Pilot-scale Freeze Dryer BFH1D4

Pilot-scale Freeze Dryer- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BFH1D4 |

| Freeze-dried area | 1.512 m² |

| Ice condenser capacity | 18kg |

| Shelf temperature | -60°C~+70°C |

| Ice condenser temperature | -86°C |

| Cold trap volume | 30L |

| Chamber type | Double |

| Max number of shelves | 12+1 |

| Shelf size | 340*500mm |

| Shelf spacing | 100mm (adjustable) |

| Number of penicillin bottlessmm) | 2820 |

| Shelf heating and cooling method | Thermal conducting silicone oil medium(temperature resistance: -100~+600 degree C) |

| Chamber and shelf surface | Atomization and electrolysis surface treatment, no dead corner residue |

| Pipeline diameter | Φ89mm |

| External valve port | - |

| Equipment power | 8kw |

| Equipment size | 1500*850*1900mm |

| Capping mode | No capping |

| Suitable clean room | Suitable |

| Vacuum sensor type | Pirani Vacuum sensor/capacitive vacuum sensor |

| Remote control and alarm | Support 2G/4G/GSM/Wi-Fi |

| Terminal judgment function | Pressure test/pressure contrast method |

| Freeze dryer front door cover | Stainless Steel |

| Inert gas filling | (Optional) Sufficient amount and time for the program to run itself |

| User function customization | Can be customized and modified according to user needs |

| Sterilization method | H₂O₂/steam sterilization |

| Voltage(V/Hz) | 380V |

Description

Pilot-type freeze dryer completely simulates the technical requirements of the industrial freeze dryer, with a compact and reasonable design, a large redundancy range, and conforms to GMP and FDA standards. The ice condensation capacity is 4~18kg, and the WRL controller and liquid temperature control shelf are adopted, so that the process of pre-freezing and freeze-drying canbe precisely controlled on the main machine, and the process results are quite comparable with the production machine. In addition to supporting the eutectic point test system, pressure rise and pressure comparison method to determine the freeze-drying end point and freeze-drying curve recording software, Yingtai pilot-type freeze dryer can also be equipped with engineering

WRL control software to directly Graphical computer control the freeze-drying process. It can be configured with H202 sterilization and high-pressure steam sterilization or integrated glove box system, which can be used for clean room operation through the wall. The cold trap and freeze-drying chamber are all designed with 316L stainless steel to ensure the cleanliness of the chamber and good ultimate vacuum and vacuum leakage rate to the greatest extent.

Pilot-type freeze dryer can be used for freeze drying of bacteria, viruses, plasma, serum components, antibodies, serum and vaccines, pharmaceutical products such as chloramphenicol, streptomycin, vitamins, enzymes, plant extracts for biochemical experiments, etc. And research and development.

Features

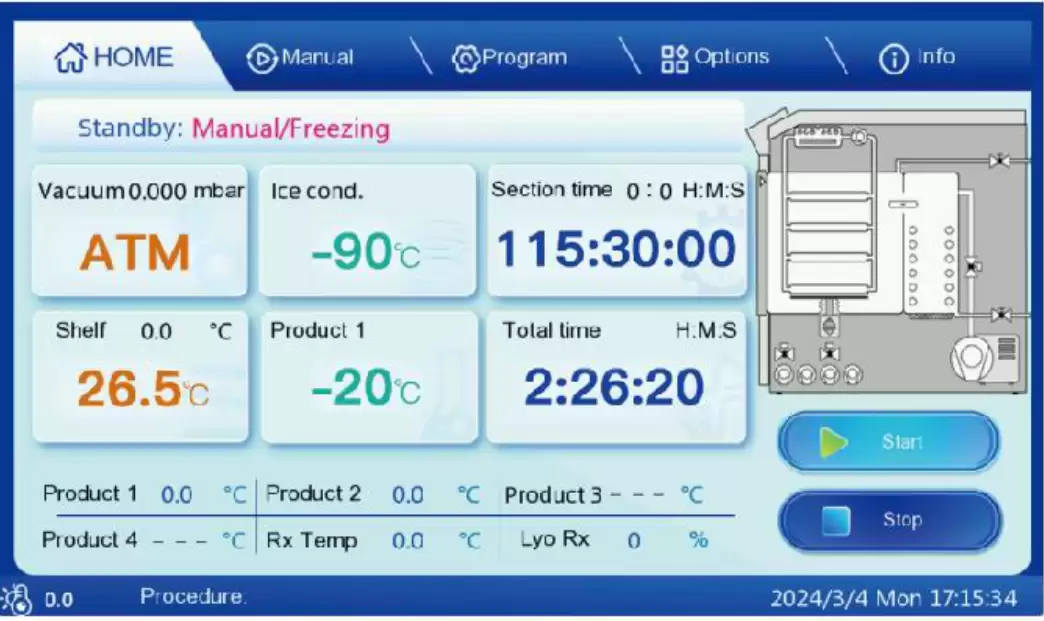

Control System:1. Control: Automatic/Manual

Can store at least 100 independent freeze-drying programs, each program contains 32 program segments(Can be customized according to user needs), each program segment corresponds to a processing stage (Pre-freezing, main drying, post-drying) and include the following segment values: Cycles, shelf temperature, vacuum and safety pressure for the heating unit.

All The equipment can be recorded in real time and the corresponding freeze-drying curves and data tables can be generated after the end of the process. The records of all data and curves comply with the corresponding regulations and standards.

It has hierarchical management authority, hierarchical management allocation authority and usage process tracking authority.

2. Remote System:

Fully support 2G/4G/GSM/Wi-Fi various connection modes.

Users can remotely view all data on the device and operate it.

Technicians can remotely perform maintenance and fault detection on equip- ment, and can remotely guide and train users.

Can remotely upgrade and change the system of the equipment.

Working Chamber:

Double-chamber stainless steel system, optional Teflon anti-corrosion treatment.

Material: stainless steel 316L; Each layer is equipped with a standard sample temperature probe.

Built-in condenser, high condensation efficiency.

Plexiglass cold trap window and stainless steel door cover(optional), can observe the ice formation in the cold trap. Applicable to clean room. Refrigerant reverse hot gas defrosting.

Layer temperature:<+1°C; Layer flatness: <+0.5mm /m square.

Vacuum System:

Vacuum pump: Domestic high-reliability two-stage rotary vane vacuum pump. Optional German Welch corrosion-resistant, anti-oil backflow vacuum pump. The vacuum pump can be selected according to user requirements.

Pump rate: 9m3/h~62m3/h, multiple specifications are optional, the ultimate vacuum can reach 2x10~5 x 10 mbr, and the oil mist filter is standard configuration.

The vacuum pipelines are all high-vacuum stainless steel vacuum tubes, which can effectively prevent vacuum leakage and corrosion.

Double anti-oil return device completely eliminates the damage and pollution caused by the oil return of the vacuum pump pipeline to the equipment and samples.

Automatic backfill air device, the system has a built-in High Efficiency Particulate Air(HEPA) filter to ensure the complete cleanliness of backfill air.

The vacuum stabilization system can stabilize the vacuum degree of the freeze-drying process through the micro-pass vacuum control valve to ensure that the samples will not be affected by excessive fluctuations in the vacuum degree.

Condensed liquid collection and discharge system, automatically completes the collection and discharge of condensed liquid after freeze-drying.

Pirani Vacuum sensor/capacitive vacuum sensor.

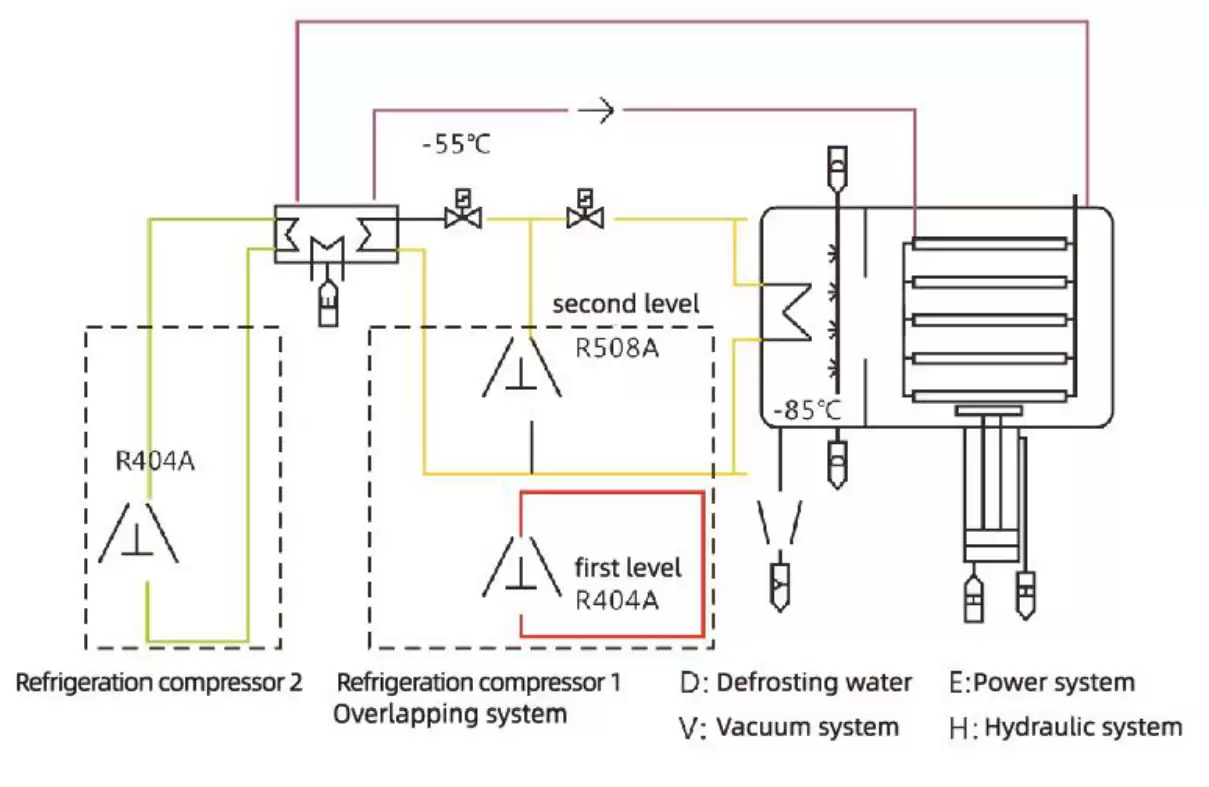

Refrigeration System:

Dual compressors, Tecumseh special compressors, air cooling(water cooling system is optional)

Refrigeration method: Cascade refrigeration method, high cooling efficiency, good reliability, using CFC-Free environmentally friendly refrigerant.

Silicone oil conducts heat, with uniform temperature and accuracy up to 0.1°C. Silicone oil has a wide temperature range, up to -100°C~+600°C

Note: "/" optional. Pilot models can be customized according to user needs