PCR Cabinet BPCR-104

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

A series of biosafety cabinets to carry out your daily applications safely and effectively. These cabinets provide sturdy and exceptional design along with features like superior protection and unique pattern of airflow. Low noise for user comfort while energy efficiency reduces operational costs.

- UV sterilization system

- Interlock function: UV lamp only can be switched on when the front window is closed, ensuring operator safety

- UV timer (1-99 minutes): When the setting time expires, the UV lamp automatically switches off in preparation for the next experiment

- Standard Accessories: UV lamp, Fluorescent lamp, Base stand, Waterproof socket*2, Shelf with IV bar

Specification

Features

Applications

| Type | PCR Cabinet |

| HEPA Filter Efficiency | 99.999% efficiency at 0.3 µm |

| Air Flow Velocity | 0.3-0.5 m/s, speed adjustable |

| Max opening | 300 mm |

| Pre filter | Polyester fibre, Washable |

| Work Surface height | 750 mm |

| Material | Main body : Cold-rolled steel with anti bacteria powder coating Work Table: 304 stainless steel |

| Front Window | 5 mm toughed glass, anti UV Motorized |

| UV Lamp | 30Wx1 emission of 235.7 nanometers, with UV timer |

| LED Lamp | 12Wx 2 |

| Illumination | ≥350 lux |

| Shelf with IV bar | Stainless steel, 502x150x50 mm |

| Caster | Universal caster with leveling feet |

| Waterproof Socket | Two, total load <500W |

| Standard Accessory | UV lamp, Fluorescent lamp, Base stand, Waerproof Socket x2, Shelf with IV bar |

| Optional Accessory | Electric Height adjustable base stand |

| Noise | ≤65dB |

| Internal Size (WxDxH) | 1200x595x550 mm |

| External Size (WxDxH) | 1300x700x1770 mm |

| Package Size (WxDxH) | 1450x930x 1450 mm |

| Gross Weight | 231 kg |

| Consumption | 600 W |

| Power Supply | AC220V+10% 50/60Hz ; 110V+10%, 60Hz |

- UV sterilization system

- Interlock function: UV lamp only can be switched on when the front window is closed, ensuring operator safety

- UV timer (1-99 minutes): When the setting time expires, the UV lamp automatically switches off in preparation for the next experiment

- Standard Accessories: UV lamp, Fluorescent lamp, Base stand, Waterproof socket*2, Shelf with IV bar

- Optional Accessories: Electric height adjustable base stand

Cell culturing, Genetics, Microbiological, Research, Cell Biology, Molecular Biology, Plant, Laboratory

Operating Manual for BPCR-104

1. Unpacking and Installation

1.1 Unpacking

1.2 Accessories Checking

1.3 Installation Conditions and Operating Environment

1.4 Installation

1.5 Checking after Installation.

2. User Instructions

2.1 Product Concept

2.2 Operating Principle/ Air Cleaning System

2.3 Protected Objects

2.4 Characteristics

2.5 Function and Structure Introduction

2.6 Instructions of Operation

2.7. Daily Maintenance

2.8 Storage

3. Technical Parameters

4. Trouble Shooting and Solution

4.1 Common Failures and Solutions

4.2 Replace the Fuse

4.3 Replace Fluorescent Light

4.4 Replace the UV lamp

5. Label Description

6. Warranty

7. Wiring Diagram

8. Replacement Parts List

1. Unpacking and Installation

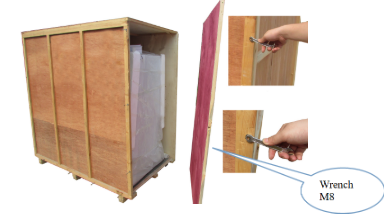

Please firstly check if the packing box is in good condition. If the packing box is damaged, please take photos.1.1 Unpacking

Method1: Unpack with a wrench M8

Figure 1

Method 2: Unpack with an electric drill

Figure 2

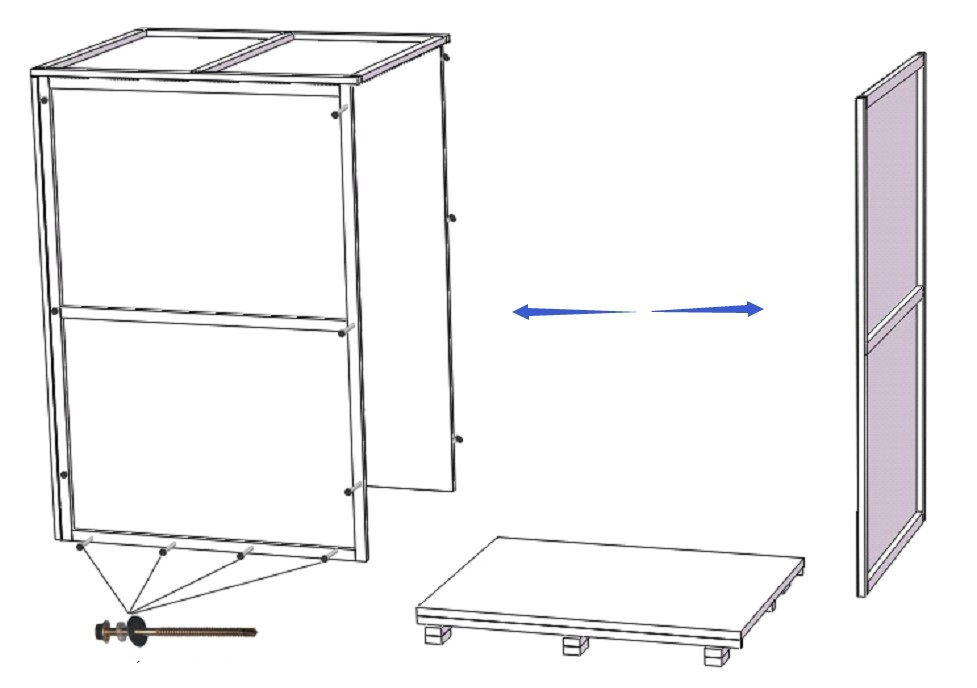

Rapid unpacking diagram ( Disassemble the screws, as are shown in the below figure, then take the wooden box to the left and right.)

BPCR-101 Figure 3

1.2 Accessories Checking

Refer to the packing list and check the accessories.Packing List

| Items | Quantity | Position |

| Main Body | 1unit | Wood packaging |

| Base Stand | 1unit | Paper (Behind the cabinet) |

| Power Cord | 1pc | Bags(Behind the cabinet) |

| Fuse (10A) | 1pc | Bags(Behind the cabinet) |

| UV Lamp(T8 20W) | 1pc | Paper(Behind the cabinet) |

| BPCR-101 User Manual | 1copy | Envelope(Behind the cabinet) |

| Test Report | 1copy | Envelope(Behind the cabinet) |

| Quality Certification Card | 1pc | Envelope(Behind the cabinet) |

| Warranty Card | 1pc | Envelope(Behind the cabinet) |

| Product Acceptance Certificate and Installation Report | 1copy | Envelope(Behind the cabinet) |

| Training Certificate | 1 copy | Envelope(Behind the cabinet) |

| Hexagon Cylinder Head Bolt M10*20 | 4 sets | Bags(Behind the cabinet) |

| Flat Washer 10+ Spring Washer 10 | 4 sets | Bags(Behind the cabinet) |

| Allen Wrench | 1pc | Bags(Behind the cabinet) |

BPCR-103 Packing List

| Items | Quantity | Position |

| Main Body | 1unit | Wood packaging |

| Base Stand | 1unit | Paper (Behind the cabinet) |

| Power Cord | 1pc | Bags(Behind the cabinet) |

| Fuse (10A) | 1pc | Bags(Behind the cabinet) |

| UV Lamp(T8 30W) | 1pc | Paper(Behind the cabinet) |

| BPCR-103 User Manual | 1copy | Envelope(Behind the cabinet) |

| Test Report | 1copy | Envelope(Behind the cabinet) |

| Quality Certification Card | 1pc | Envelope(Behind the cabinet) |

| Warranty Card | 1pc | Envelope(Behind the cabinet) |

| Product Acceptance Certificate and Installation Report | 1 copy | Envelope(Behind the cabinet) |

| Training Certificate | 1 copy | Envelope(Behind the cabinet) |

| Hexagon Cylinder Head Bolt M10*20 | 4 sets | Bags(Behind the cabinet) |

| Flat Washer 10+ Spring Washer 10 | 4 sets | Bags(Behind the cabinet) |

| Allen Wrench | 1pc | Bags(Behind the cabinet) |

BPCR-104 Packing List

| Items | Quantity | Position |

| Main Body | 1unit | Wood packaging |

| Base Stand | 1unit | Paper (Behind the cabinet) |

| Power Cord | 1pc | Bags(Behind the cabinet) |

| Fuse (10A) | 1pc | Bags(Behind the cabinet) |

| UV Lamp(T8 30W) | 1pc | Paper(Behind the cabinet) |

| BPCR-104 User Manual | 1copy | Envelope(Behind the cabinet) |

| Test Report | 1copy | Envelope(Behind the cabinet) |

| Quality Certification Card | 1pc | Envelope(Behind the cabinet) |

| Warranty Card | 1pc | Envelope(Behind the cabinet) |

| Product Acceptance Certificate and Installation Report | 1copy | Envelope(Behind the cabinet) |

| Training Certificate | 1 copy | Envelope(Behind the cabinet) |

| Hexagon Cylinder Head Bolt M10*20 | 4 sets | Bags(Behind the cabinet) |

| Flat Washer 10+ Spring Washer 10 | 4 sets | Bags(Behind the cabinet) |

| Allen Wrench | 1pc | Bags(Behind the cabinet) |

BPCR-105 Packing List

| Items | Quantity | Position |

| Main Body | 1unit | Wood packaging |

| Base Stand | 1unit | Paper (Behind the cabinet) |

| Power Cord | 1pc | Bags(Behind the cabinet) |

| Fuse (10A) | 1pc | Bags(Behind the cabinet) |

| UV Lamp(T8 40W) | 1pc | Paper(Behind the cabinet) |

| BPCR-105 User Manual | 1copy | Envelope(Behind the cabinet) |

| Test Report | 1copy | Envelope(Behind the cabinet) |

| Quality Certification Card | 1pc | Envelope(Behind the cabinet) |

| Warranty Card | 1pc | Envelope(Behind the cabinet) |

| Product Acceptance Certificate and Installation Report | 1 copy | Envelope(Behind the cabinet) |

| Training Certificate | 1 copy | Envelope(Behind the cabinet) |

| Hexagon Cylinder Head Bolt M10*20 | 4 sets | Bags(Behind the cabinet) |

| Flat Washer 10+ Spring Washer 10 | 4 sets | Bags(Behind the cabinet) |

| Allen Wrench | 1pc | Bags(Behind the cabinet) |

1.3 Installation Conditions and Operating Environment

PCR Operating Cabinet shall be placed in the protective area of an air stream, and the working area of the PCR Operating Cabinet can not be near to the door or window, and should be away from the air outlet to prevent the air flow from the ventilation system, air conditioning, door, window and personnel.At least 300mm gap must be kept in the side and back side of the PCR Operating Cabinet for inspection.

Working environment:

Only applicable for indoor operation;

Ambient temperature: 15° C ~35° C

Relative Humidity: ≤75%;

Atmospheric pressure range: 70KPa~106KPa;

Electrical parameters: Adequate power supply to the laminar flow cabinet(See 2.1.4 Technical Parameters);

Power supply need to be grounded; (Judging method: test the live wire and the neutral wire of the socket with multimeter. The voltage between live and ground should equal to the voltage of local electrical grid, and the voltage between neutral and ground should equal to 0. Otherwise the power supply is not grounded correctly);

1.4 Installation

Remove all the packing materials;Check the surface of main body to make sure there is no scratch, deformation or foreign bodies;

Confirm the complement of accessories according to the list.

Before removing the packing material, move the entire equipment to the place where it is going to be installed.

The base stand will be packed at back of main body, please take it out before installation. DO NOT INVERT, DISASSEMBLE OR TILT THE CABINET during transportation.

The base stand will be packed at back of main body, please take it out before installation. DO NOT INVERT, DISASSEMBLE OR TILT THE CABINET during transportation.1.4.1 Assemble of Base

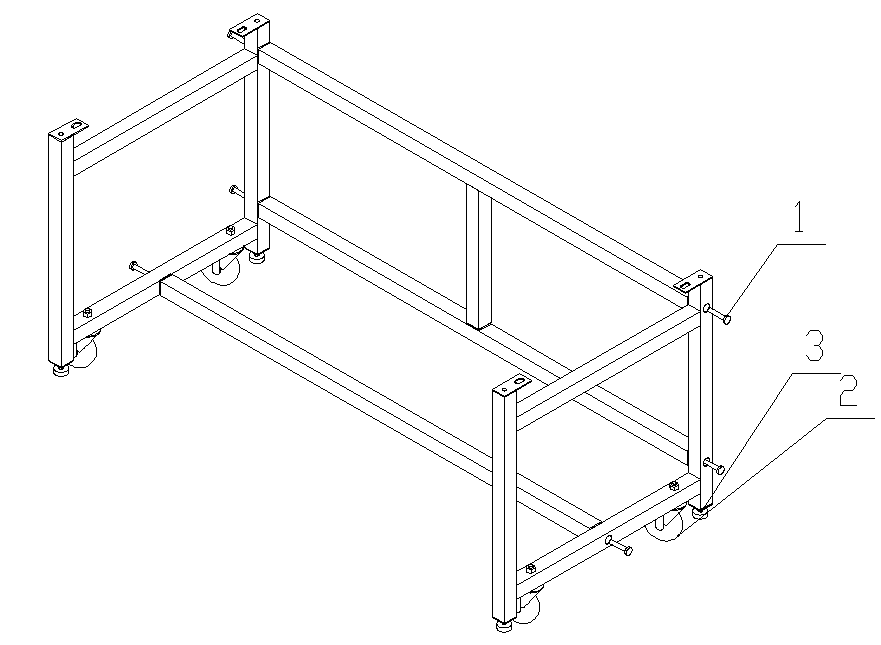

Refer to Picture 4 to assemble the base.

Figure 4

1.M10x55 Hexagon socket head cap bolts、2.caster、3.support

Unscrew the M10 × 55 hexagon socket head cap screws on the transverse bracing, both sides and the bottom of the T-shaped frame and install them as are shown in the picture, then fasten the screws. Fasten the nuts M10 on the both sides frames of the base, then assemble the base by referring to Picture 4.

As is shown in the picture, the height of the foot can be adjusted. Counterclockwise rotate the feet, when the feet height is less than the height of the casters, you can move the cabinet (or base); Clockwise rotate the feet, when the feet height is greater than the height of the casters, then the base is fixed.

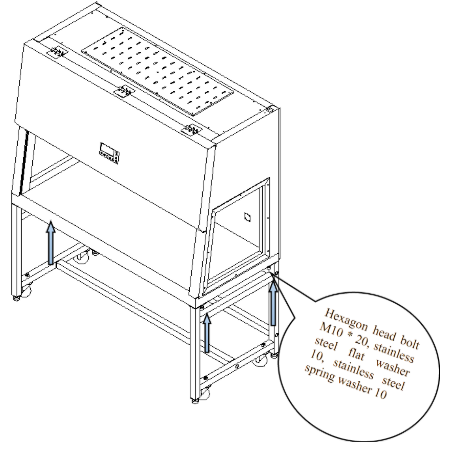

1.4.2 Connect the Main Body and the Base

Refer to Picture 5 to connect the main body and the base

Figure 4

Firstly, put the upper cabinet on the base (as is shown in Picture 5), and then align the positioning bolt for cabinet connection in the base with the mounting holes at the bottom of the left and right panels, then let the hexagon head bolt M10 * 20, stainless steel flat washer 10, stainless steel spring washer 10 pass through the base and side panels from bottom to top, and make them be secured.

After the above steps are completed, move the cabinet slightly to the proper position, remove the power cord and check whether the power cord is intact.

1.5 Checking after Installation.

First, make sure the voltage and frequency to be same as nameplate showing, and then check the follows items with power on:| Front Window | Press the up and down buttons, the window runs normally |

| Checking Items | Normal working status |

| Fan motor | Running normally |

| Fluorescent lamp | Lamp lights up after pressing button |

| UV Lamp | Lamp lights up after pressing button |

| Display screen buttons | All buttons can be used |

| Socket | Use multimeter to test voltage output after pressing the socket button |

If you have any questions please contact engineers to commissioning, debugging methods in the service manual.

If you have any questions please contact engineers to commissioning, debugging methods in the service manual.2. User Instructions

2.1 Product Concept

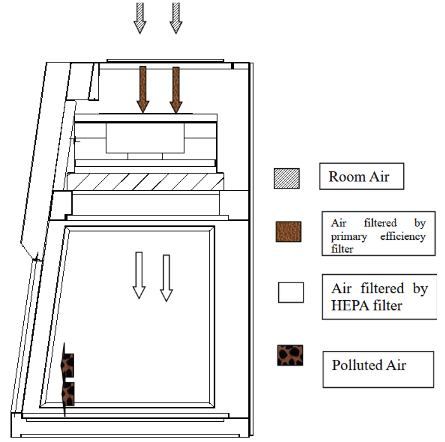

PCR operating cabinet is a kind of vertical airflow type equipment which can make the local environment with high cleanliness.2.2 Operating Principle/ Air Cleaning System

Figure 6

2.3 Protected Objects

PCR operating cabinet is to protect the experimental material, to create a local high cleanliness air environment, the main role is to ensure the accuracy of the operating area of the experiment, but for the environment and operators can’t afford protection.2.4 Characteristics

1) Cabinet body is built up of 1.2mm cold-rolled steel with anti-powder coating. Strong and steady;2) Work table is fully made up of 304 stainless steel which looks beautiful and with corrosion resistance performance;

3) Base stand is made up of cold-rolled steel with anti-powder coating;

4) Soft touch type control panel, easy to handle and beautiful appearance.

2.5 Function and Structure Introduction

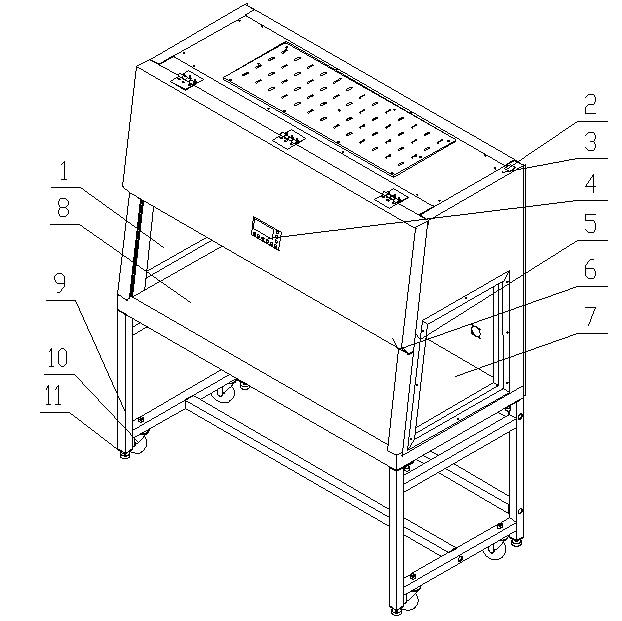

2.5.1 Structural Composition of PCR operating cabinet

Figure 7

1. Glass door

2. Power socket

3. Ground terminal

4. Control panel

5. UV lamp

6. LED light

7. Side window

8. Work table

9.Base

10. Caster

11.Support foot

Driving system of front window

Driving system consists of tubular motor, front window, hauling mechanism and limit switch.

Air filtration system

Air Filtration System is the most important system. It consists of blower and HEPA filter. The function of Air Filtration System is transferring filtered air to work area, ensure air flow velocity, and keep Class 100 cleanness of work area.

UV lamp

The entire work zone could be sterilized effectively by the UV lamp in the work zone. Emission of 253.7 nanometers could ensure the most efficient decontamination.

LED light

The PCR operating cabinet is equipped with LED light, which ensures the standard requirement of average illumination is met.

Water proof Socket

Waterproof socket is arranged in the operating area, to within the operating area of the power supply equipment and in the lighting lamp installing the front side plate (Picture 9) and need to use a socket, open the power supply equipment, press the display of the socket button (Picture 8), the waterproof socket open cover, access to electricity source plug.

Figure 8

(1) Please make sure the total load of sockets should be ≤ 500W;

(1) Please make sure the total load of sockets should be ≤ 500W;(2) Waterproof socket only when the front cover down to the waterproof, the front cover is opened, the socket can not be considered waterproof socket.

Fuse

The equipment is equipped with main power fuse, They are located near the power cord’s outlet. Fuse label is corresponding to the relevant specifications.

• Control of Front Window

Front window is motorized

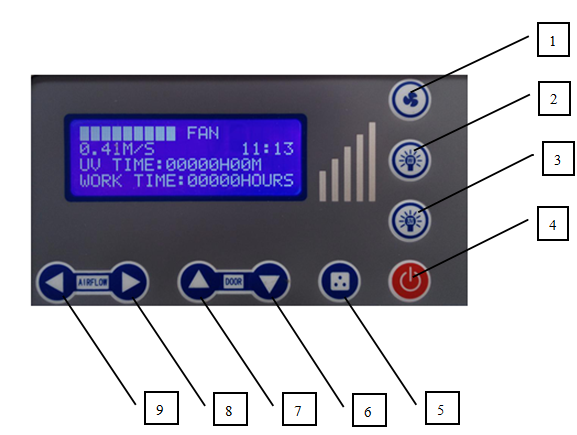

2.5.2 Introduction of Control Panel

Figure 9

1. Blower、2. Fluorescent Lamp、3. UV lamp、4. Power、5. Socket、6. Front window Down Status、7. Front window Up Status、8. Air volume decreases、9. Air volume increases

(1)

: The power button

: The power button(2)

: To control blower working status. Blower has memory function, next boot blower gear shows the last shut down, to avoid each boot need to adjust the fan, (It will not work when front window is fully closed.)

: To control blower working status. Blower has memory function, next boot blower gear shows the last shut down, to avoid each boot need to adjust the fan, (It will not work when front window is fully closed.)(3)

:To control fluorescent lamp

:To control fluorescent lamp(4)

:To control UV lamp(UV lamp, blower, fluorescent lamp and front window interlock, it won’t work when fluorescent lamp, blower, front window open )(5)

:To control UV lamp(UV lamp, blower, fluorescent lamp and front window interlock, it won’t work when fluorescent lamp, blower, front window open )(5)  : To control socket power status.

: To control socket power status.(6)

: Press Down button, front window will fall down. Each time you press, the buzzer will sound once; hold this key, the front window will continue to decline; release the button, the front window will stop declining.

: Press Down button, front window will fall down. Each time you press, the buzzer will sound once; hold this key, the front window will continue to decline; release the button, the front window will stop declining.(7)

: Press UP button, front window will raise. Each time you press, the buzzer will sound once; hold this key, the front window will continue to rise; release the button, the front window will stop rising.

: Press UP button, front window will raise. Each time you press, the buzzer will sound once; hold this key, the front window will continue to rise; release the button, the front window will stop rising.(8)

:To control blower speed down. When blower is working, if ▊number is More than 1, Each time you press, wind speed can down a gear, and the buzzer rings once.

:To control blower speed down. When blower is working, if ▊number is More than 1, Each time you press, wind speed can down a gear, and the buzzer rings once.(9)

:To control blower speed increase. When blower is working, if ▊number is less than 9, Each time you press, wind speed can increase a gear, and the buzzer rings once.

:To control blower speed increase. When blower is working, if ▊number is less than 9, Each time you press, wind speed can increase a gear, and the buzzer rings once.(10) LCD display: When powered on, from top to bottom is ▊▊▊▊▊▊▊▊▊FAN, It indicates the strength of blower wind speed, Shown below is the current state of the Winds; The right of the display is time; UV TIME, UV lamp working time; WORK TIME: HEPA filter working time.

(11) Under standby status, press the fluorescent lamp button and then press and hold the power button for 5 seconds. The clock could be adjusted after a buzz alarm. Press UP and DOWN to adjust the number and press mute button to switch from minute to hour. After setting the time correctly, press fluorescent lamp button and then press and hold the power button for 5 seconds. A buzz alarm indicates that the time has been saved).

(12) UV lamp timing: Under the standby state, decrease the front window to a minimum, press the "UV lamp control button

", turn on the UV lamp. After the UV lamp is turned on, the display shows the UV lamp timing duration under the current state, by adjusting the "fan speed

", turn on the UV lamp. After the UV lamp is turned on, the display shows the UV lamp timing duration under the current state, by adjusting the "fan speeddecrease button"

, you can decrease the timing time for 1 minute in turn, by adjusting the "fan speed increase button

, you can decrease the timing time for 1 minute in turn, by adjusting the "fan speed increase button  ", you can increase the timing time for 1 minute in turn, according to the time required to set well the time (UV lamp time duration range is 0-90M, the factory set it to be 90M).

", you can increase the timing time for 1 minute in turn, according to the time required to set well the time (UV lamp time duration range is 0-90M, the factory set it to be 90M).2.6 Instructions of Operation

2.6.1 Precautions before Operation(1) Make sure input voltage is correct and stable. The rated load of main power socket should be higher than cabinet consumption. Plug must be well grounded.

(2) Moving principles of different samples inside cabinet: When two or more samples need to be moved, be sure that low-polluting samples move to high-polluting samples. Movement of items should also follow the principles moving slowly and stably.

(3) The weight of items placed in the cabinet should not be more than 23Kg/25×25cm2;

(4) Avoid vibration: avoid using vibration equipment (eg centrifuges, vortex oscillator, etc.) inside the cabinet. Vibration would cause lower cleanliness of operating area and affect operator protection.

(5) No flame: No flame is allowed inside the cabinet. Using of fire will lead to airflow disorder, and filter damage. If sterilization is required during the experiment, infrared sterilizer is highly recommended.

(6) HEPA filter life: With the usage time increasing, dust and bacteria accumulate inside HEPA filter. Filter Resistance is getting bigger, when it reaches the maximum point, the speed requirements can’t be met. Then need contact BIOBASE service department to get a new one. The used filter should be processed as medical waste.

(7) The steel plate is under fan, which is sealed strictly in the factory. The operator is not allowed to remove or loose screws of those parts. If necessary, please contact service personal.

(8) The maximum storage period is one year. If the period is more than one year, performance test should be done

Serious declaration: BIOBASE will take no responsibility for risks caused by improper operation and man-made damages!

Serious declaration: BIOBASE will take no responsibility for risks caused by improper operation and man-made damages!2.6.2 Operation Process

• Connect to a suitable power supply

• Press the relevant key functions (related keys, function and operation of the 2.2.2 in the description); check the function keys and the operation results are consistent, and according to the above clean table technical parameters of the test whether the normal start and wind speed is up to the standard requirements, lighting and ultraviolet lamp is normal work.

• The cabinet should be sterilized by UV lamp for at least 30 minutes with the window fully closed before any experiment.

(1) For safety of eyes and skin, people should leave the room during the UV sterilization.

(1) For safety of eyes and skin, people should leave the room during the UV sterilization.(2) UV lamp should be checked regularly. It should be replaced when either the total working time reaches 600 hours or the intensity is lower than the requirement.

• Please move up the front window at the suitable height above the work table and turn on the fan. Make sure the experiment should be started after fan working for at least 30 minutes.

• For operating safety, please place the experiment materials inside the cabinet before experiment start.

• For operating safety, please place the experiment materials inside the cabinet before experiment start.• After finishing the experiment, please fully close the front window and make sure to sterilize the cabinet by UV lamp for 30 minutes before turning off the cabinet.

2.7. Daily Maintenance

Preparations before maintenance: removal of items in the equipmentPreparation of goods: cotton or towel, concentrated soap, hot water, water, medical alcohol or other disinfectants, etc.

2.7.1 Clean the Cabinet Surface

Clean the surface of working zone

Wipe the entire surface with a soft cotton cloth which has been soaked with concentrated liquid soap. Afterwards, wipe off the foam with another cotton cloth or towel which has been soaked with clean hot/warm water. At the end, wipe the entire surface with a dry cotton cloth or towel rapidly.

For the contaminated or dirty work surface and sump, use 70% rubbing alcohol or other disinfectant to wipe.

Disinfectants used for wiping should not damage the 304 stainless steel.

Disinfectants used for wiping should not damage the 304 stainless steel.2.7.2 Clean the External Surface and Front Window.

Use a piece of soft cotton cloth or towel to wipe the surface with non-abrasive household cleanser.

2.7.3 Overall Maintenance Period

The recommended interval period for comprehensive maintenance is either one year or 1000 working hours.

2.7.4 Maintenance Methods

1) Weekly or daily maintenance

Disinfect and clean the operating area;

Clean the external surface and front window around the operating area (Reference 2.4.1 instruction);

Check the various functions of the cabinet (Reference 2.4.2 instruction);

Record down the maintenance result

2) Monthly maintenance

• Clean the external surface and front window (Reference 2.4.2 instruction).

• Use towel with 70% rubbing alcohol or 1:100 dilution of household bleach to wipe the working table, the inner face of front window and the inner wall surface of the working area(exclude the top wind grid). Use another towel with sterile water to wipe those area to erase the remain of chlorine.

• Check the various functions of the cabinet;

• Record down the maintenance result;

3) Annual maintenance

Check the two lifting belt of the front window tubular motor, make sure both of them are well connected to the motor with same tightness.

Check the UV lamp and LED light.

Apply for overall performance test of the cabinet annually to ensure that the safety meets requirements. User is responsible for testing costs.

Record down the maintenance result.

When doing maintenance, please pay attention to cut off the power, so as to avoid electric shock!

When doing maintenance, please pay attention to cut off the power, so as to avoid electric shock!2.8 Storage

PCR operating cabinet should be stored in a warehouse with relative humidity not more than 75% and temperature lower than 40°C. The warehouse should have good ventilation performance without acid, alkali or other corrosive gases. Storage period shall not exceed one year. PCR operating cabinet stored for more than one year needs to be unpacked and checked before selling and using. Only the tested and qualified PCR operating cabinet could be sold3. Technical Parameters

| Model Parameters | BPCR-101 | BPCR-103 | BPCR-104 | BPCR-105 |

| External Size (W*D*H) | 800×700×1770mm | 1200×700×1770mm | 1300×700×1770mm | 1500×700×1770mm |

| Internal Size(W*D*H) | 700×600×550 mm | 1100×600×550 mm | 1200×600×550 mm | 1400×600×550 mm |

| Power Supply | 220V±10% | 220V±10% | 220V±10% | 220V±10% |

| Rated Frequency | 50Hz | 50Hz | 50Hz | 50Hz |

| Rated Power | 400W | 400W | 400W | 400W |

| Airflow velocity | 0.3~0.5m/s | 0.3~0.5m/s | 0.3~0.5m/s | 0.3~0.5m/s |

| UV Lamp Consumption | 20W | 30W | 30W | 40W |

| Fluorescent lamp Consumption | 8W(LED) | 12W(LED) | 12W(LED) | 12W(LED) |

| HEPA Filter | 99.999%(at 0.3μm) | 99.999%(at 0.3μm) | 99.999%(at 0.3μm) | 99.999%(at 0.3μm) |

| Noise | ≤65dB(A) | ≤65dB(A) | ≤65dB(A) | ≤65dB(A) |

Notes: Biobase reserves the rights to make changes in future product design, without reservation and without notification to its users.

1) Vibration amplitude

The net vibration amplitude, at a range of frequency from 10Hz to 10KHz, would not exceed 5 μm .

2) Illumination

The average illumination is more than 350 lux

3) Electrical properties

The cabinet would not breakdown in 5s when the voltage increases by 1390V (AC) within 5s. Grounding resistance ≤0.1.

4. Trouble Shooting and Solution

4.1 Common Failures and Solutions

Please confirm that the power is well connected, the cord is in good condition(without any damage) and the power lock is unlocked before trouble shooting the following problems.| Failure | Checking Part | Suggestion |

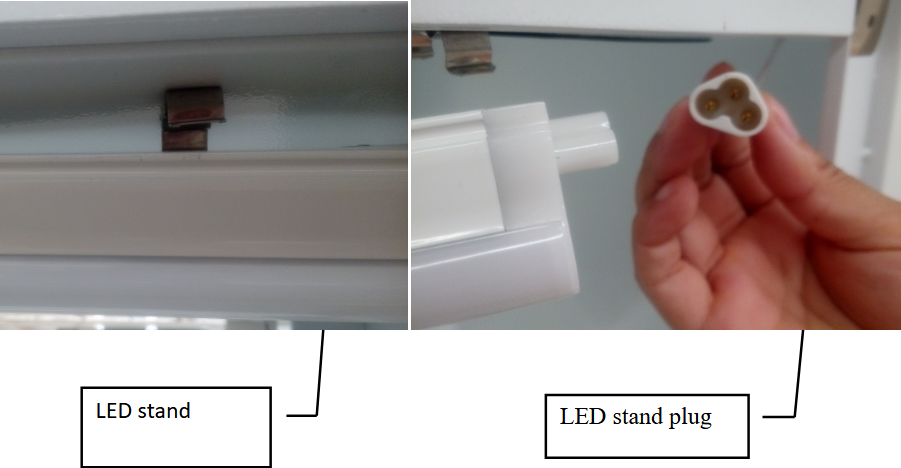

| Fluorescent lamp fails to work | Circuit | Check the circuit |

| LED stand plug | Connect the plug and stand tightly | |

| LED stand | Replace stand | |

| Control panel | Replace the control panel | |

| UV lamp fails to work | Interlock | Make sure the front window is fully closed; the fluorescent lamp and the blower are not in work. |

| Lamp holder | Connect the tube and lamp holder tightly | |

| Circuit | Check the circuit | |

| Ballast | Replace the UV lamp tube | |

| UV lamp | Check if the micro switch is broken | |

| Micro Switch | Replace the control panel | |

| Control panel | Connect the tube and lamp holder tightly | |

| Button fails to work | Control panel | Make sure the power is well connected and the fuse is in good condition |

| Check if the button is broken | ||

| Make sure the connecting wire is well connected | ||

| Replace the control panel | ||

| Blower fails to work | Micro switch | Check if the micro switch is broken |

| Blower | Replace the blower if it is defective | |

| Circuit | Check the circuit | |

| Control panel | Replace the control panel | |

| No electricity in equipment | Power supply | Check whether the power supply is well connected |

| Power wire | Check whether power cord is in good condition | |

| Fuse | Check whether the fuse is damaged | |

| Power key | Check whether the power key is locked or damaged | |

| Control panel | Replace the control panel | |

| Potential transformer | Check whether the transformer works normally | |

| Display fails to work | Connection winding displacement | Connection winding displacement |

| Display screen | Check whether the screen is in good condition | |

| Control panel | Replace the control panel |

NOTE: The above trouble shooting methods should be done by qualified electricians under safe conditions(cut off power supply). Other components should not be removed. Risk caused by failing to follow those instructions would be responsible by user.

• Please contact Biobase technical department or agent if a failure could not be traced or solved. Do NOT repair the equipment without a qualified electrician.

• The trouble shooting and repair of this equipment only could be undertaken by trained and recognized technicians;

• Please contact Biobase technical department or agent to order required component or part. The model number and the serial number of the PCR operating cabinet you purchased need to be indicated.

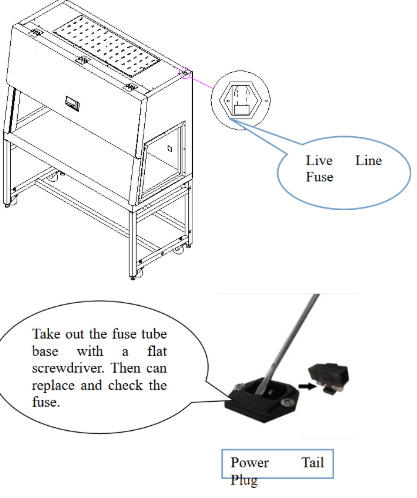

4.2 Replace the Fuse

When the fuse on the socket is being replaced, a flat-blade screwdriver should be used to lift and replace the fuse holder and then press it back.

Figure 10

4.3 Replace Fluorescent Light

When the fluorescent light needs to be changed, turn off the power. Then remove the LED stand, unplug the right side, After replacing a new LED stand, inserted into the inclined slot.

Figure 11

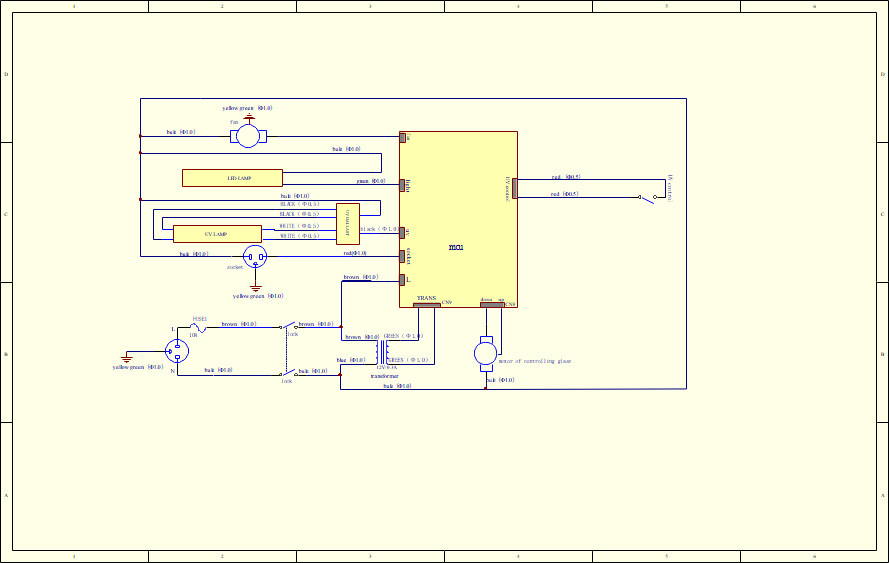

4.4 Replace the UV lamp

UV lamp lifespan supplied on the product is for the cumulative working hours of 600 hours, in order to achieve good disinfection effect, we recommended you to regularly test the intensity of UV light, you can use the UV intensity test card to confirm whether it is necessary to replace the UV lamp. When the UV disinfection lamp is being replaced, turn off the power supply, unscrew the UV lamp, remove the lamp from the lamp holder and replace a new UV disinfection lamp. Method is shown in the following picture:

Figure 12

NOTE: After changing the UV lamp, the UV lamp working time should be reset: you need to press the UV button continuously for about 5 seconds in standby state to clear the working time of the UV lamp and re-count the working time of the new UV lamp

5. Label Description

1) Fuse label(Picture 14)

Figure 13

Note: 10A power fuse label

2) Ground label (Picture 15)

Figure 14

6. Warranty

Warranty is 12 months from EX-factory date (excluding UV lamp, fluorescent lamp).Biobase would not be liable for any repair of damage caused by improper operation.

If the warranty has been expired, Biobase would still responsible for repair with relative charges.

Life time of PCR operating cabinet is 8 years from production date on the label.

Biobase would provide equipment drawings and necessary technical data for maintenance companies or personnel trained by Biobase engineers.

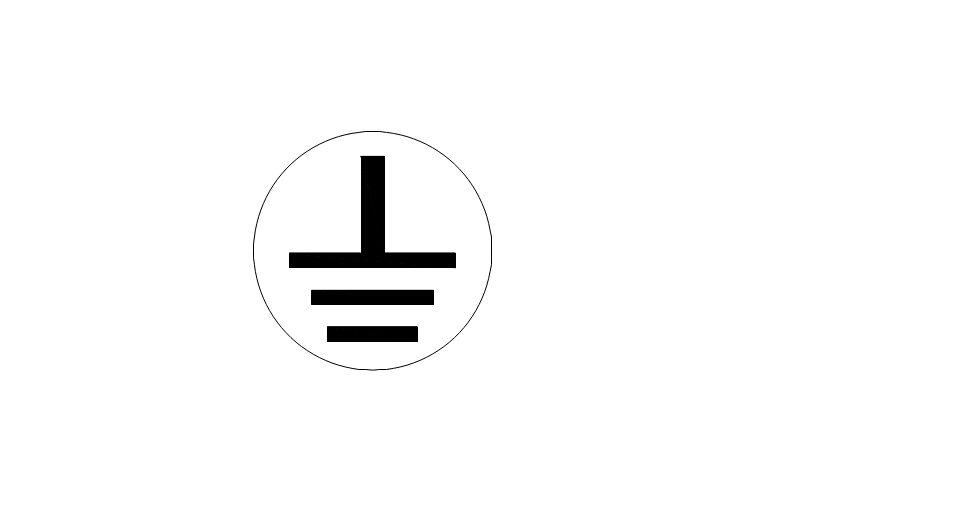

7. Wiring Diagram

Figure 15

8. Replacement Parts List

BPCR-101 Replacement Parts List| No. | Name | Specification |

| 08-01 | Fuse | 10A |

| 08-02 | Lamp holder T8 | LG13-01A |

| 08-03 | UV Lamp | T8 20W |

| 08-04 | LED T5 stand | T5 8W |

| 08-05 | UV lamp ballast | 1*TL8-20W |

| 08-06 | HEPA filter | 700*450*50 |

| 08-07 | Fan | SC225-225A1-AGT-13 |

| 08-08 | Control panel | LCD Control panel |

| 08-09 | Front window | 718*600*5 |

| 08-10 | Left Side window | (423.1-495.7)*517*5 |

| 08-11 | Right Side window | (423.1-495.7)*517*5 |

| 08-12 | Tubular motor | TMN45-10/17 |

BPCR-103 Replacement Parts List

| No. | Name | Specification |

| 12-01 | Fuse | 10A |

| 12-02 | Lamp holder T8 | LG13-01A |

| 12-03 | UV Lamp | T8 30W |

| 12-04 | LED T5 stand | T5 12W |

| 12-05 | UV lamp ballast | 1*TL8-30W |

| 12-06 | HEPA filter | 1100*450*50 |

| 12-07 | Fan | SC225-225A1-AGT-13 |

| 12-08 | Control panel | LCD Control panel |

| 12-09 | Front window | 1118*600*5 |

| 12-10 | Left Side window | (423.1-495.7)*517*5 |

| 12-11 | Right Side window | (423.1-495.7)*517*5 |

| 12-12 | Tubular motor | TMN45-10/17 |

BPCR-104 Replacement Parts List

| No. | Name | Specification |

| 13-01 | Fuse | 10A |

| 13-02 | Lamp holder T8 | LG13-01A |

| 13-03 | UV Lamp | T8 30W |

| 13-04 | LED T5 stand | T5 12W |

| 13-05 | UV lamp ballast | 1*TL8-30W |

| 13-06 | HEPA filter | 1100*450*50 |

| 13-07 | Fan | SC225-225A1-AGT-13 |

| 13-08 | Control panel | LCD Control panel |

| 13-09 | Front window | 1118*600*5 |

| 13-10 | Left Side window | (423.1-495.7)*517*5 |

| 13-11 | Right Side window | (423.1-495.7)*517*5 |

| 13-12 | Tubular motor | TMN45-10/17 |

BPCR-105 Replacement Parts List

| No. | Name | Specification |

| 15-01 | Fuse | 10A |

| 15-02 | Lamp holder T8 | LG13-01A |

| 15-03 | UV Lamp | T8 40W |

| 15-04 | LED T5 stand | T5 12W |

| 15-05 | UV lamp ballast | 1*TL8-40W |

| 15-06 | HEPA filter | 1400*450*50 |

| 15-07 | Fan | SC225-225A1-AGT-13 |

| 15-08 | Control panel | LCD Control panel |

| 15-09 | Front window | 1418*600*5 |

| 15-10 | Left Side window | (423.1-495.7)*517*5 |

| 15-11 | Right Side window | (423.1-495.7)*517*5 |

| 15-12 | Tubular motor | TMN45-10/17 |