Laboratory Vertical Autoclave BEX1B1 (BAVT-101)

Vertical Pressure Steam Sterilizer- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BEX1B1 |

| Chamber volume | 35L φ318 x 450mm |

| Working pressure | 0.22MPa |

| Working temperature | 134°C |

| Max. working pressure | 0.23MPa |

| Heat average | ≤ ±1°C |

| Timer range | 0~99min or 0~99hour59min |

| Temperature adjust range | 105~134°C |

| Power | 1 x 2.5KW/AC220V.50Hz |

| Overall dimension (mm) | 470 x 450 x 1020 |

| Transport dimension (mm) | 540 x 540 x 1140 |

| G.W./N.W | 81kg / 63kg |

Features

Fully stainless steel structure.Hand wheel type of quick-open door structure.

Door safety lock system.

LCD display of working status, touch type key.

Auto discharge the cool air, and steam discharge automatically after sterilization.

Over temperature & over pressure auto-protection.

Safe protection of water lacking.

Self-inflating type seal.

Automatically shut off with beep reminding after sterilization.

Easy to operate, safe and reliable.

With two stainless steel sterilizing baskets.

Optional drying system.

LCD display automation

Applications

The vertical pressure steam sterilizers are assembled with a heating system, micro-computer controlled system, over heat and over pressure protection system, which are reliable for the sterilizing effects, convenient for operation and energy conservation. They are ideal equipment for clinics, scientific research institutes and other organizations to sterilize surgical instruments, fabrics, glasses, culture media etc.Photos

Operating Manual

Download1. Safety Instructions

2. Explanation of symbols

3. Introduction

4. Scope of application

5. Disable

6. Normal working conditions

7. Basic parameters

8. Characteristics

9. Construction

10. The preparation

10.1 The installation

10.2 The preparation before using

11. The operation instruction

11.1 The control board instruction

11.2 Number setting and query operation

11.3 Sterilization Work Process Description

11.4 Common faults and troubleshooting

12. Safety features

12.1 Water lack overheat protection

12.2 Over voltage Protection

13. Precautions and maintenance

14. Electric scheme

15. The breaker and the fuse capacity

16. Durable years

17. Producing date

18. Accessories and the package list

Appendix 1

1. Safety Instructions

1) Please read this manual carefully and understand the requirements of all warnings and cautions before using. The users MUST check the safety performance of the sterilizer and check if the sterilizer is in good working condition before using.

2) The sterilizer should be used according to the scope of application, use method, and precautions specified as the manual said. Otherwise, the unit might be damaged or the sterilization may fail.

3) There are some safety protection features equipped with the unit to prevent operators from injury and protect equipment from the damages. The operators should understand each step before starting using.

4) Requirements for the operator: The operator must be trained be aware of the equipment's performance characteristics, working principles, and on-site operation, has a certain knowledge of the sterilization process. Before the operation, this manual must has been carefully read and understood.

5) Requirements for the maintenance person: the maintenance person should have corresponding qualifications, professional repair capabilities and familiar experience.

6) This equipment is classified as type I pressure vessel. During the using, the relevant provisions of the National Pressure Vessel Regulations should be observed. The responsible person should be identified to ensure the safe and correct use of the equipment.

7) In the process of designing and manufacturing, we have fully considered the safety use of the product, but the operator still have to check and observe the working status constantly while the equipment is running.

8)The connection between the user's network power supply and the power supply should meet the relevant requirements of the national electrical safety standards.

9) If the voltage fluctuation exceeds 10%, the equipment can not work properly.

10) The sterilizer complies with "GB/T18268.1-2010 Electromagnetic Compatibility Requirements of Measurement and controlling for Laboratory Use Electrical Equipment , Part 1: General Requirements." Please ensure an EMC environment for the normal running of the equipment.

The sterilizer meets the design and test of Class A equipment in GB4824-2013. Do not use this sterilizer next to a strong radiation source (eg. unshielded RF) as which may affect the normal working.

It is suggest that the user evaluate the electromagnetic environment primarily to ensure the sterilizer working normally.

11) In accordance with the relevant provisions of national and industrial laws and regulations, this equipment is designed and manufactured in accordance with the relevant requirements of GB4793.1-2007, and this equipment meets the relevant safety requirements of GB4793.1-2007.

12) The replacement of the door gasket is determined according to the frequency of using, the rate of natural aging, and the conditions of cleaning, disinfection, and sterilization. If no damage occurs, the door seals can continue to be used, or they should be replaced in time.

13) The equipment and accessories should be used within the specified service life, the overdue use may bring certain safety risks. Due to the aging of the equipment and accessories, there might be some safety risk and hidden dangers at the tail of the service life. Therefore, the equipment safety should be checked every time before using, and the broken spares should be replaced if necessary.

14) The disposal of the accessories of this equipment and equipment itself after the service life shall be conducted in accordance with the relevant regulations of the national and regional environmental protection, and it shall be avoided to pollute the environment or create safety hazards.

15) The quality of the water source should meet the requirements of Appendix A of YY 1007-2010.

16) The Safety valves should be regularly tested according to the relevant national regulations.

17) MUST disconnect the device before installing a fuse or performing electrical repairs. The fuse for replacement should be with a suitable current value. The model, specifications, and current values should comply with the specifications of this manual.

18) Confirm the device circuit switch status before operating on which. If malfunction happens, the device's main power switch should be immediately disconnected.

19) To ensure the safety and avoid electric shock, ensure that the equipment is properly grounded. Do not modify the grounding protection wire inside or outside the equipment or remove the wiring of the grounding protection terminal. Or the protection function of the equipment is failed, and cause a shock hazard.

20) MUST pay attention and stay away from the area with hot-proof mark, and exhaust port of the device to avoid burns.

2. Explanation of symbols

Some symbols and codes are used on the sterilizer's shell or in this manual or on the outer carton instead of the text description. The explanation is as followed:

symbols | instruction |

| Fragile items (the transport package containing fragile items, handling with care) |

| Keep Up (the transport package should be straight up during transport) |

| Avoid wet (the transport packages should be kept in dry) |

| Temperature limit (the temperature range during the transport package should be maintained) |

| Alternating current |

| Protective grounding/ (Protection conductor terminal) |

| Disconnect (the main power supply) / (cut (power)) |

| Switch on (main power) / (connect (power)) |

| Caution, shock hazard / (electricity danger) |

| Caution scalds |

| Be careful, Dangerous / (NOTE! See random file) |

PT/TT | Pressure/temperature test |

Table 1

3. Introduction

The vertical pressure steam sterilizer is consists of the shell, the sterilizing drum, the steam generator, the control system, and the power supply system.

The Vertical pressure steam sterilizers (hereinafter referred to as sterilizers in short) are equipments that sterilize articles through saturated steam.

The sterilization chamber is a single-layer structure and equipped with steam generator to create the steam itself. It discharges the steam at the lower side of the unit for the air exchange of the chamber, cross beam structure seals the cover, and with digital controlled the whole cycle.

4. Scope of application

For the clinical institutions using to sterilize the medical devices, dressings, glassware, and solution media throughout saturated steam.

5. Disable

This sterilizer cannot be used to sterilize items that cannot bear the high temperature, high pressure or wet.

6. Normal working conditions

a) Ambient temperature +5°C~+40°C

b) Relative humidity ≤85%RH

c) Atmospheric pressure 70kPa~106 kPa

Note: By using the sterilizer, the operator should consider the impact of the local atmospheric pressure on the parameter settings.

d) Power supply AC 220V±22V,50Hz±1Hz.

Note: The water supply should not affect the sterilization process and does not damage the sterilizer or sterilized items. The quality of water supply should comply with the provisions of YY 1007-2010 Appendix A.

7. Basic parameters

Capacity 35L

Max.work pressure 0.22MPa

Max.work temperature 134°C

Heat evenness ≤±1°C

Timer range 0~99min

Temp.range 0~134°C

Power consumption 220(1±10%)V 50(1±2%)Hz

Stereo power / voltage 2500W

Characteristic Cooling air release,sterilize,timing,air release,timing,alarm

Safety Over pressure,over temperature protection device:auto pressure release,lack water and overheat protection,over current power cut off ;the door be locked when the pressure inner over0.027MPa,with the function of interlock;

Dimension 450mmx450mmx1010mm (LxWxH)

Trans Dimension 570mmx550mmx1150mm (LxWxH)

G.W 72Kg

8. Characteristics

• Equipped with a pressure/temperature controller, the pressure setting range is 0.07 to 0.22MPa (corresponding to a saturated steam temperature of 115 to 134°C).

• Equipped with a timer to automatically control the sterilization time.

• Equipped with a safety valve and pressure gauge, the relief valve would automatically releases the pressure when the sterilization pressure exceeds the maximum allowable value.

• The immersed type electric heating tube, which is with anti-dry function. When the water level is lower than the specified water level line, the sterilizer automatically cuts off the heating power and alarms at the same time.

• If the door cover doesn't closed tightly, the machine cannot be started .

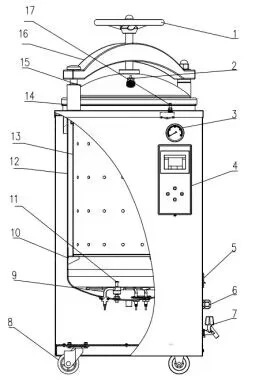

9. Construction

Figure 1

Outline structure

1.hand wheel

2. self locking device

3. pressure gauge

4.control board

5 .circuit breaker

6.power cord

7. water tap

8.pulley

9.heater

10.probe

11.low water level protector

12.container

13.inner pot

14.gasket

15.screw rod

16.cross arm

17.cover controller

10. The preparation

10.1 The installation

Equipment placement:

a) The equipment should be placed on a flat surface.

b) The equipment should be kept at a certain distance from the wall, 30 cm from the left wall, 20 cm from the back wall, and 80 cm from the right wall.

c) DO NOT place the steam vent of the safety valve too close to the power outlet, and DO NOT be blocked by anything.

Power connection:

a) Power requirements: single-phase AC 220V ±10%, 50Hz

b) The equipment MUST be reliably grounded. If the outlet does not have a ground end, the equipment must be grounded with a separate grounding conductor before connecting the power.

Warning:

(1) The power cord must be connected to the power switch for only use. Do not twist or pull the power cord, which might cause damages and looseness to the wires, and bring fire hazard or electric shock.

(2) The equipment must be grounded reliably. Do not connect the ground wire to plastic pipes, gas pipes, water pipes, etc.

10.2 The preparation before using

a) Check if the power supply parameters are consistent with product requirements.

b) After piling the items, place them on a sieve plate sequentially, and leave some appropriate gaps between the packages. We suggest to make the packages into 20cm x 20cm x 10cm. The dressing and the textile should not be tightly packed.

d) Prepare a sterilizing indicator (chemical indicator card or biological indicator ).

11. The operation instruction

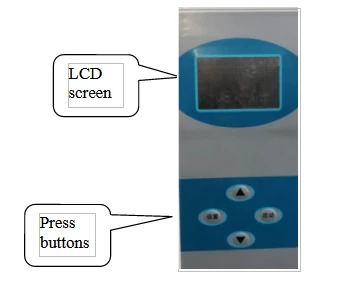

11.1 The control board instruction

The operation panel is shown in below figure

Figure 2

Other instruction

Break switch

At the lower side of the sterilizer, which is used during the equipment is under standby status.

Drain knob

At the lower part of the sterilizer, which is used for the discharge of water from the container (see fig.1).

11.2 Number setting and query operation

• Press the setting button "☞" to flash, press the "▲" and "▼" buttons to select the required mode. The self-define mode is for the freely set.

• Press the "SET" button again: modify the sterilization temperature, and the temperature display flashes. If you select the fixed mode, the temperature cannot be set.

• Press the "Set" button again to modify the sterilization time.

• Press the "Set" button again to modify the drying time.

• Press the "SET" button again, to choose print or not. At the TIME area, the HOUR position shows 05, if the MINUTE position shows 00 means no print or 01 means print.

• Press the "SET" button again, to choose drain the water or not after sterilizing. At the TIME area, the Hour position shows 05, if the MINUTE position shows 00 means no draining or 01 means draining.

• Press the "SET" button again to save the parameter, and exit.

• Set the clock: Press the "▲"for 5 times to set the YEAR, MONTH, DATE AND TIME.

• Long time press the "SET" button for 5 seconds by the unit is standby, the exhausting valve can be open, long time press the "ENT" button, which is for emergency use to pause the unit.

11.3 Sterilization Work Process Description

11.3.1 Preparation

1) Turn on the power and turn on the power break switch.

2) Open the lid of the container, take out the drums and add water manually till it reach the high level. (Use distilled water)

3) Standby indicator light is on. The high water level indicator lights up.

4) After piling the items, place them on a sieve plate sequentially, and leave some appropriate gaps between the packages. We suggest to make the packages into 20cm x 20cm x 10cm. The dressing and the textile should not be tightly packed. And don't forget to place the sterilizing indicator.

5) After placing the drum into the container, close and turn clock-wisely the hand wheel till the lid is closed. Don't close too tight as that might bring damage to the rubber gasket.

6) Set sterilization parameters (see parameter settings for details).

The Sterilizing time can be set by the followed table 2, please set the sterilizing time and temperature according to different item required.

Items | Sterilizing time (min) | Pressure (MPa) | Temperature(°C) |

Rubber | 15 | 0.1~0.11 | 121 |

Textile | 15~50 | 0.1~0.22 | 121~134 |

Instrument | 8~40 | 0.1~0.22 | 121~134 |

Glass ware | 10~40 | 0.1~0.22 | 121~134 |

Bottled fluid | 20~40 | 0.145 | 121~126 |

Table 2

ATTN : The instrument, textile ,and fluid is the fixed mode, the self-define mode can be used to set the parameter freely.

11.3.2 Heating

Press the START key, the equipment starts to heat.

11.3.3 Sterilizing

By the value of the temperature reach the setting parameter, It start to clock wisely timing .

11.3.4 Drying

After finish the sterilizing, the temperature is lower than 100°, the pointer of the pressure gauge turns to zero, then the machine starts drying with the door opens.

11.3.5 End

After the drying, the sterilized items can be taken in 20~30 mins.

Note: When sterilizing the fluid or the fluid in the glass container, do not exhaust the steam immediately after the sterilization is finished. The rapid exhaustion will cause the liquid boil and over flow, even cause the glass into burst.

11.4 Common faults and troubleshooting

Faults | troubleshooting | remark |

01 | the sensor in the chamber is in malfunction. | |

02 | the pressure sensor in the chamber is broken. | |

03 | the temperature sensor of the dry belt is broken. |

Table 3

12. Safety features

This sterilizer has the following safety features.

12.1 Water lack overheat protection

Water shortage or no water is in the container, which would lead to the heating tube is under over heat, the sterilizer would automatically cut off the power supply by then. At this point, Please cut off the power directly. The cover can not be open till the pressure inside the chamber is back to zero. Then open the cover, add the water into the container, close it and screw the hand wheel tightly. Turn on the power break switch until the high level is displayed, the sterilizing can be proceed.

12.2 Over voltage Protection

When the inlet line supply voltage >AC280V, the sterilizer will automatically cut off the heating power. At this point, turn off the power and check that the power supply is normal (AC220V) before restarting.

13. Precautions and maintenance

Alarm: the operator should observe the relevant provision of The Regulation On Safety Inspection Of Special Equipment and Inspection Procedure For Pressure Vessel In use.

13.1 The operator should read carefully this manual before using, who should have the operation knowledge and intensify the sense of responsibility, strictly operate the unit according to the step of the manual said the is required to do the maintenance as below, to ensure the unit is in good condition and normally running, to prevent the accident from happening.

13.2 Ensure there is enough water in the container, keep the water is at the high level and the corresponding lamp is always on. NOTE: Over much water would affect the drying of the textile.

13.3 Before the heating, MUST strictly follow the provision to eliminate the cold air from the container, or the sterilizing result would be affected.

13.4 Don't sterilize the different kinds of items at the same time, such as textile and solutions, rubber and instrument. Otherwise, the sterilizing result would be affected.

13.5 For sterilizing the solution, which should be filled into a glass bottle (or vessel) that is resistant to the high temperature. Caution the overfill, generally, it is advisable to fill the glass bottle (or vessel) with a volume of 1/2 to 3/4. And the bottle mouth should be tightly filled with the gauze. Do not use a stopper (such as a rubber stopper or cork stopper) which is without a through hole to fill the bottle mouth. The glass bottle (or vessel) should be placed in a protective container and put into the sterilization chamber, that is important to prevent the glass bottle from the burst or damage.

13.6 Every day after sterilizing, drain the water from the container. Dry the sterilizer and scrub the water stain frequently to ensure the sterilizing result and prolong the service life.

13.7 if there is much water incrustation that cannot be clean, the followed solution is suggested to use: add 0.75 kg of caustic soda and o.25kg of kerosene into 10L clean water and mix them. Pour the solution into the container and let it soak for 10-12hours, then the water incrustation can be cleared and then finally rinse with clean water.

13.8 Test the sterilizing temperature, sterilizing time and sterilizing result by the stationary point thermometer, sterilizing indicator or other biological method, to ensure the reliable and best sterilizing result.

13.9 The equipment is a kind of pressure vessel, Must avoid the impact during working, and forbidden to use over pressure. If the pressure displayed is exceed the maximum allowable value but the safety valve doesn't open to release, the unit should immediately pause to use. The safety valve might has been failed, please check and exchange it. Don't start to use the unit again until the safety valve is qualified. The safety valve and the pressure gauge should have to be verified every year at the local Technical Supervision Bureau.

13.10 The gasket is wearing part, which should have to check frequently. If the feature is changed or deformed or aging hardening, the spares should be changed immediately.

13.11 The replaced fuse should be comply with the provision as the manual said, the model and the specification should be same as the old one.

13.12 Ensure the safety grounding of the unit, Ensure the power socket grounding well.

13.13 Keep clean of the unit.

13.14 No special requirement for the transportation and storage. If long time no using, which should have to store in a shady , dry and ventilated place, and make the necessary dust proof work.

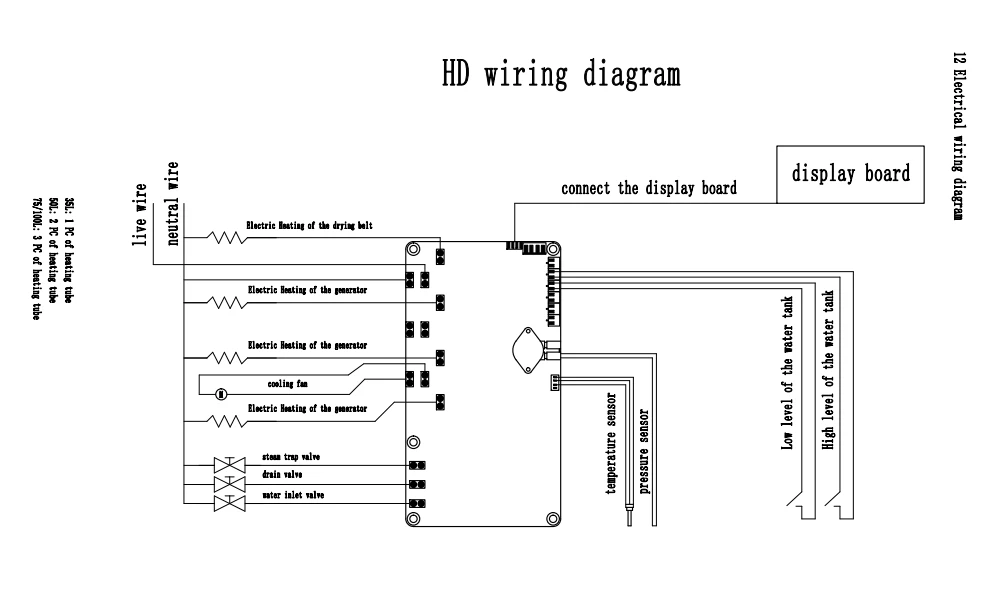

14. Electric scheme

Figure 3

15. The breaker and the fuse capacity

a) Breaker rating current:16A

b) Fuse specification :F1 250V/0.5A φ5x20mm

16. Durable years

Under the normal using and maintenance, the recommended service life of the unit is 7 years.

17. Producing date

See the nameplate

18. Accessories and the package list

NO. | Name | Quantity | Marks |

1 | Main body | 1 | |

2 | Sterilizing baskets | 2 | |

3 | Sieve board | 1 | |

4 | Chamber handle | 1 | |

5 | Inner lid | 1 | |

6 | Exhausting tube | 1 | With one fix hoop |

7 | User's manual | 1 |

Table 4

Appendix 1

BRIEF OPERATION STEPS

1. Insert the exhaust nozzle into the exhaust steam quick change connector.

2. Connect the power(220V) and turn it on, add the water till the high level indicating lamp is on.( the water floating ball should be immersed into water)

3. Press "☞" button and it flashes, then press "▲""▼"button to choose the mode in need, and the self-define mode is for freely setting the parameter , as below:

Press "SET" button again, to revise the sterilizing temperature, please note which can not be changed by the fixed mode.

Press the "SET" button again, to revise the sterilizing time. (132°C~134°C)

Press the "SET" button again, to revise the drying time. (0~30mins)

Press the "SET" button again, to choose print or not. At the TIME area, the HOUR position shows 05, if the MINUTE position shows 00 means no print or 01 means print.

Press the "SET" button again, to choose drain the water or not after sterilizing. At the TIME area, the Hour position shows 05, if the MINUTE position shows 00 means no draining or 01 means draining.

Press the "SET" button again to save the parameter, and exit.

Set the clock: Press the "▲"for 5 times to set the YEAR, MONTH, DATE AND TIME.

Parameter | Minimum value | Maximum valve | Default | Remark |

MODE | 0 | 3 | 0 | 0-instrument 1-textile 2-fluid 3-self define |

Sterilizing temperature | 105°C | 134°C | 134°C | |

Sterilizing time | 0 | 6000 mins | 30 mins | |

Drying time | 0 | 6000mins | 30mins | |

05 Print | 0 | 1 | 0 | 0-no print 1-print |

06 Drain water | 0 | 1 | 0 | 0-no drain 1-drain |

Table 5

Long time press the "SET" button for 5 seconds while the unit is standby, the exhausting valve can be open, long time press the "ENT" button, which is for emergency use to pause.

4. Press the "ENT" to start. ( The user could press the ENT button to start the cycle directly for second time use, the unit

5. After the sterilizing, it automatically exhausts the steam, DON'T open the cover till the temperature shows 102°C, take out the inner lid, and replace the outer lid back to the position, no need to lock, left some gap for drying. (The outer cover can not be open till the hand wheel is screwed to the top). Shut off the power after the drying is finished.

6. Attention

1).The exhausting tube should be reliable fixed from the both sides.

2).It is suggest using the distilled water, changing the tap water every day.

3). Read the manual carefully before using.