Water Bath BGI1BR1 (BBWA-3201)

Circulating Bath, Water Bath, Water Bath- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BGI1BR1 |

| Electrical Requirement | 220V 50Hz |

| Power Consumption | 500W |

| Temperature Range | RT+5~100°C |

| Temperature Stability | ±0.5°C |

| Display Resolution | 0.1°C |

| Chamber Volume | 15.8L |

| Interior Dimension (WxDxH, mm) | 330x300x160 |

| Exterior Dimension (WxDxH, mm) | 570x220x260 |

| Timing Range | 1~9999min |

Features

Microprocessor controller (with timing function)• Microprocessor control with timing function.

• Digital display.

• Audible and visible alarm for over temperature.

Applications

Provided for precise and constant temperature and auxiliary heating in colleges industrial and mining enterprises and scientific research departments.Accessories For Purchase

| Images | Name |

| Intelligent programmable temperature controller |

| RS485 connector |

| Printer |

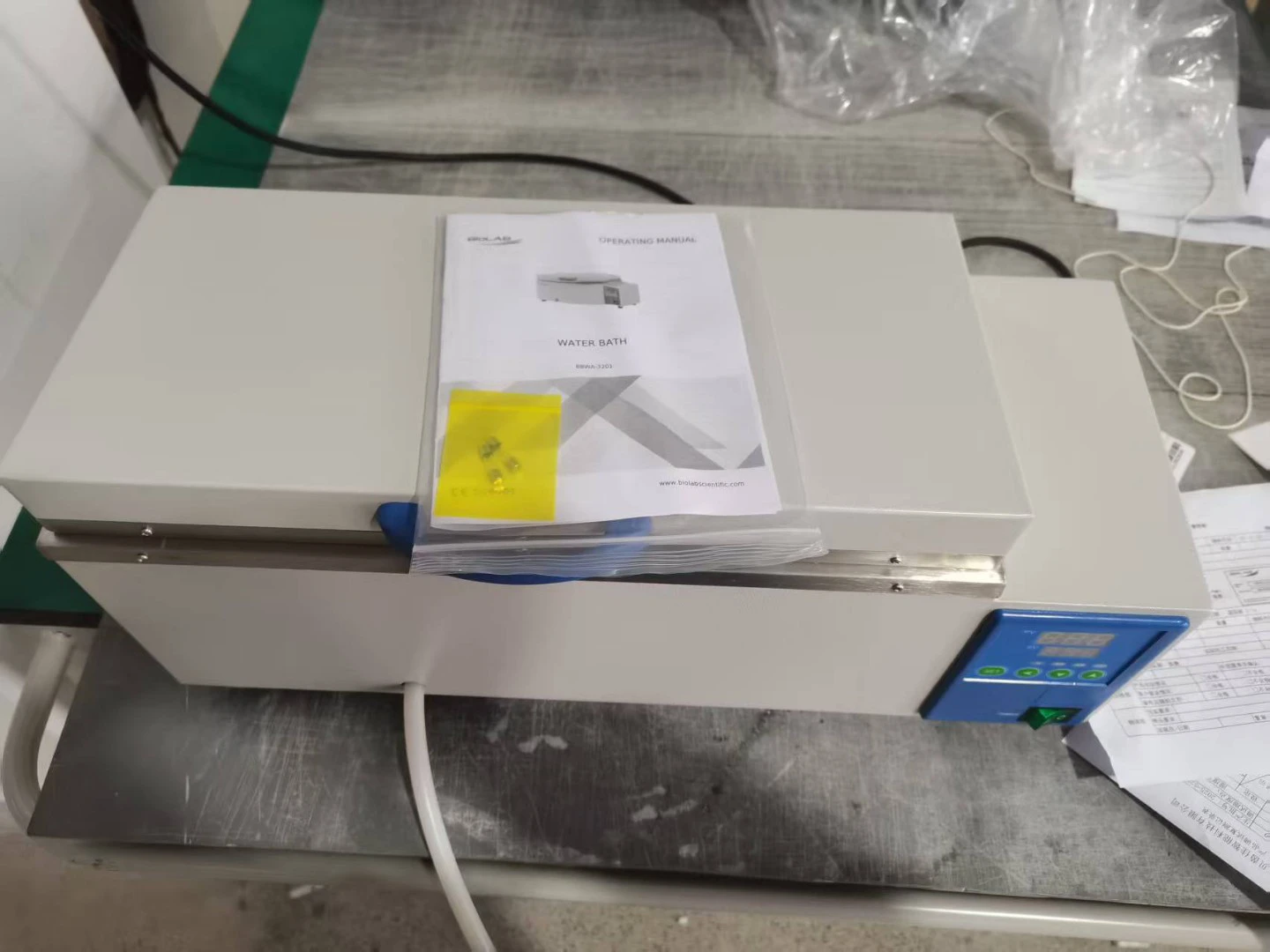

Photos

Operating Manual

Download1. Scope of Application

1.1 Main Technical Parameters

1.2 Structural Description

1.3 Usage

1.4 Operating methods

2. Operation

2.1 Switching on the instrument

2.2 Setting of parameters

3. Precautions

4. Maintenance

5. Failure handling methods

6. Packing list

1. Scope of Application

It is used for precise temperature keeping and auxiliary heating by industrial and mining enterprises, colleges and universities, scientific research institutes and various labs, etc.

1.1 Main Technical Parameters

Model | BBWA-3201 |

Mains voltage | 220-240V 50Hz/60Hz |

Power consumption(W) | 500 |

Range of temperature control | RT + 5 - 99°C |

Temperature fluctuation | ± 0.5°C |

Tracking alarm | ±2°C |

Dimension of the working room(MM) | 420´180´105 |

1.2 Structural Description

The shell of the electrothermal constant- temperature water tank is made of high quality steel plates.The surface is coated with plastic, internal liner, top cover and shelf are made of optimal corrosion-resistant stainless steel. on the bottom is a U-type electrical heating tube directly immersed into water, thus reducing largely heat energy loss; the interlayer adopts hard polyamine resin for insulation, the temperature control device on the right side has a power switch (or two switches: one for power supply and the other for water pump). Instrument control panel has temperature-regulation knob, heating and tracking alarm indicators and temperature digital display, the temperature control meter adopts a micro-computer, thus making the temperature control precise and reliable. BCHT-3302 is specially designed with one low noise magnetic drive pump on the bottom of the right side of the water tank, in order to guarantee the precision of temperature control of the water tank.

1.3 Usage

1. Fill clean warm water into the water tank up to 1/2 ~2/3 of the full height.

2. Set the power switch to "ON" and then figures will appear on the temperature control instrument panel, indicating the power supply is on; if the water pump switch exists, set it to "ON" too.

3. When the measured temperature reaches the set temperature, the heating will be interrupted and the heating indicator will go out, and the temperature will become stable after 60 minutes of temperature keeping. If the temperature in the water tank exceeds the set temperature over 2 °C (alarm temperature can be set arbitrarily), the alarm indicator of the temperature control instrument is on and the power of the heater will be automatically switched off in the meantime.

1.4 Operating methods

1.4.1 COMMANDS and DESCRIPTION

Figure 1

1. (PV) display

* Display measured value

* Various prompts are displayed according to the status of the instrument.

2. (SV) display

* Display set value

* Display various parameter values according to the status of the instrument

3. AT (running indicator light): It lights up when the controller is working, flashes during auto-tuning, and goes off when it stops;

4. HEAT (heating indicator light): It lights up when there is heating output.

5. ALM (alarm indicator light): Lights up when there is an alarm output, and the buzzer sounds.

6. COLD (refrigeration indicator light): on when there is refrigeration output; (Note: this product has no COLD refrigeration function)

7. Used to adjust various parameter values or enter the auto-tuning state

8. Used to adjust the internal parameter value or enter the self-tuning state

9. Shift key: used to shift the set value, internal parameter and observe the timing running time;

10. Function keys:

* Setting value modification

* Recall of parameter symbols and confirmation of parameter modification.

1.1.The  button permits the working parameters setting.

button permits the working parameters setting.

1.2.The  button permits to change quickly the digital value (Program, units, tens, etc.) of the parameter you are editing.

button permits to change quickly the digital value (Program, units, tens, etc.) of the parameter you are editing.

1.3. In combination with the  key allows access to menus with password.

key allows access to menus with password.

1.4.  and

and  adjustment buttons allow you to increase or decrease the value of the operating parameter being edited.

adjustment buttons allow you to increase or decrease the value of the operating parameter being edited.

2. Operation

2.1 Switching on the instrument

1. Connecting the power cord to a power outlet with a protective ground connection.

2. Turn on the instrument by pressing the ON / OFF Button and the display will light up. The display shows the initialization sequence and then the instrument is ready for use.

NOTE: Every time you turn the instrument beeps intermittently, the icon of visual alarm and the word "end" appear on the display, indicating that a heating cycle had been done before. Press any button to silence the audible signal and the icon appears.

2.2 Setting of parameters

2.2.1 Working temperature

1.When the instrument is switched on, pressing  button, to set temperature value PV shows

button, to set temperature value PV shows  . Set the desired temperature value (in Celsius degrees) pressing keys.

. Set the desired temperature value (in Celsius degrees) pressing keys.

2.It's possible a quick movement between the digits using the  button.

button.

3.Confirm the set value with another press of  button.

button.

2.2.2 Working time

1.After confirming the temperature, the last value of the set time (timer), PV shows  Set the desired value, by pressing

Set the desired value, by pressing  or

or  keys. It's possible a quick movement between the digits using the

keys. It's possible a quick movement between the digits using the  button.

button.

2. Confirm the set value with another press of  button.

button.

NOTE: the value indicates the operating mode "continuous", that means once you start the operating cycle by the START / STOP button, it continues maintaining the set temperature until it is stopped manually (START/STOP)

3. If you set a value of time, such as 1 hour, the instrument will reach the set temperature and maintain it for an hour.

2.2.3 Start/stop heating cycle

1.After setting the operating parameters, pressing  and

and  for few seconds button with long pressure (4-5 seconds), the heating cycle starts for the defined time in hh:mm or continuous (00:00). The word "end" at the top right corner of the display disappears, the message RUN appears in the bottom left corner and the display shows contemporary: timer, temperature measured inside the chamber, set temperature and fan speed if present (see Picture 4).

for few seconds button with long pressure (4-5 seconds), the heating cycle starts for the defined time in hh:mm or continuous (00:00). The word "end" at the top right corner of the display disappears, the message RUN appears in the bottom left corner and the display shows contemporary: timer, temperature measured inside the chamber, set temperature and fan speed if present (see Picture 4).

2.At any time, you can always manually stop the cycle by pressing the pressing

and  button with long pressure (4-5 seconds).

button with long pressure (4-5 seconds).

3.Once the set time or after manual stop, the instrument beeps intermittently, the icon of visual alarm and the word "end" appear on the display. Pressing any button, it's possible to silence the audible signal and the icon appears.

NOTE: the acoustic signal will not end until it is stopped by the operator, but the heating cycle is terminated so for the samples inside the instrument will remain exposed to the internal temperature of the chamber.

2.2.4 Functions with password access

Access to menu with password

1. Simultaneously pressing the  for 4 seconds, you can access some functions and parameters that are password protected.

for 4 seconds, you can access some functions and parameters that are password protected.

2. To access these sub menus and avoid mistakenly entering in the operating parameters setting, it is recommended to firstly press the SHIFT key, keep it pressed, and then press the SET / PROG for a few seconds.

3. After making this keys combination, on the right top part of the display instead of the word TIME, "Lk" (lock) appears close to "0003" (password).

Below the passwords and access sequence to the various parameters/functions.

PASSWORD | FUNCTION / PARAMETER | DESCRIPTION |

0003 | tm | Safety temperature limiter for samples protection |

Po | Restart mode after absence of power supply | |

AL | Temperature range for over temperature alarm | |

Pb | Temperature offset on single point | |

PK | Temperature offset on the entire ramp | |

LK | Input the password LK=3, the above parameters can be updated. |

Please don't change the parameter value not listed above.

3. Precautions

1. The shell of the water tank shall be grounded effectively to guarantee the safe use.

2. Before filling water, never press down the power switch so as to prevent the electrical heating tube from being burnt.

3. When any sound and light alarms are sent out from the water tank, please check whether the set temperature deviates from the normal range or not. If not, stop use and invite the professional personnel to inspect it or hand it over to our factory for repair.

4. Unless necessary, never disassemble the side plate of the temperature control unit so as to guarantee safety.

4. Maintenance

1. Always keep the internal and external of the water tank clean, do not wipe the shell with the chemical solution, which can cause chemical reaction, to prevent any chemical reaction.

2. If the instrument is not to be used for a long time, cover it with a plastic thin film dust shroud and place it in a drying room so as to prevent the temperature control instrument from being moisturized and out of use.

3. The instrument is not suitable to be used in the environments of high voltage, heavy current, intense magnetic field or corrosive gases to prevent the instrument from being damaged by intervention and prevent the persons from the risks of the electroshock.

5. Failure handling methods

Problems | Causes | Handling methods |

1. No supply | 1.The plug is not inserted well or the wire is disconnected. | 1. Insert the plug and connect the wire. |

2. Fuse is open. | 2. Replace the fuse. | |

2. The temperature in the cabinet does not increase. | 1. The set temperature is low. | 1. Adjust the set temperature. |

2. The electric heater does not work. | 2. Replace the electric heater. | |

3. The temperature control instrument does not work. | 3.Replace temperature control instrument. | |

4. The cyclic fan does not work. | 4. Replace the fan. | |

3.The set temperature has a big difference from the temperature in the cabinet. | 1.The temperature sensor does not work. | 1. Change temperature sensor. |

2.The fine tuning potentiometer for setting temperature is not adjusted well. | 2. Adjust the potentiometer. | |

4.The over-temperature alarm is abnormal. | 1. The set temperature is low. | 1. Adjust the set temperature. |

2.The temperature control instrument does not work. | 2. Replace the temperature control instrument. |

6. Packing list

No. | Type | Name | Unit | Qty. | Remarks |

1 | Document | Operating instructions | 1 | ||

2 | Document | Packing list | 1 | ||

3 | Spare part | Fuse core | 2 |