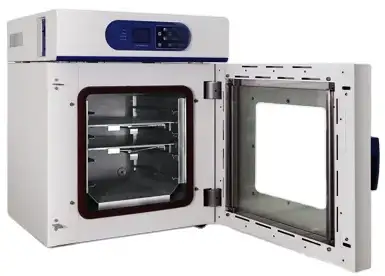

Vacuum Oven BEV1C4 (BOVA-202)

Vacuum Drying Oven, Vacuum Drying Oven(high-end Configuration)- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BEV1C4 |

| Control System | 10-segment programmable microcomputer PID intelligent automatic control system |

| Vacuum Degree display | Digital display |

| Vacuum degree control | Electronic automatic control |

| Temp. Range (°C) | RT+5°C~250°C |

| Temperature resolution (°C) | ±0.1 |

| Temp. Fluctuation (°C) (RT+10°C~240°C) | ±0.5 |

| Timer Range | 0~99h, or 0~9999min, can be chose |

| Working environment | Ambient temperature: 10~30°C, Humidity<70% |

| Insulation materials | Imported environmental protection type material |

| External Dimensions (HxWxD) mm | 783x635x550 |

| Internal Dimensions (HxWxD) mm | 375x348x385 |

| Interior Volume (L) | 50 |

| Interior materials | SUS304 stainless steel inner |

| Standard tray number | 2 |

| Power (W) | 1250 |

| Supply voltage | Single phase AC220V/50Hz |

| Net weight (KG) | 70 |

| Shipping weight (KG) | 73 |

| Packing size (HxWxD) mm | 900x715x670 |

Description

Vacuum Drying Oven designed for drying heat-sensitive and easily oxidized substances, especially suitable for powder or granular samples, and effectively reducing the drying time, which is used in biopharmaceutical, medical utilities, agricultural research and other fields.Vacuum Drying Oven adopts cavity preheating technology, and S.H-Transfer Shelf heat transfer advanced patented technologies, to ensure the smooth progress of the experiment and culture of the sample.

Adopt valve electronic control technology, combined with automatic CNC vacuum, make operation more convenient, greater accuracy.

IQ, OQ, PQ and other related certification services.

CE certification. Two-year warranty period.

Features

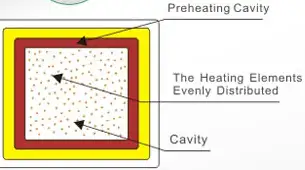

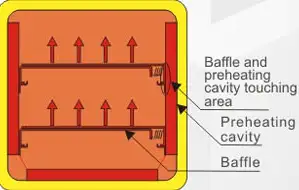

Cavity Warm-up TechnologyThe advanced cavity preheat technology is the heating elements evenly distributed around the inner chamber, the pre-heating of the cavity inner wall, and then through the heat transfer and forced-fan convection, so that the cavity temperature of every point can accurately achieve and maintain setting value, thus ensuring uniform distribution of cavity temperature;

With uniform distribution of heat, so low energy consumption, heat is not easily lost, and enables customers to use cost reduction.

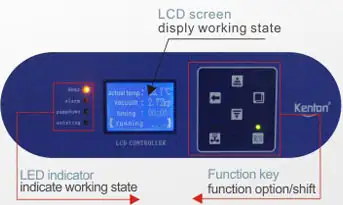

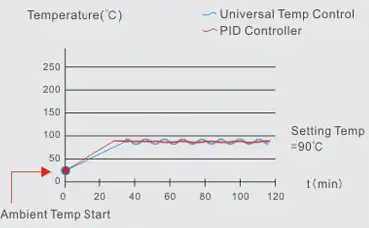

Programmable PID Control

Integrated, dot-matrix LCD display, Chinese and English subtitles, all parameters would be clear at a glance

User-friendly design. Display parameters: temperature, vacuum, cycle, run time, run/stop.

Adaptive PID controllers precisely control the temperature, prevent temperature soaring, keep the working room temperature stable and uniform.

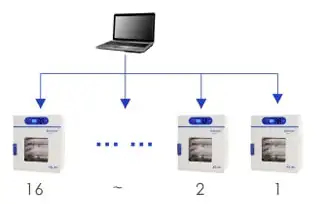

User password protection, built-in multifunctional memory menu, connect to multiple devices (up to 16 units) by RS485 interface at the same time, real-time monitoring.

Programmable multistage control, to meet customer needs, temperature control up to 10 sets. Time setting: 0-99 h, 0-9999 min, programs can be executed automatically cycles.

Set operations with beep tips.

Can use the remote control of computer software, professional supporting the operation programmable software (optional).

Micro-computer intelligent controller

Software

Power socket and Rs485 interface

Shelf Heating Transfer Technology

Leading international record shelf heat transfer technology, increase effective contact area between shelf and pre-heating chamber, make shelf temperature and pre-heating chamber temperature consistent. Shelf heat transfer technology successfully resolved problems that reduced heat transfer under vacuum, so that sample would be the most direct and optimized heat transfer.

Baffle heating transfer technology

Excellent Imported Temperature And Vacuum Sensor

Imported industrial temperature sensor PT100, short response time, low self-heating temperature.

Imported pressure sensors, to provide accurate pressure value, provide an effective guarantee for vacuum stability control.

Pt100temperature sensor

Vacuum sensor

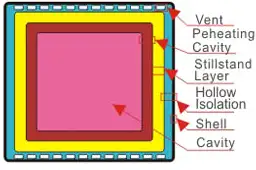

Pro- Insulation Technology

Based on the effective use of heat as a concept, use complete isolation design between the liner and shell to avoid energy loss due to heat transfer.

Adopt imported high-density thermal insulation material wrapped liner, effective heating insulation and stillstand.

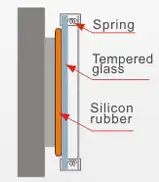

Good silicone door seal, isolation-type hinge design, equip with buckle door handles, ensure excellent sealability.

Pressure protection

Double protection observation window

Accessories For Purchase

| Name |

| Portable printer |

| Gas interface |

| Software |

| Vacuum pump. |