Benchtop Low Speed Centrifuge BCBL-201

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Designed around your applications to provide you competent sample processing and reliable results. Microcomputer programmable with excellent temperature controls and low noise operation maximize your productivity. Highly efficient with low maintenance requirements, it is an ideal separation tool for multiple research applications.

- Microcomputer controlled programmable operation with touch panel

- TFT true-colour LCD wide screen displays set and run conditions for easy monitoring

- Brushless DC Motor ensures low maintenance, high efficiency and constant speed of rotation

- Store 20 programs in centrifuge memory which are retained even after powering down the centrifuge

Specification

Features

Applications Optional Accessories

| Maximum Capacity (No of tubes x Vol.) | 24×10ml |

| Maximum Speed | 4000 rpm |

| Speed Increment | ±50 rpm |

| Speed Accuracy | ±30 rpm |

| Maximum RCF | 2600xg |

| Time Range | 1min |

| Overall Dimension | 500x470x280 mm |

| Program | 20 user programs |

| Control | Microcomputer |

| Display | LCD |

| Noise Level | ≤60dB |

| Weight (Net/Gross) | 20/25 kg |

| Power | 275 W |

| Power Supply | 220V 50Hz 10 |

- Microcomputer controlled programmable operation with touch panel

- TFT true-colour LCD wide screen displays set and run conditions for easy monitoring

- Brushless DC Motor ensures low maintenance, high efficiency and constant speed of rotation

- Store 20 programs in centrifuge memory which are retained even after powering down the centrifuge

- Fully stainless steel structure and stainless steel cavity makes the machine safe and more efficient

- Acceleration/Deceleration takes around 30 sec to 1 min

- Multiple layers of shock absorbers with auto balancing function

- System is complemented by multiple new accessories, including tube racks, centrifuge adapters and rotors

- Safety features: Self diagnostic, Rotor unbalance detector, Lid protection, over speed protection, over temperature protection

Cell Separation, Precipitation, Sample Processing, Clinical, Cell Culture, Microplate Processing, Biochemistry, medical diagnosis

| Accessory Code | Name | Description | RPM | RCFxg |

| 2301509006 | Fixed Angle Rotor | 24x10ml | 4000 | 2600xg |

| 2301509007 | Fixed Angle Rotor | 12x20ml | 4000 | 2600xg |

| 2301509008 | Fixed Angle Rotor | 18x10ml | 4000 | 2600xg |

Operating Manual for BCBL-201

1. The name and model of the product

2. Features and applications

3. The operation principles

4. Technical parameters

5. The rotor parameter

6.The operation procedures

7. Safety Notice

8. Warranty Service Instruction

9. Comment Malfunctions and Obviating Methods

10. Transportation and storage of the machine

11. Unpacking and examination of the machine

1. The name and model of the product

Benchtop Low Speed Centrifuge BCBL-2012. Features and applications

Benchtop Low Speed Centrifuge BCBL-201( This machine below is short for this centrifuge machine.),The series centrifuge is widely applied in biology, chemistry, medicine, agriculture and forest science, food safety, blood station and clinical test.This machine features good rigidity, high strength and corrosion proofing, owing to its high material of steel and its surface with spurt models processing. Meanwhile, this machine possesses the advantages of succinct structure, small volume, low noise, smooth temperature rise, high efficiency, safe and reliable, and it is fit for the experimental analysis with fewer samples and more separation steps.

This machine adopts the advanced technologies like microcomputer control, direct drive brushless DC motor, TFT Zhencai touch panel, mute mechatronics electronic lock and so on.

The features of this machine are as followed:

Step 1: Set up the rotor mode, the rotating speed and the needed time.

The vibration-absorption effect of this machine works very well by the application of its special damper. This machine also has a self-balance function.

Step 2: Set up the rotor mode, the rotating speed and the needed time.

The special PWM-controlled speed control system assures its high control accuracy and its fast acceleration and deceleration function, which provides different acceleration and deceleration time to be freely chosen. To meet the requirement of labs, the brushless DC motor also assures the operation of the machine in a quiet working state. The carbon brush doesn’t need to be replaced, so there are no carbon pollutions.

Step 3: Set up the rotor mode, the rotating speed and the needed time.

This machine has a parameter-saving function, and it can calculate the RCF value automatically. Step 4: Set up the rotor mode, the rotating speed and the needed time.

There are many rotors with different levels. The tube frame can be replaced, and there are many tubes, convenient to choose.

Step 5: Set up the rotor mode, the rotating speed and the needed time.

This machine has a protective function owing to its electronic lock. When its faceplate is uncovered, the centrifuge machine cannot be operated.

This machine can be safely operated in the environment with the temperature within 5 to 40 centigrade, under RH<80%, and without conducting dust, explosive gas and corrosive gas.

3. The operation principles

The centrifuge machine helps to separate, condense or purify the different density components (or particles) of the solutions by the usage of centrifugal sedimentation principal.After placing the centrifuge tubes with equivalent test solutions in the test tubes around the rotors symmetrically and starting the machine, the RCF produced in the high-speed rotary of the rotors, which are driven by the motor, separates the different density components (or particles) in the test solutions. The value of RCF depends on the rotating radius “r” (the horizontal distance from the position of the test solutions to the axle center) and the rotating speed “n”, and here is the calculation formula.

RCF=1.118×10-6n2r×g

n------------ The rotating speed (r/min)

r------------The rotating radius (mm)

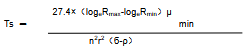

The time (Ts) needed during the separation and deposition of the mixed solutions is calculated by this formula:

Type: Rmax------The rotating radius of the test solutions having the farthest distance with the axle center

Rmin------The rotating radius of the test solutions having the nearest distance with the axle center

ρ------The density of the mixed solutions (g/cm3)

μ------ The viscosity of the mixed solutions (p)

n ------ The rotating speed (r/min)

r------The particle’s radius (cm)

б--The particle’s density (g/cm3)

4. Technical parameters

Maximum rotate speed 4000r/minMaximum centrifugal force 2320×g

Maximum capacity 24X10ml

Time range 1min~99h59min59s

Rotate speed precision ±30r/ min

Noise ≤60dB

Power AC 220V 50/60HZ

Dimension(L×W×H) 500×470×280mm

Weight 20kg

5. The rotor parameter

| Model | Product name | Maximum capacity | Maximum rotate speed(r/min) |

| BCBL-201 | centrifuge | 4000 | |

| Angle rotor | 8×20ml | 4000 |

6.The operation procedures

Step 1: Place the centrifuge machine on the platform and ensure its balance. Shake the machine with hands to check out whether the machine has been placed stably or not.Step 2: Plug the supply cord into the outlet and press down the power switch (the power switch is on the right bottom of the machine).

Step 3: After pressing down the button of

STOP & OPEN”, put the rotors on the motor shaft, and connect the rotors with motor shaft tightly together by tightening the screw nuts (the move

STOP & OPEN”, put the rotors on the motor shaft, and connect the rotors with motor shaft tightly together by tightening the screw nuts (the moveshould be very gentle and substantially shaking and pressing should be avoided, so as to protect the flexible support system of the motor. Then, place the adapter with test tubes on the rotors and rotate the rotors. The rotors should be turned flexibly, the adapter should be rotated freely, and there should be no block or collision.

Step 4: Place the centrifuge tubes into the test tubes. The centrifuge tubes should be placed symmetrically, and the test solutions in the tubes should be even, so as to make sure the equilibrium operation of the machine.

Step 5: Cover the faceplate and check out whether it is covered tightly, or the centrifuge machine cannot be operated.

Step 6: Set up the rotor mode, the rotating speed and the needed time.

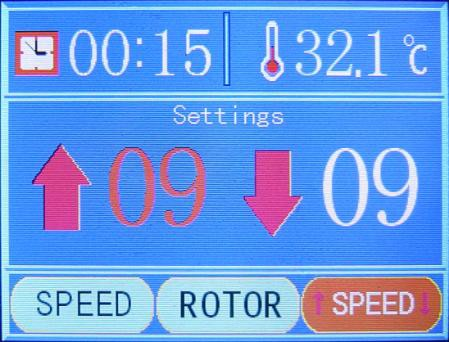

The control panel of the machine is as shown below.

The diagram of the control panel.

1.:The operation and time setting area.

2.:The display area of the parameter numbers

3.:The operation icon.

4.:The setting of rotor modes.

5.:The setting of rotating speed.

6.:

The “SET” button.

The “SET” button.7. :

The “RCF” button.

The “RCF” button.8.:

The “START” button.

The “START” button.9. :

The “UP” button.

The “UP” button.10.:

The “DOWN” button.

The “DOWN” button.11. :The temperature setting and display area.( This is the cavity temperature, and non-refrigerated centrifuge has no such setting function.)

12. :The display area of rotating speed and centrifugal force.

13. :The shift button of rotating speed and centrifugal force.

14. :The area of acceleration and deceleration

15. :

The “INPULS” button

The “INPULS” button16.:

The “Enter” button

The “Enter” button17. :

The “STOP & OPEN” button

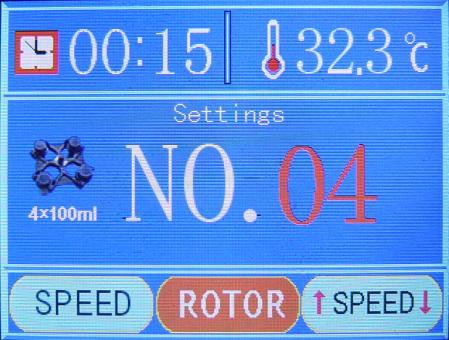

The “STOP & OPEN” button1) The display panel of the startup

Press the “

UP” or “

UP” or “  DOWN” button to choose the proper parameter set. Attention: There are 20 sets of parameter set ranging from 00 to 19.

DOWN” button to choose the proper parameter set. Attention: There are 20 sets of parameter set ranging from 00 to 19.As it is shown below:

2) Press the

SET” button to enter the first adjustment panel, or touch the screen and click the rotating speed area to enter the same panel.

SET” button to enter the first adjustment panel, or touch the screen and click the rotating speed area to enter the same panel.As it is shown below:

①Press the “

UP” or “

UP” or “  DOWN” button to adjust the rotating speed value.

DOWN” button to adjust the rotating speed value.Attention: The slowest rotating speed is 100r, and the fastest is the maximum rated speed of the rotor. 50r rotating speed can be adjusted by each press. Pressing the “UP” or “DOWN” button fixedly can adjust the speed value continuously.

As it is shown below:

②Press the “

SET” button to enter the rotating speed adjustment panel. Next, press the

SET” button to enter the rotating speed adjustment panel. Next, press the“

UP” or “

UP” or “  DOWN” button and press the “

DOWN” button and press the “  SET” button again to enter the time adjustment area. The needed minutes can be chosen by pressing the “

SET” button again to enter the time adjustment area. The needed minutes can be chosen by pressing the “  UP” or “

UP” or “  DOWN” button.

DOWN” button.As it is shown below:

③Press the “

SET” button to enter next step, and the needed hours can be chosen by

SET” button to enter next step, and the needed hours can be chosen bypressing the “

UP” or “

UP” or “  DOWN” button. As it is shown below:

DOWN” button. As it is shown below:

3) On the bottom of the first adjustment panel, press the “

SET” button to enter the second adjustment panel (the adjustment panel of rotor modes), or touch the screen and click the rotor number area to enter the same panel. As it is shown below:

SET” button to enter the second adjustment panel (the adjustment panel of rotor modes), or touch the screen and click the rotor number area to enter the same panel. As it is shown below:

Press the “

UP” or “

UP” or “  DOWN” button to choose the rotor number.

DOWN” button to choose the rotor number.Attention: Please take the real objects as the reference, and find the corresponding real rotor pictures and rotor number.

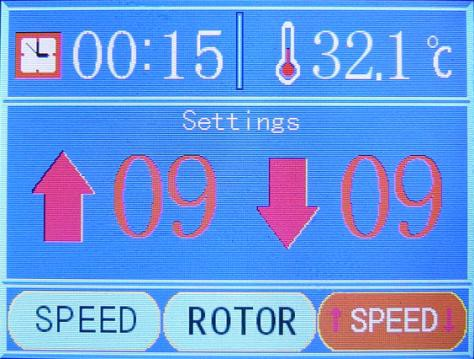

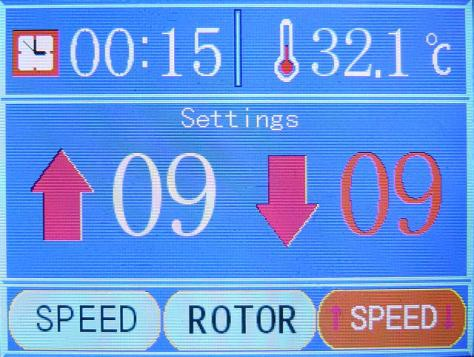

4) Press the SET” button to enter the third adjustment panel (the adjustment panel of acceleration and deceleration), or touch the screen and click the acceleration and deceleration area to enter the same panel. As it is shown below:

①Press the

DOWN” button to adjust the deceleration of the rotating speed, or touch the screen and click the icon to do the same operation. There are 10 deceleration levels: 0 is the

DOWN” button to adjust the deceleration of the rotating speed, or touch the screen and click the icon to do the same operation. There are 10 deceleration levels: 0 is theslowest while 9 is the fastest. As it is shown below:

② Press the “

UP” button to adjust the acceleration of the rotating speed, or touch the screen and click the icon to do the same operation. There are 10 acceleration levels: 0 is the slowest while 9 is the fastest.

UP” button to adjust the acceleration of the rotating speed, or touch the screen and click the icon to do the same operation. There are 10 acceleration levels: 0 is the slowest while 9 is the fastest.As it is shown below:

5) When finishing every step mentioned above, press the “ ENTER” button for about 2 seconds to preserve the adjusted value, and then withdraw from the adjusted state.

6) . After checking out the settings mentioned above, press the “

START” button to start the operation of the machine. During the operation, the current centrifugal force can be displayed on the window by pressing the “

START” button to start the operation of the machine. During the operation, the current centrifugal force can be displayed on the window by pressing the “  RCF” button, or touching the screen and clicking the RCF icon. Repress the button, and the rotating speed value can be displayed again.

RCF” button, or touching the screen and clicking the RCF icon. Repress the button, and the rotating speed value can be displayed again.8 ) When counting down to 0, the centrifuge machine stops working automatically. During the operation, pressing the “

STOP & OPEN” button can also stops the operation of the machine. When the rotating speed reaches 0, the buzzer would make a buzzing sound, and the cue wordswould be displayed on the window. The faceplate can be removed.

STOP & OPEN” button can also stops the operation of the machine. When the rotating speed reaches 0, the buzzer would make a buzzing sound, and the cue wordswould be displayed on the window. The faceplate can be removed.9 )When press the “

IMPULS” button and hold for a few seconds, the rotors would start rotation slowly; when the rotating speed reaches its fastest speed, the rotors would not accelerate

IMPULS” button and hold for a few seconds, the rotors would start rotation slowly; when the rotating speed reaches its fastest speed, the rotors would not acceleratethe speed any more. When relax the “

IMPULS” button, the rotors begin the deceleration until they stop rotating. During the deceleration process, the “

IMPULS” button, the rotors begin the deceleration until they stop rotating. During the deceleration process, the “  IMPULS” button cannot be

IMPULS” button cannot beany longer; when the rotors stop the rotation completely, the centrifugal process would restart by

pressing and holding the “

IMPULS” button.

IMPULS” button.10 、 After the rotors stop the rotation completely, press the “

STOP & OPEN” button to uncover the faceplate (if the faceplate could not be removed because of its high rebound force

STOP & OPEN” button to uncover the faceplate (if the faceplate could not be removed because of its high rebound forceagainst the seal ring on top of the centrifugal chamber, please press the faceplate slightly with one

hand and repress the “

STOP & OPEN” button with the other to open the faceplate), and take out the centrifugal tubes carefully. The whole separation process is done.

STOP & OPEN” button with the other to open the faceplate), and take out the centrifugal tubes carefully. The whole separation process is done.11、Turn off the power switch, and cut off the power of the centrifugal machine

7. Safety Notice

1 . This machine should not be used in the humid places with high temperature and large fugitive dust.2. To ensure the safety and its centrifugal effect, this machine should be placed in the solid, quakeproof and horizontal platform, and all four undercarriages should be given the balanced load.

3. The solutions in the centrifugal tubes should be seen as even as possible. If the solutions in the tubes vary too much, there would be a large scale of vibration. In this kind of situation, the operating machine should be stopped its operation and checked to meet the requirement of the solutions in

the tubes. The centrifugal tubes should be placed symmetrically in the even numbers, and the nut caps connecting the rotors with the motor shaft should be tightened.

4. During the operation process, the centrifugal machine cannot be moved, and the faceplate cannot be uncovered.

5. The faceplate should not be uncovered in the situation that the motor and the rotors do not stop the operation completely.

6 . The power supply has its own earth wire, so the null line and the earth wire cannot be used together, so as to prevent the damage of electric shock.

7. After the whole separation, the centrifuge machine should be cleaned up in time, the power switch should be turn off, and the power supply should be cut off.

8 . It should be very careful to take out the rotors. The proper way is to knock upward slightly the rotors on the bottom by using nonmetal tools (like the handle of the screwdriver) until the connection between the rotors and the motor shaft becomes loose. The rotors should not be pulled out directly with hands after loosening the nut caps, so as not to damage the flexible support system of the machine.

9、The rotors ad the centrifugal tubes should be checked regularly. If there are any cracks or aging phenomena, those components should be replaced immediately.

Instruction: There is an emergency device on the bottom of the machine. If the sample should be taken out during the power outage, the faceplate can be uncovered by pulling the stainless wire on the bottom after the rotors stop the operation. But this device is forbidden to be used during the operation process.

8. Warranty Service Instruction

The warranty period of this centrifuge machine lasts one year since its purchased day. During the warranty period, if the machine is damaged by artificial factors, maintenance services would be provided with some appropriate fee. After the warranty period, all repairs are billed at cost.9. Comment Malfunctions and Obviating Methods

There is a malfunction display window. When the machine breaks down, the buzzer would make a buzzing sound and the cue words would be displayed on the window.1. Overheat.

2. Overspeed.

3. The faceplate uncovers.

4. If the faceplate becomes open during the operation, the machine would enter the stall mode. The malfunction obviation or operation work should be done after the rotating speed turns back to 0.

5. If the setting goes wrong, for example, when the setting rotating speed exceeds the maximum rated speed of the rotors, the machine would automatically run with the maximum rated speed of the rotors.

6. If the operating temperature is too high and the cavity temperature is over 55 centigrade, the machine cannot be operated. After its cooling, the machine goes back to work normally.

Besides the malfunctions mentioned above, please contact the technicians of the manufacturer to obviate the malfunctions. The obviating methods of the common malfunctions are as followed.

| common malfunctions | causes | obviating methods |

| The monitor doesn’t work after connecting with the power supply. | There is no 220V power supply. | Check the power supply. |

| The fuse is melted. | Change the fuse. | |

| The machine can work but the speed cannot be accelerated, or the machine sounds or smells strangely. | The control system goes wrong. | Send the machine to the manufacturer for the maintenance. |

| The actual rotating speed is inconsistent with the setting or displaying rotating speed. The machine runs unstably or even out of control. | The control system goes wrong. | Send the machine to the manufacturer for the maintenance. |

10. Transportation and storage of the machine

1. The outer container has been done the rainproof, dampproof and quakeproof treatment when delivery. The centrifuge machine has been fixed in the outer container, and the outer container should not be inverted, flung or collided violently during the transportation, so as to protect the machine and the accessories.2.If the machine is not used for a long time, the machine should be packed according to the dampproof and quakeproof requirement (the motor shaft should be painted a thin layer of lubricating grease), and preserved in the well-ventilated indoor places with the temperature ranging from -5centigrade to -40 centigrade, under RH<80%, and without corrosive gas.

11. Unpacking and examination of the machine

1. Place the outer container in accordance with the “UP” sign on it, and take out the machine after unpacking the outer container.2. Please check and examine the machine and the accessories according to the packing list. If there are any mistakes, please contact the supplier or the marketing department of the manufacturer in time.

The quality warranty card of the product

(The warranty should be based on this card)

| The name and model of the product | |

| The serial number of the product | |

| Manufacture date | |

| Address of the manufacturer | |

| Telephone number |