Sample Concentrator BCON-106

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Concentrator refers to the amount of a substance in a defined space. Concentration is especially used for concentrating or preparing sample in batches in laboratory.

- The height of the air chamber plate can be adjusted. The length of a standard gas needle is 150 mm

- LED displays immediate temperature and diminis-"C; i Operation is simple and convenient

- Built in overheat protection, automatic fault detection an alarm devices

- The entire equipment can be put into ventilation cabin concentration sample is in toxic solvents

Specification

Features

Applications Optional Accessories

| Temp. Control Range | R.T.+5°C ~100°C |

| Temp. Setting Range | 5 °C ~ 150 °C |

| Temp. Stability @ 40 ~100 °C | ± 0.5 °C |

| Temp. Stability @ 100~150 °C | ± 1 °C |

| Block Temp. Uniformity @ 100 °C | ±0.5 °C |

| Block Temp. Uniformity @ 150 °C | ±1 °C |

| Temp. Display Accuracy | 0.1 °C |

| Heating Speed | ≤30 min (40 °C to 150 °C ) |

| Time Range | 1 min ~99 h 59 min |

| Needle Plate Max. Lift Stroke | 285 mm |

| Gas-in Joint Outer Diameter | Φ7 mm |

| Nitrogen Pressure | ≤0.1 MPa |

| Nitrogen Flow Rate | 0~10 L/min |

| Needle Length | 150 mm |

| Sample Capacity | 2 standard block |

| Voltage | AC 220 V/AC 110 V, 50/60 Hz |

| Power | 200 W |

| Fuse | 250 V, 2 A / 3 A, Φ5 x 20 |

| Dimension (WxDxH) | 200x230x525 mm |

| Net Weight | 5.1 kgs |

- The height of the air chamber plate can be adjusted. The length of a standard gas needle is 150 mm

- LED displays immediate temperature and diminis-"C; i Operation is simple and convenient

- Built in overheat protection, automatic fault detection an alarm devices

- The entire equipment can be put into ventilation cabin concentration sample is in toxic solvents

- Synchronously working with heating by dry bath in the bottom and nitrogen blowing on the surface accelerates liquid evaporator sample concentration

- Unique patented design for air channel control system, enhances air tightness and reduces potential leakage; easy to operate air needle to realize channel switch; the switching stat

- channel is clear at a glance

Drug screening, hormone analysis, liquid phase

| Accessory Code | Name | DESCRIPTION | SUITABLE GAS CHAMBER TYPE |

| 3900611006 | Block | 6 mm x 12 | NDK200-1N: 12-needle |

| 3900611007 | Block | 7 mm x 12 | NDK200-1N: 12-needle |

| 3900611008 | Block | 10 mm x 12 | NDK200-1N: 12-needle |

| 3900611009 | Block | 12mm x 12 | NDK200-1N: 12-needle |

| 3900611010 | Block | 13 mm x 12 | NDK200-1N: 12-needle |

| 3900611011 | Block | 15mm x 12 | NDK200-1N: 12-needle |

| 3900611012 | Block | 16mm x 12 | NDK200-1N: 12-needle |

| 3900611013 | Block | 19mm x 12 | NDK200-1N: 12-needle |

| 3900611014 | Block | 20mm x 6 | NDK200-1N: 6-needle |

| 3900611015 | Block | 26mm x 6 | NDK200-1N: 6-needle |

| 3900611016 | Block | 28mm x 4 | NDK200-1N: 4-needle |

| 3900611017 | Block | 40mm x 2 | NDK200-1N: 2-needle |

| 3900611018 | Block | 0.5ml tube x 12 | NDK200-1N: 12-needle |

| 3900611019 | Block | 1.5ml tube x 12 | NDK200-1N: 12-needle |

| 3900611020 | Block | 2.0ml tube x 12 | NDK200-1N: 12-needle |

| 3900611021 | Block | 0.2ml tube x 12 | NDK200-1N: 12-needle |

| 3900611022 | Block | customized | customized |

Operating Manual for BCON-106

1.Safety Warnings and Guidelines

1. Introduction

2. Specifications

2.1 The normal working condition:

2.2 Basic Parameters and Performance.

3. Preparations

3.1 Structure Description

3.2 Instrument Installation

3.3 Button instruction:

4. Operation Guide

4.1 Temperature and time set:

4.2 Operation and stop:

4.3 Temperature error adjustment

4.4 The exchange of the metal block

5. Error Analysis and Recovery Processing

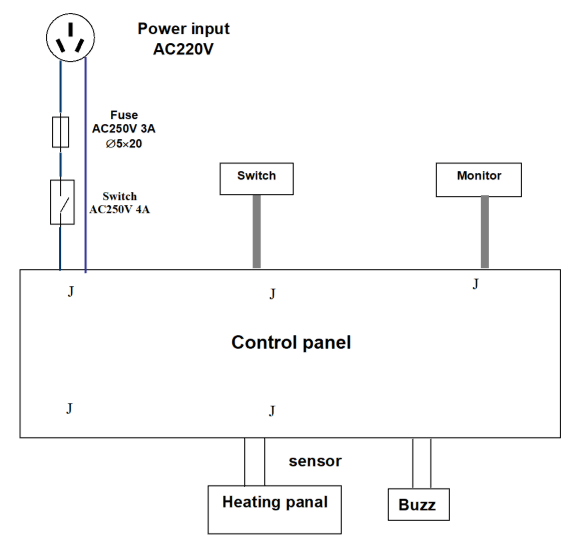

Annex 1: Wiring Diagram

1.Safety Warnings and Guidelines

1 Important Operation Information of The SecurityUsers should have an entire conception of how to use the instrument properly before operating it. Please read this operation manual carefully before using the instrument.

It is forbidden operating before read the operation manual. Serious burn may be scalded by the heating, or even electric shock hazard may happen. Read the guidelines and directions below and carry out the precautionary measure according to them.

2 Security

To operation, maintenance and repair the instrument, please comply with the basic guidelines and the remarked warnings below. Otherwise, the instrument will suffer effect on the scheduled working life and also on the protection provided.

This product is a normal and an indoor using instrument, meet the standards of normal equipment of GB9706.1 Class I-B.

This product is a normal and an indoor using instrument, meet the standards of normal equipment of GB9706.1 Class I-B. Before operation, read the manual carefully. These units are designed for using in the laboratory environments by who’re knowledgeable in safe laboratory practices.

Before operation, read the manual carefully. These units are designed for using in the laboratory environments by who’re knowledgeable in safe laboratory practices. The operator should not open or repair the instrument by himself. Otherwise, the instrument will lose the qualification of repair guarantee or cause accidents. The company will repair the instrument based on warranty description.

The operator should not open or repair the instrument by himself. Otherwise, the instrument will lose the qualification of repair guarantee or cause accidents. The company will repair the instrument based on warranty description. A.C. power’s grounding should be reliable to safeguard against an electric shock. The 3-pin plug supplied with thermo-shaker’s power cable is a safety device that should be matched with a suitable grounded socket.

A.C. power’s grounding should be reliable to safeguard against an electric shock. The 3-pin plug supplied with thermo-shaker’s power cable is a safety device that should be matched with a suitable grounded socket. The temperature of metal block and top cover shell may be very high during the operation. There may be scald or boiling of the liquid. It is strictly prohibited any part of the body touching the instrument.

The temperature of metal block and top cover shell may be very high during the operation. There may be scald or boiling of the liquid. It is strictly prohibited any part of the body touching the instrument. Close the test tube lid before put the tube into the block. Liquids may spill out in the block or onto the device if the tube lid is opened, which will damage the block or the device.

Close the test tube lid before put the tube into the block. Liquids may spill out in the block or onto the device if the tube lid is opened, which will damage the block or the device. Make sure the voltage is complying with the voltage required. Make sure the rated electrical outlet load no lower than the demand. Power line should be replaced with the same type if it any damage. Make sure there is nothing on the power line. Hold the jack when pull out the power line. Do not pull the power line. Do not put the power line in ambulatory place.

Make sure the voltage is complying with the voltage required. Make sure the rated electrical outlet load no lower than the demand. Power line should be replaced with the same type if it any damage. Make sure there is nothing on the power line. Hold the jack when pull out the power line. Do not pull the power line. Do not put the power line in ambulatory place. The instrument should be put in the place where of low temperature, little dust, no water, no sunshine or hard light, and of good aeration, no corrosively gas or strong disturbing magnetic field, and far away from central heating, camp stove and other hot resource. Do not put the instrument in wet and dusty place. The vent on the instrument is designed for aeration. Do not wall up or cover the vent. The distance between each device should be more than 100cm when there is more than one instrument.

The instrument should be put in the place where of low temperature, little dust, no water, no sunshine or hard light, and of good aeration, no corrosively gas or strong disturbing magnetic field, and far away from central heating, camp stove and other hot resource. Do not put the instrument in wet and dusty place. The vent on the instrument is designed for aeration. Do not wall up or cover the vent. The distance between each device should be more than 100cm when there is more than one instrument.

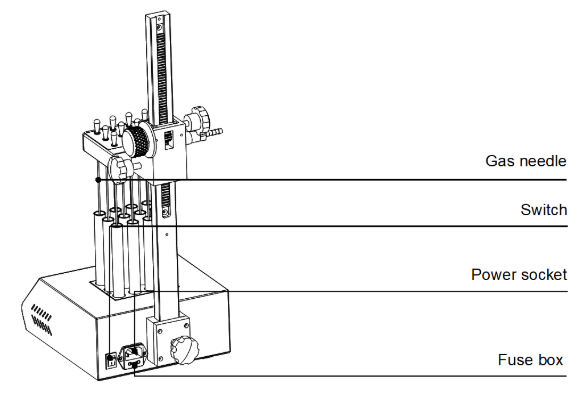

Main switch is on the rear of the device. Turn to “I” to power on the device, and Turn to “O” to power off the device.

Main switch is on the rear of the device. Turn to “I” to power on the device, and Turn to “O” to power off the device. Power off when operation finished. If long period do not use the instrument, pull off the connector plug, cover a cloth on the instrument to prevent from dust.

Power off when operation finished. If long period do not use the instrument, pull off the connector plug, cover a cloth on the instrument to prevent from dust. Pull the connector plug from the jack at once in the following case, and contact the vendor.

Pull the connector plug from the jack at once in the following case, and contact the vendor.- There is some liquid flowing into the instrument;

- Drenched or fire burned;

- Abnormal operation: such as abnormal sound or smell;

- Instrument dropping or outer shell damaged;

- The function has obviously changed.

3 Instruments Maintenance

The well in the block should be cleaned by the cloth stained with alcohol to assure good heat translation between the block and the test tube and no pollution. If there are smutches on the instrument, clean them with cloth.

Power off when cleaning the instrument. Do not drop the clean fluid in the well when cleaning.Corrosive clean fluid is strongly prohibited.

Power off when cleaning the instrument. Do not drop the clean fluid in the well when cleaning.Corrosive clean fluid is strongly prohibited.4. After-sales service

1) Warranty content

Within a month from the delivery date, the cause of failure due to material and manufacturing defects, the Company will be responsible for the guarantee replacement

Within 12 months from the delivery date, the cause of failure due to material and manufacturing defects. The company will prove to be defective instruments selected for repair or replacement

The product must be sent to the maintenance department of the company by the user. The freight will be borne by the user. The Company will bear the return shipping costs.

Over the warranty period, the Company will receive appropriate maintenance costs.

2) Warranty coverage

The above warranty is not suitable for improper maintenance, damage caused by unauthorized repair or modification.

1. Introduction

The nitrogen sample concentrator BCON-106 is mainly used for concentrating or preparing sample in batch. Such as drug screening, hormone analysis, liquid phase and mass spectrometry in the analysis of sample preparation. It works by blowing nitrogen in the surface of sample which is being heated to accelerate evaporating and separating the solvent in the samples without oxygen. Instead of the rotary evaporation instrument, nitrogen sample concentration can efficiently concentrate dozens of samples simultaneously.Feathers

1. Patent individually control gas needles to avoid gas waste. Gas pressure is uniform from every needle. Simple close/open gas by just up/down the needles.

2. The height of the air chamber can be adjusted.

3. Suit for different types of tubes or vials.

4. LED display immediate temperature and diminishing time. Operation is simple and convenient.

5. Built in overheat protection, automatic fault detection and fault beep alarm devices.

6. The entire equipment can be put into ventilation cabinet when the concentration sample in toxic solvents.

7. Synchronously working with heating by dry bath in the bottom and nitrogen blowing on the surface accelerates liquid evaporation and sample concentration.

8. Standard configured air cavity and adjustable bracket.

2. Specifications

2.1 The normal working condition:

The room temperature: 5C 30CThe relative humidity: ≤70%

The using power: AC220V / AC110V ~ 50-60Hz

2.2 Basic Parameters and Performance.

| Model Parameters | BCON-106 |

| Temperature Range | R.T.+5°C ~ 150°C |

| Heating Time | ≤30min (from 40°C to 150°C) |

| Temperature Accuracy (40~100°C) | ±0.5°C |

| Temperature Accuracy (100~150°C) | ±1°C |

| Temperature Uniformity (100°C) | ±0.5°C |

| Blocks Quantity | 2 blocks |

| Time Range | 99h59min |

| Nitrogen Flow Rate | 0~10L/min |

| Nitrogen Pressure | ≤0.1MPa |

| Power | 400 W |

| Dimensions (mm) | 260 x 200 x 525 |

| Weight(kg) | 6.1kgs |

3. Preparations

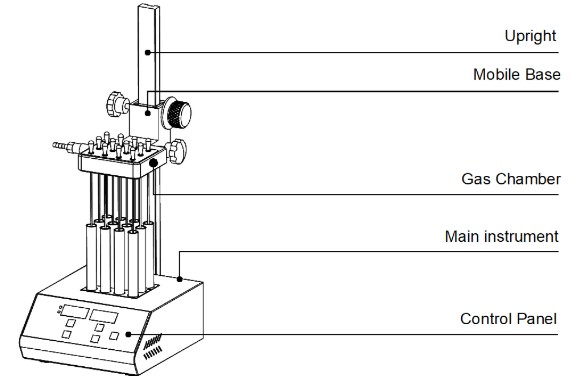

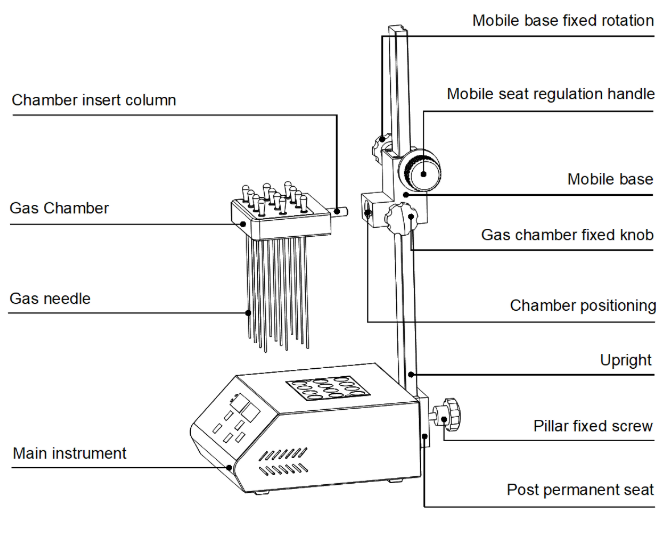

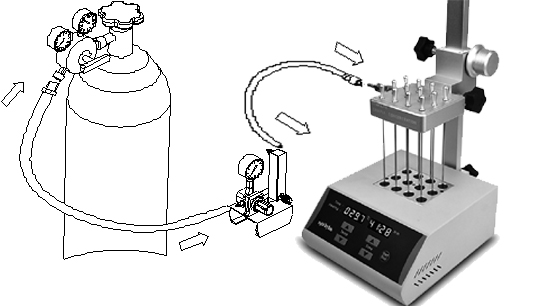

This chapter introduces the instrument’s mechanical structure, keyboard and each key’s function and some preparations before power on. You should be familiar with this chapter before the instrument is first operated.3.1 Structure Description

3.2 Instrument Installation

3.2.1 Assembly

Installation steps:

1) Put the dry bath on the bench smoothly and solidly

2) Fully insert the column into a square hole of the column holder behind the host, then srew knob into the column mounts, and finally tighten the knob to secure the uprights

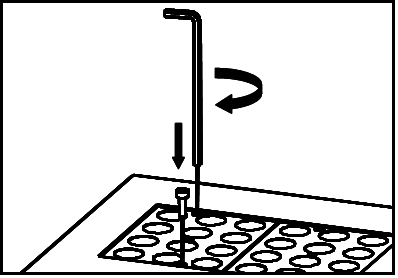

3) Screw fixed knob of the mobile seat into the threaded hole on the left side of the mobile seat, then hold knob of mobile seat and counterclockwise rotate the hand wheel adjustment. When reach the desired position, we can tighten the knob to fix mobile seat. Clockwise rotating the hand wheel adjustment, the mobile seat will decline (as shown in the picture).

Note: When move the seat, two hands must be used in conjunction with operating mobile seat fixed knob and hand wheel adjustment

4) Screw fixed knob of the gas chamber into the threaded hole on the left side of the movable block, then insert column of gas chamber into the corresponding hole of the front movable block. Fully inserted column of gas chamber, then tighten fixed knob. (as shown in the picture)

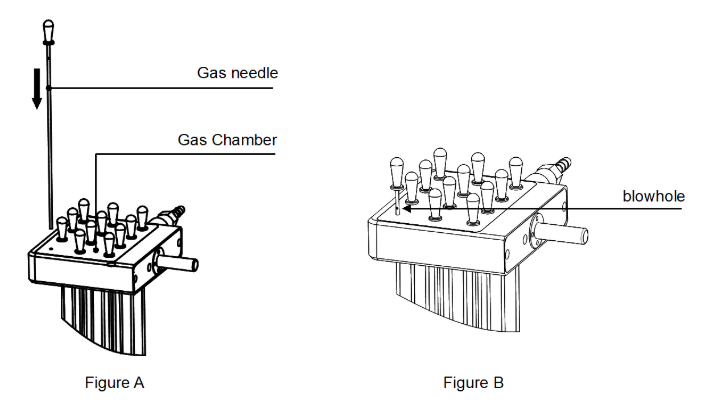

3.2.2 Gas needle installation

1) Twist the gas needles one by one into the hole until the needle pass through the gas chamber, insert the needle till the needle head reach the chamber top (refer to below Figure A).

Lift up the needle a bit till see the blowhole, the needle is sealed, gas will not be pressed out from that needle (refer to below Figure B). If the needle is requested in use, insert the needle back.

2) After install air needles, then flip the gas chamber and insert into the mobile base, so we can fix the gas chamber with knob.

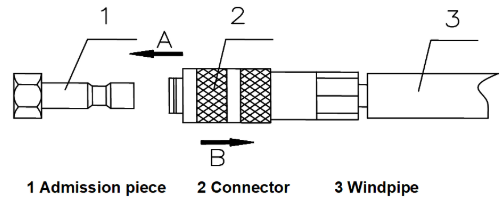

3) With the Quick Connection on the part of gas joint, so users can easily and quickly pass nuff source. As follow:

Tighten part 2(Connector), Target 1(Admission piece), force to the direction A. The spring parts within the connector will tighten automatically to part 1(Admission piece). Press part 2 to B direction, the spring member within the connector will automatically disengage. Trachea separates from the gas distribution chamber

4) Loosen the knob and turn the hand wheel adjustment till the gas needle is inserted into the top of the test tube about 10mm above the fluid. Then fix and tighten mobile base.

5) Turning on the gas source when needed.

Note: Don’t the input gas pressure greater than 0.08Mpa. The causing of the gas chamber’s bad seal and leak, thus waste of the gas source. We should keep the gas pressure smaller than 0.04Mpa, when the gas needle number less than 16.

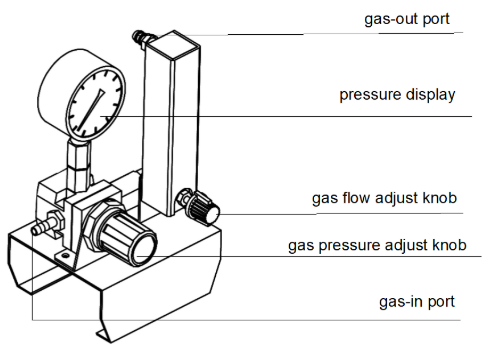

3.2.3 Gas Control Valve (optional purchasing auxiliary)

Structure

Pull out the gas pressure adjust knob, clockwise rotate the knob to increase pressure, anticlockwise rotate the knob to decrease pressure. Push back the knob to lock pressure.

Clockwise rotate the gas flow adjust knob to increase flow rate, anticlockwise rotate the knob to decrease flow rate till shut off it.

3.2.4 Installation of nitrogen flow rate adjusting valve

The composition of nitrogen flow rate adjusting valve.

As the above picture, connect the outlet of the nitrogen flow regulator valve with outlet port of

the host with a short hose (about 1.5m). See page 8 the no. 6, Connect the inlet of nitrogen flow regulator valve with outlet port of the host with a long hose (about 3m)

Note: Slowly open the valve of the nitrogen bottle to control the outlet pressure between 0.1MPa to 0.2MPa, and then open the valve adjusting knob to keep pressure value at 0.02MPa. According to the number of holes, we can adjust the pressure appropriately (usually between 0.02MPa and 0.05MPa optional).

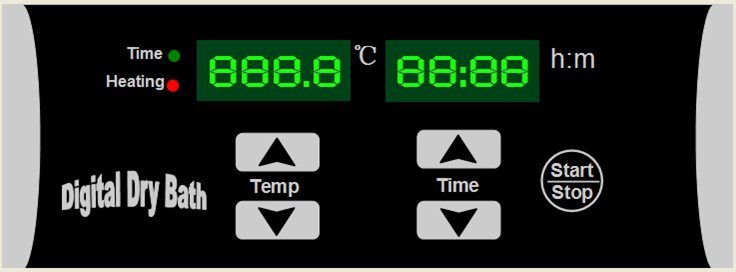

Operation panel:

3.3 Button instruction:

Decreasing button: decrease the figure set;

Decreasing button: decrease the figure set; Increasing button: increase the figure set;

Increasing button: increase the figure set;START/STOP Run/stop button: Run when you press the button once after setting the temperature and the time. Stop when you press this button for 2s.

4. Operation Guide

4.1 Temperature and time set:

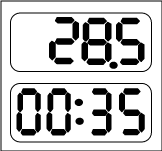

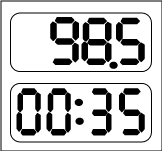

a). The LED will display “ ” as the chart when the Instrument powers on and the Instrument goes into the initial state with the sound of “du…”.

” as the chart when the Instrument powers on and the Instrument goes into the initial state with the sound of “du…”.

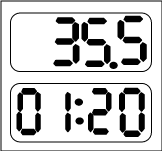

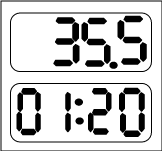

b). About 2s later, the figure 28.5 is the block’s current temperature; 00:35 in the time display is the last set time.

Press

or

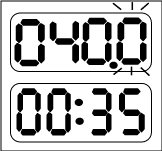

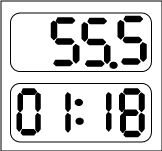

or  of the “Temp” key and keep off at once. Now, the value in the temperature display is the former setting temperature. As shown in the left drawing, the last digital of the setting temperature is flickering. If you want to set the temperature to 55.5°C, do as follows:

of the “Temp” key and keep off at once. Now, the value in the temperature display is the former setting temperature. As shown in the left drawing, the last digital of the setting temperature is flickering. If you want to set the temperature to 55.5°C, do as follows:

Keep pressing

, when it reach 55.5°C, stop Pressing, it will auto save as 55.5°C

, when it reach 55.5°C, stop Pressing, it will auto save as 55.5°CKeep pressing the above keys for 2 seconds. We can modify the value fleetly. It is very convenient.

c). Press

or

or  of the “Time” key and keep off at once, the value in the time display is the former setting time. Shown in the left drawing is 00:35 (35minutes). At same time, the last digital is flickering.

of the “Time” key and keep off at once, the value in the time display is the former setting time. Shown in the left drawing is 00:35 (35minutes). At same time, the last digital is flickering.If you want to change the time to 01:20, do as follows:

Keep pressing

, when it reach 01:20, stop Pressing, it will auto save as 01:20.

, when it reach 01:20, stop Pressing, it will auto save as 01:20.

Notes: If the time setting is 00:00, meaning the time of operation is forever, the Instrument run constantly in setting temperature.

4.2 Operation and stop:

a) After accomplishment of the temperature and time setting, press the button of START/STOP and keep off at once, the Instrument begins operating. The temperature rises with the sound of the “du...”.

Meanwhile, there is current temperature in the temperature display, and the radix point is flickering regularly during the rise process.

When the temperature stops to rise, the flickering also stops. “ : ” in the time display begins flickering, then the counting down starts.

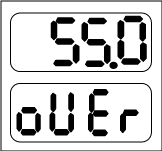

When the timing is stopped, the operation is also stopped. The buzzer alarms. Current temperature in the temperature display and “

” in time display mean “over”, the complishment of the operation.

” in time display mean “over”, the complishment of the operation.b). After accomplishment of the operation, the instrument is in standby mode waiting for new declaration. Then pressing the keys near “Temp” or “Time” can reset the temperature or the time. Pressing START/STOP, it will operate according to last setting.

c). Press START/STOP for 2s during the operation, it will stop running. Press this button again, operation will continue.

4.3 Temperature error adjustment

The temperature of the Instrument has been adjusted before it is sold out. In case there is deviation between the actual temperature and the displayed temperature, you can do as follow for temperature calibration.NOTICE:

1) The instrument has 2 calibration temperature points to ensure the veracity.

It is linearly adjusted on 40°C and 100°C. The temperature accuracy will be within ±0.5°C after temperature calibration.

2) Both the environmental and the block temperature should be lower than 35°C

when calibration.

Adjustment Methods:

a) Power on the instrument, it enters into waiting interface. Make sure the current temperature in display is below 35°C. If the temperature is higher than 35C, please wait until it down below 35C.

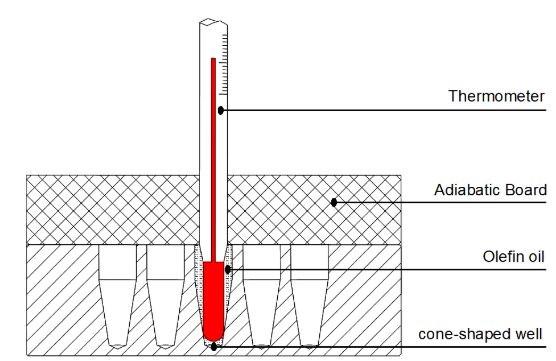

b) Inject olefin oil into one of block well, and then put a thermometer into this well (the precision of the thermometer should be 0.1°C and the temperature ball should be absolutely immerged into the olefin oil in the block well). Adiabatic material is needed on the block to separate it from the circumstance. (refer to below Figure A)

Figure A

NOTICE: To ensure the calibration precision, read the actual temperature value after the temperature reaches calibration points for at least 20 minutes.

c). Press

and

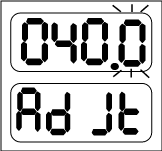

and  simultaneously to enter the temperature calibration interface as the right chart. LED display “

simultaneously to enter the temperature calibration interface as the right chart. LED display “  ” in the time display, the temperature display the current temperature and the program auto control the temperature to 40°C.

” in the time display, the temperature display the current temperature and the program auto control the temperature to 40°C.

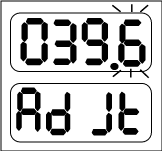

When the temperature reaches 40°C, the decimal digit begins to flicker. Wait for at least 20 minutes, the actual temperature of thermometer is 39.6°C, press

or

or  of temperature to amend the temperature value to 39.6, Press “Start/Stop” to confirm.

of temperature to amend the temperature value to 39.6, Press “Start/Stop” to confirm.

Program saves the value.

Temperature rises to 100(C automatically.

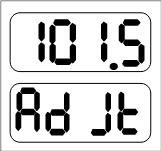

d). When the temperature reaches 100C, the decimal digit begins to flicker. Wait for at least 20 minutes, the actual temperature of thermometer is 101.5C, press

or

or  of temperature to amend the temperature value to 101.5, Press “Start/Stop” to confirm.

of temperature to amend the temperature value to 101.5, Press “Start/Stop” to confirm.

e). After temperature have been adjusted, press

and

and  simultaneously to exit the temperature calibration and return to waiting interface.

simultaneously to exit the temperature calibration and return to waiting interface.

Notice:

After temperature calibration, the temperature display is the same as the practical temperature of block.

Press

and

and  simultaneously during the calibration to exit the adjustment procedure, the calibration is invalid.

simultaneously during the calibration to exit the adjustment procedure, the calibration is invalid.4.4 The exchange of the metal block

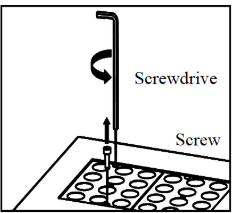

| a) Pull out the two screws which fix the block to the heating board with the screwdriver. |  |

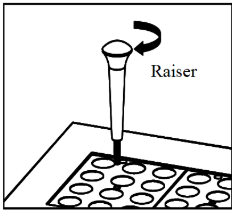

| b) Fix the raiser in the center well of the block. |  |

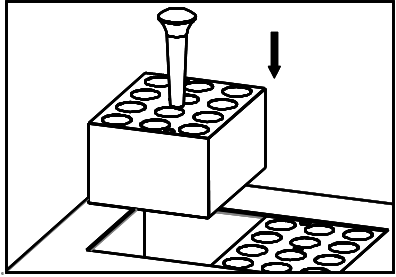

| c) Pull out the raiser with the block. |  |

| |

Notice: It is a little complicated to exchange the block, please be a bit patient.

5. Error Analysis and Recovery Processing

| NO. | Fault phenomenon | Cause analysis | Recovery processing |

| 1 | No signals on the display when the instruction is powered on. | No power | Check the connection of power |

| Broken fuse | Exchange fuse(250V 4A Ф5x20) | ||

| Broken switch | Exchange the switch | ||

| Others | Contact to the seller | ||

| 2 | The actual and displayed temperatures are quite different. | Broken sensor or loose contact of the block | Contact to the seller |

| 3 | “ ERR ” in the display with the alarm of “du...” | Broken sensor or the environmental temperature is below zero. | Contact to the seller |

| 4 | no heating of the block | Broken sensor. | Contact to the seller |

| Solid state relay damage | |||

| Broken heater | |||

| 5 | Key doesn't work | Key broken | Contact to the seller |

Annex 1: Wiring Diagram

(Below diagram is just for reference. It is subject to change without prior notice.)