Natural Convection Oven BONC-101

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

With easy to clean interiors and natural convection circulation system for efficient heating of chamber, this oven can be relied on for general laboratory applications.

- 304 stainless steel, mirror polishing processing, easy to clean and maintain

- Natural convection with low noise

- PID controller with over temperature alarm and Timer function ensures precise and reliable control

Specification

Features

Applications

| Capacity | 27 L |

| Temperature Range | RT+10-200°C |

| Ambient Temperature | +5-35°C |

| Temperature Stability | ±1°C |

| Display Resolution | 0.1°C |

| Internal Dimension | 320Wx300Dx355H mm |

| Exterior Dimension | 460Wx520Dx660H mm |

| Shelves | 2 |

| Power consumption | 850 W |

| Electrical Requirement | AC 220V, 50Hz |

- 304 stainless steel, mirror polishing processing, easy to clean and maintain

- Natural convection with low noise

- PID controller with over temperature alarm and Timer function ensures precise and reliable control

Drying, Roasting, Laboratory, Research, Engineering, Industry, Agricultural, Biology

Operating Manual for BONC-101

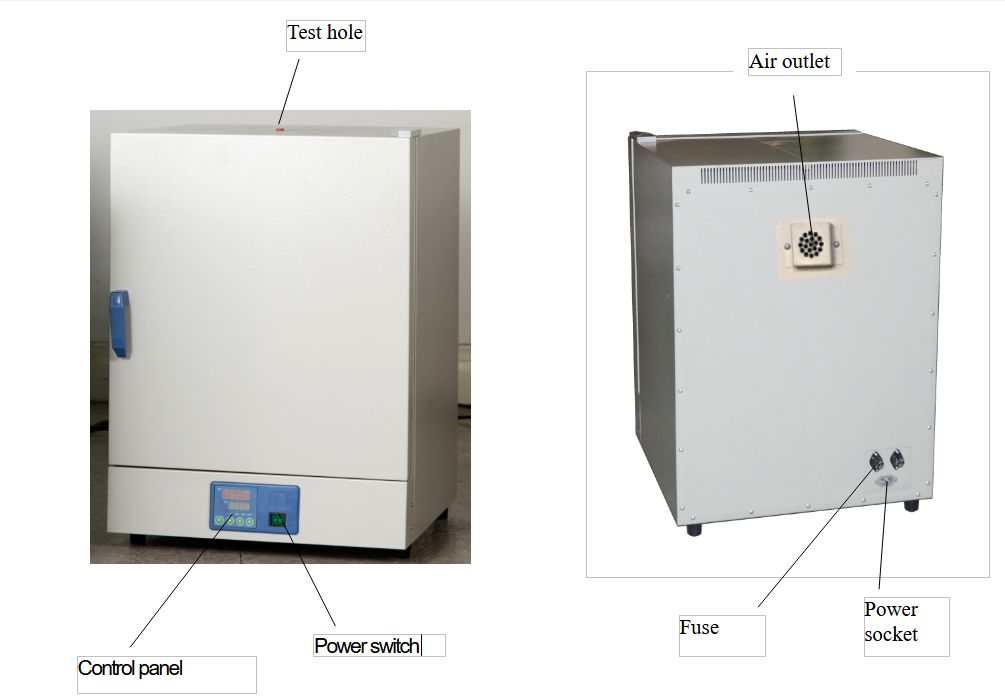

1. Sketch:

2) Scope of application

3) Technical indexes:

4. Structural description

5. Method of use

6. Precautions:

7. Operating methods

8. Wiring diagram

9. Failure handling methods

Packing list

1. Sketch:

2) Scope of application

Apply to the drying, braking, wax melting and sterilization of the articles in industrial and mining enterprises, colleges and universities, scientific research and medical units, labs, etc.3) Technical indexes:

| Mode | BONC-101 | BONC-102 | BONC-103 | BONC-104 | BONC-105 | |

| Power Voltage | AC220V±10% 50-60HZ | |||||

| Range of Controlling Temperature | (RT+10)℃~200℃ | |||||

| resolution of Controlling Temperature | ±0.1°C | |||||

| Output Power | 850W | 1000W | 1400W | 2000W | 2200W | |

| Volume | 27L | 56L | 96L | 140L | 200L | |

| Working Size(mm) | 320*300*355 | 400*330*415 | 450*430*505 | 520*500*575 | 570*560*640 | |

| Appearance Size(mm) | 460*520*660 | 540*550*720 | 590*650*810 | 660*720*880 | 710*780*945 | |

4. Structural description

BONC 100 series of natural convection oven consist of the box, temperature control system, electric heating system.Liner 304 stainless steel, semi-circular arc corners transition, shelf bracket height adjustable and free handling, easy to clean the work room, insulation layer using ultra-fine glass wool for filling.

Temperature control system is the main component of intelligent temperature controller. Pt100 platinum resistance as a temperature sensing element, the use of PID control heating system. Controller also has timing control, temperature error correction, deviation alarm protection and other functions.

Natural convection drying oven, electric heating system for the resistance wire heating tube, no fan.

This series of products has the advantages of high temperature control precision, small overshoot, small fluctuation and deviation over-temperature protection. In addition, it can according to the needs of users to increase matching an independent over-temperature protection system, can improve product safety performance.

5. Method of use

1) Put the articles to be dried into the drying cabinet, close well the door and turn the air door adjusting knob to position.

position.2) Move the power switch to “ON”. The power indicator light lights up and figures appear on the temperature control instrument.

3) Select the required set temperature, the numeric temperature displayed at the moment is the temperature in the cabinet and the heating indicator light lights up, showing that the instrument has been in the heating and temperature-rising state. After a period of time, when the displayed temperature is near to the set temperature, the heating indicator light is flickering for many times. Under usual conditions, after heating for 90 minutes, the temperature control will be the constant temperature state.

4) When the required working temperature is lower, adopt the two-stage set method. For example, if the required temperature is 80℃, first set 70℃ and after the overshoot temperature starts to drop back, then set 80℃, which can reduce and even eliminate the phenomenon of overshoot temperature, thus enable the inside cabinet to attain the temperature-constant state as early as possible.

5) Select the different drying times according to the different humidity of different articles, e.g., the articles to be dried are more humid, turn the air door adjusting knob to “ 三 ” position so as to vent the humid air in the cabinet.

6) When the drying process being over, if not to immediately take the articles out, first turn the air door adjusting knob to close the air door, or let open the air door and move the power switch to “OFF”, then opening the cabinet door immediately to take out articles, but take care not to be scalded.

6. Precautions:

1) The shell of the drying cabinet shall be well grounded to guarantee the safe use.2. The drying cabinet shall be placed inside one well-ventilated room, surrounding which no inflammable and explosive articles are available.

3) The drying cabinet has no explosion-proof device, so never place inflammable and explosive articles inside for drying.

4) The articles in the cabinet shall not be too crowded. Certain space shall be left so as to facilitate the circulation of hot air.

5) Always keep the internal and external of the cabinet clean. In case it will not be used for a long time, please cover it with a plastic thin film dirt shroud and put it in a drying room.

7. Operating methods

1) Preparation before useThe product should work under the following conditions of use:

- Ambient temperature: 5℃~40℃.

- The relative humidity is not more than 85%.

- Atmospheric pressure: (86~106) KPa.

- The altitude is not higher than 2000 meters.

- There is no strong vibration source and strong electromagnetic field around.

- It should be placed on a stable, level, without serious dust,

Indoors without direct sunlight and no corrosive gas.

- Leave enough space around the product, as shown in the upper right figure, and should not be placed under the fire alarm.

- The power supply voltage of the product is shown in the technical indicators (Attached Table 1 to Table 3).

- Place reasonably, adjust the position and quantity of the shelves, and put in the work items. It is necessary to maintain a certain gap (>100mm) around the upper and lower sides, and the weight should be such that the shelves are not deformed by bending.

2) Power on

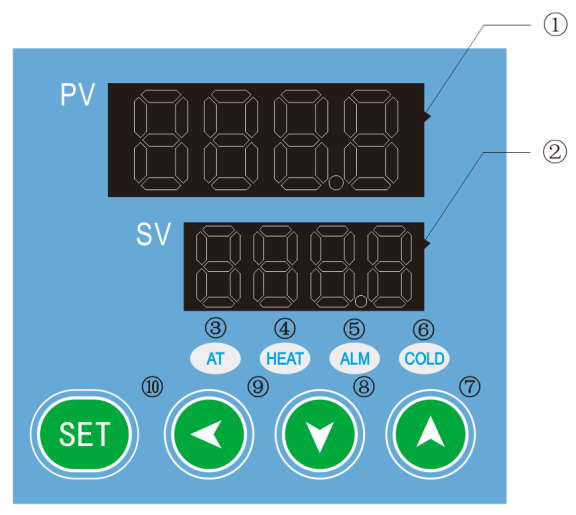

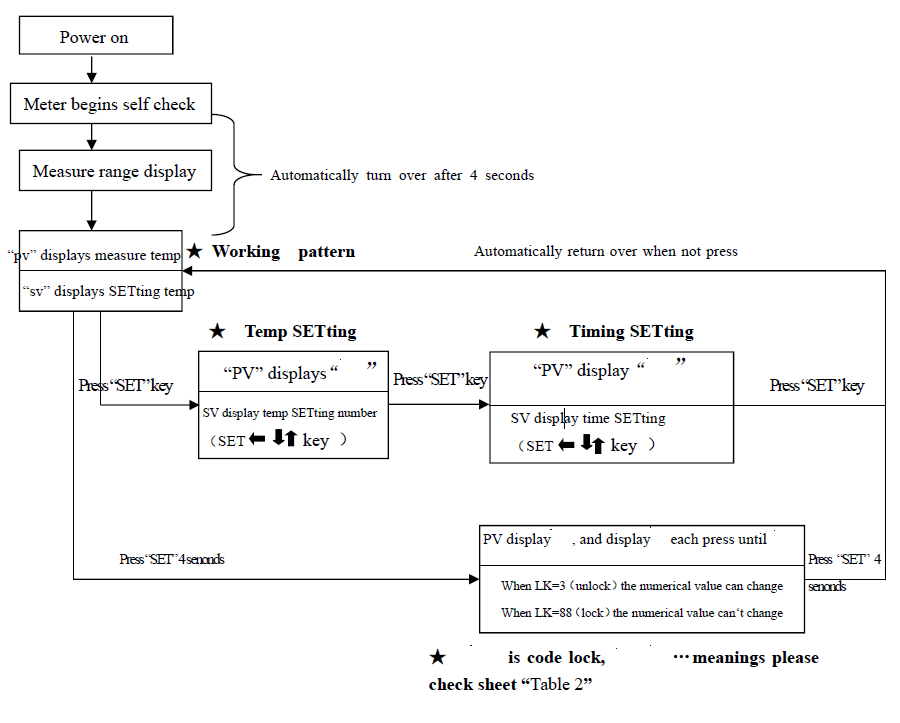

Figure 1

- The layout of the product temperature controller panel (see Figure 1).

- Close the door of the box, and the handle should be vertically downward.

3) Adjust the air door to a suitable position according to the moisture level of the item.

4) Turn on the power, the indicator light is on and the fan running sound can be heard.

5) The temperature controller enters the working mode after about 4 seconds of self-checking procedure, that is, the PV screen displays the measured temperature, and the SV screen displays the set temperature. When PV<SV, the HEAT light should be on, indicating that the temperature controller enters the heating state.

6) Check temperature control accuracy.

7) Put a 0.5°C indexed mercury thermometer (or a digital thermometer with a resolution of 0.1°C) into the product working room.

The mercury probe of the thermometer should be in the geometric center of the effective space of the studio

8) Choose a point within the temperature control range of the product and set the SV temperature control value. When the PV measurement value is equal to the set value, keep it at constant temperature (1~2) hours or so (depending on product specifications, the constant temperature time may vary) , Observe that the difference between the actual measured temperature value of the mercury thermometer and the measured value displayed by the temperature controller PV should be ≤±1.0℃.

9)Temperature and timing setting

- In the working mode, press the key

once, the PV screen will display

once, the PV screen will display  characters, press

characters, press  or

or  key, to make the SV screen display the required temperature value. (Refer to Appendix 2 for the process of recalling each function)

key, to make the SV screen display the required temperature value. (Refer to Appendix 2 for the process of recalling each function)- Press the key

again, the PV screen will display

again, the PV screen will display  characters,press

characters,press  or

or  key, make the SV screen display the required time value. (Refer to Appendix 2 for each function call process)

key, make the SV screen display the required time value. (Refer to Appendix 2 for each function call process)- When the setting

is 0, the controller cancels the timing function and the controller runs all the time. When the ST setting is not 0, the controller has the timing function. When the running time of the controller is up, the SV screen displays "END", the buzzer buzzes, the controller stops working, press any key to mute the sound, press and key

is 0, the controller cancels the timing function and the controller runs all the time. When the ST setting is not 0, the controller has the timing function. When the running time of the controller is up, the SV screen displays "END", the buzzer buzzes, the controller stops working, press any key to mute the sound, press and key  and

and  at the same time for 4 seconds to restart.

at the same time for 4 seconds to restart.- When the controller is in the working mode, just press the key

, the PV screen will display "TIME", and the SV screen will display the running time of the controller. Press the shift key again, and the controller will return to the working mode.

, the PV screen will display "TIME", and the SV screen will display the running time of the controller. Press the shift key again, and the controller will return to the working mode.- In the timing state, press the key

again to return to the working mode and enter the working state.

again to return to the working mode and enter the working state.10) Upper deviation alarm setting.

The upper deviation setting is reasonable, which can protect the system from over-tolerance or out-of-control temperature control. It must be used when the product is working.

The upper deviation setting is reasonable, which can protect the system from over-tolerance or out-of-control temperature control. It must be used when the product is working.

- When the product leaves the factory, AL=10~15 is generally set, that is, the alarm temperature is: (SV+AL)℃.

- Press the "SET" key for about 4 seconds. When the PV screen displays the characters

, release it and open the electronic lock

, release it and open the electronic lock  before you can modify the relevant parameters.

before you can modify the relevant parameters.Unlock procedure: Press and hold

for 4 seconds. When the PV screen displays

for 4 seconds. When the PV screen displays  characters, use the key

characters, use the key

to change the value of the SV screen from "0" to "Unlock password=3" (user layer password), and then open the electronic lock (After 1 minute without any operation, the temperature controller will automatically return to working mode).

to change the value of the SV screen from "0" to "Unlock password=3" (user layer password), and then open the electronic lock (After 1 minute without any operation, the temperature controller will automatically return to working mode).- Press the key

a few times, when the PV screen displays characters

a few times, when the PV screen displays characters  , use the key

, use the key

to set a reasonable upper deviation value (AL).

to set a reasonable upper deviation value (AL).- After over-temperature, the buzzer will alarm intermittently, and the over-temperature light

will be on for a long time, press any key to silence.

will be on for a long time, press any key to silence.- When the temperature exceeds the AL value from the high temperature operating value set to the low temperature, it will also give an alarm, which is a normal situation, just press Mute.

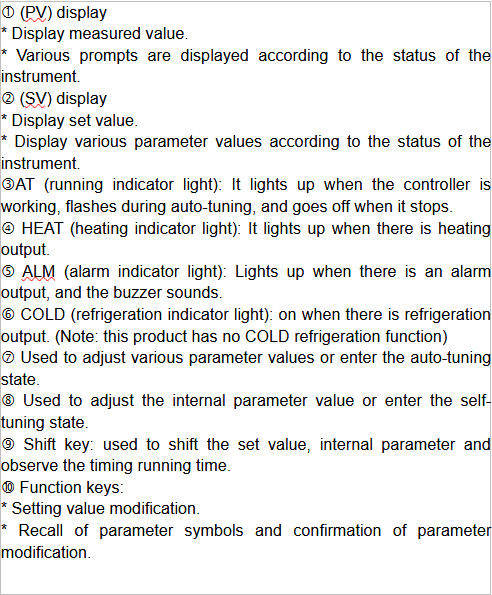

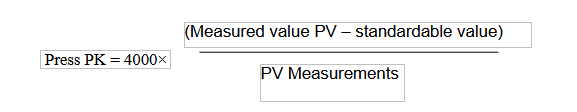

11) Methods to improve the accuracy of temperature control.

- After the product has been used for a period of time, the temperature control accuracy should be checked according to the method 2.6, if it exceeds ±1.0℃, it can be corrected according to the following method:

- Enter the temperature controller parameter menu (see item 4.2)

- Opening the electronic lock (see item 4.3)

- Long press the "SET" key, go to the symbol

, enter LK=3 for accuracy correction, the correction method is as follows:

, enter LK=3 for accuracy correction, the correction method is as follows:

After the formula is calculated, use the key

to modify on the basis of the original PK value at the factory (Note: One correction is inaccurate, and the correction can be repeated until it meets).

to modify on the basis of the original PK value at the factory (Note: One correction is inaccurate, and the correction can be repeated until it meets).- Use of optional accessories "independent temperature limit controller"

The over-temperature protector is an independent protection system. When the temperature controller fails and the temperature is out of control, when the temperature in the working room reaches the temperature limit setting value of the over-temperature dial, the over-temperature protector will automatically cut off the heating and sound an alarm.

(As shown in the right picture) When the temperature in the working room is lower than the temperature limit.

After the set value, the protection system is eliminated and the instrument resumes work.

Repeat this way until the fault is eliminated.

- The specific operations are as follows:

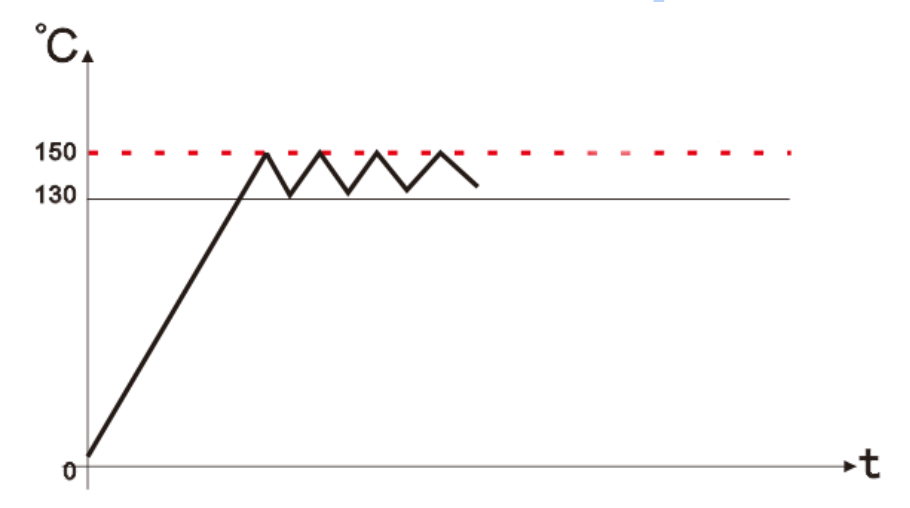

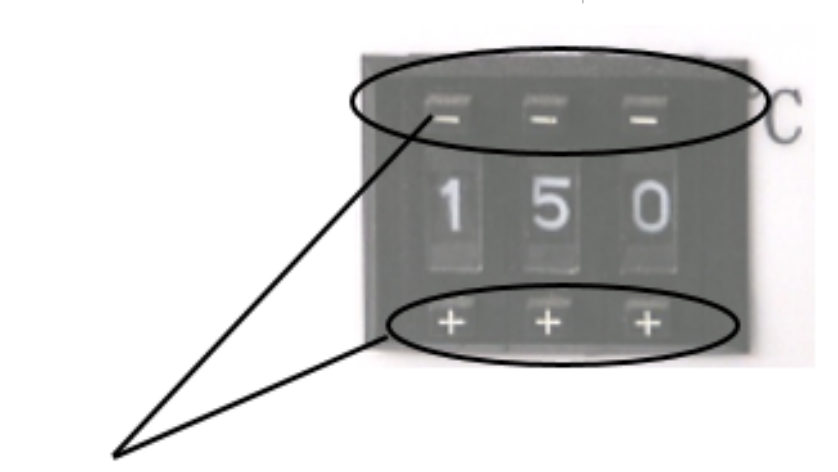

The temperature limit setting value should be greater than or equal to • (SV+AL) + (10~15)℃.7.9.7 See Figure 2, use the + and-buttons on the over-temperature setting dial on the panel the required temperature limit .

Example: SV=130℃, AL=10.

Then 150℃ should be set up

12) Maintenance and Instructions.

- Upon completion of each operation, first switch off the power. Open the box door and wait till the temperature is cooled down in the box before taking out the cultivated goods.

- In case of keeping the product idle for a long period of time, it is necessary to clean the product in and out. Pull out the power plug and cover it with the plastic anti-dust cap.

- If the environment for storage has a high humidity, it is necessary to regularly (about 1 month) power on for heating to dehumidify.

- Before using it again or in case of any change in technical requirement, it is necessary to check the accuracy of thermal control (see the relevant sections).

- Except for change of such parameters as SV, AL, Pk, Lk to change other control parameters, it is necessary to obtain consent from our Service Center or such parameters can be adjusted by the special personages.

13) Sequence to pick up the functions of the instrument

14) Following table lists the function parameters:

| Symbol | Name | Setting range | Description | Factory set value | |

/tM | Setup of maxi temperature permissible by the instrument | 37.0-320.0 | Stop heating beyond maxi temperature and give alarm. | ||

/Po | Boot mode | 0~1 | ①when PO =0, after open the power, the controller in a stopped state, need to press the set key + increase key at the same time for more than 4 seconds to start running. ②when PO =1, after open the power, the controller will be running. | ||

/AL | Alarming setting | 0-Full Range 0.0-Full Range | When temperature is beyond SV+AL, the ALM indicator turns on. The buzzer sounds and the heating power turn off. | ||

/Pb | Zero point adjust (intersection) | -100-100 -100.0-100.0 | When the zero error comparatively smaller and the full point error comparatively larger, to update this value should be needed. Ordinary for pt100, updating this value is rarely needed. | ||

/PK | Full point adjust(intercept) | -1000-1000 seconds | When the zero error comparatively larger and the full point error also comparatively larger, to update this value should be needed. PK=4000× (setting value-actual value)/actual value. For pt100 adjusting this value is need at first time. | ||

/LK | Password key | 0-255 | Input the password LK=3, the above parameters can be updated. | ||

8. Wiring diagram

Figure 2.9. Failure handling methods

| Problems | Causes | Handling methods |

| 1. No supply | 1. The plug is not inserted well or the wire is disconnected. | 1. Insert the plug and connect the wire. |

| 2. Fuse is open. | 2. Replace the fuse. | |

| 2. The temperature in the cabinet does not increase. | 1. The set temperature is low. | 1. Adjust the set temperature. |

| 2. The electric heater does not work. | 2. Replace the electric heater. | |

| 3. The temperature control instrument does not work. | 3. Replace temperature control instrument. | |

| 4. The cyclic fan does not work. | 4. Replace the fan. | |

| 3. The set temperature has a big difference from the temperature in the cabinet. | 1.The temperature sensor does not work. | 1. Change temperature sensor. |

| 2. The fine tuning potentiometer for setting temperature is not adjusted well. | 2. Adjust the potentiometer. | |

| 4.The over-temperature alarm is abnormal. | 1. The set temperature is low. | 1. Adjust the set temperature. |

| 2. The temperature control instrument does not work. | 2. Replace the temperature control instrument. |

Packing list

| No. | Type | Name | Unit | Qty. | Remarks |

| 1 | Document | Operating instructions | 1 | ||

| 2 | Document | Packing list | 1 | ||

| 3 | Spare part | Fuse core | 2 |

The articles in this list conform to those loaded in the box. Packing worker: No.2