Laboratory Horizontal Autoclave BEM2U1 (BAHZ-810-A)

Large Horizontal Autoclave- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BEM2U1 |

| Capacity | 450L |

| Door | Automatic |

| Display | 7-inch LCD touch screen |

| Designed Pressure | Inner chamber: -0.1/0.3MPa; Jacket: 0.3MPa |

| Working Pressure | 0.21MPa |

| Designed Temp. | 150°C |

| Max Working Temp. | 134°C |

| Temp. Precision | ±0.2°C |

| Built-In Steam Generator | 0.8MPa |

| Sterilization Time | 0~99min |

| Drying Time | 0~99min |

| Vacuum system | Water circulating vacuum pump |

| Chamber Material | S30408 |

| Chamber Size(W*D*H) | 672*1000*672mm |

| Altitude | ≤2000m |

| Trolley | 2 external sterilization trolleys, 1 internal sterilization trolley |

| Standard Accessories | Trolleys, printer |

| Optional Accessories | Sheet metal side cover, air compressor, liquid program |

| Consumption | 35kVA |

| Power Supply | AC380V, 50Hz(Standard); AC380V, 60Hz(Optional); AC220V, 50/60Hz(Three phase, Optional); Wiring Method: Air switch |

| External Size(L*W*H) | 1260*1314*2050mm |

| Net Weight | 1035kg |

| Package Size(L*W*H) | Main instrument: 1500*1424*2360mm; Trolleys: 1550*630*1900mm |

| Gross Weight | Main instrument: 1220kg; Trolleys: 150kg |

Description

The large horizontal autoclave extracts vacuum and fills steam into the sterilization room for many times to make the sterilization chamber reach a certain vacuum degree, and then fills saturated steam to reach the set pressure and temperature, so as to achieve the purpose of sterilization of the sterilized substance.Features

1. Motorized double-door, inflatable sealing ring, more reliable and stable sealing performance.2. Standard thermal printer, convenient for customers to store and record sterilization data.

3. The main structure is a rectangular annular reinforcing rib structure, with low residual stress, strong bearing capacity under pulsating alternating pressure and temperature loads, and long container life.

4. Using a brand-new operation interface, programmable controller PLC and 7.0-inch color touch screen, the whole process is automatically controlled by the program, which can simultaneously display the jacket pressure and inner chamber temperature, inner chamber pressure, operating status, fault alarm and other information.

5. Equipped with an intelligent drying system, the residual humidity after drying of the equipment does not exceed 0.2%, and the residual humidity after drying of the dressing does not exceed 1%.

6. Equipped with a sterilizing high-efficiency air filter to ensure sterile air in the cavity and avoid re-contamination.

7. The equipment is connected to an external water source, so there is no need for manual water replenishment. After the customer selects the program, the equipment can complete the entire process from water injection to drying without human intervention. After the program is completed, a voice prompts the completion of sterilization.

8. The inner chamber is designed with an independent steam inlet, and the steam does not pass through the jacket, which prevents the carbon steel of the jacket from contaminating the sterilized items, and prevents the jacket pressure drop from affecting the drying effect.

9. Double-door channel type, pressure, mechanical and electronic 3-layer safety interlocking device, and has over-temperature protection and over-pressure protection, which can eliminate potential safety hazards.

10. There are fabric programs, instrument programs, rubber programs, solid DIY programs and enhanced programs. Auxiliary programs for drying programs and water adding programs. BD, leak test, PCD test program. Liquid program is optional.

11. The shell is made of 304 stainless steel, which is easy to clean.

Operating Manual

Download1. Brief Introduction

2. Technical Parameters and Other Instructions

3. Product Composition and Performance

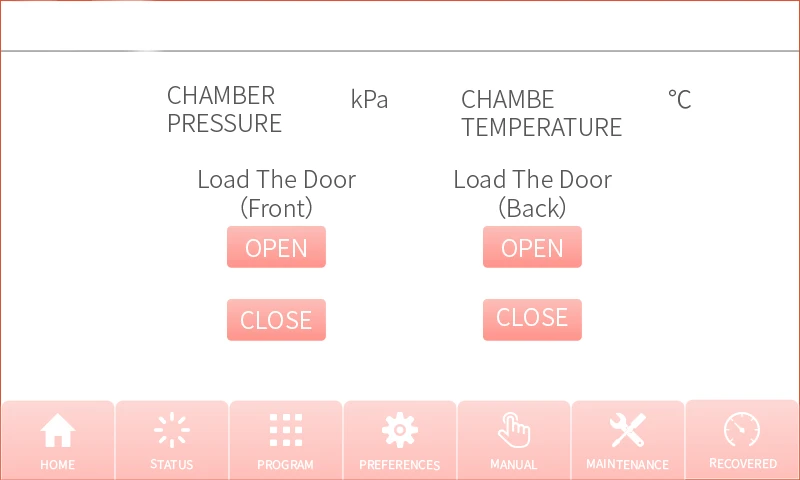

3.1. Product composition

3.2.Product property

3.3.The sterilization unit

4. Installation

4.1. Cartridge inspection

4.2. Equipment installation

4.3. Testing of equipment

5. Operation

5.1. Seal door

5.2. Program run and its parameter settings

5.3. Manual manipulation

5.4. System maintenance

5.5. Parameter setting

5.6. Equipment identification instructions:

6. Daily maintenance, repair and operation procedures of the equipment

6.1. Equipment daily maintenance and maintenance

1. Brief Introduction

Product name: BAHZ-810-A Horizontal Autoclave

Warning First time using this product, please read this manual carefully!

Warning First time using this product, please read this manual carefully!

When appear  Warning Check the documents to identify the nature of the potential danger and the measures that must be taken.

Warning Check the documents to identify the nature of the potential danger and the measures that must be taken.

Horizontal Autoclave (motorized door) is one of the high-grade sterilization equipment series developed and produced by our company according to the latest national standard - "Technical Requirements for Large-scale Steam Sterilizers - Automatic Control Type". It is a sterilization device that fully meets the requirements of CSSD and GMP specifications. This series of sterilizers can be used for medical treatment, pharmaceutical, scientific research and other units for surgical instruments, dressings, fabrics and other sterilization purposes.

Warning! This sterilizer should not be used for the sterilization of the undesigned use of loads, such as petroleum products and powder items such as petroleum jelly.

Warning! This sterilizer should not be used for the sterilization of the undesigned use of loads, such as petroleum products and powder items such as petroleum jelly.

Danger It is strictly prohibited to use the equipment to sterilize the liquid sealed with glass bottles or glass ware, because the change of temperature and pressure in the operation process may cause the glass products to burst, thus endangering the equipment or personnel.The elimination of sterilization indoor air of the equipment adopts the so-called pulsation method of multiple vacuum extraction and multiple steam injection, so that the indoor air exclusion amount reaches above 99%, so as to ensure that the temperature uniformity throughout the room can reach 0.5°C, and ensure the reliable sterilization effect.

Danger It is strictly prohibited to use the equipment to sterilize the liquid sealed with glass bottles or glass ware, because the change of temperature and pressure in the operation process may cause the glass products to burst, thus endangering the equipment or personnel.The elimination of sterilization indoor air of the equipment adopts the so-called pulsation method of multiple vacuum extraction and multiple steam injection, so that the indoor air exclusion amount reaches above 99%, so as to ensure that the temperature uniformity throughout the room can reach 0.5°C, and ensure the reliable sterilization effect.

Sterilization indoor shell material is Q235 carbon steel, the internal surface by mechanical polishing and electric polishing treatment, not only beautiful, but also greatly enhanced the corrosion resistance ability. The design and production of the sterilization room shall fully comply with the requirements of the GB150 Steel Pressure Vessel and the Safety Technical Supervision Regulations of the Pressure Vessel.

The inner surface of the door plate material is S30408, the outside is Q235A reinforcing reinforcement, and the outside is all coated with insulation material to minimize heat radiation. The lifting motor of the door is used to drive the chain and other drive mechanism; the silicone seal strip is tightly pressed on the door plate, which is not only sealed reliably, but also can greatly reduce the labor intensity of the operator compared with the manual door. The sterilization is double door (i. e., double door), the front and rear door sealing strip can be operated separately, the front door can be opened separately, when the front door is sealed, so that the bacterial door can be effectively isolated from the sterile area and meet the requirements of GMP and hospital CSSD specification.

Using the touch screen as the man-machine control interface, the temperature, pressure, time and other parameters in the operation process of the program can be dynamically displayed dynamically, and it can be printed and used for archiving for future reference.With the programmable controller (PLC or PC) for program control, with strong function, high reliability, flexible use and other characteristics.

2. Technical Parameters and Other Instructions

1. Model: BAHZ-810-A;

Normal working pressure :0.12MPa/0.21MPa ;Rated working temperature:121°C/134°C

2. Set range of pulsation times:1-99 times;

3. Set the range of the sterilization time:0-9999s;

4. Dry time setting range:0-9999s;

5. Safety valve setting pressure:0.28MPa;

6. Water source: pressure0.15-0.3MPademineralized water;

7. Compressed air:0.5MPa-0.7MPa After oil removal, water filtration and dust filtration treatment;

8. Power supply:AC 380V/50Hz(Power shall be subject to the specific equipment order number) ;control power source :AC 220V/50Hz/0.5kW.

9. Compressed gas source pressure controller:lower limit :0.4MPa。

10. Product inner size(mm):

450L:672±2*672±2*1000±5

11. Dimensions (mm):

450L:1285±10*1385±10*2135±15

12. Net weight :BAHZ-810-A:1035kg,Require ground load bearing2t/m2。

13. Main sterilization factor and its strength, sterilization principle and microbial killing category: using saturated steam as sterilization factor; sterilization temperature range and load temperature; for steam sterilization, using the principle of heat factor killing microorganisms, the saturated humid steam as the sterilization factor, in the environment of high temperature, high pressure and high humidity, according to the combination of certain pressure and time. This device can kill both bacteria and spores.

14. Scope and method of use: for sterilization of wet resistant and heat resistant medical devices. Use the method as detailed in the instruction manual.

15. Note: See the instructions for details.

16. Service life of the whole machine: 5 years.

17. Operative norm :《GB 8599-2008 Large-scale steam sterilizer technology requires automatic control type》

3. Product Composition and Performance

3.1. Product composition

The sterilizer consists of sterilization chamber, sealing door, external decoration cover, pipeline system and control system.

3.2.Product property

The lower limit of the sterilization temperature range is the sterilization temperature, and the upper limit shall not exceed the sterilization temperature + 3°C.

At the maintenance time, the temperature measured at the sterilization chamber reference measurement point, the temperature of any test point in the standard test package, and the corresponding saturated steam temperature calculated on the basis of the sterilization chamber pressure shall meet the following requirements:

--Should be within the sterilization temperature range;

--The difference between the points at the same time shall not exceed 2°C.

For the sterilizers with the sterilization temperatures of 121°C and 134°C, the maintenance time was 20min and 7min, respectively.

3.3.The sterilization unit

BAHZ-810-A The standard sterilizer is 3.

4. Installation

Warning Whether the correct installation of the sterilization equipment is used will play an important role in its daily performance.

Warning Whether the correct installation of the sterilization equipment is used will play an important role in its daily performance.

The equipment is transported after wooden packing and shall be checked for damage before unpacking.

4.1. Cartridge inspection

• After the inventory, carefully check whether the parts of the equipment are in good condition, damaged or lost. If any, make a record well, and contact our company in time.

• Carefully check whether the connection or fixings are loose or tightened during the long-distance transportation process. Attach the M22 adjustment bolt to the rack floor first if required.

• After unpacking the equipment, please refer to the equipment packing list to check and record whether the equipment and its random accessories are complete. If you have any questions, please contact our company.

4.2. Equipment installation

Equipment installation shall be under the guidance of professional personnel and under the responsibility of professional construction personnel.

Warning Equipment must be installed according to the requirements of the Company, Otherwise, the Company shall not be liable for the consequences caused by the incorrect installation.

Warning Equipment must be installed according to the requirements of the Company, Otherwise, the Company shall not be liable for the consequences caused by the incorrect installation.

1)Equipment occupies space occupation and installation requirements

•For the convenience of operation and maintenance, the height of the room should be at least 2.9 meters, and the distance between the left and right sides of the sterilizer and the wall should not be less than 0.5m. When the single sterilizer is installed, the distance between the back end and the wall shall not be less than 0.5m. The distance between the front and rear operation surface of the sterilizer and the opposite wall should be at least 1.5 times of the total length of the equipment, so that the sterilization vehicle can turn freely, push and pull easily.

• Ground: this series of equipment has two ways of ground installation and pit installation. The required surface shall be flat. If installed upstairs, consider whether to reinforce the floor according to the bearing situation of the floor.

• Room ventilation and heat dissipation: According to the latest requirements of CSSD, it is recommended to partition the equipment after being in place to reduce the impact of environmental noise and heat on the working environment. In order to control the temperature of the working environment, a set of ventilation device should be installed in the working room and above the equipment.

• Equipment drainage: The drainage outlet should be slightly larger than the sterilto reduce the back pressure; the drainage pipe should be separately led to the trench, so that part of the gas discharged from the equipment during work will not affect other rooms. The trench is at least 200mm wide and 200mm deep.

Warning The setting of drainage pipe shall prevent the generation of drainage back pressure, otherwise the sterilization or drying effect will be affected due to the poor discharge of condensate water. Drainage pipe materials shall be high temperature resistant (140°C) and anti-aging materials.

Warning The setting of drainage pipe shall prevent the generation of drainage back pressure, otherwise the sterilization or drying effect will be affected due to the poor discharge of condensate water. Drainage pipe materials shall be high temperature resistant (140°C) and anti-aging materials.

2)Various equipment power equipment requirements

• Steam source: it is best to set up a steam water separator on the steam source pipe. The separator can remove the solid particles and condensate carried in the steam delivery process to enable the sterilizer to obtain a high-quality steam source. The steam source pressure is 0.30- -0.50MPa. If the steam source pressure is too high (> 0.5MPa), the pressure relief valve should be added to the transmission pipeline to ensure that the steam source pressure fluctuation does not exceed 10%. Industrial steam source pipe for 1 inch internal thread connection. If the sterilization equipment is far away from the boiler, the diameter of the steam transmission pipe should be increased to reduce the pipe resistance. When double steam, pure steam line is 1 inch joint. Steam conveying pipeline shall be insulated to reduce the loss of steam. In order to observe the steam supply situation timely, the steam source valve and a pressure gauge of 0-1MPa shall be installed on the steam source pipeline into the interlayer or inner chamber.

• Water source: the inlet pipe is a 1 / 2 inch thread pipe. Connect a 0-0.6MPa range pressure gauge and valve to the inlet sterilwater pipe to observe and control the water pressure.

Warning Softened water shall be used to ensure long-term operation of the water ring pump and condenser.

Warning Softened water shall be used to ensure long-term operation of the water ring pump and condenser.

• Compressed gas source: (gas source pressure: 0.5-0.7MPa) compressed gas pipe is 8 (or 6) hose. Compressed air shall be directed by the main road near the sterilizer and fitted with a stop valve, a pressure relief valve, a pressure gauge, and an 8 (or 6) plug-in direct terminal quick change connector.

• If there is no compressed gas source, you can buy a 60 L / minute medical oil-free compressor for a single set of equipment to support the use.

• power supply: the power supply shall be three-phase five-wire system (three-phase fire wire, one zero wire, one ground wire), the user is required to have two power wires, one is for the power power cord of liquid ring vacuum pump, the other is for the control wire. Install the power switch box near the equipment on the rear wall of the sterilizer with a three-phase switch switch (or circuit breaker) and a single-phase switch switch (or circuit breaker). A ground wire must be laid and a control cable with ground number "ground" must be reliably connected to the ground wire.

3)Equipment installation connection

•Move the equipment to the selected location.

•Adjustment level

After the carrier equipment is in place, lift the support with the adjustment bolt on the foot of the equipment to suspend the four wheels, place the level instrument on the guide rail of the sterilization chamber, and adjust the above bolts to level the left and right directions of the sterilization device. Then adjust the four bolts on the handling wheel to ensure that the height of the rail matches the height of the sterilization inner guide rail, and lock the fixing nuts (the front two directional wheels should be consistent with the direction of the carrier guide rail). Push the sterilization vehicle from the carrier into or out of the sterilization room, and ensure that the sterilization vehicle should be convenient in and out, and the carrier can push and pull flexibly.

• Water, electricity and steam connection

According to the specific installation location and installation requirements of the equipment, connect water, electricity, steam and compressed gas with the sterilization.

Warning The power supply ground cable

Warning The power supply ground cable  must be reliably grounded!!The grounding identification is Equipment junction box is welded with M516 bolts connected to the whole shell and connected to the ground wire.

must be reliably grounded!!The grounding identification is Equipment junction box is welded with M516 bolts connected to the whole shell and connected to the ground wire.

4.3. Testing of equipment

The mobile gate Horizontal Autoclave has pre-set up several procedures, during the debugging process, the user can modify the program parameters according to the use requirements.Read chapter 5 for the specific parameter settings《Instructions for the use of equipment》。

•Before commissioning, first check whether the electrical partial wiring and socket fall off or become loose, and whether the connection of water inlet, drainage, steam inlet and compressed air inlet is correct.

• Open the water source valve, the steam source valve, and the air compressor valve. Observe whether the pressure indicators meet the use requirements.

1)Check the rotation direction of the vacuum pump

Turn on the power switch to make the touch screen into the manual operation state, start the vacuum pump, and observe whether the rotation direction of the motor fan of the vacuum pump is consistent with the arrow direction marked on the pump body, otherwise any two load lines on the three-phase load switch should be replaced.

2)Check the operation condition of each valve piece

• The pneumatic valve -- is manually operated to open each pneumatic valve one by one to watch whether the red display head of each pneumatic valve extends out.

• Solenoid valve -- in the manual operation state, open each solenoid valve, with a screwdriver gently close to the top of the solenoid valve, should feel a strong magnetic attraction.

3)No-load test of the sterilizer

• Before the program runs, the pressure protection test should be conducted according to the instructions in Chapter 5 "Equipment Use Instructions". If the test is unqualified, it means that the pipeline connected with the inner room is leaking. At this time, please check carefully, eliminate the leakage point, and re-test until the test is qualified, otherwise, the sterilization effect of the equipment will be affected.

• Parameter setting: refer to the basic parameters of the equipment in Chapter 5.

• After parameter setting, normal empty load operation of fabric, instruments, lumen instruments, B-D experiment and other procedures,Please read chapter 5 for the specific procedure《Instructions for the use of equipment》。

4) Load test

The above procedures are carried out under no-load, and the load test should be carried out after passing the no-load test.

In the load test, the loading amount of sterilized articles such as instruments and fabric shall not exceed 80% of the inner chamber volume, and shall be placed on the joist of the sterilization vehicle as required, and the dressing pack and equipment room shall keep a 10mm clearance. The load test must test the sterilization effect of the central center of the package according to the standard requirements.

Conduct B-D test procedures, chemical test test and biological test for the sterilizer according to Chapter 7 to observe whether the test results meet the requirements.

Warning Allow the sterilizer to modify the program parameters according to the actual situation during debugging.

Warning Allow the sterilizer to modify the program parameters according to the actual situation during debugging.

5) Emergency stop switch

The device is equipped with an emergency stop switch on the front and rear end panels. When the equipment program needs to stop the operation, press the switch to stop the program; then press the switch device is in preparation again.

5. Operation

Warning Non-operators do not touch the control screen to ensure the clarity of the screen!

Warning Non-operators do not touch the control screen to ensure the clarity of the screen!

5.1. Seal door

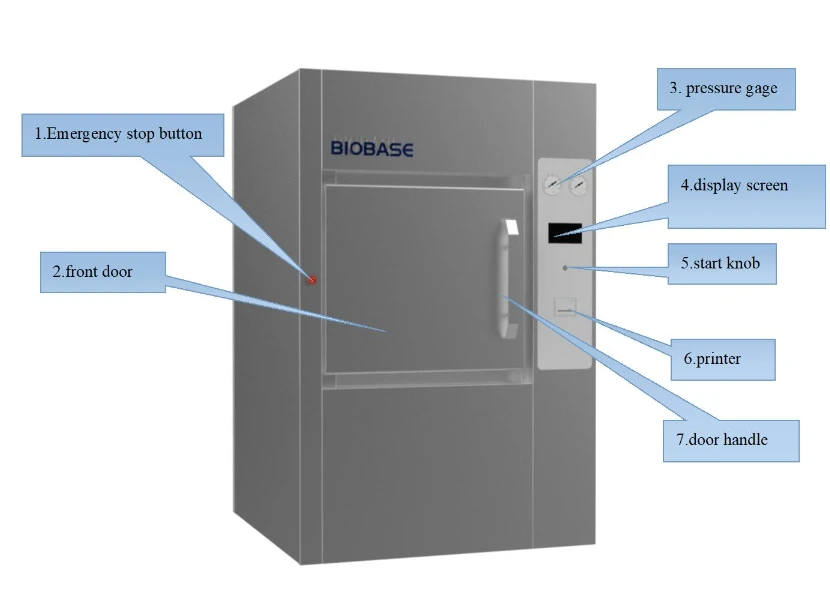

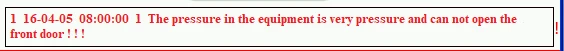

First press chapter 4《 equipment installation 》To prepare the sterilizer, open the general control power supply, steam source, water source, compressed gas source, and open the operation power switch. After the touch screen is powered on, after a period of self-inspection, you can enter the first picture shown in FIG. 1, which timely displays the inner chamber pressure of the equipment and the temperature of the inner chamber, and also performs the screen switching operation.

Figure 1

In this screen, there are "front door operation" and "back door operation", two controls relative to the front and rear doors, and the buttons can complete the corresponding functions.

The specific opening and closing operations are as follows:

1)The front door

In the open door opening state, gently close the door to the end frame, when the upper teeth of the door plate enter the sterilization chamber rack, indicating that the front door is closed.

In the manual screen, press the "Close the front Door" button in the front door operation area to close the front door operation. During the front door, press the Close button again to stop the door operation. Make the door completely closed before closing, otherwise the alarm shown in Figure 2 will appear below the main screen. After the door is completely closed, close the door again.

Figure 2

During the closing process, if the operation is abnormal, the program will automatically cancel the closing operation, and the touch screen will display the alarm information, and the alarm sound will prompt the -- buzzer to indicate the corresponding alarm information. The screen is as shown in Figure 3:

This screen will display for 5 seconds, the buzzer will ring for 5 seconds, and the screen will automatically turn off after 5 seconds.

Figure 3

When the vacuum pump starts while closing the front door, while the solenoid valve moves, pull the sealant strip in the sealing groove of the front end box, and the door motor moves. After the door plate reaches the closed position, the door stroke switch is closed, the front door indicator light is on, and close the front door operation is completed. When the door needs to be sealed, the compressed air passes through the solenoid valve into the front-end frame sealing groove, and the sealant strip is pushed out and close to the door plate, to realize the sealing of the door.

2)The front door open

After sterilization, the internal chamber pressure is ± 10KPa. Opening the front door also requires you to switch the touch screen to the door manual screen. After pressing the "open the front door" button on the touch screen, the vacuum pump and the electric ball valve act first, and the compressed air in the sealing groove of the front end box is extracted, and pull the sealant strip back to the sealing groove. After 15 seconds, the door motor moves (if the starting position of the door is not closed, the delay of 15 seconds is unnecessary). In the process of opening the door, if the door motor appears overcurrent protection, indicating that the door meets abnormal resistance in the opening process, the control system will automatically cancel the door opening operation, and prompt the corresponding information, as shown in Figure 4. During the opening of the front door, the front door status indicator light is flashing. When the door panel reaches the opening position, the front door indicator light is out, and the opening front door operation is completed, and the sealed door can be opened.

Open the door operation cannot be performed in the following cases:

① The internal compartment pressure is not between-10Kpa and 10Kpa. If the door is opened, the alarm screen shown in Figure 4 will appear:

Figure 4

The alarm is over after 5 seconds.

② The back door is not closed or the back door is not in the normal closed position. The corresponding alarm information is shown in Figure 5 in the alarm screen.

Figure 5

3)Back door gate (double gate)

The backdoor operation is performed by pressing the Close Door button switch on the rear panel. Related information is displayed on the touch screen on the front panel, and the closing process closes the front door along with other related operations.

4)Back door is open (double gate)

The open back door operation is performed by pressing the "open door" button switch on the rear panel of the device. The related information is displayed on the touch screen on the front panel, opening the opening process and opening the front door with other related operations.

5)Door safety interlock device

The equipment is a pressure vessel. In order to ensure the safety of the equipment operators, the equipment design must ensure that the current and back door is not closed; when the indoor pressure is greater than or lower than the predetermined value, any door of the front and back door shall not be opened.

During the operation of the program, the door safety linkage device will be started, which passes through the pressure sensing mechanism and the micro-switch to make the action of the front door and the back door of the sterilizer fully meet the above requirements.

6)Front and rear door interlock sealing mechanism

The Ministry of Health CSSD recently requires that the sterilization area and the sterile area should be isolated, meaning that the front door is allowed to be opened only if the back door is fully sealed, and vice versa. The sealing of the front and rear doors of this series of equipment is performed by its own solenoid valve and a set of control lines, which fully meet the requirements of CSSD.

7)Compressed gas pipeline pressure control device

The device will off the operation of the program when the compressed gas source pressure is below 0.36MPa. At this time, the screen will be shown in Figure 6, with an alarm sound alarm.

Figure 6

8) Matters need attention

• When closing the door, don't push too hard to break the door switch.

•It is not easy to be too tight or too loose when adjusting the door to the positioning and fixed component, and the tightness should not be automatically open when the door is closed in place.

• When the equipment failure or power failure needs to open the door, we must first see whether the inner chamber pressure is zero, confirm to rotate the manual rod with the ratchet wrench along with the equipment accessories, raise the door, and then open the door.

•When the display area of the touch screen value is displayed as "#", the PLC does not communicate with the touch screen. Please check the communication line.

5.2. Program run and its parameter settings

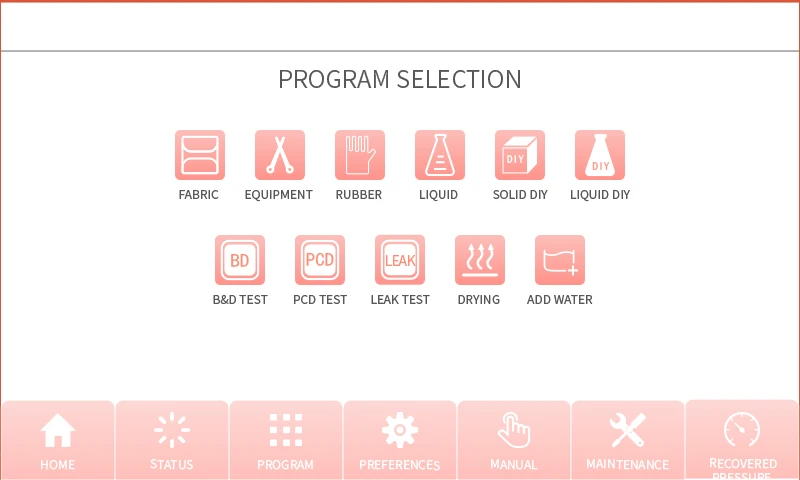

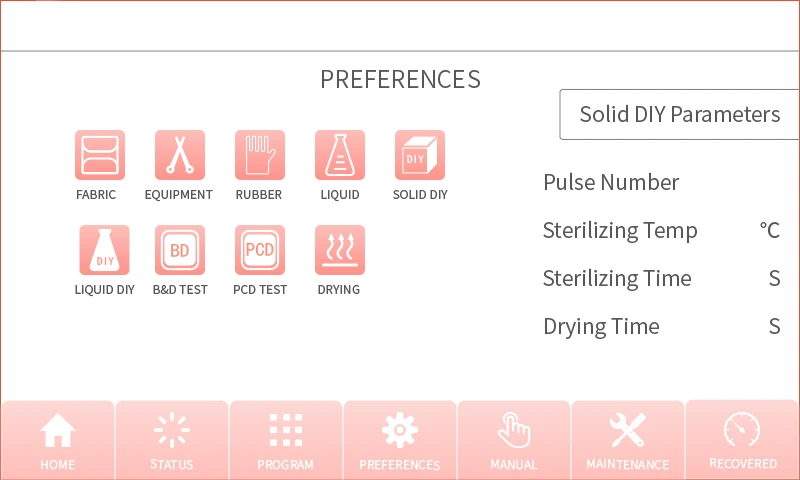

Click the program selection button on the home page to enter the running program selection interface,The control system has 4 sterilization procedures, 3 detection procedures and 2 auxiliary procedures, as shown in Figure 7. Users can select the application as needed.The following working temperature of each program, sterilization time and so on to do a brief description.

Program type | The sterilization temperature/°C | The sterilization time/min | drying time/min | Holding temperatue / °C | soakingtime/mn | The number of pulsations | Pulse upper limit /kPa | Pulse lower limit /kPa | Total time/min | ||

Deviceprogram | 134 | 7 | 20 | ---- | ---- | 3 | 60 | -80 | 55 | ||

The dressing procedure | 134 | 7 | 20 | ---- | ---- | 3 | 60 | -80 | 60 | ||

Rubber program | 121 | 20 | 20 | ---- | ---- | 3 | 60 | -80 | 60 | ||

Solid custom | 134 (105-134) | 20 (1-99) | 10 (1-99) | ---- | ---- | 3(1-6) | 60 | -80 | |||

Dry program | ---- | ---- | 15 | ---- | ---- | ---- | ---- | ---- | |||

BD test | 134 | 3.5 | 2 | ---- | ---- | 3 | 60 | -80 | 40 | ||

Vacuum test | evacuate: 300s test: 600s | 40 | |||||||||

PCD test | 134 | 3.5 | 8 | ---- | ---- | 3 | 60 | -80 | 45 | ||

All application parameters of the device are set in the parameter screen. Press "parameter setting" on the touch screen to pop the user login dialog box. After entering the correct password, press the OK key and the user will log in.

Some parameters already default and you can modify some parameters for each program. First determine the value of each parameter, and then manually touch the input box after each parameter, the set parameters will be displayed in the corresponding display box.

Figure 7

Here is a brief description of the sterilization items for each program:

Program type | meanings |

Device program | Metals such as scalpel, surgical forceps, tweezers and ceramic instruments were sterilized |

The dressing procedure | Surgical clothes, dressing packs, cotton cloth, masks and other items were sterilized |

solid body DIY | For solid state articles for sterilization at high temperature, it is necessary to modify the sterilization temperature, sterilization time, drying time, custom sterilization, such as conventional equipment, glassware, rubber, etc |

Rubber program | Mainly suitable for rubber products, heat-resistant plastics, such as petri dishes and other items sterilization |

Dry program | Dry the load |

BD test | Check the penetration effect of the equipment steam and the cold air elimination effect |

Vacuum test | Check the equipment for leaks |

PCD test | Test the effect of the equipment on the lumen and cavity-like load sterilizer |

1) The following will be a brief introduction of the program operation procedures and the parameters setting situation commonly used by the device:

1.Fabric program running procedures and the setting of the parameters

The parameters of the fabric program have been preset in the PLC, and users cannot modify them themselves.

To achieve a satisfactory sterilization effect, each parameter is usually set at:

The number of pulsations:Three times

The sterilization temperature:134°C

The sterilization time:7 Minutes

Dry time: 20 minutes

The number of pulsations--The effect of pulsation is to force out the cold air in the sterilization room and sterilization items through the vacuum pump before sterilization. The amount of cold air exclusion determines the degree of uniformity of the temperature in the sterilization room, so as to determine the sterilization effect. The number of pulsation times and the size of the pulsation amplitude determine the complete air exclusion. According to the calculation, the pulsation can discharge the cold air in the sterilization room by more than 99.2% for three times.

The following table describes the operating state of each control valve and pump during this procedure. The work flow chart of the program is shown below:

manpower manpower button voluntarily  entrucking

entrucking

The sterilization room  close

close  The program begins Pulse

The program begins Pulse

The number of pulsations to The sterilization temperature reached a lower limit to

vacuum  heating-up

heating-up  The sterilization time to Pressure to

The sterilization time to Pressure to

exhaust steam zero

sterilization exhaust steam

Dry time to Pressure to return to empty zero manpower

vacuum drying  Into the air

Into the air  finish

finish

manpower

manpower  open the door

open the door  unload

unload

2.Device program running process and parameters setting

The parameters of the device program have been set in PLC and cannot be modified by users.The parameter is generally set to:

Number of pulse movements: 3 times

Sterization time: 6 minutes

Sterilization temperature: 134°C

Dry time: 10 minutes

The following table describes the corresponding operating state of each control valve piece and pump during this procedure. The work flow chart of the program is shown below:

manpower manpower button voluntarily

entrucking

entrucking  The sterilization room

The sterilization room  close

close  The program begins Pulse

The program begins Pulse

The number of pulsations to The sterilization temperature reached a lower limit to

vacuum  heating-up

heating-up

The sterilization time to Pressure to exhaust steam zero

sterilization exhaust steam

Dry time to Pressure to return to empty zero manpower

vacuum drying  Into the air

Into the air

finish

manpower

open the door  unload

unload

3.The B-D program running process and the setting of the parameters

The parameters of the BD program are preset in the PLC and cannot be modified by users.

This program parameter value is preset in the program according to the supply room management specification requirements. However, it is slightly different from the equipment or test strip used for BD test; the specific parameters should be modified according to the requirements of BD test strip or test strip manufacturer (the sterilization temperature of BD test ranges from 121 to 137°C).The general preset value (00135 for 3M) is:

Number of pulse movements: 3 times

Sterization time: 3.5 minutes

Sterilization temperature: 134°C

Dry time: 10 minutes

The following table describes the corresponding operating status of each control valve piece and pump during this procedure. The workflow flow chart is shown below:

manpower manpower button voluntarily

BD test pack The sterilization room close The program begins Pulse

The number of pulsations to The sterilization temperature reached a lower limit to

vacuum heating-up

The sterilization time to Pressure to exhaust steam zero

sterilization exhaust steam

Dry time to manpower manpower

dry finish open the door unload

3.Customize the parameter settings

The parameters of the custom program can be modified by users in the parameter screen.

The above is a brief introduction of the operation process and parameter setting of the main programs of the equipment. The other procedures and the above programs are the same, which will not be introduced here. The following is a brief introduction to the program running interface and the start and exit processing of the program.

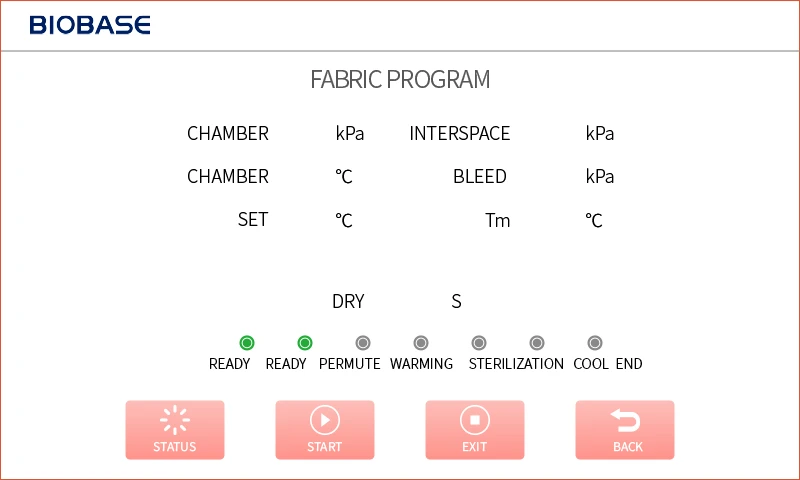

Click the program selection button on the program selection interface to enter the program startup screen. Take the dressing program as an example to make a brief introduction, click the dressing program button on the program selection interface to switch to the program startup interface.Figure 10

Figure 10

The startup and operation interface can display the operation data such as the inner chamber pressure and the inner chamber temperature in real time. Click the start program button device at the interface to automatically start the program operation,At each stage of the program, clicking the return button interface will return to the previous interface,The automatic program will continue and clicking the Exit program button screen will pop the confirmation interface

Click OK to exit the program, and do the subsequent processing after the program exits. After the inner chamber resumes the normal pressure, the display screen and the buzzer will prompt the exit to open the front door, and press the return button to return to the program running interface. Click the running state button will enter the running state interface as shown in Figure 12, the running state interface will display the real-time status of each electromagnetic and pump, and can display real-time value of components such as chamber pressure, temperature, and during the operation of the program, and the pulse times, sterilization time, drying time of real-time display. Clicking the Back button will return to the program running interface.

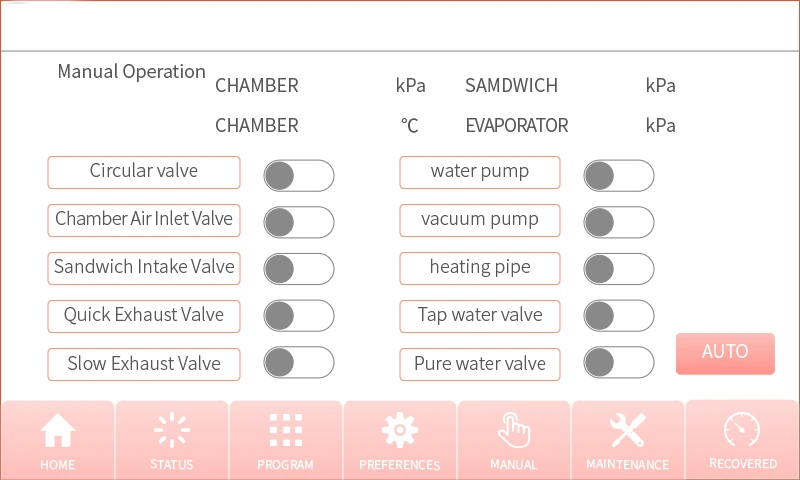

5.3. Manual manipulation

In order to cope with special circumstances (such as sterilization pressure at the door) and facilitate maintenance and debugging, the system is set for manual operation. The method of entering the manual operation screen is to touch the "Manual Operation" button in the main screen and enter the picture shown in FIG. 13:

Figure 13

When the device is running automatically running a selected program, the manual function fails, all valves or vacuum pumps cannot be opened or closed by clicking manually clicked, and can only be switched manually when the program ends and the touch screen status indicates a manual status.

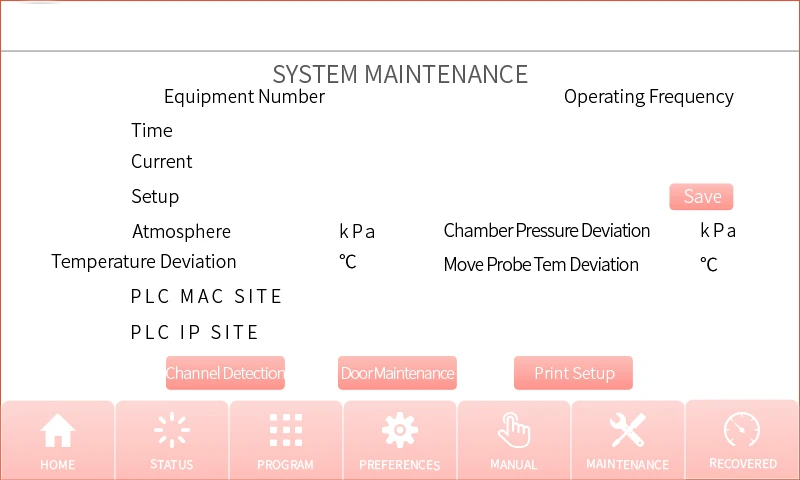

5.4. System maintenance

Click the system maintenance button on the screen to enter the correct password to enter the system maintenance interface as shown in Figure 13. This interface has the display of device operation number and times, equipment time setting, atmospheric pressure and calibration of each temperature, and also includes the entry buttons of channel detection, door maintenance and printing setting interface.

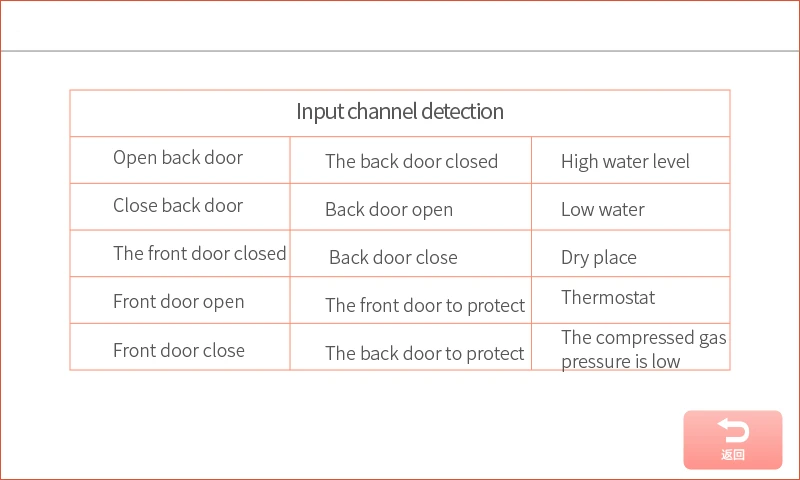

Click the channel detection button to enter the channel detection interface, as shown in Figure 14,This interface can view the status of each input data, which provides convenience for equipment maintenance and troubleshooting.

Figure 14

Click the door maintenance button to enter the door maintenance interface as shown in Figure 15. This interface can give customers the permission to open the back door. When not sterilized, you can click the ON on this interface to open the back door to facilitate the troubleshooting and maintenance of the back door.

Click the print setting to enter the printing setting screen as shown in FIG. 16, which allows the user to set the opening of the printing function and the time interval for data printing.

5.5. Parameter setting

Click the parameter settings button on the screen to enter the correct password to enter the parameter settings interface as shown in Figure 17

Figure 17

Entering the parameter setting interface, users can change and view the program parameters. In order to achieve good sterilization effect, the following program parameters cannot be changed: fabric program, device program, rubber program, BD program, PCD program. And the solid custom and drying parameters customers can change the parameters according to their own needs. Click the corresponding program parameters on the interface to enter the corresponding parameter interface.

Matters need attention:

• During manual operation, when the inner chamber of the inlet valve resumes the normal pressure, the inlet valve should be closed in time to avoid affecting the subsequent operation.

• Do not open the inlet air valve F4 when the inner chamber is under pressure.

• When entering the manual operation, the printer will not print records on the running process parameters.

In the Manual Picture, press the return button and the screen goes to the Main Picture.

5.6. Equipment identification instructions:

High attention should be taken, and the instructions are indicated to identify the potential dangers and the countermeasures to be taken.

High attention should be taken, and the instructions are indicated to identify the potential dangers and the countermeasures to be taken.

High temperature logo

High temperature logo

Drainage sign

Drainage sign

ON OFF Power identification

safety valve Safety valve identification

Earthing identification

Earthing identification

Exhaust logo

Exhaust logo

6. Daily maintenance, repair and operation procedures of the equipment

The equipment is running normally without any fault, but it should be repaired after a certain time. The fault is not only related to the service life and internal quality of the equipment parts, but also related to the correctness of the use of the equipment and the daily maintenance. Many faults are caused by improper use, incorrect operation, and no attention to routine maintenance and regular maintenance.

The correct use and daily maintenance of sterilization equipment are necessary to extend the service life of the equipment and reduce faults. This chapter will provide a brief introduction to precautions and maintenance.

6.1. Equipment daily maintenance and maintenance

1)Equipment daily maintenance and maintenance

• Turn off the touchscreen power supply.

• Turn off the control power supplies and power supplies.

• Close the steam source valve. Close the steam valve into the sandwich, and the steam in the interlayer will naturally condense and drain from the sandwich trap.

• Close the compressed air valve or power off the air compressor.

• Close the water supply valve.

• Clean the inside of the sterilization chamber (inner chamber) and the sterilization vehicle.

When the temperature of the sterilization chamber and the sterilization vehicle drops to near room temperature, scrub it with a neutral detergent, then rinse it with tap water, and finally dry it with a barren cloth.

Clean up the fiber chips and sediment attached to the front and lower filter of the inner chamber to ensure that the vacuum rate, the smooth flow of condensate water and the temperature indication coincide with the pressure.

Warning The cleaning personnel should first enter the inner room, first close the emergency stop switch (power switch), and take the key of the switch with him before entering the inner room to work.

Warning The cleaning personnel should first enter the inner room, first close the emergency stop switch (power switch), and take the key of the switch with him before entering the inner room to work.

• When the sterilizer is not working, open the front door to prevent the sealing performance and service life of the door sealing ring due to long-term compression deformation.

• Check the door seal ring for damage and clean it with a clean soft cloth.

2)Routine maintenance of the main components

• Pneumatic corner seat valve: the pneumatic valve is a powerful on-off valve, all are imported high-quality valve, high reliability, when the use should pay attention to the impact of foreign bodies in the pipeline on the valve parts.

• Liquid ring vacuum pump: vacuum pump uses water ring seal for vacuum. Water rings seal and energy conversion. Because the exhaust has a lot of water in the discharge of steam, so the process of work should be constantly replenished water, but the water should not be too large, too large will increase the power loss of the pump, the working environment of the pump, the water according to the actual situation by the pump through the automatic absorption of the water tank. Water quantity and water temperature directly affect the vacuum rate and the life of the pump. The lower the water temperature, the higher the ultimate vacuum degree, and the general maximum requirement does not exceed 25°C. When stopping for a long time, you should open the pump bottom screw plug, put the pump memory water clean, and then block the water release hole, filled with saponification liquid. Otherwise, the pump is easy to rust or freeze crack pump body, affecting the pump efficiency and service life.

• Hydrobic valve (pneumatic corner seat valve, solenoid valve): the internal chamber exhaust pipe has a small corner seat valve for the internal chamber drainage, the sandwich exhaust valve has a small solenoid for jacket drainage, the drainage work is normal or not directly affects the sterilization effect. If the water cannot be discharged normally, the drain valve should be opened for cleaning. At work, a small amount of steam discharge is a normal phenomenon.

•Safety valve: Install one safety valve each in the jacket and the inner chamber. On the sterilization device to protect the equipment and personal safety, jacket safety valve installed above the cabinet, the inner chamber safety valve on the side of the cabinet, the opening pressure and back pressure has been adjusted when the factory, the user do not adjust to avoid accidents due to improper adjustment, but need to half a year to its hand pull several times, wash with steam, to prevent its parts for a long time not action corrosion, when sterilization overpressure safety valve working for some reason.

Warning Remember not to contact the safety valve handle directly by hand, use a screwdriver or tie a cloth to pull, to prevent steam damage to the operator!

Warning Remember not to contact the safety valve handle directly by hand, use a screwdriver or tie a cloth to pull, to prevent steam damage to the operator!

• Pressure regulating valve (if optional): when leaving the factory, the inlet steam pressure regulating valve has been adjusted, the user if there are special requirements, can readjust. The two film boxes of the pressure regulator are prone to stretching or compression for a long time, easy to welding and corrosion, if found, steam leakage should be replaced in time.

• Debacterial air filter: the filter works in the vacuum breaking stage, and has the characteristics of high filtration accuracy, energy saving, safety and reliability. The gas filtration accuracy can effectively solve the repollution of the sterilized items after entering the air into the inner chamber, and the filter element can be used for one to two years in general.

• Filter: each steam inlet and the inlet pipe has a filter, its function is to filter out the impurities in the steam pipe and the inlet pipe, to ensure the subsequent pipeline and the reliable action of each valve, so it is necessary to be cleaned regularly to prevent blockage. When cleaning, screw out the lower plug, clean the filter screen, and then tighten the plug. In addition, one filter should be installed in front of the trap and the inner chamber trap. These two filters are crucial for the normal trap of the jacket and the inner chamber, so the filter should be removed and cleaned regularly.

• One-way valve (check valve): the door evacuation pipe is equipped with a one-way valve, which should be checked regularly, to avoid foreign bodies affecting its one-way sealing performance. The simplest way is to use the nozzle suction test after cleaning, no feeling of air leakage is normal.

• Solenoid valve: in order to make the solenoid valve work normally, the solenoid valve valve core and valve seat must be scrubbed once a season, to prevent the impurities in the pipeline from affecting its opening and closing.

Note: Check whether the solenoid valve is electric, you can use a screwdriver to test the nut on the valve head for magnetism.

• Condenser: pay attention to the quality of water, excellent water quality will condense a large amount of scale inside the condenser, will affect its condensation effect, so it should be chemical scaled according to the situation. For a long time shutdown, unscrew the lower part of the condenser, clean the water stored inside, and then plug the water hole.

3)Maintenance of the electrical components

• Electrical components and connections are strictly prohibited to contact with the water. If the water is accidentally stained with the water, the power supply should be turned on only after the treatment.

• It must be dust-proof and dust once a season.

• The plug seat of each connection, each plug element should be often checked for loose, loose should be tightened.

4)Removal of scale

Because the water quality in some areas is too hard, the long-term operation of the equipment will deposit a large amount of scale in the pump and in the pipeline, and the accumulation of scale will affect the normal operation of the equipment. It is recommended to use water sources that meet the boiler water standards or deionized water, and use all kinds of chemical descalers for comprehensive descaling treatment regularly (recommended once half a year).

Scaling process:

① Remove the water from the vacuum pump and the condenser first.

② There is a flange connection at the drainage outlet of the vacuum pump, remove the flange screw, pour the chemical scale removal agent into the vacuum pump from the vacuum pump, fill the vacuum pump, the condenser and the pipe connected with the inner chamber, and wait for about 4