Home Spectrophotometer

Spectrophotometer

Single Beam UV Visible Spectrophotometer

Single Beam UV Visible Spectrophotometer

Single Beam UV Visible Spectrophotometer BSSUV-201

Single Beam UV Visible Spectrophotometer BSSUV-201

Spectrophotometer

Spectrophotometer

Single Beam UV Visible Spectrophotometer

Single Beam UV Visible Spectrophotometer

Single Beam UV Visible Spectrophotometer BSSUV-201

Single Beam UV Visible Spectrophotometer BSSUV-201

Single Beam UV Visible Spectrophotometer BSSUV-201

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Designed to conserve benchspace, our product offers the measurement range of 190-1100nm at bandwidth of 2nm. Engineered for a wide range of applications, our systems provide dependable performance and reliable results. It produces the photometric range of -0.3 to 3 A; 0-200 %T and photometric accuracy of ±0.3%T which makes it suitable for various quantitative assays.

- Wavelength range: 190nm-1100nm

- Bandwidth: 2nm

- Detector: Silicon Photodiode

- Stray Light: It is achieved in range of ≤0.05 %T

Specification

Features

ApplicationsAccessories Optional Accessories

| Wavelength Range | 190-1100 nm |

| Wavelength Accuracy | ±1nm |

| Wavelength Reproducibility | ≤0.3 nm |

| Wavelength Repeatability | ≤0.3 nm |

| Spectral Bandwidth | 2 nm |

| Photometric Range | 0.200%T, -0.3-3A, 0-9999C |

| Photometric Accuracy | ±0.5 %T |

| Photometric Repeatability | ≤0.2 %T |

| Stability | ±0.0001 A/h at 500 nm |

| Baseline Flatness | ±0.004 A |

| Stray Light | ≤0.05 %T |

| Light Source | Deuterium Lamp and Tungsten-Halogen Lamp |

| Gross Dimension (W/D/H) | 420x300x160 mm |

| Display | 128x64 Dots LCD |

| Noise | ±0.004 A |

| Weight (Net/Gross) | 13 kg |

| Power | 300 W |

| Power Supply | AC 220V/50Hz or AC110/60Hz |

- Wavelength range: 190nm-1100nm

- Bandwidth: 2nm

- Detector: Silicon Photodiode

- Stray Light: It is achieved in range of ≤0.05 %T

- Light source: Deuterium and tungsten halogen lamp

- A wide range of standard cuvettes can be used based on the sensitivity or sample volume requirements

- The sample analysis software provides the scanning, fixed wavelength analysis, quantitative analysis, data collection, storage, export, and reporting.

- USB port and parallel port

- Inclusive of standard PC software

- With additional feature of an easy access USB port available in the unit which enables results to be stored directly to a USB memory stick for easy transfer of data. It can store up to 200 results.

- Provides Photometric, Quantitative, Kinetics, Wavelength scan, Multi-wavelength and DNA/Protein Test functions

- Enables building of calibration curves and further implementation of associated tests

- Formation of multi-point standard curve using calibration curve method enables measurement of unknown sample concentration

- Implements sample measurement after addition of coefficient of curvilinear equation using coefficient method

- Automatic wavelength calibration and automatic deviation repair

- Easy changing of deuterium and tungsten lamp excluding the need for debugging

Most suitable for quantitative determination assays and toxicological assays in environmental, industrial, pharmaceutical fields.

| Accessory Code | Name | Unit |

| 3000606019 | Glass cuvette (10 mm) | 4 pcs |

| 3000606021 | Quartz cuvette (10 mm) | 2 pcs |

| 3000606023 | Dustproof cover | 1 pc |

| 3001715006 | Power Cord (US/EU) | 2pcs |

| 3000606026 | Software CD | 1 pc |

| 3000606028 | USB Cable | 1 pc |

| Accessory Code | Name | Description | Light Path LxWxH (mm) | Volume | Unit | Light Path LxWxH (mm) |

| 3000606007 | Single Position Water Jacketed Ambient Cell Holder | 10 mm | ||||

| 3000606008 | 4-Position Cell Holder | 10 mm | ||||

| 3000606009 | 4-Position Cell Holder | 50 mm | ||||

| 3000606010 | 4-Position Cell Holder | 100 mm | ||||

| 2902406006 | Adjustable Cell Holder for Micro Cuvettes | |||||

| 2902406007 | Transparent Film Holder | |||||

| 3000606012 | Tube Holder | |||||

| 3000606013 | Thermostatic Controller | |||||

| 3000606014 | Auto Sampler | |||||

| 3000606015 | Auto Thermostatic Sampler | |||||

| 3000606016 | Micro Printer | |||||

| 3000606017 | Tungsten Lamp 6V; 10W (PH) | |||||

| 3000606018 | Tungsten Lamp 12V; 20W (PH) | |||||

| 3000606020 | Tungsten Lamp 12V; 20W (OSRAM) | |||||

| 3000606022 | D2 Lamp A510YXU Milasi | |||||

| 3000606024 | Glass Cuvette | 5x10x45 | 1.7 ml | Set (4 pcs) | ||

| 3000606025 | Glass Cuvette | 10x10x45 | 3.5 ml | Set (4 pcs) | ||

| 3000606027 | Glass Cuvette | 20x10x45 | 7 ml | Set (4 pcs) | ||

| 3000606029 | Glass Cuvette | 30x10x45 | 10.5 ml | Set (4 pcs) | ||

| 3000606031 | Glass Cuvette | 40x10x45 | 14 ml | Set (4 pcs) | ||

| 3000606033 | Glass Cuvette | 50x10x45 | 17.5 ml | Set (4 pcs) | ||

| 3000606034 | Glass Cuvette | 100x10x45 | 35 ml | Set (4 pcs) | ||

| 3000606035 | Quartz Cuvette | 5x10x45 | 1.7 ml | Set (2 pcs) | ||

| 3000606036 | Quartz Cuvette | 10x10x45 | 3.5 ml | Set (2 pcs) | ||

| 3000606037 | Quartz Cuvette | 20x10x45 | 7 ml | Set (2 pcs) | ||

| 3000606038 | Quartz Cuvette | 30x10x45 | 10.5 ml | Set (2 pcs) | ||

| 3000606039 | Quartz Cuvette | 40x10x45 | 14 ml | Set (2 pcs) | ||

| 3000606040 | Quartz Cuvette | 50x10x45 | 17.5 ml | Set (2 pcs) | ||

| 3000606041 | Quartz Cuvette | 100x10x45 | 35 ml | Set (2 pcs) | ||

| 3000606042 | Micro Quartz Cuvette | 10x2x2.5 | 50 ml | Set (2 pcs) | ||

| 3000606043 | Micro Quartz Cuvette | 10x2x5 | 100 μl | Set (2 pcs) | ||

| 3000606044 | Micro Quartz Cuvette | 10x2x10 | 200 μl | Set (2 pcs) | ||

| 3000606045 | Micro Quartz Cuvette | 10x2x25 | 500 μl | Set (2 pcs) | ||

| 3000606046 | Micro Quartz Cuvette | 10x2x45 | 700 μl | Set (2 pcs) | ||

| 3001906006 | Quartz Flow Cuvette | Set (2 pcs) | ||||

| 3000606047 | Micro Quartz Cuvette | Set (2 pcs) | 10x2x45 |

Operating Manual for BSSUV-201

CHAPTER 1 PREFACE

1. Safety

2. General

3. Electrical

4. Warning

5. Performance

6. Radio Interference

CHAPTER 2 INTRODUCTION OF THE INSTRUMENT

1. Brief Introduction of the Instrument

2. Working Principle

3. Structure

4. Unpacking Instructions

5. Specifications

CHAPTER 3 INSTALL INSTRUMENT

1.Environment Required

2. Installation

CHAPTER 4 OPERATION INTRODUCTION

1. Software Structure

2. Basic Operation

3. Preparation before test

4. Measure

5. System Functions

CHAPTER 5 Instrument Maintenance

1. Daily Maintain

2. Troubleshooting

3. Fuse Replacement

CHAPTER 1 PREFACE

1. Safety

Read the following before installing and using the instrument and its accessories. This instrument should be operated by appropriate laboratory technicians.2. General

The apparatus described in this manual is designed to be used by properly trained personnel in a suitable equipped laboratory. For the correct and safe use of this apparatus it is essential that laboratory personnel follow generally accepted safe procedures in addition to the safety precautions called for in this manual.The covers on this instrument may be removed for servicing. However, the inside of the power supply unit is a hazardous area and its cover should not be removed under any circumstances. There are no serviceable components inside this power supply unit. For this instrument, avoid touching the high voltage power supply at all times.

Some of the chemicals used in spectrophotometry are corrosive and/or inflammable and samples may be radioactive, toxic, or potentially infective. Care should be taken to follow the normal laboratory procedures for handling chemicals and samples.

3. Electrical

Before switching on the apparatus, make sure it is set to the voltage of the local power supply (see Installation).The power cord shall be inserted in a socket provided with a protective earth contact. The protective action must not be negated by the use of an extension cord without a protective conductor.

4. Warning

Any interruption of the protective conductor inside or outside the apparatus or disconnection of the protective earth terminal is likely to make the apparatus dangerous. Intentional interruption is prohibited.Whenever it is likely that the protection has been impaired, the apparatus shall be made inoperative and be secured against any unintended operation.

Note:NEVER touch or handle the power supply on this instrument due to the high voltage! The protection is likely to be impaired if, for example, the apparatus

▲Shows visible damage

▲Fails to perform the intended measurements

▲Has been subjected to prolonged storage under unfavorable conditions

▲Has been subjected to severe transport stresses

5. Performance

To ensure that the instrument is working within its specification, especially when making measurements of an important nature , carry out performance checks with particular reference to wavelength and absorbance accuracy. Performance checks are detailed in this manual.6. Radio Interference

For compliance with the EMC standards referred to in the EC Declaration of Conformity, it is necessary that only shielded cables supplied by us are used when connecting the instrument to computers and accessories.CHAPTER 2 INTRODUCTION OF THE INSTRUMENT

1. Brief Introduction of the Instrument

This instrument is a single beam, general purpose instrument designed to meet the needs of the Conventional Laboratory, This instrument is ideal for various applications, such as: Chemistry, Biochemistry, Petro-chemistry, Environmental Protection, Food and Beverage Labs, Water and Waste Water Labs and other fields of quality control and research.This instrument incorporates a 128×64 dots matrix LCD display for photometric results, easy operation and wavelength range of 200nm to 1000nm. This instrument is ideal for measurements in the visible and ultraviolet wavelength region of the electromagnetic spectrum.

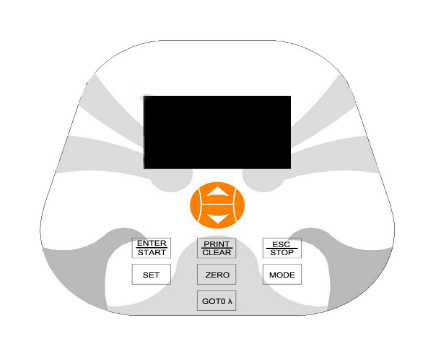

Fig 2-1 Front View

Fig 2-2 Control Panel

2. Working Principle

Different matter has different but special absorbance wavelength point. Also, when at the fixed wavelength point, the absorbance has some relation to the substance’s (Always transparent Solution) concentration and its thickness. The relation can be concluded as the following Formula which is called Lambert-Beer Law.T= I/Io

A=KCL= -log I/Io

A Absorbance

C Concentration of the Solution

K Absorbance Coefficient of the Solution

L The length of the Solution in the light path

I The intensity of the light focused on the A/D after it permeate the solution to be measured. I o The intensity of the light focused on the A/D after it permeate the Solution.

Note: When test, the solvent is usually taken as the Reference Solution and its Transmittance is considered as 100%T. While the Transmittance of the sample to be tested is a relative value which is got comparing to that of the Reference.

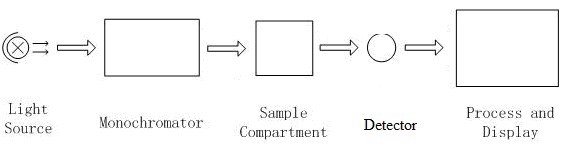

3. Structure

The spectrophotometer consists of five parts:1. Halogen or deuterium lamps to supply the light;

2. A Monochromator to isolate the wavelength of interest and eliminate the unwanted second order radiation;

3. A sample compartment to accommodate the sample solution;

4. Detector to receive the transmitted light and convert it to an electrical signal; and

5. A digital display to indicate absorbance or transmittance. The block diagram (Fig 2.4) below illustrates the relationship between these parts.

Fig 2.4 Block diagram for the Spectrophotometer

In your spectrophotometer, light from the lamp is focused on the entrance slit of the mono-chromator where the collimating mirror directs the beam onto the grating. The grating disperses the light beam to produce the spectrum, a portion of which is focused on the exit slit of the mono-chromator by a collimating mirror. From here the beam is passed to a sample compartment through one of the filters, which helps to eliminate unwanted second order radiation from the diffraction grating. Upon leaving the sample compartment, the beam is passed to the silicon photodiode detector and causes the detector to produce an electrical signal that is displayed on the digital display.

4. Unpacking Instructions

Carefully unpack the contents and check the materials against the following packing list to ensure that you have received everything in good condition.Packing List

—--------------------------------------------------------------------------------Description Quantity

Spectrophotometer……………………………………………………………. 1

Power Cord……………………………………………………………………… 1

1cm Glass Cuvettes…………………………………..………………………….1 Set of 4 1cm Quartz Cuvettes…………………………………...………………. ………1 Set of 2 User’s Manual…………………………………………………………………… 1

Dust Cover……………………………………………………………………… 1

Note: The Printer mentioned in this manual is an optional accessory, it does not come standard with the instrument.

5. Specifications

| Wavelength Range | 190-1000nm |

| Band Width | 2nm |

| Wavelength Accuracy | ±1nm |

| Wavelength Repeatability | 0.5nm |

| Wavelength Setting | Auto |

| Photometric Accuracy | ±0.5%T |

| Photometric Repeatability | 0.3%T |

| Photometric Display Range | 0-200%T, -0.3-3.0A, 0-9999C |

| Stability | 0.002A/h @ 500nm |

| Stray Light | ≤0.3%T@220nm, 360nm |

| Data Output Port | USB |

| Printer Port | Parallel Port |

| Display | 128*64 Dots LCD |

| Lamps | Deuterium Lamp & Tungsten Halogen Lamp |

| Detector | Silicon Photodiode |

| Power Requirement | AC85~250V |

| Dimension (L*W*H) | 420*280*180mm |

| Weight | 11kg |

CHAPTER 3 INSTALL INSTRUMENT

1.Environment Required

To ensure the best performance, the following conditions are required:- The best working temperature range is 16-30℃ and the humidity is 45-80%.

- Keep it as far as possible away from the strong magnetic or electrical fields or any electrical device that may generate high-frequency fields.

- Set the unit up in an area that is free of dust, corrosive gases and strong vibrations.

- Remove any obstructions or materials that could hinder the flow of air under and around the instrument.

- The power requirement is AC85V~265V.

- Use the appropriate power cord and plug into a grounded outlet.

- If the local voltage is not stable enough, a Power Stabilizer is required.

- Be away from direct sunlight

2. Installation

Step 1: Check the packing listUnpack the contents, check the materials with the Packing List. Any damage or Lost found, please contact us or the local dealer.

Step 2: Position

Place the instrument on the stable table carefully.

Step 3: Install printer (Optional)

Make sure the printer is power off, link the printer’s data cable to the instrument’s parallel port.

Step 4: Link the power cord

Make sure the instrument’s power switch is in the Off condition, link the power cord to the instrument and insert another end in the socket provided with a protective earth contact.

Step 5: Switch on the power

Check again, make sure that all the links are right. Switch on the power. The instrument can be used to measure after self-test and pre-warm.

CHAPTER 4 OPERATION INTRODUCTION

1. Software Structure

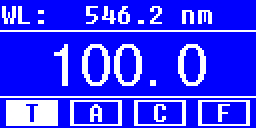

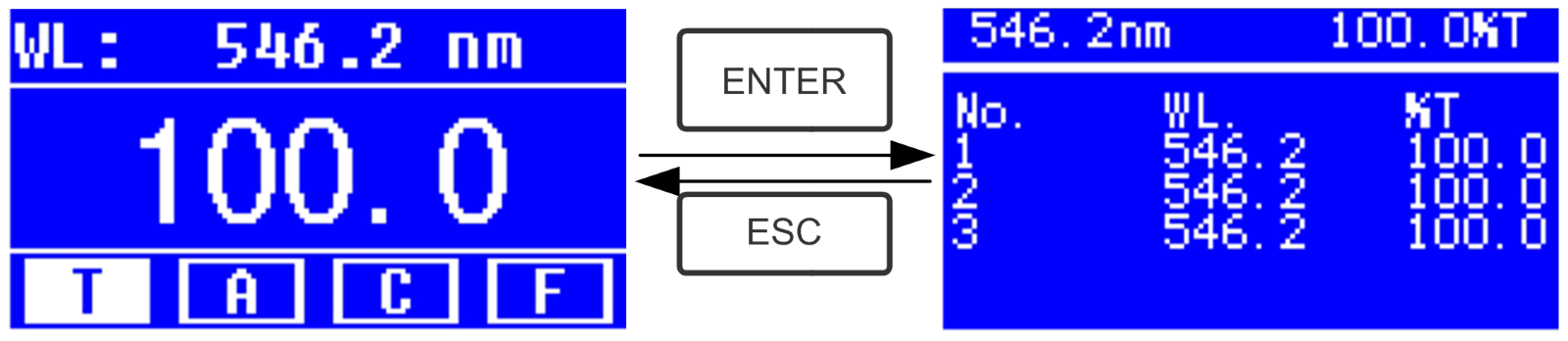

1.1 Main Interface

Fig 4-1 Main Interface

After 20 minutes’ warm-up, the system goes into main interface. (Fig.4-1) Press the key of

to change the functions.

to change the functions.1.2 Firmware Functions

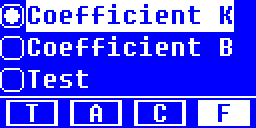

The firmware consists of 5 functions: T, A, C, F and system functions

1) T

To measure the Transmittance of a sample in a fixed wavelength point. The test result can be stored in the RAM, total 200 groups of data can be stored.

2) A

To measure the Absorbance of a sample in a fixed wavelength point. The test result can be stored in the RAM, total 200 groups of data can be stored.

3) C-Standard Curve Method

Set up standard curve by standard samples; use the new curve to measure the unknown sample’s concentration. The curves and the test results can be stored in the RAM. Total 200 curves can be stored.

4) Coefficient Method

Input the values of the curve equation’s coefficient, and then measure the unknown sample’s concentration.

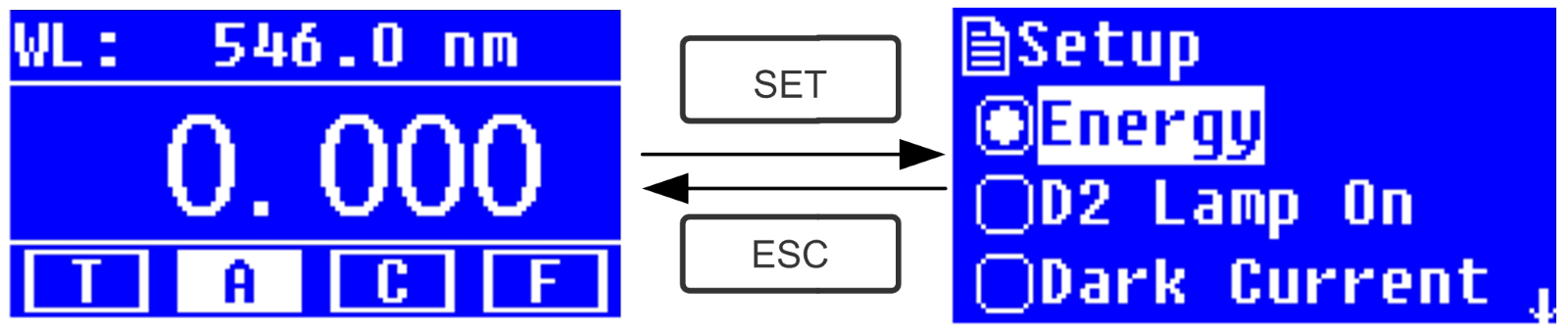

5) Setup-System Functions

Press the key of

on the keypad to go into system functions (Only available in T MODE and A MODE). Light source management; Get Dark Current; Calibrate Wavelength and Load default, etc.

on the keypad to go into system functions (Only available in T MODE and A MODE). Light source management; Get Dark Current; Calibrate Wavelength and Load default, etc.2. Basic Operation

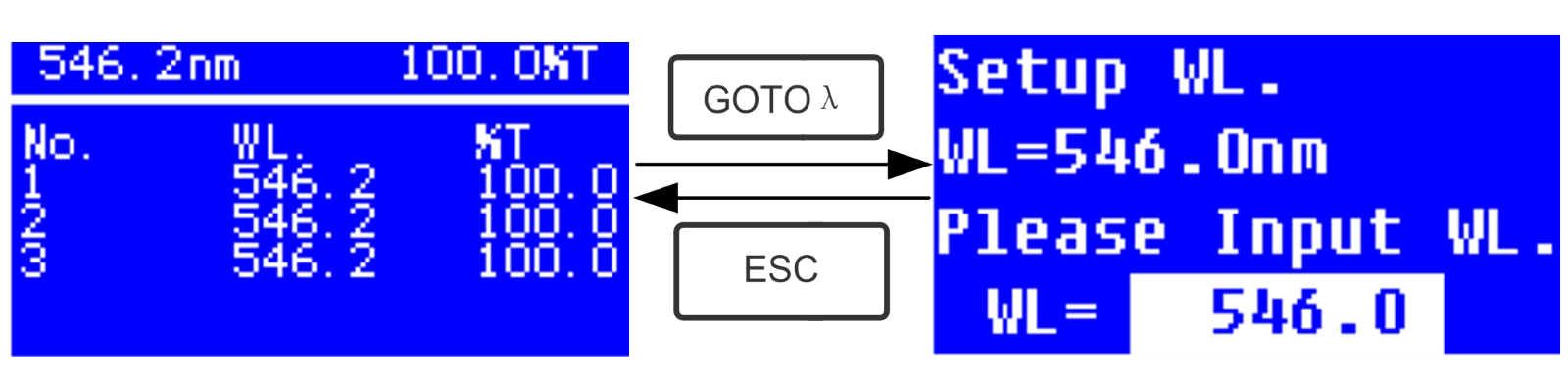

2.1 Set WavelengthIn the measurement

to go into wavelength setting Interface. Use Arrow Key to increase or decrease the value of wavelength,then

to go into wavelength setting Interface. Use Arrow Key to increase or decrease the value of wavelength,then  to confirm. When arriving at the setting wavelength point, it sets 100%T/0Abs automatically.

to confirm. When arriving at the setting wavelength point, it sets 100%T/0Abs automatically.2.2 Delete the test result and stored data

In the measurement Interface,press

to delete the test result and stored data.

to delete the test result and stored data.2.3 Calibrate 100%T/0Abs

Put the Reference in the light path, press

to calibrate 100%T/0Abs。

to calibrate 100%T/0Abs。2.4 Text BoxMeasure the samples

Put the samples in the light path and press

Print the test result to measure.

Print the test result to measure.2.5 Print the test result

In the Measurement Interface, press

to print the result.

to print the result.3. Preparation before test

3.1 Switch on the instrument and begin the system self-test(Diagnostic Program)Make sure to remove all the blocks in the light path; Close the compartment lid and switch on the power; Then the system will begin self-test.

Note: During the course of Diagnostic Program runs, please DON’T open the lid of the compartment!

3.2 Pre-warm

When the diagnostic program finished, it goes into pre-warm condition. 20 minutes is required before measure.

3.3 Check the Cuvettes

The cuvette should be clear and there’s no solution remains on the transparent surface. If the wavelength is below 340nm, Quartz Cuvette is a must.

4. Measure

4.1 T-Mode

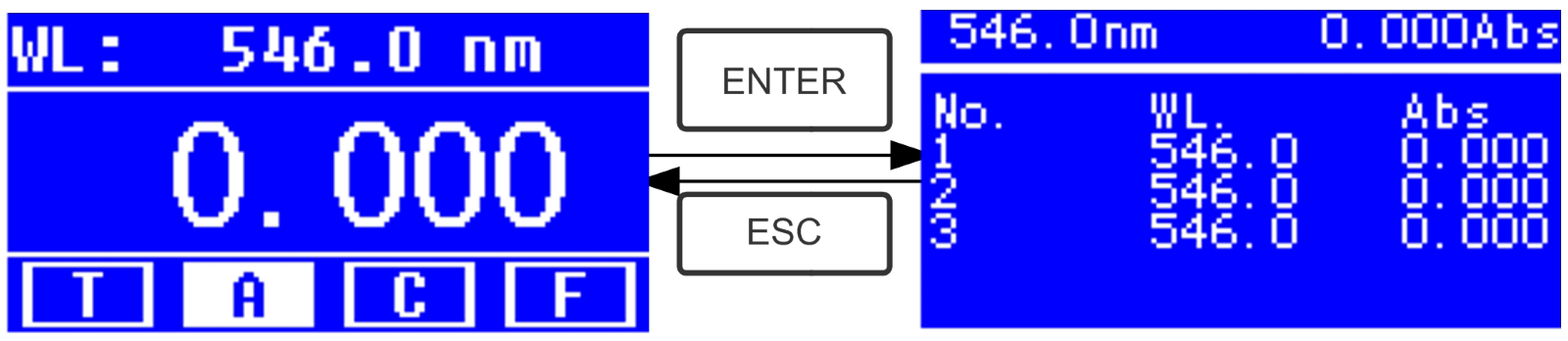

Step 1, Go into T Mode Interface

In the Main Interface

, Key to move the cursor on “T” , you’ll see the current sample’s T% value. Press

, Key to move the cursor on “T” , you’ll see the current sample’s T% value. Press  to go into Continuous Measurement Interface.(Fig. 4-2)

to go into Continuous Measurement Interface.(Fig. 4-2)

Fig. 4-2

Step 2, Set Wavelength

Press

to set Wavelength,input the wavelength value by the Arrow Key, then press

to set Wavelength,input the wavelength value by the Arrow Key, then press  to confirm.(Fig. 4-3)

to confirm.(Fig. 4-3)

Fig. 4-3

Step 3, Calibrate 100%T/0Abs Put the Reference Solution in the light path,press

to calibrate 100%T/0Abs;

to calibrate 100%T/0Abs;Step 4, Measure Sample

Put the unknown concentration sample in the light path, press

to measure,and the result displays in the data sheet. At the same time, the test result will be stored in the RAM automatically.

to measure,and the result displays in the data sheet. At the same time, the test result will be stored in the RAM automatically.Repeat this step to finish all the samples measurement.

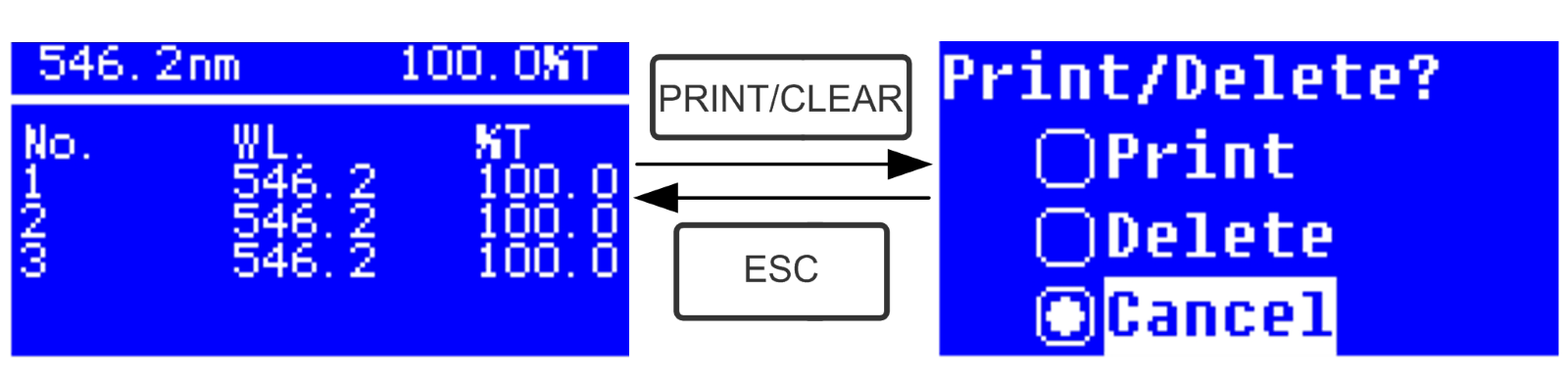

Step 5, Print or Delete the data

Press

to go into the following interface.(Fig.4-4)

to go into the following interface.(Fig.4-4)

Fig.4-4

1. When the optional Printer is linked to the instrument, if you want to print out the test result, use Arrow Key to choose “Print”, then press

to confirm. After printing, the data will be deleted from the RAM

to confirm. After printing, the data will be deleted from the RAM2. If you want to delete the saved data, move the cursor on the item of “Delete”, then press

to confirm.

to confirm.4.2 A-MODE

Step 1, Go into A Mode Interface

In the Main Interface, press

Key to move the cursor on “A” , you’ll see the current sample’s Absorbance value.

Key to move the cursor on “A” , you’ll see the current sample’s Absorbance value.Press

to go into Continuous Measurement Interface.(Fig. 4-5)

to go into Continuous Measurement Interface.(Fig. 4-5)

Fig.4-5

Step 2-5 is the same as T-mode, please refer to the corresponding operation in 4.1.

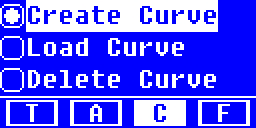

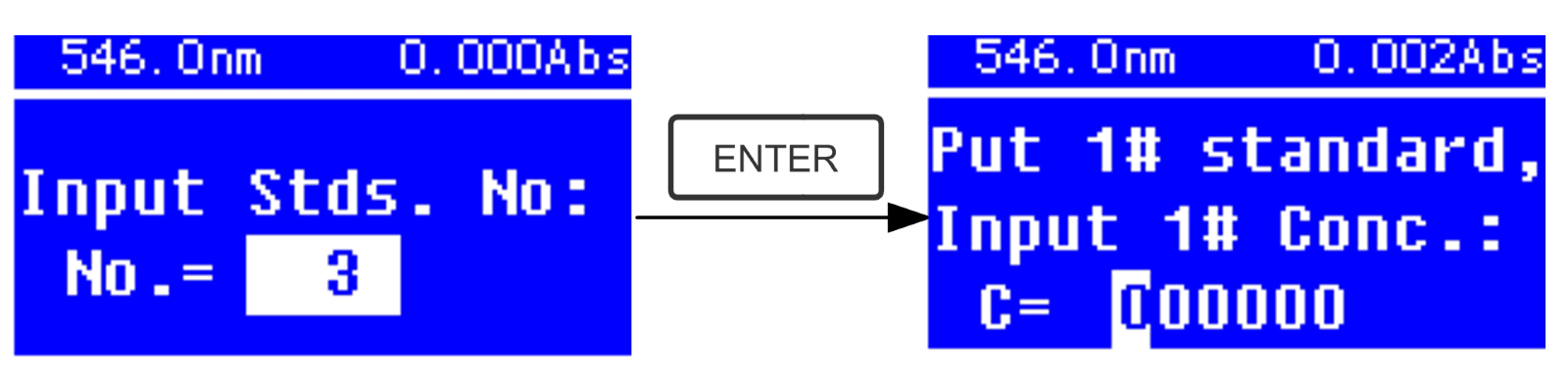

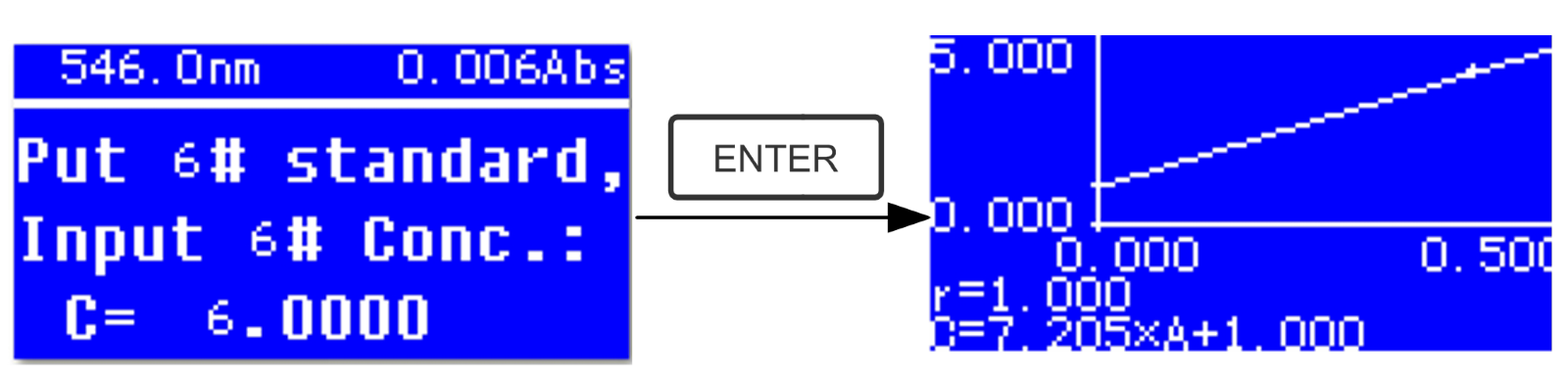

4.3 C-MODE (Standard Curve)

1. Go into C-MODE Interface

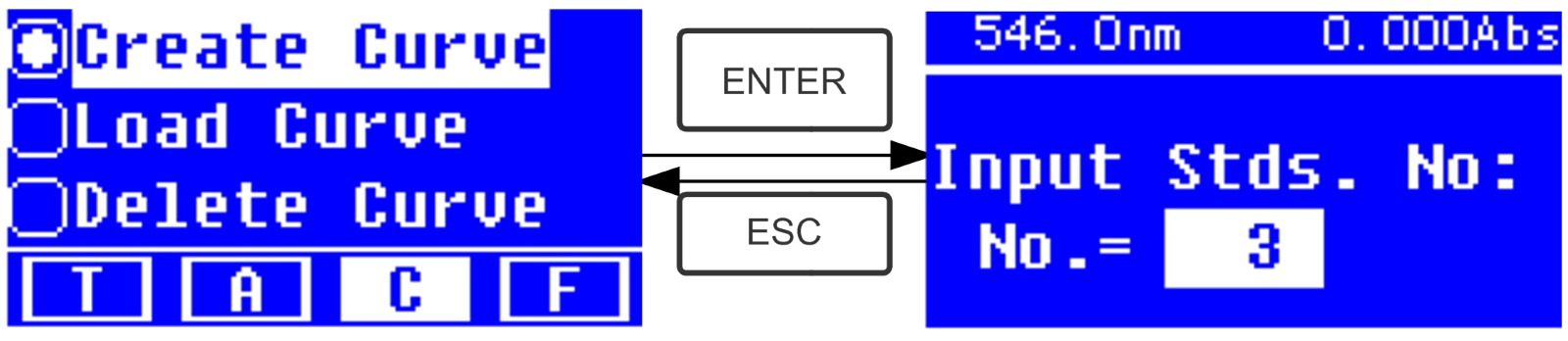

In the Main Interface, press Arrow Key to move the cursor on “C”, then you’ll see the following Interface. (Fig.4-6) Here you can create a new curve, or you can load a saved curve. If you want to delete a saved curve, just choose “Delete Curve”.

Fig. 4-6

2. Create Curve

If you want to create a new standard curve by several standard samples, Use Arrow Key to move the cursor on “Create

Text BoxCurve”, then press

to confirm. The system will ask you to input the quantity of your standard samples. (Fig.4-7)

to confirm. The system will ask you to input the quantity of your standard samples. (Fig.4-7)

Fig.4-7

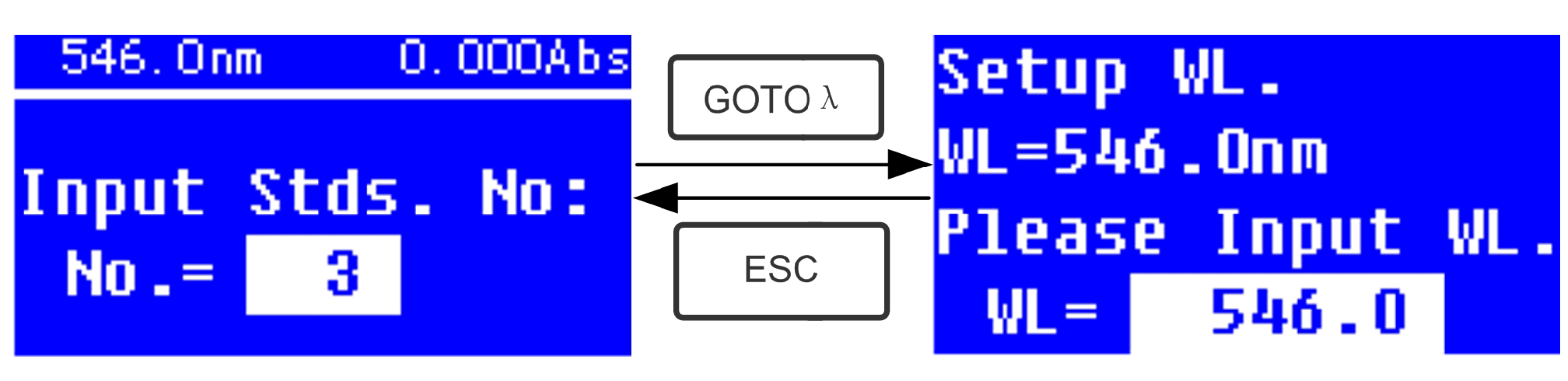

Note: The default quantity is “3”. Please don’t change the value at this time, you should set the Wavelength at first.

Step 1, Set Wavelength

Fig. 4-8

Press

to go into the wavelength setting interface,input the WL. Value by the Arrow key and press

to go into the wavelength setting interface,input the WL. Value by the Arrow key and press  to confirm.(Fig. 4-8)

to confirm.(Fig. 4-8)Step 2, Input the quantity of the standard samples

Use Arrow Key to input the quantity of the standard samples, then press

to confirm. The system will go into the following interface. (Fig. 4-9)

to confirm. The system will go into the following interface. (Fig. 4-9)

Fig. 4-9

Step 3, Calibrate 100%T/0Abs

Put the Reference Solution in the light path,then press

to calibrate 100%T/0Abs

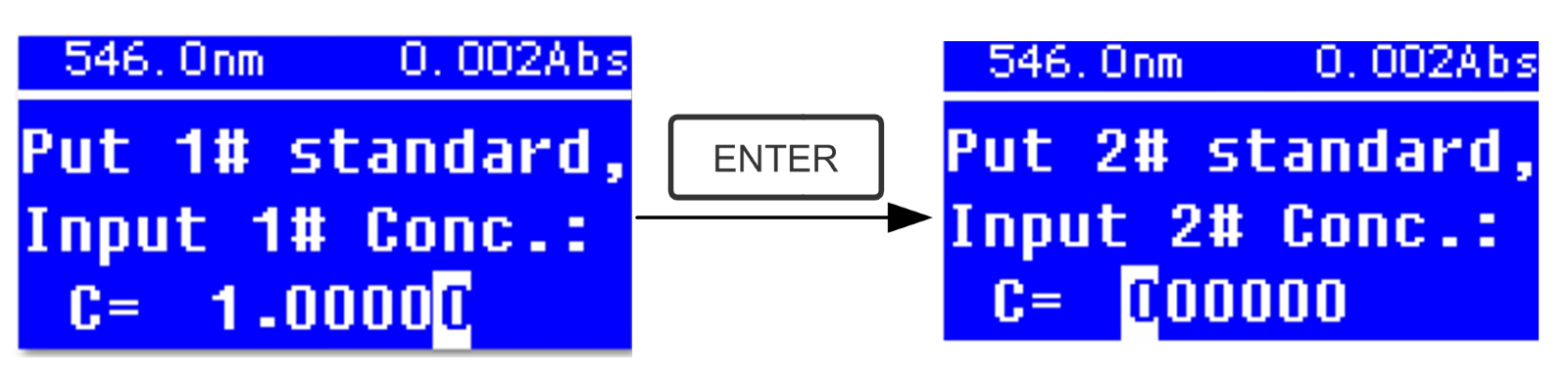

to calibrate 100%T/0AbsStep 4, Input Standard Samples’Concentration

- Pull the 1# Standard Sample in the light path and input the value of its concentration by the Arrow key, then press

to confirm. The system will go into the next interface. (Fig.4-10)

to confirm. The system will go into the next interface. (Fig.4-10)- Pull the 2# Standard Sample in the light path and input its concentration, then press

to confirm.

- Repeat the above step till the last sample’s concentration is finished.

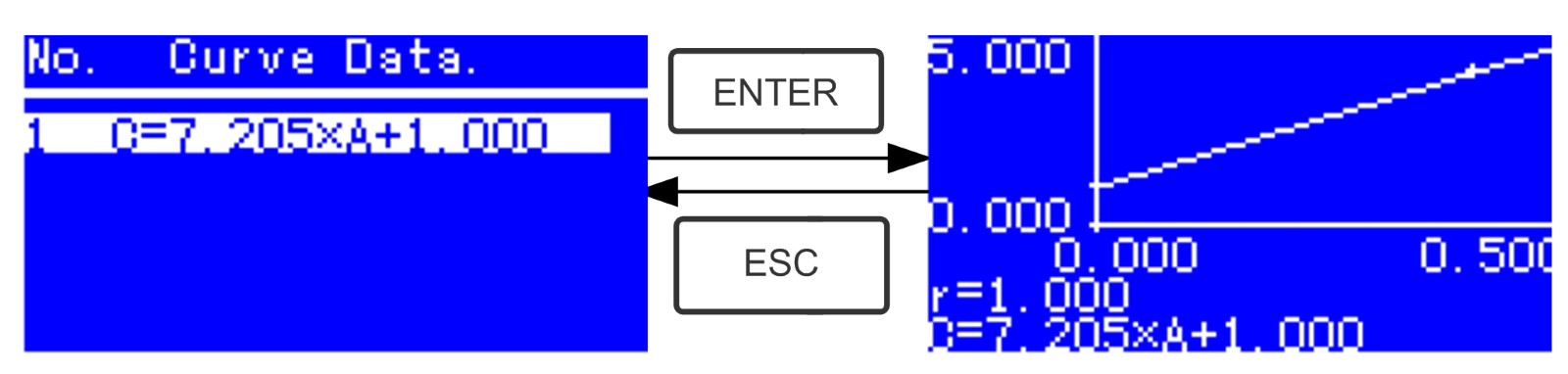

Step 5, Display the Curve

When the last standard sample finished, double press

to confirm. then the Standard Curve and its equation will display on the screen automatically. (Fig. 4-11) At the same time, the Curve Equation will be saved in the RAM automatically.

to confirm. then the Standard Curve and its equation will display on the screen automatically. (Fig. 4-11) At the same time, the Curve Equation will be saved in the RAM automatically.

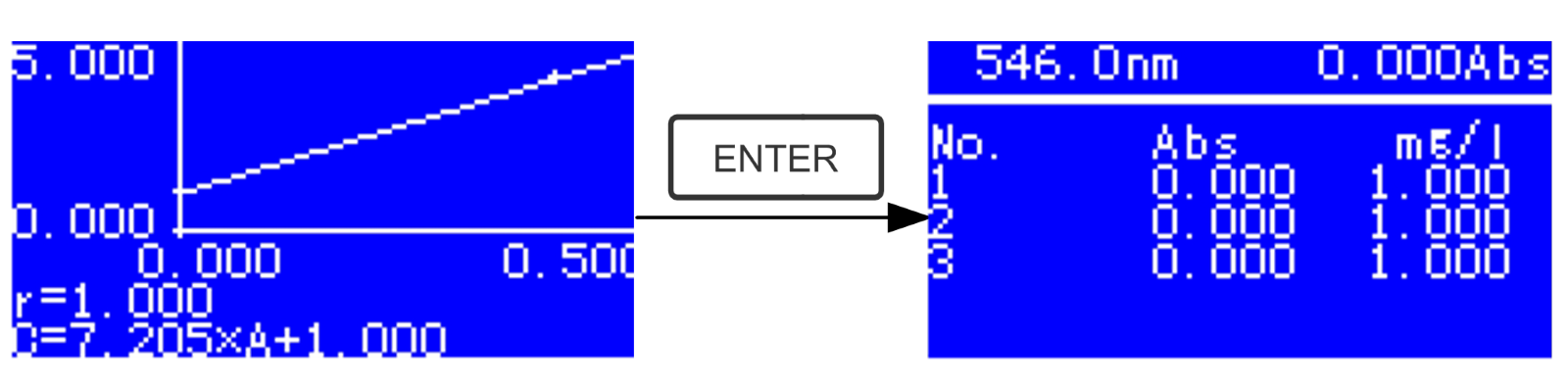

Fig. 4-11

Note: If there’s some mistake during the operation, the system will beep 3 times and return the initial interface automatically. Of course, the curve can not be displayed on the screen.

Step 6, Measure Samples

Fig. 4-12- Pull the Reference solution in the light path and press

to go into the continuous measurement interface. (Fig. 4-12)

to go into the continuous measurement interface. (Fig. 4-12)- Pull the unknown sample in the light path, then press

Text Boxto measure.

Text Boxto measure.The result will be displayed on the screen one by one. At the same time, the data will be saved in the RAM automatically. Total 200 groups of data can be saved.

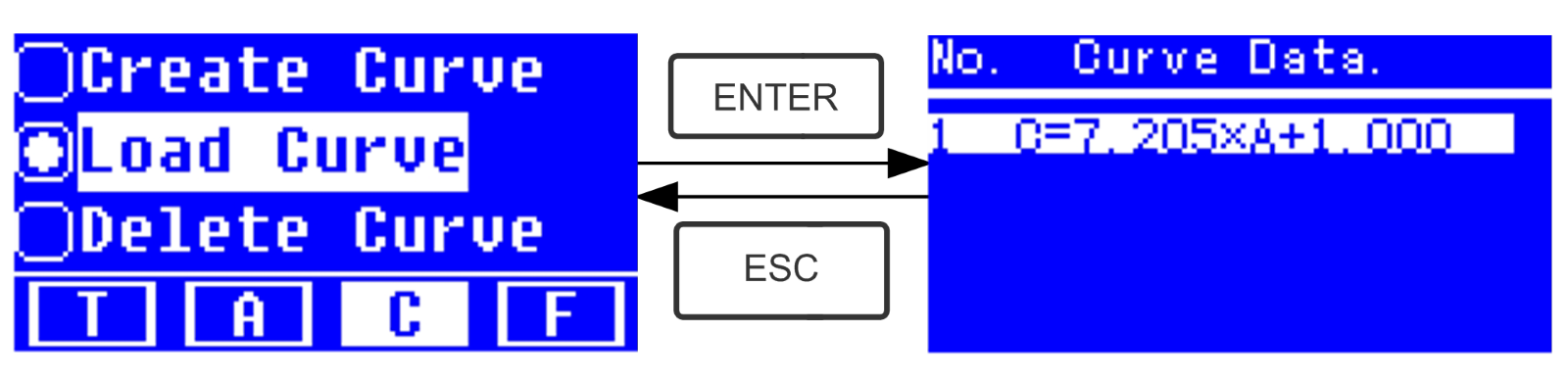

3. Load Curve

All the curve equations will be saved in the RAM automatically. If you want to reload the saved curve, just follow the following steps:

Fig. 4-13

- Move the cursor on “Load Curve” and press

to confirm. Then the system will go into the curve equation record interface.(Fig. 4-13)

to confirm. Then the system will go into the curve equation record interface.(Fig. 4-13)

Fig. 4-14

Move the cursor on the equation that you need and press

to confirm. Then the corresponding curve will display on the screen. (Fig. 4-14)

to confirm. Then the corresponding curve will display on the screen. (Fig. 4-14)Press

to go into sample continuous measure interface and measure samples. (Fig. 4-12)

to go into sample continuous measure interface and measure samples. (Fig. 4-12)Note: When you reload the curves, the wavelength will be set at the point where you creat the Standard Curve automatically.

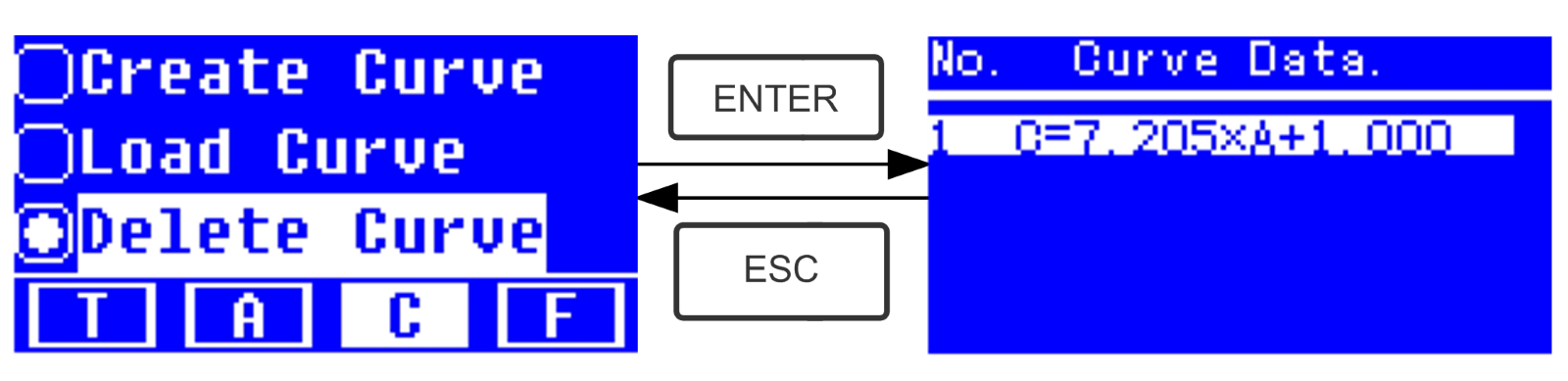

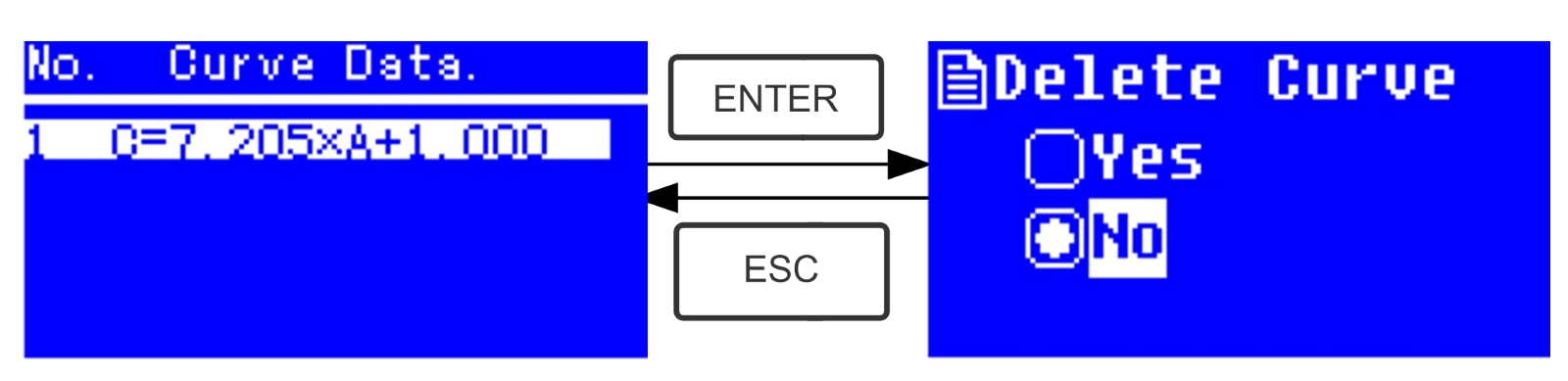

4. Delete Curve

Fig. 4-15

Move the cursor on “Delete Curve” and press

to confirm. Then the system goes into the curve equation choosing interface. (Fig. 4-15)

to confirm. Then the system goes into the curve equation choosing interface. (Fig. 4-15)- Move the cursor on the curve equation that you want to delete and press , then system will ask you to confirm again. (Fig. 4-16)

Fig. 4-16

- Move the cursor on “Yes” and press

to confirm, then the curve equation will be deleted. If you don’t want to delete it, just choose “

to confirm, then the curve equation will be deleted. If you don’t want to delete it, just choose “  ” or press to return.

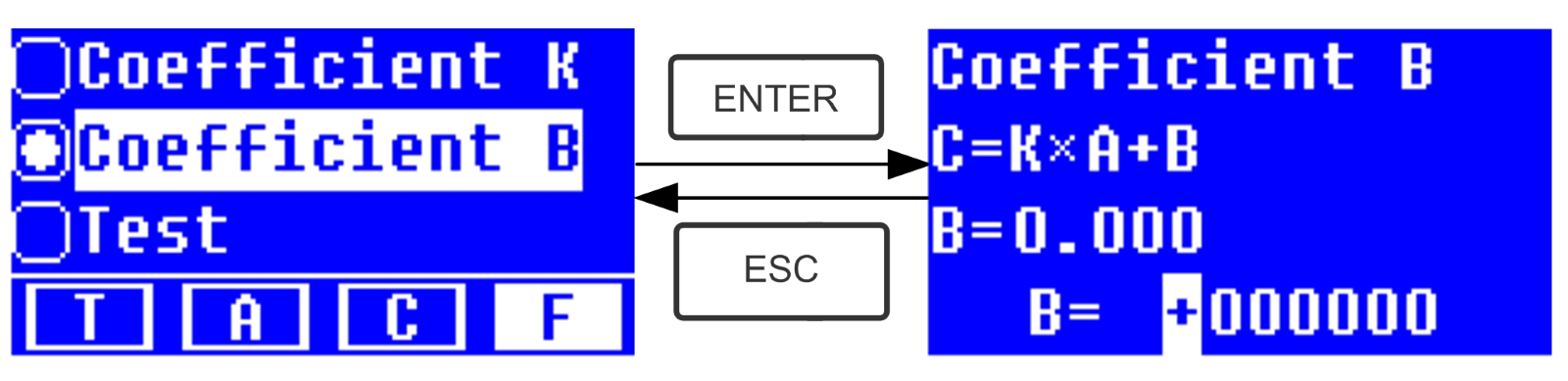

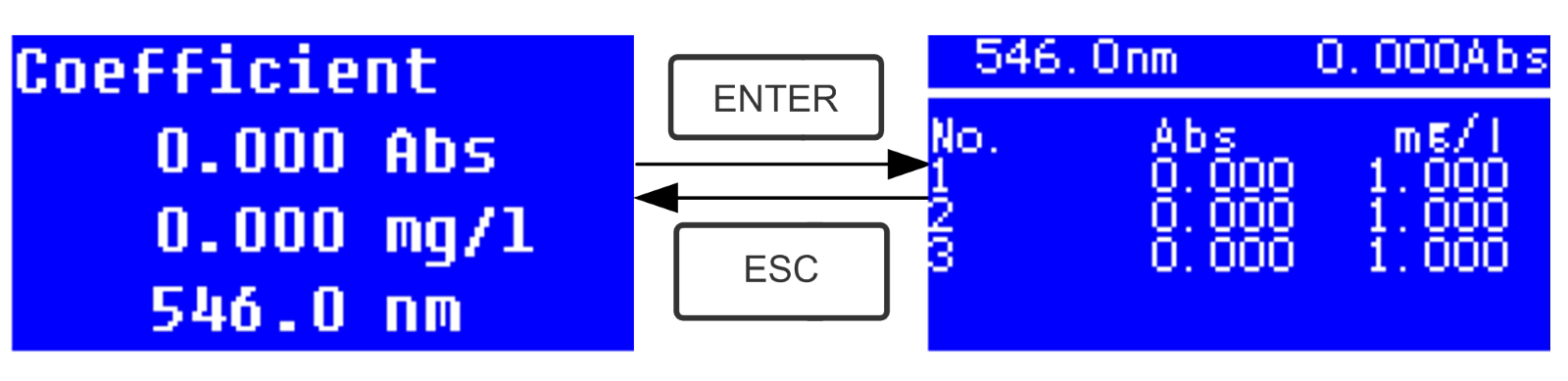

” or press to return.4.4 F-MODE (Coefficient Method)

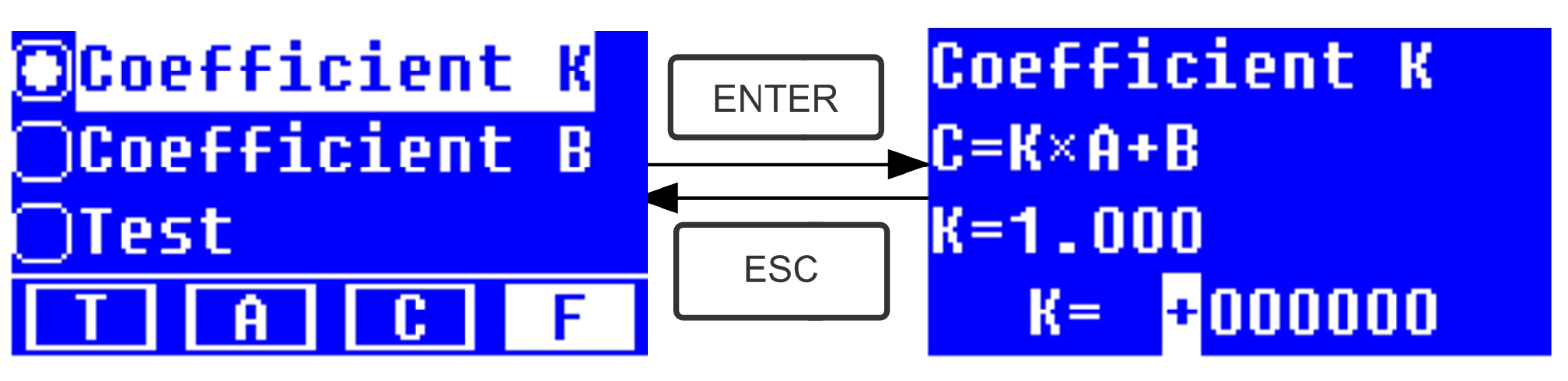

1) Go into F-MODE Interface

Fig. 4-17

Press Arrow Key to choose “F” in the Main Interface, and you’ll see the following Interface. (Fig. 4-17)

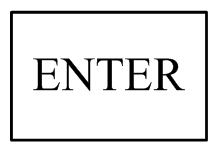

2) Parameter Setting

- Use Arrow Key to move the cursor on “Coefficient K” and press

to go into K setting interface.Fig. 4-18;Input every bit of K by Arrow Key and press

to go into K setting interface.Fig. 4-18;Input every bit of K by Arrow Key and press  to confirm. When the last bit finished, system will return the former Interface automatically.

to confirm. When the last bit finished, system will return the former Interface automatically.

Fig. 4-18

- Input the value of B in the same way(Fig. 4-19)

Fig.4-19

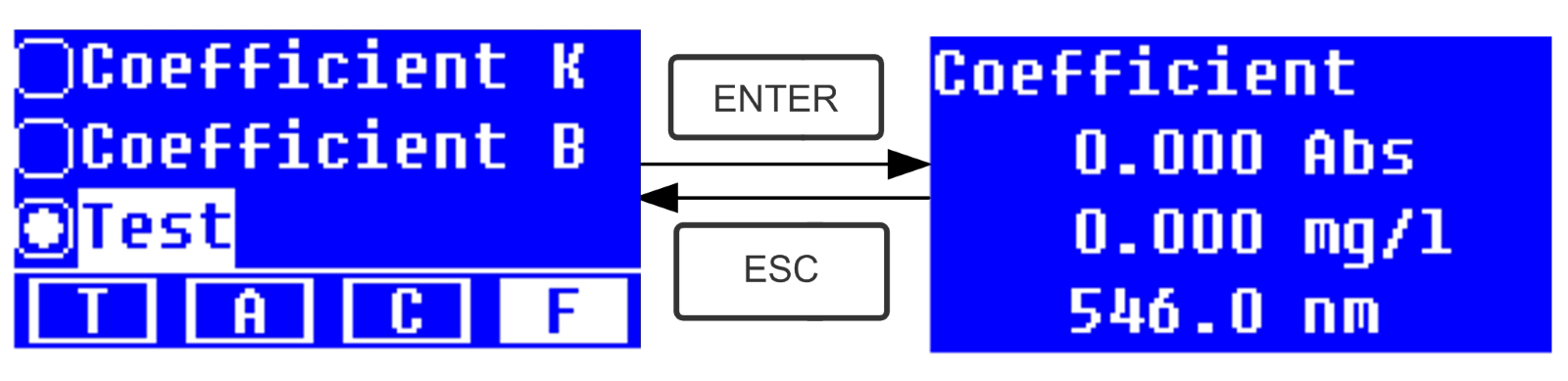

3) Test Samples

Step 1, Go into pre-test Interface

Move the cursor on “Test”, then press

to go into pre-test Interface. (Fig.4-20)

to go into pre-test Interface. (Fig.4-20)

Fig.4-20

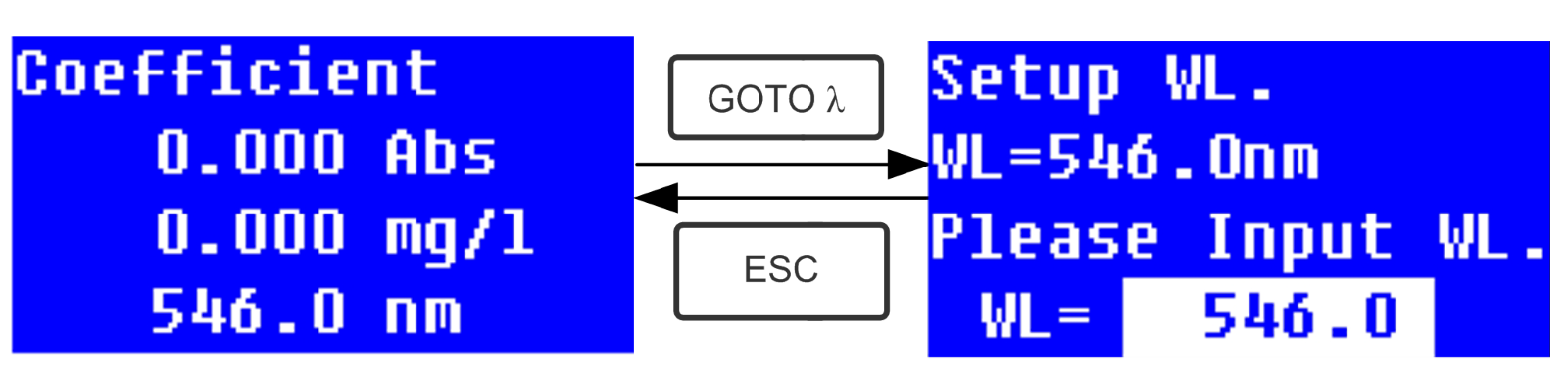

Step 2, Set Wavelength

Fig. 4-21

Press

to go into wavelength setting interface,input the wavelength value by Arrow key and press

to go into wavelength setting interface,input the wavelength value by Arrow key and press  to confirm. (Fig. 4-21)

to confirm. (Fig. 4-21)Step 3, Calibrate 100%T/0Abs

Press

to go into continuous measurement interface (Fig. 4-22). Pull the Reference Solution in the light path,then press

to go into continuous measurement interface (Fig. 4-22). Pull the Reference Solution in the light path,then press  to calibrate 100%T/0Abs;

to calibrate 100%T/0Abs;

Fig. 4-22

Step 4, Measurement

Pull the samples to be measured in the light path, press

to measure, then the result will be displayed on the screen . Repeat this step to measure other samples. All the test results will be listed on the screen and stored in the RAM automatically. They can be reload even after a sudden power cut.

to measure, then the result will be displayed on the screen . Repeat this step to measure other samples. All the test results will be listed on the screen and stored in the RAM automatically. They can be reload even after a sudden power cut.Step 5, Print or Delete the Test Result

In the continuous measurement interface, press

In the T mode or A mode of Main Interface, press functions(Fig. 4-23),4.1 for details.

In the T mode or A mode of Main Interface, press functions(Fig. 4-23),4.1 for details.5. System Functions

In the T mode or A mode of Main Interface, press functions(Fig. 4-23)to print or delete the test result. Please refer to Chapter Key to go into system

Fig. 4-23

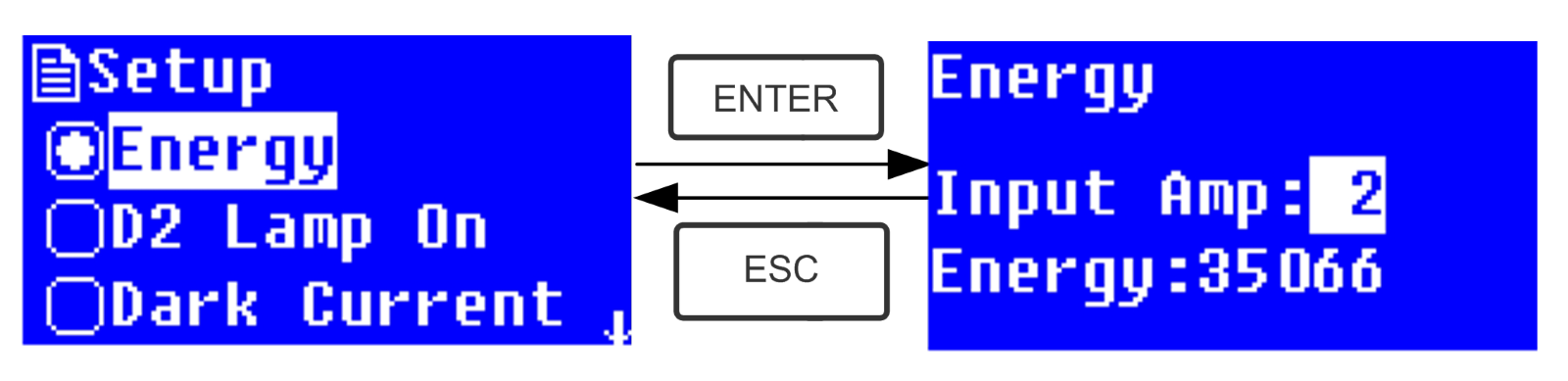

1) Energy

To see the energy of present wavelength. Move the cursor on “Energy”, then press

Text Boxto confirm. (Fig.4-24)

Text Boxto confirm. (Fig.4-24)Note: Users seldom use this function. It’s useful for service man to judge the fault.

Fig. 4-24

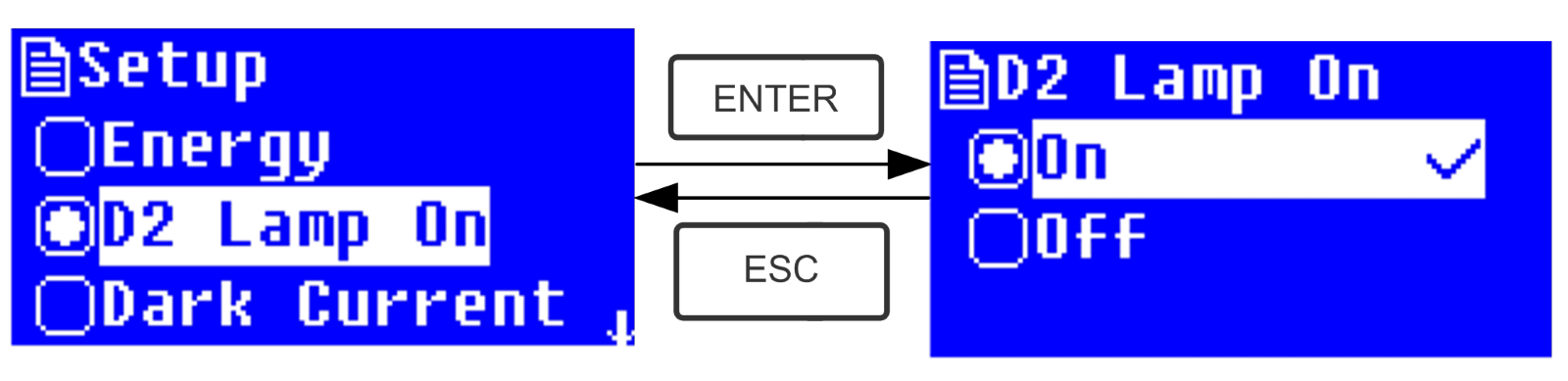

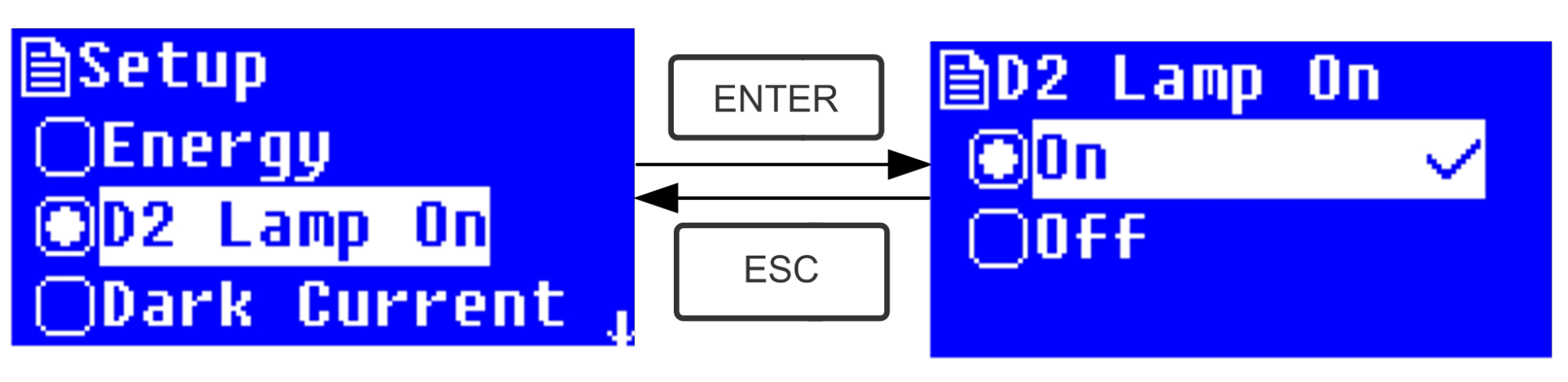

2) D2 lamp management

When the wavelength point needed is in the range of 340-1100nm , the D2 lamp can be switched off to prolong its life time.

When the wavelength point needed is in the range of 340-1100nm , the D2 lamp can be switched off to prolong its life time.

Use Arrow key to choose “D2 Lamp On” and press

to go into D2 lamp setting interface(Fig. 4-25). Use Arrow key to choose “On ”or “Off” and press

to go into D2 lamp setting interface(Fig. 4-25). Use Arrow key to choose “On ”or “Off” and press  to switch on or switch off the D2 lamp. Press

to switch on or switch off the D2 lamp. Press  to return.

to return.

Fig. 4-25

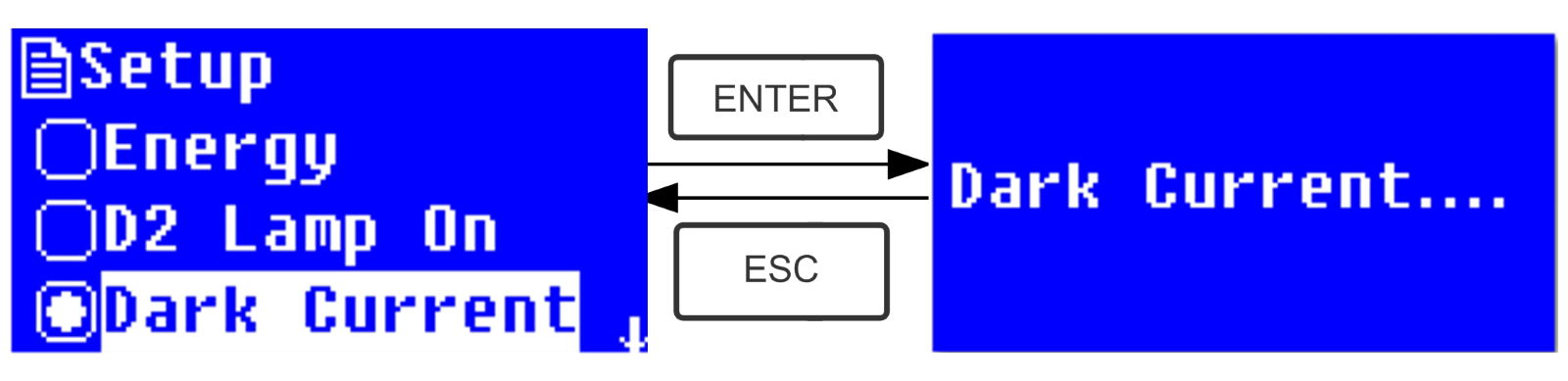

3. Get Dark Current

When the working condition changes, A dark current calibration is required before any measurement. Use Arrow key to choose “Dark Current” and press

When the working condition changes, A dark current calibration is required before any measurement. Use Arrow key to choose “Dark Current” and press  to confirm. (Fig. 4-26)

to confirm. (Fig. 4-26)Note: Remove the cuvettes from the light path before this action, don’t open the lid of the compartment during the course of calibration.

Press

to return when it finishes.

to return when it finishes.

Fig. 4-26

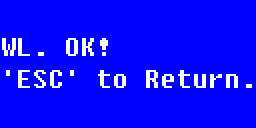

When it finishes, it will display the following words on the screen. (Fig.4-27) If it displays “Dark Current Err”, you should check if there’s something else in the compartment and repeat this step.

Fig. 4-27

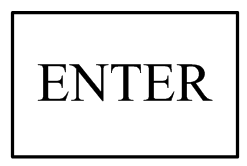

4. Wavelength Calibration

After some time, the energy of lights would drop off and there will be some but slight influence on the test result. In this case, users can reset the wavelength to compensate. We suggest the users to calibrate the wavelength every one or two months.

After some time, the energy of lights would drop off and there will be some but slight influence on the test result. In this case, users can reset the wavelength to compensate. We suggest the users to calibrate the wavelength every one or two months.Remove all the blocks in the light path and close the lid of the compartment, press Arrow Key to choose “Calibrate WL.” and press

to begin the calibration ( Fig. 4-28 ) . The lid of the compartment should not be opened during the calibration.

to begin the calibration ( Fig. 4-28 ) . The lid of the compartment should not be opened during the calibration.

Fig. 4-28

Fig. 4-29

When it finishes, it will display the following words on the screen. (Fig.4-29) If it displays “Wavelength Err”, you should check if there’s something else in the compartment and repeat this step.

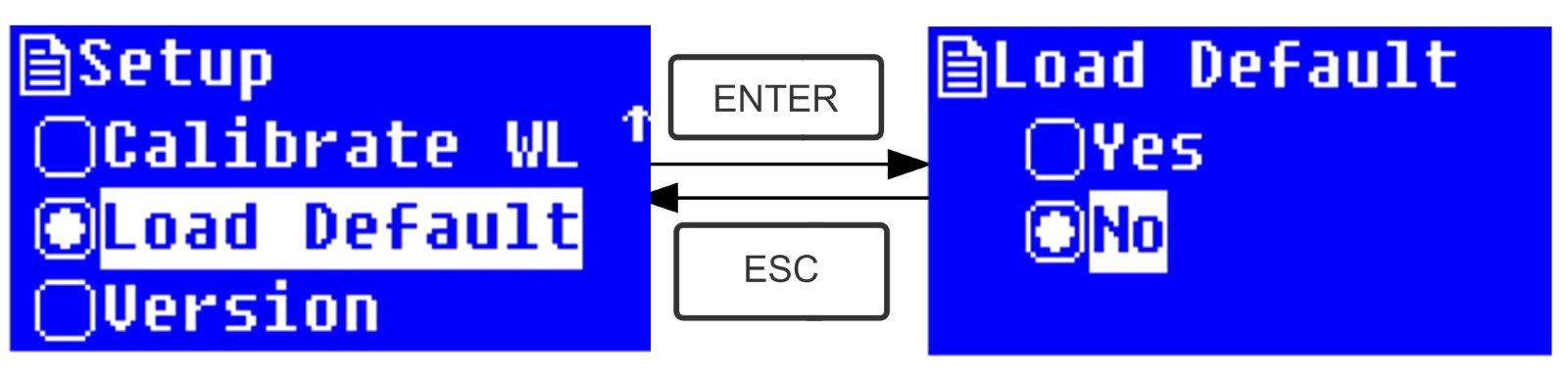

5. Load Default

Press Arrow Key to choose “Load Default” and press

to confirm.(Fig. 4-30), press Arrow Key to choose “Yes” and press

to confirm.(Fig. 4-30), press Arrow Key to choose “Yes” and press  to confirm. Then the system will recover the default setting when leave factory. Choose “No” with

to confirm. Then the system will recover the default setting when leave factory. Choose “No” with  pressed to cancel the operation and return.

pressed to cancel the operation and return.

Fig. 4-30

Note: All the saved data and curves would be deleted from the RAM once “Yes” is chosen!

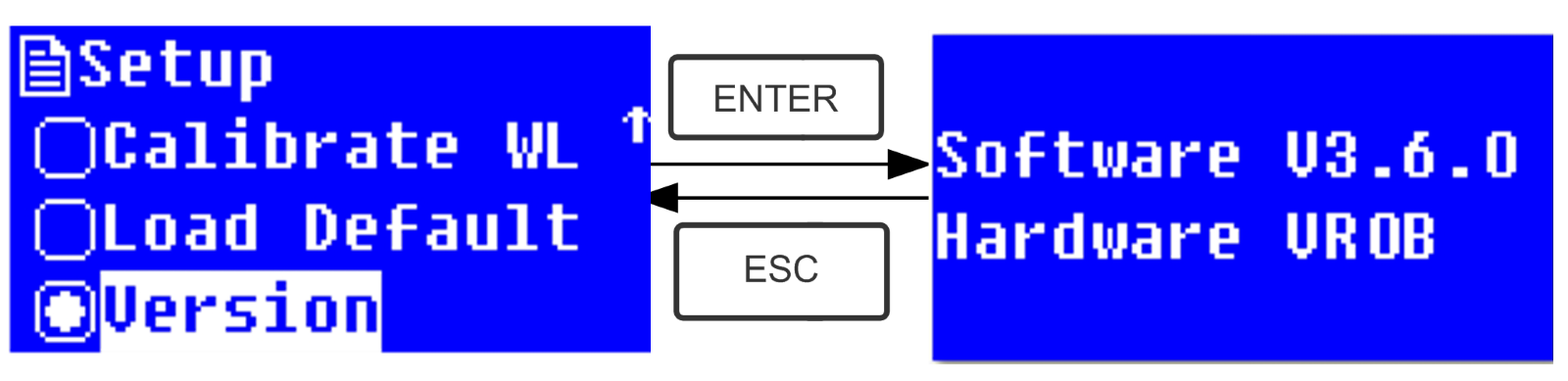

6. Version Press Arrow Key to choose “Version” and press

to confirm. You’ll see the version of the software and hardware. (Fig.4-31). Press

to confirm. You’ll see the version of the software and hardware. (Fig.4-31). Press  to return.

to return.

Fig. 4-31

Note: For the reason of update, the version you see on the screen may be different from the above one.

CHAPTER 5 Instrument Maintenance

To keep the instrument work in good condition, constant maintain is needed.1. Daily Maintain

1) Check the compartmentAfter measurement, the cuvettes with sample solutions should be taken out of the compartment in time. Or the volatilization of the solution would make the mirror go moldy. Users must pay more attention to the corrosive sample and liquid easy to volatilize. Any solution remains in the compartment should be wiped off immediately.

Surface Clean

2) The cover of the instrument is with paint. Please use wet towel to wipe off the drip on the surface immediately. Organic solution is forbidden to be used to clean the cover. Please wipe off the dirt on the cover timely.

3) Clean the cuvettes

After every test or after a solution change, the cuvettes should be cleaned carefully, or the remains on the surface would cause measuring error.

2. Troubleshooting

1) Dark Current Error when self-testPossible Cause

Open the lid of the compartment during the course of self-test

Solution

Close the lid of the compartment and switch on the power again.

2) No response after power on

Possible Cause

- Bad contact in power supply

- Fuse melt

Solution

- Improve the contact

- Replace a new fuse

3) Printer not work, printer error

Possible Cause

- No power supply

- Bad contact in power supply

- Bad contact of the data cable

Solution

- Switch on the power supply

- Improve the contact

- Improve the contact

4) No Stable Reading

Possible Cause

- No enough pre-warm

- Glass cuvettes used in UV Range

- No stable Sample

- Much higher sample concentration

- Low voltage or unstable power supply - Lights defect

- Light used up

Solution

- Increase the pre-warm time

- Use Silicon Cuvettes.

- Improve the sample

- Dilute the sample

- Improve the power condition

- Replace a new lamp

- Replace a new lamp

5) Worse Repeatability

Possible Reason

- Unstable sample

- Cuvettes polluted

Solution

- Improve the sample

- Clean the cuvettes

6) Incorrect reading

Possible Reason

- Dark Current Error

- Worse matching of the cuvettes

Solution

- Re-get the dark current

- Improve the matching of the cuvettes

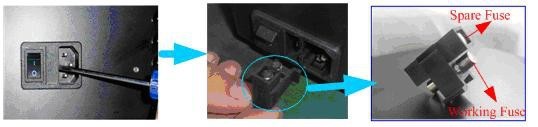

3. Fuse Replacement

Danger! Be sure to switch off the power and unplug the socket before replacement!

Danger! Be sure to switch off the power and unplug the socket before replacement!Step 1: Tools preparation

Prepare a 3×75 Flat Blade screwdriver

Step2:Switch Off the power supply

Switch off the power supply, and unplug the socket.

Step 3: Take out the Fuse Seat

Take out the fuse seat by the screwdriver. (Fig.5-1)

Fig. 5-1

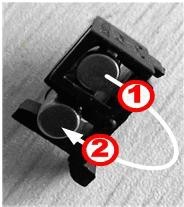

Step 4: Replace a new fuse

Pick out the spare fuse and replace it to the working position. (Fig.5-2)

Fig. 5-2

Step 5: Reset the fuse seat

Replace the fuse seat in the power socket

Step 6: Switch on the power

Plug the socket and switch on the power