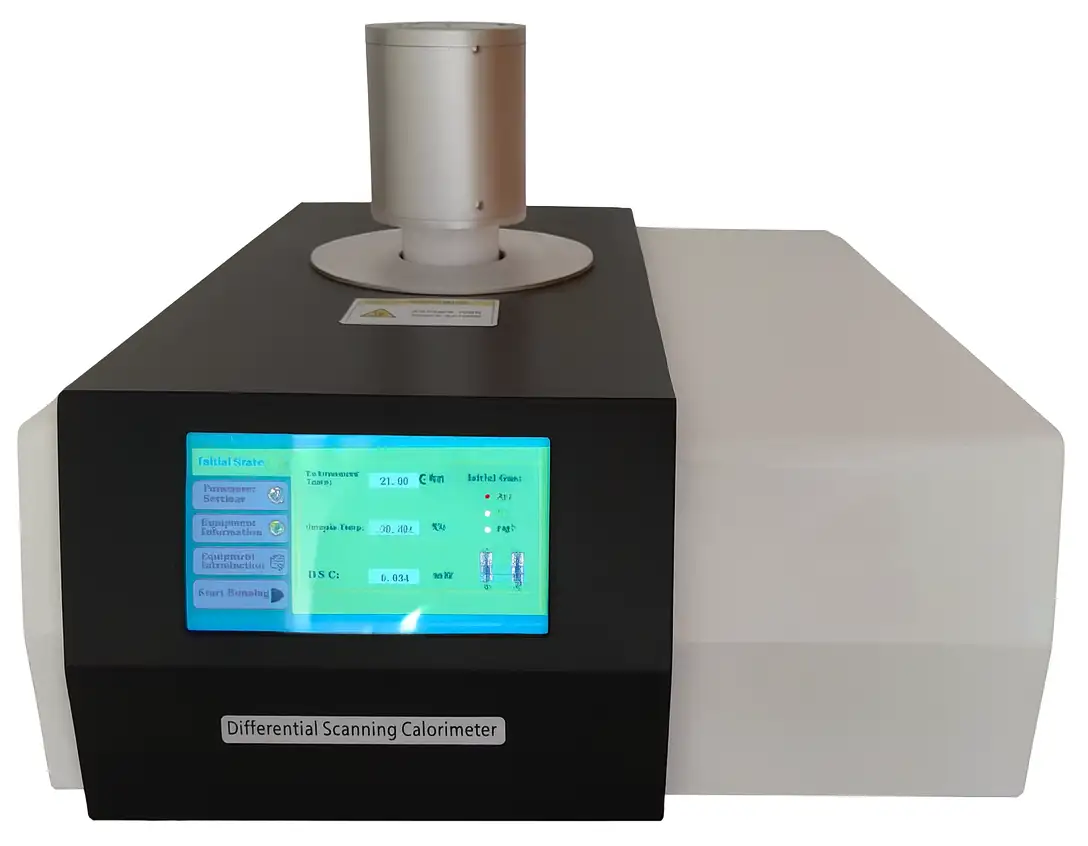

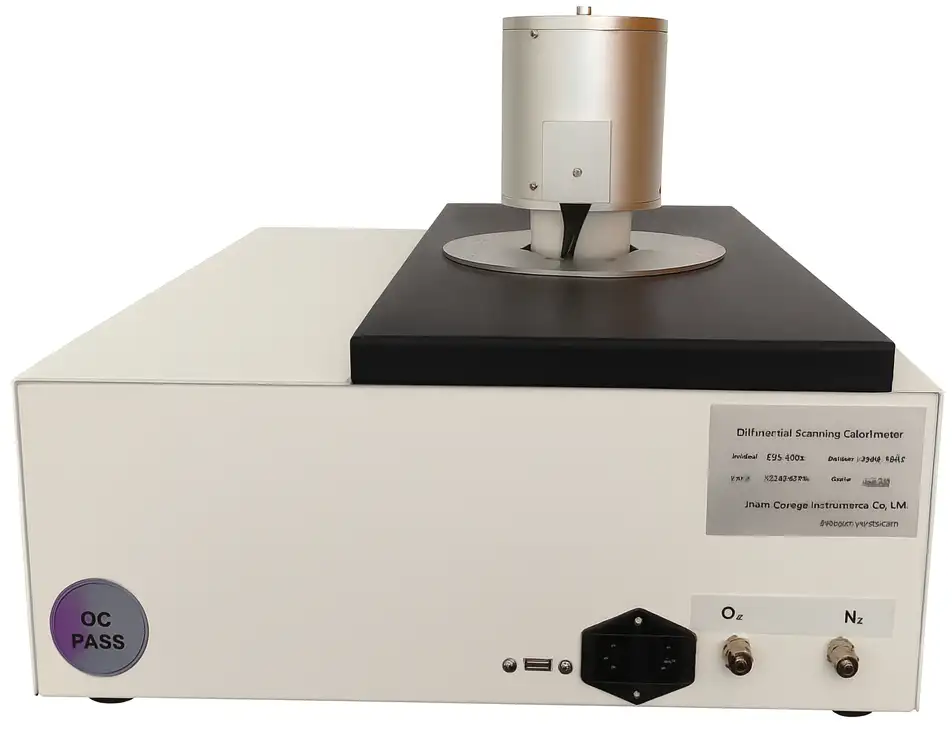

Colorimeter BHJ1F1 (BDSC-110)

Differential Scanning Calorimeter- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BHJ1F1 |

| Temperature range | Room temperature ~ 1100°C |

| Temperature resolution | 0.001°C |

| Temperature fluctuation | ±0.001°C |

| Temperature repeatability | ±0.01°C |

| Heating rate | 0.1 ~ 100°C/min |

| Constant temperature time | Program setting |

| Temperature control mode | Heating up, constant temperature, cooling down (Full automatic program control) |

| DSC range | 0 ~ ±600 mW |

| DSC resolution | 0.01 μW |

| DSC sensitivity | 0.001 mW |

| Working power supply | AC 220V / 50 Hz or customized |

| Atmosphere control gas | Nitrogen, oxygen (Program setting / automatic switching) |

| Gas flow | 0 ~ 200 mL/min |

| Gas pressure | 0.2 MPa |

| Display mode | 24-bit color, 7-inch LCD touch screen display |

| Data interface | Standard USB interface |

| Parameter standard | With reference materials (indium, tin); user can adjust temperature manually |

| Thermocouple configuration | Multiple thermocouples: sample, furnace, and internal ambient temperature measurement |

Description

This model is one of the most accurate DSC series products launched by the company. The sensor is made of imported material E-pair, which has high accuracy, high sensitivity and good repeatability. The signal acquisition circuit has shielding protection, strong anti-interference, and extremely high baseline stability and repeatability.It can be used to test glass transition temperature, phase transition temperature, melting point, enthalpy value, curing temperature, product stability, oxidation induction period, etc. It is competent in the research of pipes, polymers, chemicals, food, medical treatment and many other fields, and its products serve universities, enterprises, third-party measurement and quality inspection units, with a wide range of applications to meet the testing needs of various industries.

Features

1. 7-inch touch screen with rich display information.2.New furnace structure, better baseline and higher precision. Heating by indirect conduction, high uniformity and stability, reduced pulse radiation, better than traditional heating mode.

3.USB communication interface, with strong universality, reliable communication without interruption, and support for self recovery connection function.

4.Automatic switching of two atmospheric flows, fast switching speed and short stabilization time. At the same time increase one way protective gas input.

5.The software is simple and easy to operate.

6.Ultra high sensitivity,accuracy,0.001mw,0.001°C.

7.Excellent technical indicators,Superior performance,High cost performance,Widely used.

Furnace structure

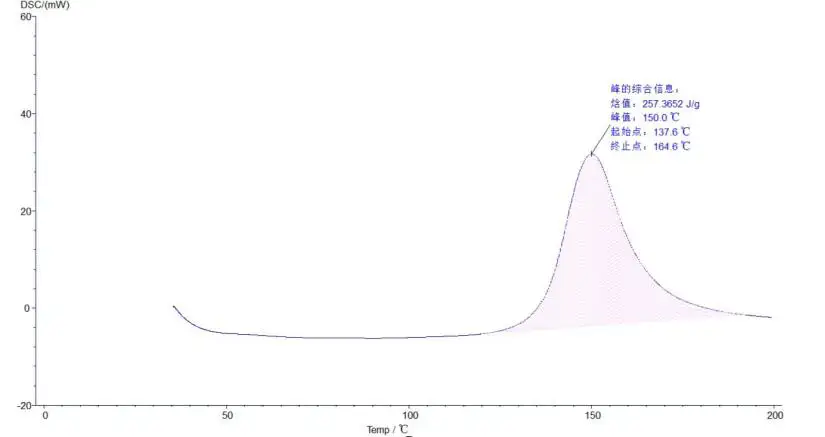

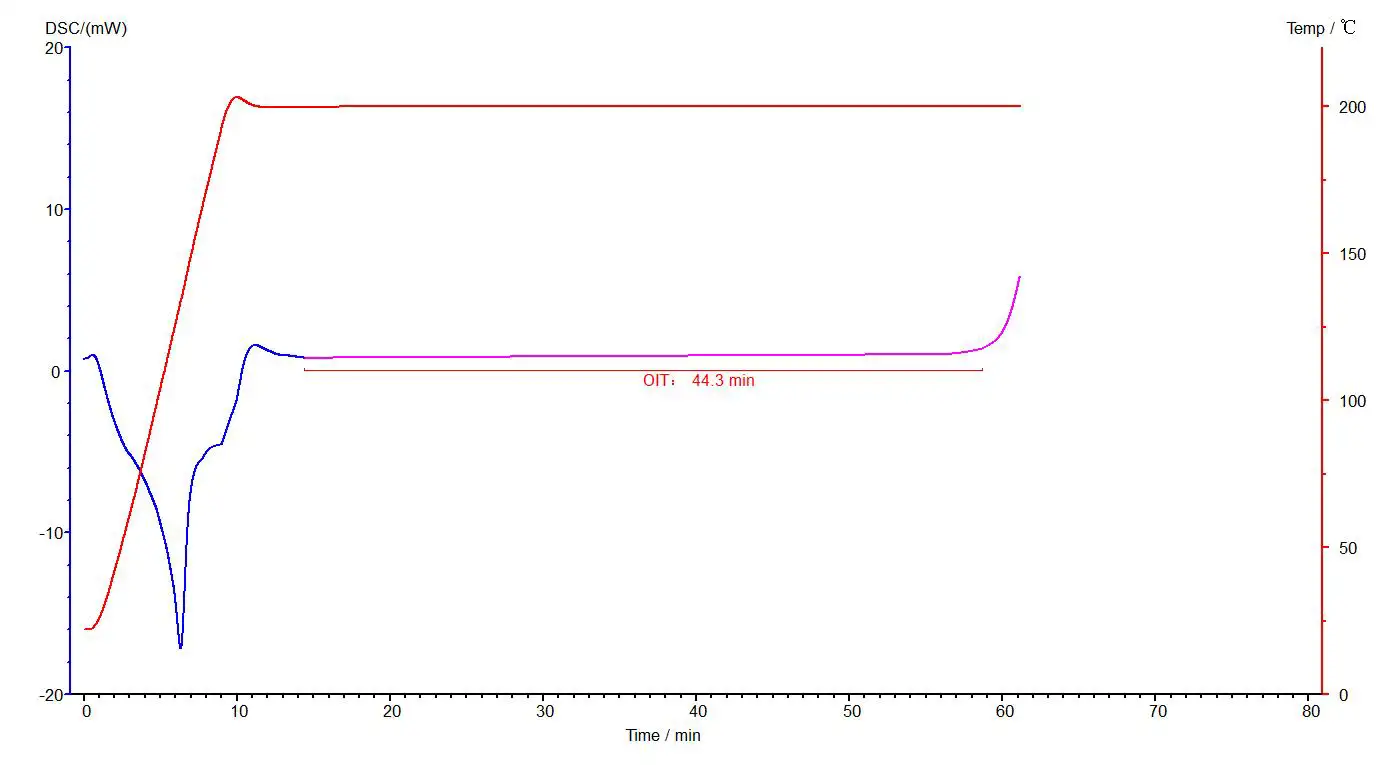

Map analysis of some test cases

1.Oxidation period test of PE, PPR and other pipes:

The oxidation induction time (OIT) was measured by DSC (differential scanning calorimeter). The sample is usually heated to the specified temperature and constant temperature under nitrogen atmosphere, and then switched to oxygen atmosphere. After a period of time, the material begins to oxidize and release heat. The released heat is detected by the sensor, and the induced oxidation time (OIT) is obtained through software analysis. The length of the oxidation induction time is a parameter of the oxidation decomposition resistance of the reaction material, which is still very meaningful. Usually, the parameter must be detected for buried plastic pipes.

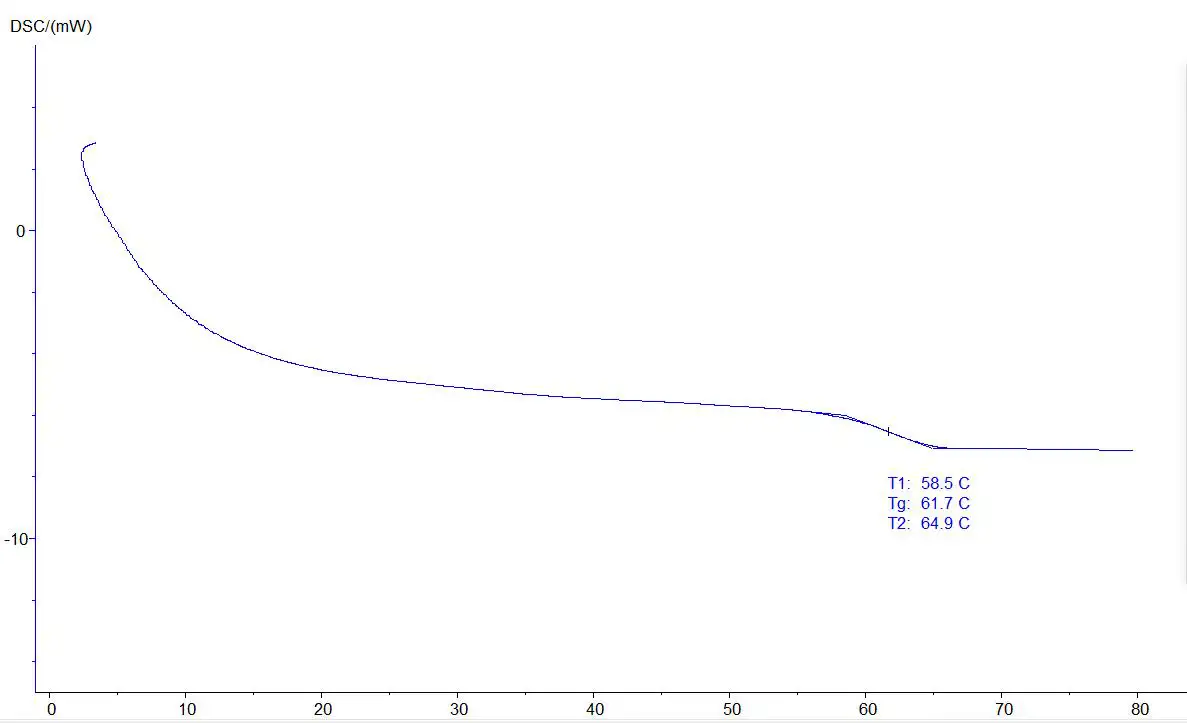

2. Glass transition test of resin and other materials:

For amorphous polymers, when the polymer changes from a high elastic state to a glass state through cooling, or from a glass state to a high elastic state through heating, the process is called the glass transition, and the temperature at which the glass transition occurs is called the glass transition temperature. For crystalline polymers, the glass transition refers to the transition of the amorphous part from the high elastic state to the glass state (or the glass state to the high elastic state). Therefore, glass transition is a common phenomenon in polymers. However, the

glass transition phenomenon is not limited to polymers, and some small molecular

compounds also have glass transition.

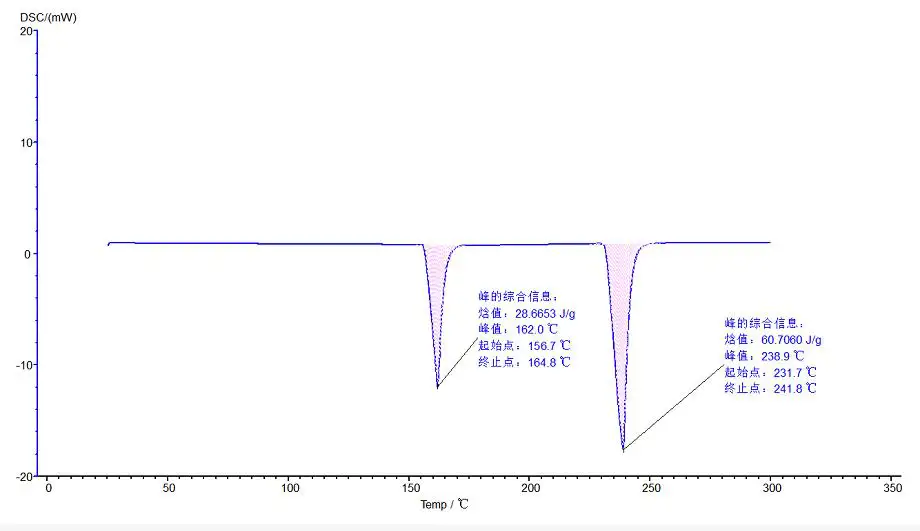

3. Material melting point and enthalpy test (thermal stability test):

The melting point is the temperature at which a solid changes its state of matter from solid to liquid, and the peaks of multi-component mixtures are also multi-peaks; The measurement of enthalpy value is also applicable to the measurement and analysis of crystallinity.

4. Curing test of glue and other materials:

Refers to the process of material from low molecular weight to high molecular weight, and the strength of solidified sample will be higher;