Orbital Shaker BSOR-101

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Our product is an accurately designed, microprocessor controlled with double Decker platform to save your valuable lab space. Three eccentric shaft balancing drive ensures shaking with uniform speed. Speed adjustment settings permit both gentle and vigorous shaking. Varieties of platforms are available for different glassware and vessels.

- Microprocessor PID controller, with timing function, resume operation

- automatically if power off unexpectedly,.

- DC Brushless motor, wide speed control with long using life, maintenance free.

- Speed controller ensures smooth start /stop which can prevent the liquid spill to damage the equipment.

Specification

Features

Applications

| Speed Range | 40~300 rpm |

| Maximum Configuration | 250x48 pcs or 500 mlx30 pcs or 1000 mlx20 pcs or 2000 ml x 12 pcs or 5000 ml x 5 pcs (every desk) |

| Shaking Speed Accuracy | ±1 rpm |

| Timing Range | 0~99:59H |

| Motion | Orbital |

| Amplitude | 35 mm |

| Operation | Continuous/Timed |

| Tray | 1 Layer |

| Platform Dimension | 800x600 mm |

| Overall Dimension | 895x740x460mm |

| Display | LCD |

| Power | 250 W |

| Power Supply | AC220V±10% 50Hz±2% |

- Microprocessor PID controller, with timing function, resume operation

- automatically if power off unexpectedly,.

- DC Brushless motor, wide speed control with long using life, maintenance free.

- Speed controller ensures smooth start /stop which can prevent the liquid spill to damage the equipment.

- LCD display for time and speed

- Stainless-steel plate, easy clean and assemble.

- Overspeed alarm

- Wide range of clamps for using with a variety of vessels

- Optional programmable controller.

Stability, Dissolution Studies, Liquid Extractions, Protein Precipitation, Small Peptide Synthesis, Dilutions

Operating Manual for BSOR-101

1. Instruction for Safety

1.1 Danger !

1.2 Warning!

1.3 Caution!

2. Product introduction

3. Product us

4. LCD controller operation method

4. Alarm function

5. Product maintenance and attention points

6. Appendix

6.1 Technical indicators

6.2 Troubleshooting

Packing list

1. Instruction for Safety

1.1 Danger !

The improper use of this unit may cause property damage and / or personal injury.1. This product must be earthed reliably and kept far away from electromagnetic interference source (Zero line or neutral line should never be used as earth wire).

2. Please ensure the voltage and frequency of the power supply is compatible with the incubator power requirements prior to use.

3. The product should be connected to a separate power outlet and both the plug and outlet are earthed properly.

4. It is not allowed to pull off or insert the power plug wantonly without turning off the power switch while the product is in operation.

5. It is not permissible to lengthen or shorten the power line at random.

6. No repairs may be done without permission and the equipment must be maintained by an electrician entrusted by our company.

1.2 Warning!

Caution (It may cause serious loss in property or injuries and deaths)1. Operation shall be done only after the directions for use are read and understood fully.

2. 304 stainless steel is not acid resistant, please pay attention to anti-corrosion measures.

3. The power line should never be drawn directly when pulling off the plug.

4. In one of the following cases, the power plug must be pulled off:

- Replacement of fuse.

- Under inspection and repair when the product fails.

- Suspension from use for a long time.

- In movement.

5. The product is placed on a hard and firm work surface (ground). It must be adjusted to the horizontal level of the cabinet with 4 adjustable feet and the height of the casters from the ground is not less than 5mm! And check that it is stable, to avoid shifting of the oscillating box due to long-time work and falling from the bench, to cause serious loss in product or property injury and deaths.

1.3 Caution!

Otherwise its service life may be affected, resulting in its inability to work regularly.1. Some space shall be left around the product.

2. The product must be put into use under given working conditions.

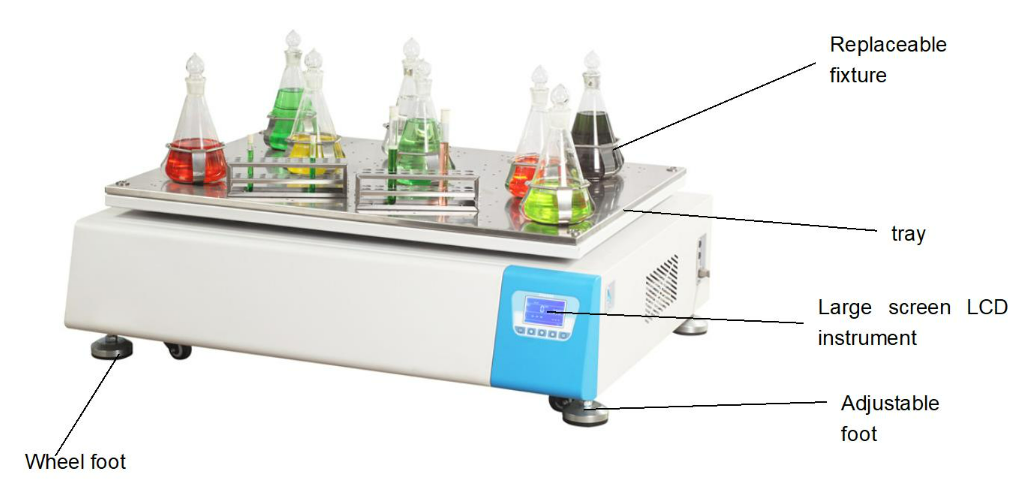

2. Product introduction

1. Front View (take BSOR-107/108 as an example)

Shaker (single layer)

3. Product us

1. Preparation before use1.1 Ambient temperature: 15 ° C ~ 35 ° C, relative humidity is not more than 85%;

1.2 Power supply: (220 ± 22) V (50 ± 1) Hz;

1.3 Atmospheric pressure: (86 ~ 106) KPa;

1.4 The altitude is not higher than 2000 meters;

1.5 There is no strong vibration source and strong electromagnetic field around it;

1.6 There should be no serious dust and no corrosive gas in the room;

1.7 Place it on a stable, sturdy surface that is not exposed to direct sunlight. Install the four supporting feet that come with the unit on the base of the product and check that it is stable.

1.8 There should be a space gap of not less than 50cm around the product (front, back, left, right, top).

2. Main features

2.1 Three-dimensional eccentric drive mechanism, smooth and stable operation, durable and reliable.

2.2 Intelligent sound and light alarm environment scanning micro-processing controller, tilting humanized pattern operation interface control panel, large-screen backlit LCD screen, more good visual effects.

2.3 With the operating parameter memory saving function, it can avoid cumbersome operations.

2.4 Operation parameter encryption lock to avoid human error.

2.5 High-precision frequency control system with frequency accuracy of ±1 rpm. The liquid crystal display shows the set frequency and actual frequency.

2.6 The movement is made of high quality cast iron and NSK imported bearings to make the machine more durable

2.7 AC induction long life motor, wide speed regulation, constant torque, constant speed, no carbon brush, maintenance free.

2.8 Unique motor overheating, temperature out of control automatic power off protection device.

2.9 With timing function, the training time is set between 1 minute and 500 hours, and the LCD displays the time and remaining time. At that time, the instrument will automatically stop and sound and light alarm.

2.10 Electrostatic spray box, stainless steel electric polishing spring, flask clamp.

2.11 The whole machine is silently designed.

4. LCD controller operation method

1. Controller panel diagram

1.1 Indicator description

1)TIME:Time display window; TIME shows the running time when the controller is running;

2)REV:Display measurement speed;

3)SET:Display set speed, or display parameter code.

1.2 Key Description

①

Function key: Used for setting value modification; parameter recall, parameter modification confirmation;

Function key: Used for setting value modification; parameter recall, parameter modification confirmation;②

Shift key: When in the setting state, click this button to shift;

Shift key: When in the setting state, click this button to shift;③

Decrease key: When in the setting state, click this button to decrease the number by one. Press and hold the button to decrease the number continuously;

Decrease key: When in the setting state, click this button to decrease the number by one. Press and hold the button to decrease the number continuously;④

Add key: When in the setting state, click this button to add one to the number, long press this button to continuously increment the number;

Add key: When in the setting state, click this button to add one to the number, long press this button to continuously increment the number;⑤

Start/stop button: Press and hold this button for more than 4 seconds to control the running/stop of the program;

Start/stop button: Press and hold this button for more than 4 seconds to control the running/stop of the program;2. Operation steps

1)Timing function:Click once

key, when the time is set to 0, there is no timing function when the time setting is not 0, the controller has the timing function, press

key, when the time is set to 0, there is no timing function when the time setting is not 0, the controller has the timing function, press  key, the TIME value flashes, indicating that the time can be set as needed, By increasing, decreasing and shifting the keys, the required time value is set. When the time is up, the TIME window displays the “END” buzzer sound, which can be silenced by pressing any key.

key, the TIME value flashes, indicating that the time can be set as needed, By increasing, decreasing and shifting the keys, the required time value is set. When the time is up, the TIME window displays the “END” buzzer sound, which can be silenced by pressing any key.2)Speed setting:Tap again

key, the “REV SET” window value flashes, indicating that the speed can be set as desired. The required speed is set by the increase, decrease and shift keys.

key, the “REV SET” window value flashes, indicating that the speed can be set as desired. The required speed is set by the increase, decrease and shift keys.Note:① Each time a parameter is modified, it needs to be confirmed by pressing the “

” key;

” key;② After all the parameters are set, press the “

” button and wait for about 4 seconds to start running.

” button and wait for about 4 seconds to start running.3. Reservation function

3.1 Long press

key, When the LCD screen displays LK, enter the password 3, click the MODE button to find the KA, and increase the KA to 3 by adding, reducing and shifting the keys, that is, selecting the controller to reserve the boot;

key, When the LCD screen displays LK, enter the password 3, click the MODE button to find the KA, and increase the KA to 3 by adding, reducing and shifting the keys, that is, selecting the controller to reserve the boot;3.2 Press the key

in the standard state, the TIME value flashes, indicating that the time can be set as needed. Set the required time value for the scheduled power-on by adding, reducing and shifting keys,and then press the key

in the standard state, the TIME value flashes, indicating that the time can be set as needed. Set the required time value for the scheduled power-on by adding, reducing and shifting keys,and then press the key  to confirm the setting, After the machine is powered off, and the power is turned on,the scheduled start time starts to count down, when the countdown is 0, the machine will automatically start running.

to confirm the setting, After the machine is powered off, and the power is turned on,the scheduled start time starts to count down, when the countdown is 0, the machine will automatically start running.4. Alarm function

When the oscillating load is too heavy and the motor is overloaded for more than 10 seconds, the meter beeps and the oscillation stops. Press any key to silence.5. Product maintenance and attention points

1. Maintenance points1) Product storage conditions

1 Ambient temperature: (-40 ~ +55 ° C);

2 Relative humidity is not more than 95%;

3 atmospheric pressure: (80 ~ 106) KPa;

4 The altitude is not higher than 2000 meters;

5 There is no corrosive gas around.

2. Points to note

1) The product is placed on the hard and firm work surface (ground). It must be adjusted to the horizontal level of the cabinet with 4 adjustable feet and the height of the casters from the ground is not less than 5mm! And check that it is stable to prevent the movement caused by the oscillation during long-term work, causing the product to fall and causing serious damage to the product or personal injury.

2) After the equipment is grounded, if the ground is not flat, it must be leveled and cannot be used for tilting; the left and right sides of the equipment should be more than 50cm.

3) The equipment should be kept away from electromagnetic interference sources and should have good grounding.

6. Appendix

6.1 Technical indicators

| Model Specification | BSOR-101 |

| voltage | AC220V±10% (50±1%)HZ |

| input power | 250W |

| Tray speed | 40~300 rpm |

| Speed accuracy | ±1 rpm |

| Pendulum amplitude | 35mm |

| Timing range | 0~99:59H |

| Rocker size | 800×600 mm 2 |

| Number of rocking plates | Single layer |

| Standard configuration | 500ML 30 |

6.2 Troubleshooting

| Problem | Problem reason | Solution |

| The tray does not work, the LCD screen has no display | External power is not connected | the power plug plugged in or not; Power outlet no power or poor contact. Power switch is not open or break down. |

| Fuse burned | Exchange the appropriate fuse | |

| The tray is running and the LCD screen is not working properly. | High frequency interference source in the same line | Press the parameter modification/confirm button to resume display Eliminate the same line interference source or set up a dedicated line |

| loud noise | The instrument is placed unevenly | Adjust the left foot of the instrument to make the instrument stand smoothly |

| Porous tray loose | Tighten the tightening nuts at the four corners of the tray |

Packing list

Product Name: Shaker| No. | Type | Name | Unit | Qty. | Remarks |

| 1 | Document | Operating instructions | 1 | ||

| 2 | Document | Packing list | 1 | ||

| 3 | Spare part | Fuse | 2 | ||

| 4 | Spare part | Power cable | 1 | ||

| 5 | Spare part | Beaker clip | See Sheet |