Class II Biosafety Cabinet BEV1J2

Biological Safety Cabinet- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BEV1J2 |

| Clean rating | International standard ISO14644.1 CLASS 5 (US209E, CLASS 100) |

| Inflow velocity | Net weight (KG) |

| Down-flow velocity | 0.35 m/s |

| Down-flow velocity precision | ±0.015 m/s |

| Noise level (dB) | ≤65 |

| Vibration half-peak value | ≤3 μm (X, Y, Z direction) |

| High efficient filter | with ULPA super efficient filter, efficiency 99.999%; |

| Light intensity (LX) | ≥650 |

| Pressure difference range (Pa) | 0-500 |

| Working environment | Environment temp. 10-30°C, relative humidity under 70%, no obvious vibration and dust |

| External dimensions (HxWxD, mm) | 2210x1420x850 |

| Working zone dimension (HxWxD, mm) | 700x1300x500 |

| Power supply voltage | Single phase AC220V/50HZ |

| Power (W) | 350 |

| Net weight (KG) | 210 |

| Gross weight (KG) | 235 |

| Package size (HxWxD, mm) | 1720x1590x1110 |

Description

Biological safety cabinets (BSC) is clean equipment in biological experiments, to prevent damage of the experimental operation of poisonous and harmful airborne particles, in order to protect the safety of the operator and the environment in the experiment.BSC provides reliable security. Standard with a HEPA filter to protect products and environment, plenum leak prevention technology, innovation stable inflow speed system, with LCD screen, microcomputer control technology, especially for biological contamination of a variety of high-risk experiments.

Meet the domestic YY0569-2005 BSC requirements and NSF / ANSI 49-2008, the European Union EN12469: 2000 BSC standard, to provide users with a satisfactory safety assurance.

IQ, OQ, PQ and other related certification services.

CE certification. Two-year warranty period.

Features

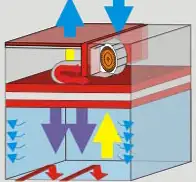

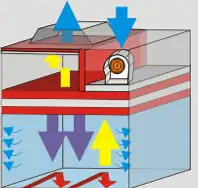

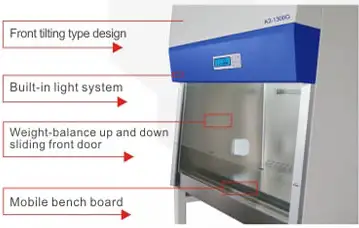

Clean Air TechnologyEquipped with German EBM high airflow and low energy consumption fan, based on airflow mechanics principle, arc-shaped large-diameter inlet design to reduce turbulence generated, to ensure low noise operation of the system.

Reasonable duct design, optimization of the plenum tank, with the design of micro-shaped mesh layer outflow wind deflector, non-convex, no dead corners to ensure uniformity and stability of the airflow.

Equipped with long life exhaust HEPA and downflow ULPA, >99.995% efficient at 0.12 μm particles.

BSC have two types: A2 Type: 70% inner circulation, 30% exhaust; B2 Type: 100% exhaust. Work zone width: 1000 mm and 1300 mm.

Low energy consumption motor

A2 (70%inner circulating, 30%discharge)

B2 (100%discharge)

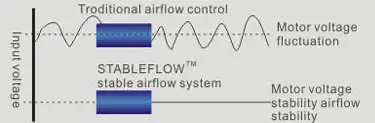

Stable Fan Speed System

High air flow fan, the system will automatically track and adjust the air volume and pressure, to balance the role of compensation, with the design of micro-shaped mesh layer outflow wind deflector, so airflow has more stability and uniformity.

stable airflow system

Micro-mesh lamina flow board

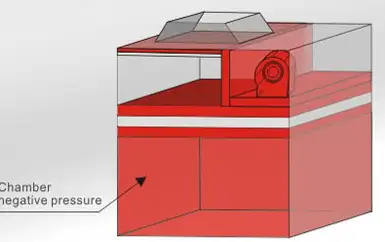

Plenum Leak-proof Technology

Around the work zone at the top and side wall plenum design, so that the discharge of polluting gases completely in a plenum environment, equipped with indoor backplane to a molding design, is an effective way to avoid the possibility of leakage.

Equipped with the accurate pressure sensor to monitor the pressure of the working area, where there is abnormal situation such as breakage of the filter zone or negative pressure seal failure, the system will automatically stop the fan running, and through sound and light alarm prompts the operator, thus avoiding due to leakage caused damage.

Plenum leak-proof technology

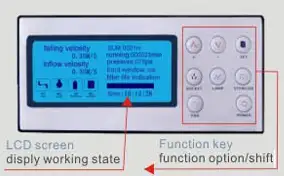

Microcomputer Control

The integrated LCD screen. Display inflow/downflow speed, pressure, filter life, failure alarm and other parameter status.

The user-friendly design, with sterilization, lighting interlock function, front window overhigh alarm and front window closed then the fan shut down.

Fan speed is adjustable according to the need to adjust the appropriate amount of fan.

Excellent Imported Sensor: Air Velocity Sensor And Pressure Difference Sensor

Imported air velocity sensors collect data of high precision, the performance of corrosion-resistant, anti-interference ability, real-time monitoring and control cabinet status.

Imported pressure difference sensor is responsive, effectively monitoring the pressure of the work zone and plenum.

Pressure difference sensor

Air velocity sensor

Accessories For Purchase

| Name |

| Exhaust pipe and fan(no installation accessories) |

| Air interface, water interface and switch valve |