Liquid Suction Vacuum Pump BFA1DD4 (BVAP-201)

Liquid Suction Vacuum Pump- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BFA1DD4 |

| Max. flow rate | 8L/min |

| Vacuum degree | -0.065Mpa |

| Vacuum display mode | Vacuum gauge |

| Negative pressure adjustment range | 0~-0.065Mpa |

| Waste liquid bottle capacity | 1000mL |

| Foot switch | / |

| Voltage | DC24V 0.8A |

| Power | 8W |

| Fuse | / |

| Dimension (mm) | W.130xD.288xH.300 |

| Net Weight | 1.6kgs |

Description

The liquid suction filtration vacuum pump series is mainly used for separation of culture fluid and culture tissue after biochemical culture, extraction of cell culture waste liquid, and suction of various waste liquids in the laboratory. Different flow specifications are available to meet more experimental needs, and it is the best experimental assistant indispensable for the laboratory aseptic workstation.Features

Pumping filter brackets are equipped on both sides of the instrument, easy to store and select the suction filter accessories.Standard equipped with multi-function suction filter handle and 5 kinds of suction head accessories to meet more requirements of suction experiments.

Sealed waste liquid bottle cap design, quick-insertion sealing joint, convenient to get out of the fuselage bottle and clean up waste liquid.

Normally open control mode and foot switch control mode, to meet more experimental requirements.

Waste liquid bottle, suction filter fittings and dish filter can all be used for autoclave sterilization.

There is a liquid level protection switch in the waste liquid bottle to prevent the waste liquid from overflowing and being sucked into the pump chamber to ensure no troubles in suction filtration.

There is a PTFE dish shape filter between the bottle and the pump to protect the environment from harmful gas pollution.

The self-locking quick connector can be quickly and easily separated from the pipeline, which is convenient for safely cleaning the waste bottle.

Built-in high quality oil-free vacuum pump, no maintenance, low noise and long life.

The standard handheld multifunctional suction filter handle and 5 kinds of suction head accessories can meet the needs of more suction experiments.

Accessories Included

| Images | Name | Material | Quantity |

| Hand-held operator | POM | 1 |

| Eight-channel retractable tip plastic extraction head | POM | 1 |

| Eight channel stainless steel extraction head | POM+SUS304 | 1 |

| Single channel plastic extraction head | POM | 1 |

| Single channel retractable tip plastic extraction head | POM | 1 |

| Single channel stainless steel extraction head | POM+SUS304 | 1 |

| Foot switch (For ZK26E/35/42 use only) | Al | 1 |

Operating Manual

Download1. Introduction

2. Specifications

2.1 Normal Operating Conditions

2.2 Basic Parameters and Performance

2.3 Product accessories and parameters

3. Basic operating instructions

3.1 Structure Description

3.2 Operation panel diagram and description

3.3 Instrument installation diagram and description

4. Operation Guide

4.1 Notice before Operation

4.2 Using Steps

4.3 Special reminder after use

5. Failure Analysis and Trouble Shooting

Appendix A

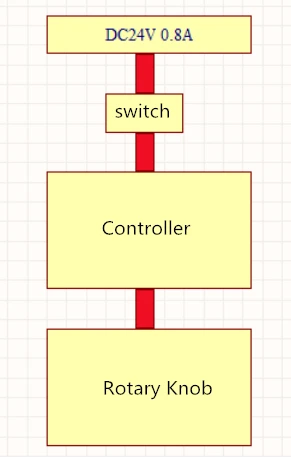

Mini Vacuum Pump Wiring Diagram

1. Introduction

The mini vacuum pump series is mainly used for separation of culture fluid and culture tissue after biochemical culture, extraction of cell culture waste liquid, and suction of various waste liquids in the laboratory. Different flow specifications are available to meet more experimental needs, and it is the best experimental assistant indispensable for the laboratory aseptic workstation.

Product Features

Pumping filter brackets are equipped on both sides of the instrument, easy to store and select the suction filter accessories.

Standard equipped with multi-function suction filter handle and 5 kinds of suction head accessories to meet more requirements of suction experiments.

Sealed waste liquid bottle cap design, quick-insertion sealing joint, convenient to get out of the fuselage bottle and clean up waste liquid.

Waste liquid bottle, suction filter fittings and dish filter can all be used for autoclave sterilization.

There is a liquid level protection switch in the waste liquid bottle to prevent the waste liquid from overflowing and being sucked into the pump chamber to ensure no troubles in suction filtration.

There is a PTFE dish shape filter between the bottle and the pump to protect the environment from harmful gas pollution.

The self-locking quick connector can be quickly and easily separated from the pipeline, which is convenient for safely cleaning the waste bottle.

Built-in high quality oil-free vacuum pump, no maintenance, low noise and long life.

2. Specifications

2.1 Normal Operating Conditions

Working Environment Temperature: 4□C □45□C

Relative Humidity: ≤70%

Power: AC100V~230V, 50/60Hz

2.2 Basic Parameters and Performance

Model | BFA1DD4 |

Max. flow rate | 8L/min |

Vacuum degree | -0.065Mpa |

Vacuum display mode | Vacuum gauge |

Negative pressure adjustment range | 0~-0.08Mpa |

Waste liquid bottle capacity | 1000mL |

Voltage | DC24V 0.8A |

Power | 8W |

Dimension | W.130xD.288xH.300mm |

Net Weight | 1.6kgs |

Table 1

2.3 Product accessories and parameters

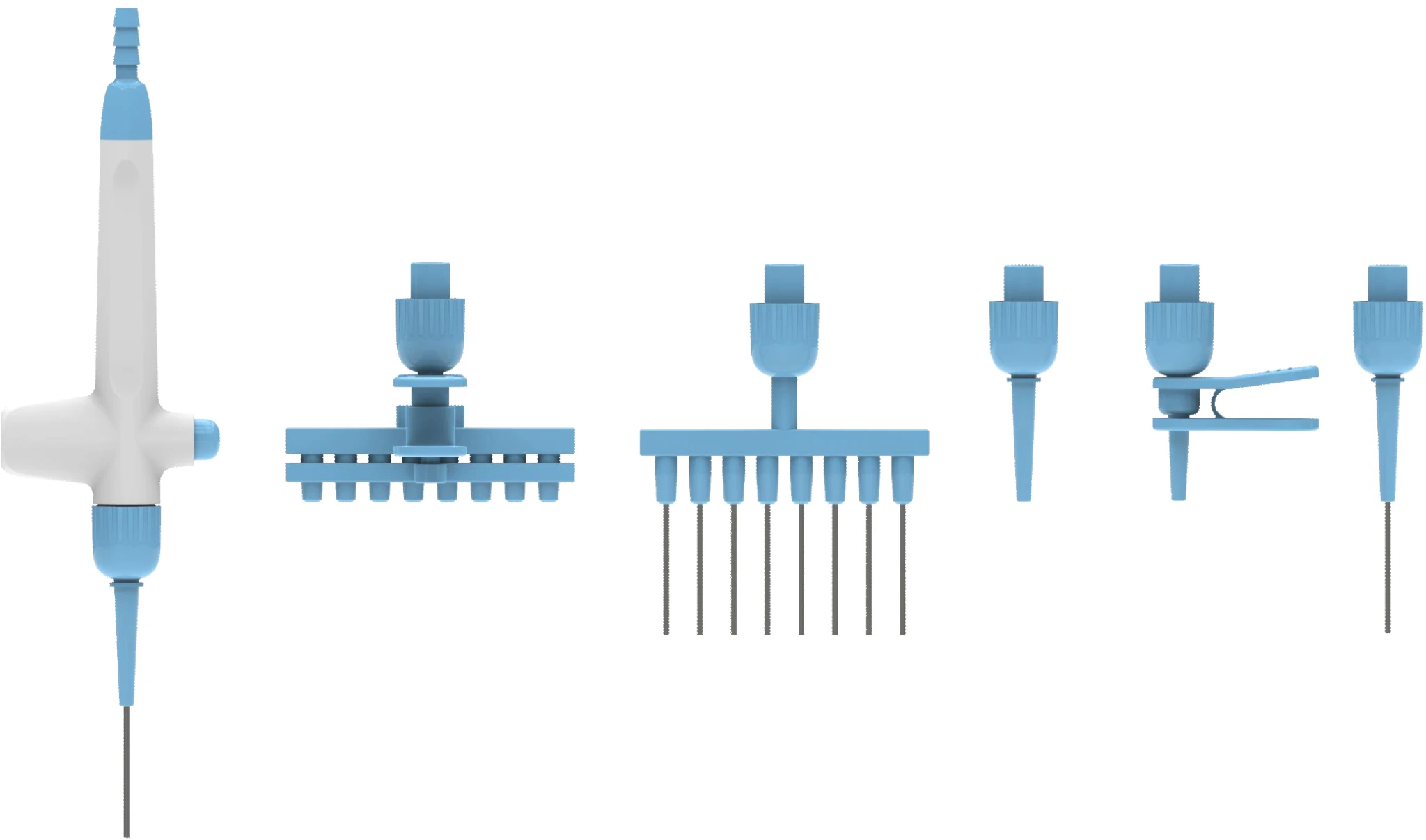

Figure 1

Mode l | Name | Material | Quantity |

BF-A | Hand-held operator | POM | 1 |

BF-B | Eight-channel retractable tip plastic extraction head | POM | 1 |

BF-C | Eight channel stainless steel extraction head | POM+SUS304 | 1 |

BF-D | Single channel plastic extraction head | POM | 1 |

BF-E | Single channel plastic extraction head | POM | 1 |

BF-F | Single channel stainless steel extraction head | POM+SUS304 | 1 |

Table 2

3. Basic operating instructions

This chapter mainly introduces the structure of the instrument, the functions of the operation panel, and preparations before starting the machine. When using the instrument for the first time, you should be familiar with this chapter before starting up.

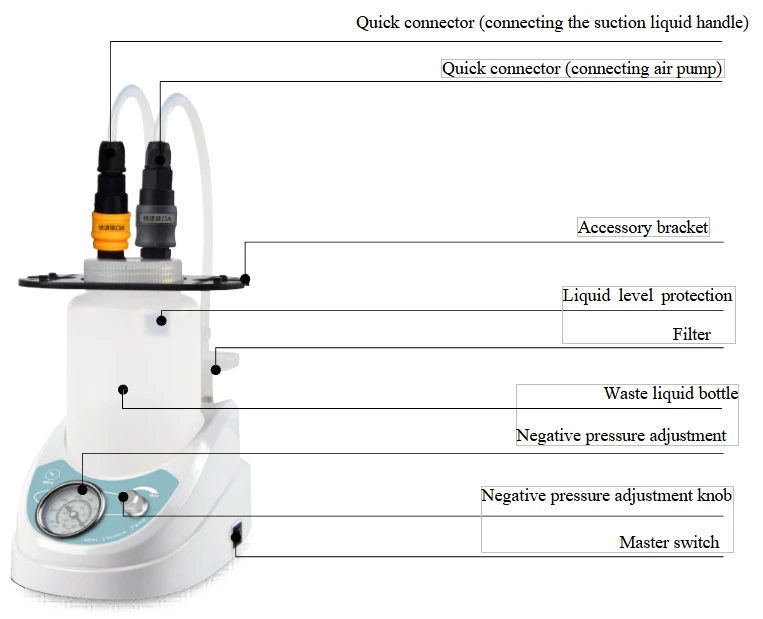

3.1 Structure Description

Figure 2

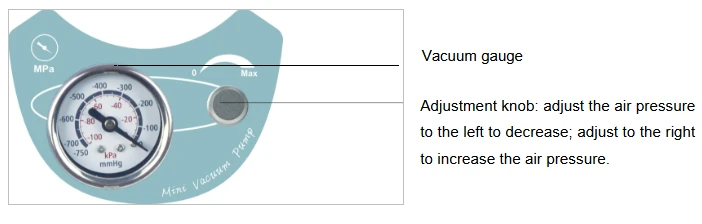

3.2 Operation panel diagram and description

Figure 3

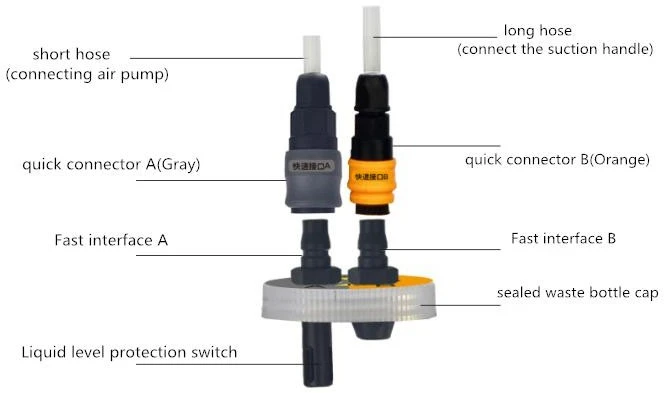

3.3 Instrument installation diagram and description

Figure 4

a) connect the quick connector A to the quick interface A; connect the quick connector B to the quick interface B;

b) Long hose connection suction handle; short hose connection vacuum pump (instrument) filter interface end.

4. Operation Guide

4.1 Notice before Operation

a) Be sure to confirm that the quick connector is connected correctly before use. The gray quick connector A with one end of the liquid level sensor should be connected to the filter!

b) When the filter is contaminated by the medium, the filter should be replaced. The filter is marked with the OUT output port connected to the air pump, and the IN inlet interface is connected to the quick connector A.

c) If the instrument fails and the pump does not work, check the fuse.

d) The waste bottle should retain a small amount of water for easy cleaning, but do not use any chemicals, disinfectants and detergents inside to prevent container leakage.

e) Place the instrument in a dry, clean, well-ventilated area; do not use a flammable environment.

f) If the power cord is damaged, it must be replaced by the manufacturer or its service agent or qualified personnel to avoid a hazard.

g) When the waste liquid bottle is about to be filled, please pour it out in time to avoid overflow, which may cause inconvenience and pollution.

h) Before stop working, make vacuum pump empty run for one minute, discharge the residual liquid in the path. If viscous liquid retention occurs, please use clean water to do a pipe cleaning.

i) In order to extend the life of the motor, the continuous operation of the vacuum pump should be less than 30 minutes. If the temperature is too high, turn off the power and restart after the temperature drops.

j) The vacuum pump cannot be started under negative pressure. When the start under negative pressure does not work, the internal negative pressure needs to be eliminated. It is recommended to unplug the quick connector and re-plug it.

4.2 Using Steps

a) Place the vacuum pump on the operating table smoothly.

b) Turn on the power on/off switch.

c) Adjust the negative pressure adjusting knob to set the vacuum degree.

d) Use the suction handle to suck up the liquid.

e) After use, disconnect the instrument from the air pump and empty run for one minute to drain the residual and corrosive gases in the pump to avoid affecting the service life of the components inside the pump.

f) Turn off the power and stop working.

★ Reminder: If there is no air pressure when the liquid suction handle sucks liquid, you need to adjust the position of the sealing cover and press it gently to ensure stability before sucking the liquid.

4.3 Special reminder after use

After use, please clean the liquid residue on the instrument in time, move the instrument at the same time, and clean the air outlet position of the instrument and the desktop position to prevent corrosion of the instrument or desk.

5. Failure Analysis and Trouble Shooting

No. | Phenomenon | Possible Causes | Processing Procedure |

1 | Do not operate when switch on the power | No power | Check the power connection |

Low voltage of power supply | Access standard voltage | ||

Motor is in thermal protection status | Wait till the motor temperature down to normal | ||

Pump inside is negative pressure | Restart after eliminate the negative pressure | ||

Low temperature, membrane hard-shelled | Wait till the temperature raise to normal | ||

2 | Pump proper functioning, vacuum degree cannot achieve | Check the gas tightness | Ensure the gas tightness of each point |

Foreign matter on membrane of pump | Clean the membrane | ||

Broken membrane | Exchange the membrane | ||

air outlet plug up | Clean the air outlet | ||

3 | Pump proper functioning, Pointer does not move. Pump at rest, pointer is not turn to 0. | Broken negative pressure meter | Exchange the negative pressure meter |

Table 3

Appendix A

Mini Vacuum Pump Wiring Diagram

(This drawing is for reference only and is subject to change without prior notice)

Figure 5