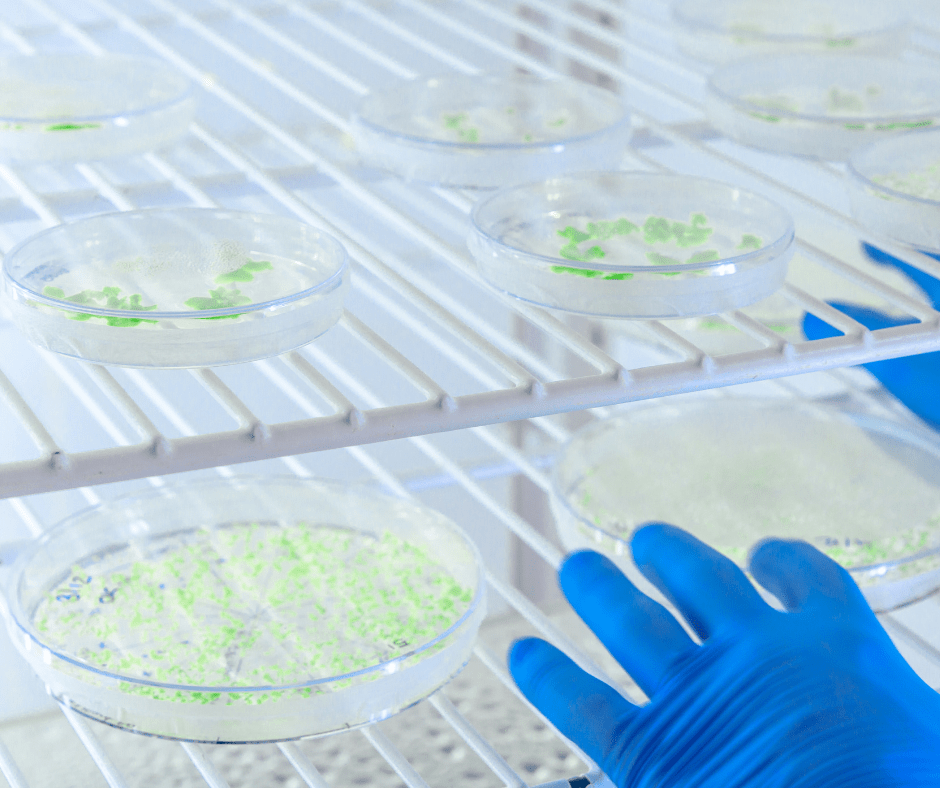

3.Vessels to be shaking

Shakers can hold vessels of varying sizes and shapes for mixing. The vessels placed on shakers are beakers, jars, conical flasks, side arm flasks, tubes.

glassware

Vortex mixers can hold small test tubes, vials, centrifuge tubes, eppendrofs.

centrifuge tube

testube

eppendroff

4.Motion makes a difference

Shakers offer varied set of motions that allows user to decide from

| Orbital motion | Entire platform performs circular orbit motion. |

| Reciprocating motion | Platform performs “back and forth” sloshing motion. |

| Vortex motion | Shakers attain speed up to 3200rpm for vigorous mixing of capped vessels. |

| Rotating motion | Shakers gently spin the sample by tilting at a rotation angle allowing “rise and fall” motion |

| Hand motion | Shakers duplicate the “up and down” action associated with the handshake. |

| Rocking motion | Platform shakers offer rocking “see-saw” motion or consistent 3D rocking motion. |

The motorized drive shafts beneath the cup head of the vortex mixers rotates rapidly thereby transferring circulatory motion to the sample containers loaded in the mixer. Therefore, the sample fluids start circulating and undergo turbulent flow, in other word it creates a vortex for proper homogenization.

5.Temperature

Shakers are designed with special features to act like incubators to maintain optimal conditions of temperature while carrying out homogenization. Some shakers like Thermoshaker Incubator can be used to grow thermophiles hence their temperature can range as high as 80ºC while units that are used for protein expression applications are refrigerated models like Cooled shaking incubator that can lower up to 4ºC.

Vortex mixers are designed as regular mixing devices of liquid samples for easy mixing to avoid traditional ‘finger vortex’ method hence they are operated only in room temperature that is 37 ºC.

6.Speed

The RPM capabilities of an instrument can have a huge impact on its performance depending on specific application.

Shakers offer speed variability. Some units will shake as fast as 3000 rpm while others shake as low as 100 rpm. Speed is usually high in digital shakers which gets compromised when one uses the analog model. The speed also gets limited when the unit is stacked. Adjusting the speed of the shaker depends solely on the application since shakers are used to mix the sample contents while maintaining many parameters like aeration, temperature, motion.

Vortex mixers show variable speed settings ranging from 100 to 3200rpm because their main purpose is for mixing and homogenization of the sample. The speed settings usually depends on the viscosity of the liquid sample.

7.User Control:

Shakers are fully automated where the user has only control over setting the parameters like motion, temperature, speed, timer. The vessels placed on the shaker then moves accordingly but the user doesn’t have to interfere or hold the vessels continuously since clamps are provided for the same purpose.

Vortex mixer can be set to run continuously but users have to hold the vessels or to run only when downward pressure is applied to the rubber piece by the user.

8.Types

| Shakers | Mixers |

| Platform shaker has a table board that oscillates horizontally wherein the beakers and the jars contents to be mixed are nested in the plate. | Mini vortex mixer is essential for spinning applications. It is a stable tool in molecular biology lab. |

| Orbital shaker has a circular shaking motion with slow shaking which is suitable for culturing microbes, washing blots and general mixing. | Multitube vortex mixer fulfills high-throughput vortex mixing applications as well as analytical methods that require multiple samples. |

| Incubator shaker is a mix of incubator and shaker that has an ability to shake while maintaining the optimal conditions for incubating microbes or DNA replication. | Pulsating vortex mixer facilitates a unique pulsating motion which decreases the heat generation while mixing ensuring no clumps. |

9.Digital or Analog?:

| Shakers | Mixers |

| Digital: These are maintenance free models. They have more features- temperature and speed alarms to the ability to transfer data to computers. They also offer high shaking rpm. | Digital: They offer more precise speed controls. Speed can be adjusted using touchpad. Precise speed is displayed on LED screen. Additional options of timer and speed can be added. |

| Analog: Cheaper model as compared to digital. They require maintenance annually owing to the brushes in the motors that need replacement. They usually have limited speed range. | Analog: These models are available in simple designs and are cheaper. Speed of these mixers are regulated using knobs that can be turned from right to left. |

10.Uses & Applications

| Shakers | Mixers |

| Diagnostic testing | General mixing & Homogenization |

| Bacterial suspension | Cell culture applications |

| Extraction procedures | Chemical synthesis |

| Staining and Destaining | Sample preparation |

| Solubility studies | Quality control |

Parameters to consider before ordering::

| Shaker | Mixer |

| Vibration speed | Container capacity |

| Speed adjustability | Viscosity of liquid sample |

| Capacity of vessels | Speed of mixing |

| Movement of plates | Speed variability |

| Vibration of plates | Horsepower |

It is of utmost importance to consider the application objectives, test type, volume and the speed of the movement of the specimen types that are being processed to buy the right equipment for the lab. Right considerations ensure right equipment for accurate results.

At Biolab, we understand the need to select the right equipment for the homogenization is an important task. We are a team of trained professionals, who are ready at your command to assist you in selection of the product as per your requirements. We make your choice easier; making your lab more user friendly.

Get in touch with us for more insight on shakers, mixers, stirrers, rollers, rotators and other laboratory solutions. Our expert team is happy to guide you to select the right product.

You May Also Like