Laboratory Horizontal Autoclave BEO1F1 (BAHZ-401-B)

Horizontal Autoclave, Standard- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BEO1F1 |

| Capacity (L) | 180 |

| Dimension (L*W*H) (mm) | 796x1485x1612 |

| Chamber dimension (mm) | Φ500x1150 |

| Net weight | 650kg |

| Power | 16KW |

| Chamber material | S30408 |

| Sterilization temp. | 115°C~135°C |

| Rated working pressure | 0.25MPa |

| Pressure gauge range | -0.1~0.5MPa |

| Safety valve set pressure | 0.28MPa |

| Sterilization time range | 1~6000 min |

| Controller | PLC industrial control system |

| Sterilization mode | Liquid, Liquid with warming, Rubber, Hollow instrument, Sold 1, Sold 2, Wrapped instrument, Fabric,Self-defined, Safety valve test |

| Safety device | Evenly distributed inter lock, auto door lock, water level detection, safety valve, over pressure protection,trouble shooting, electric protection |

| Accessory | Stainless steel baskets with wheels(x2), storage plate |

| Option | [Load thermometer(Floating PT100 sensor), printer, USB, trolley(2801. only),3Q adapting joint,IQ/OQ/PQ documents,walter Sllpp'}-" Pressure sensor |

| Installation requirements | |

| -Working power | Three-phase five-wire system 380N 50/60HZ |

| -Water source requirements for tap water | pressure 0.15~0.3MPa |

| -Requirements for softened water source | 0~0.3MPa (no lower limit requirement for conductivity) |

| -Drainage requirements | with sewage |

| Packing Dimension | 200*160*210 |

| CBM | 6.72 |

| Net Weight | 633 |

| Gross weight | 663 |

Features

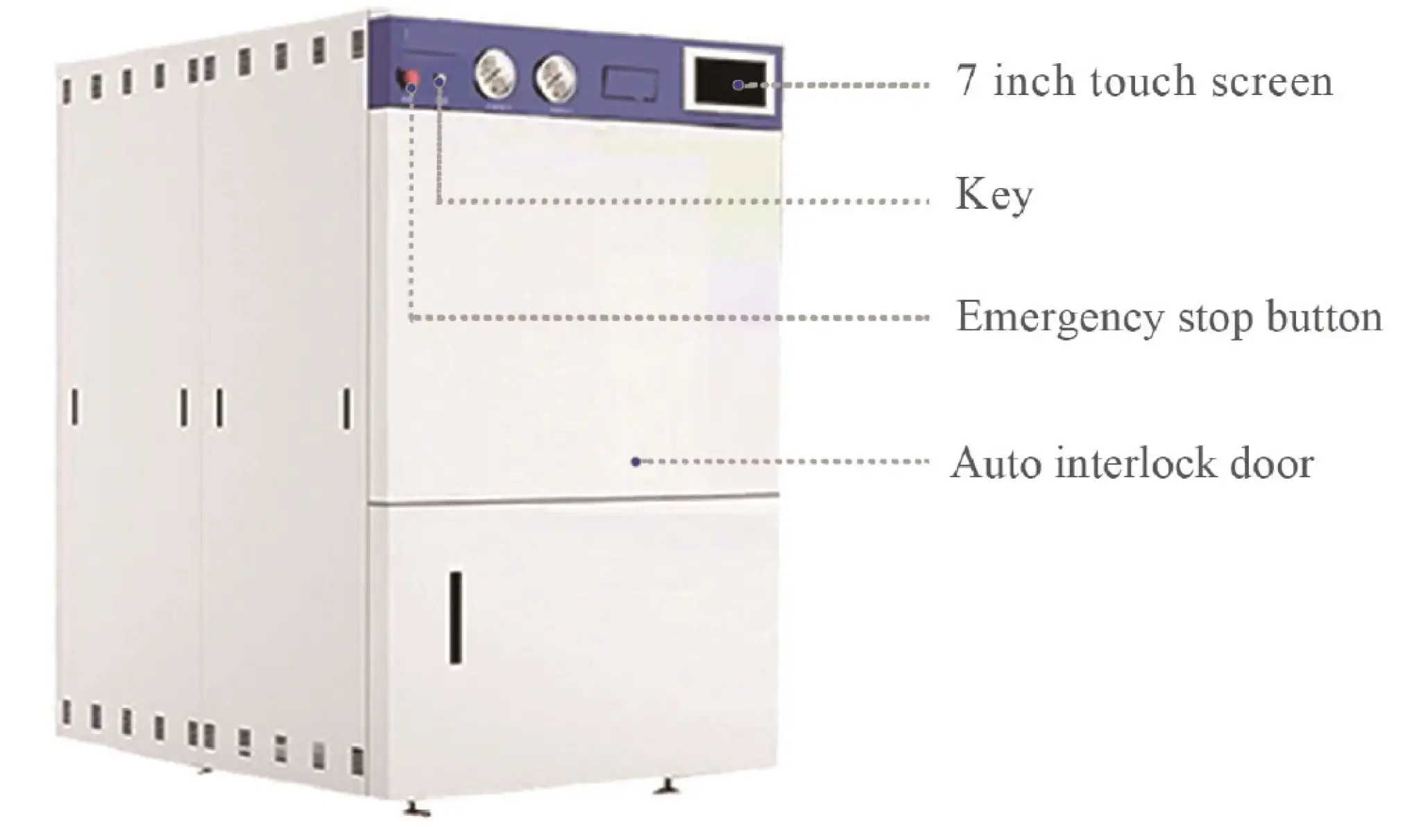

Safety:

Evenly distributed inter lock

Pressure evenly distributed, safer than traditional door.

Auto door lock

Machine cannot start if lid is not locking well by checking mechanically and electrically.

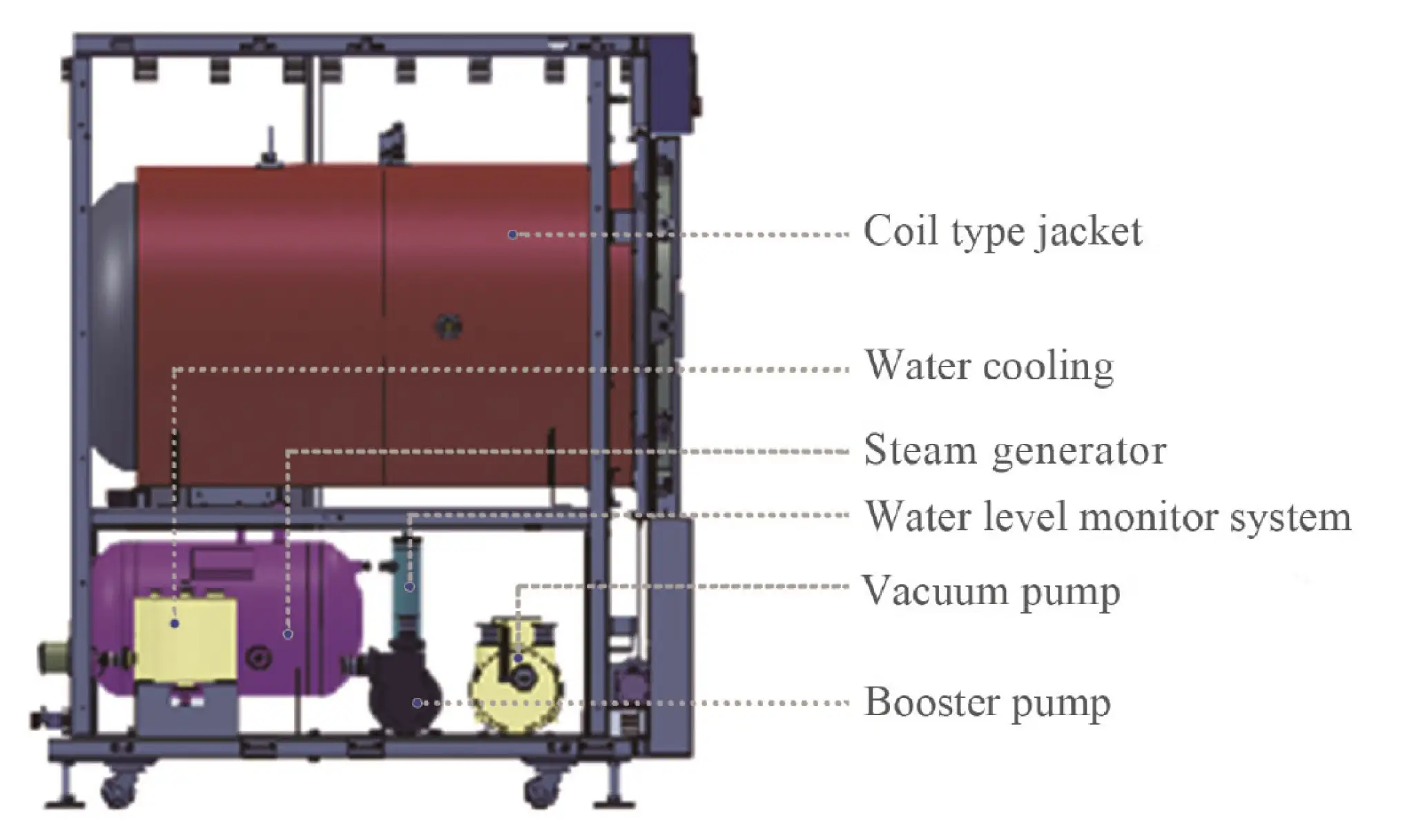

Water level monitor system

Automatic detection of steam generator water level, automatic supply in case of water shortage, no lower limit requirement for conductivity, suitable for users with pure water pipelines, superior to traditional conductivity water level detection methods.

Management

The instrument requires a key to power on for a good control of the instrument.

Emergency stop button

Can stop the machine by one button in an emergency situation.

Double protection for over pressure

Mechanical and electric sensing systems, once pressure is abnormal, the system will cut power, release the pressure and send out an alarm.

Automatic trouble shooting

System will monitor the working status, and will cut the power, send out alarm, and report the error information once any abnormal situation detected.

Temperature detection

The system monitors the temperature changes in the sterilization chamber in real-time. Once the temperature is too high or abnormal, the power is immediately cut off for protection.

Electrical protection

Equipped with a highly sensitive electrical protection system, effectively providing leakage, overcurrent, and short circuit protection.

Multiple monitoring system

Multiple pressure and temperature sensors to detect temperature and pressure in different parts.

5 level of permission management

The operation permissions for instruments are divided into five levels, with each level of user having an independent password and multiple IDs that can be assigned. Each level of user has limited access to certain usage permissions.

Support/Anti pressure system (Option)

A system to help prevent overflow of the sterilized liquid during the sterilization process and to help prevent bursting of the sealed bags/cans/bottles.

Advanced:

Automatic door

Simply push the chamber door lightly and the system will automatically lock; click the open door button, the chamber door will automatically open.

PLC Industrial control system

Professional industrial control system with high stability, achieving fully automatic and dynamic control of the sterilization process, and can be easily maintained, queried, verified, recorded, and extended for upgrading.

Separate steam generator

Adopting a high-power three-way heating device, it automatically generates steam to supply the sterilization chamber, and has functions such as automatic control of water inlet, heating, and prevention of dry burning and overpressure.

6 level of exhaust speed control

After sterilization, you can choose different exhaust speeds, and you can adjust it freely at any time of exhausting.

Drainage temperature can be set

Provide a large capacity water tank that can set the temperature for the discharge of sterilized water, so as to protect your sewer piping.

7 inch touch screen

LCD touch screen, using text, data, and graphical methods to dynamically display various states, and using touch control to facilitate human-machine dialogue and editing operation steps.