Magnetic Stirrer BMGS-104

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Magnetic stirrer series offers many work modes, Strong magnetism, 30° bevel control panel, Brushless DC motor for convenient operations. Automatic reverse rotation for better-mixing result. Slip-proof and stable. Programmable memory can store nine common set S1 ~ S9, Meet the different kinds of experimental demands.

- Metal exterior, high strength, high temperature and corrosion proof.

- TFT LCD screen holographic display speed, starting and ending time, number of cycles and programming node.

- DC stepper motor, stable performance, low noise, long life.

- A variety of operating modes, including constant stirring, stirring cycle and so on.

Specification

Features

Applications

| Capacity | Max. Stir Capacity-3 L |

| Stirring Positions | 1 |

| Speed Range | 5~200 rpm Step 1 rpm |

| Platform Material | Stainless Steel |

| Dimension | 180x283x88 mm |

| Weight | 2.2 Kg |

| Power Supply | 100-240V,50-60Hz |

- Metal exterior, high strength, high temperature and corrosion proof.

- TFT LCD screen holographic display speed, starting and ending time, number of cycles and programming node.

- DC stepper motor, stable performance, low noise, long life.

- A variety of operating modes, including constant stirring, stirring cycle and so on.

- Programmable memory can store nine common set S1 ~ S9 , a key switch calls.

- 30 ° bevel control panel for sitting and standing position perspective.

- Magnetic mixing technology, low-speed smooth, designed specifically for cell culture which requires low speed stirring.

- Low shear gradual acceleration and stopping cell growth protection.

Cell Culture, Laboratory, Research, Medical

Operating Manual for BMGS-104

1 Introduction

2 Specifications

2.1 The Normal Operation Condition

2.2 The Basic Parameters and Specifications

3. Preparation

3.1 Structure Description

3.2 Keyboard and Display Panel

3.3 Key Function

3.4 Power Connection

4. Operation Guide

4.1 Speed, time, cycle times and selection of preset Settings

4.2 Stop / Start

5. Failure Analysis and Trouble Shooting

Appendix A:Wiring Diagram of BMGS-104

1 Introduction

Our cell magnetic stirrer interface is user-friendly, uses ultra-low speed, ultra-quiet magnetic drive to simulate the dynamic process of cell fermentation tank. By mixing and stirring to improve the fluidity of the liquid and promote the gas exchange, can increase the flow of the culture fluid around the suspension cells and the adherence of the adherent cells to the microcarriers, effectively promote the cell growth while providing the minimum shear force. Very suitable for suspended cells, adherent microcarriers in high-density culture, accurate and uniform speed, is conducive to the balanced growth of cells.Features:

1. Using 3.5-inch color screen as a display interface, friendly visual interface, allowing users to more intuitive operation;

2. Adopt stepping motor, stable performance, precise control, long life, excellent starting and stopping response;

3. Stainless steel sheet metal shell, high strength, high temperature, anti-rust, anti-corrosion;

4. Machine design compact, 50 ° bevel control panel for seated and standing point of view;

5. This magnetic stirrer can realize intermittent circulation work mode.

2 Specifications

2.1 The Normal Operation Condition

Ambient Temperature: 5°C ~40°CRelative Humidity: ≤70%

Power: AC100-230V~ 1A

2.2 The Basic Parameters and Specifications

| Type Parameter | BMGS-104 |

| Motor type | stepping motor |

| Motor input power | 12W |

| Voltage | AC100-240V |

| Frequency | 50/60Hz |

| Fuse | 250V 1A Ø5*20 |

| Quantity of Stirrer Point | 1 point |

| Maximum applicable culture bottle specification | 3 L |

| Speed Range | 5-200rpm |

| Interface display | 3.5-inch color screen |

| Timing range | 0s 99min59s |

| Dimension (WxDxH) | 180*283*88 mm |

| Net Weight | 1.8 kgs |

| Allowable ambient temp. | 5℃-40℃ |

| Allowable relative humidity | ≤70% |

3. Preparation

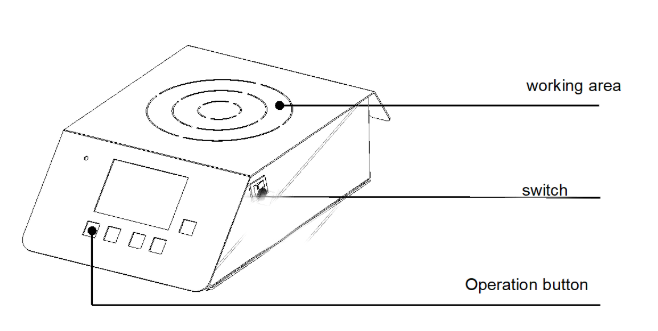

This chapter mainly describes the instrument’s mechanical structure, the keyboard and functions of each key, as well as preparations before power on. Please learn this chapter well before the orbital shaker is to be operated at the first time.3.1 Structure Description

3.2 Keyboard and Display Panel

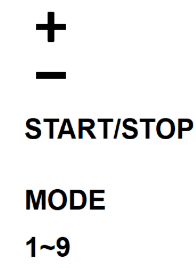

3.3 Key Function

-Increase the number of settings

-Decrease the number of settings

-Start/Stop key. After the speed and time setting is completed, press this key to start running. During operation, continue to press this key for 2 seconds to stop the operation.

-Parameter setting switch button

-Selection of preset Settings

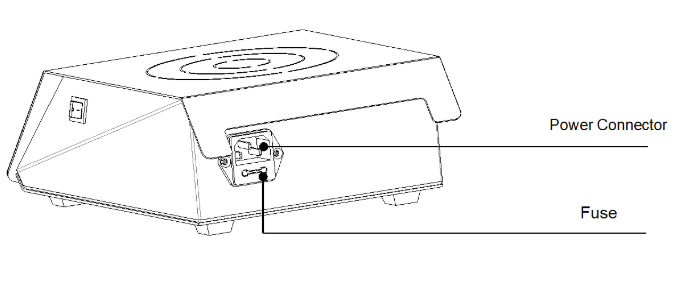

3.4 Power Connection

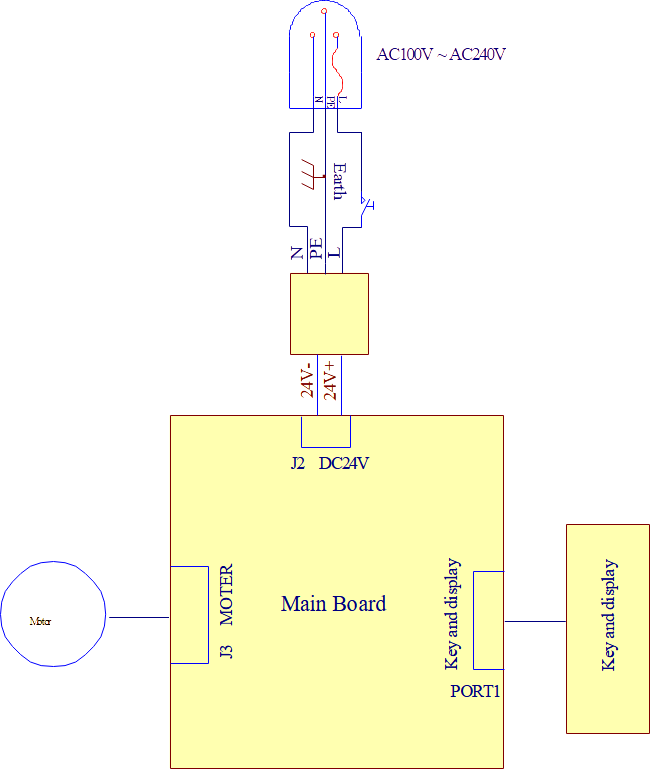

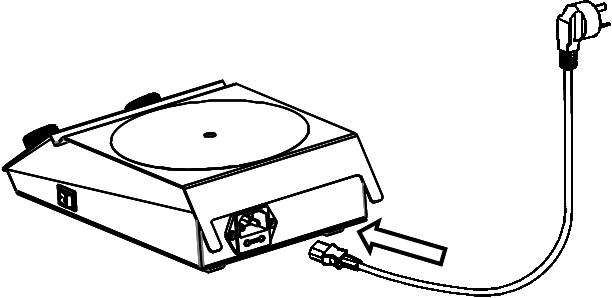

Put the instrument on a horizontal and even working table. Connect power as below figure. DC socket is on the rear part of the instrument. Voltage should be between 100V and 240V. AC100-240V

AC100-240V

4. Operation Guide

4.1 Speed, time, cycle times and selection of preset Settings

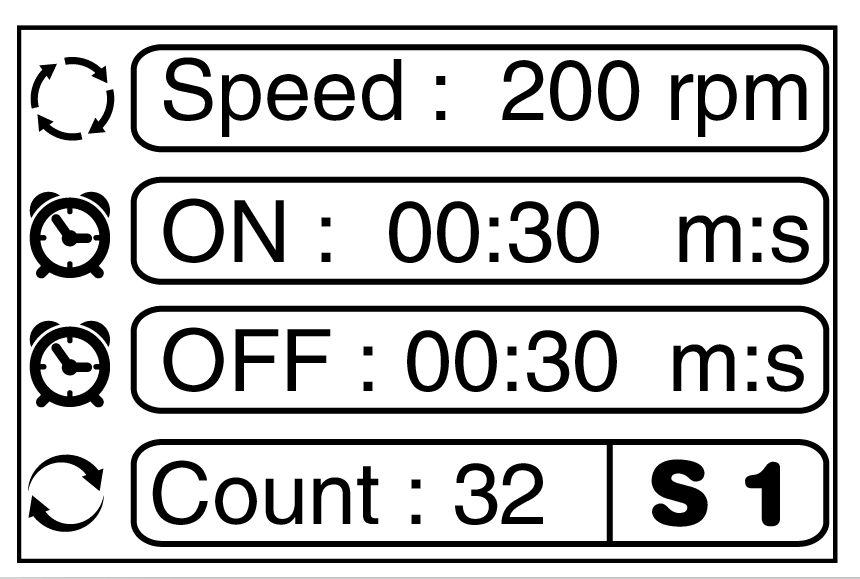

a) Turn on the power switch, the display will show the user interface, which is the last running parameter setting before the machine is turned off.

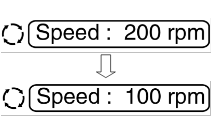

b) Press “MODE” button once, a white frame will be displayed at the periphery of the upper right picture. At this time, the speed can be set. Press the "+" key to increase the speed (short press is a single digit increment, if long press, the first 6S is incremented by one digit, 6S later, it is incremented by tens digit until the maximum speed is 200rpm). Pressing the "-" key decreases the speed (The same rules as "+") and the speed range is 5 ~ 200rpm. For example: change the speed from 200rpm to 100rpm, just let the periphery of the upper right picture show a white frame, and then press the "-" key to make the number 200 become 100.

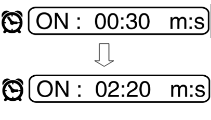

c) Press “MODE” button twice, the white frame will be displayed on the periphery of the upper right picture. At this time, the running time can be set. Press the "+" key to increase the time (short press is incremented by 1 second, If long press, the first 6S is 1 second increments, 6S ~ 10S is incremented by 10 seconds, 10S later is incremented by 1 minute until 99 minutes and 59 seconds), press the "-" key, the time decreases (the same rules as the "+" ), The time range 1S ~ 99min59S. For example, change the running time from 30s to 2min20s, just let the periphery of the upper right picture show a white frame and press the "+" key to change the number 30 to 220.

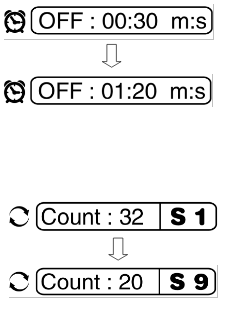

d) Press “MODE” button three times, a white frame will be displayed at the periphery of theupper right picture. At this time, the stop time can be set (the setting method is the same as the operation time setting method), and the time range is 0S ~ 99min59s. For example, change the stop time from 30s to 1min20s, just let the periphery of the upper right picture show a white frame and press the "+" key to change the number 30 to 120.

e) Press “MODE” key four times, the white frame will be displayed on the periphery of the upper right picture. At this time, the number of cycles can be set. Press the "+" key to increase the number of cycles, press the "-" key, the number of cycles decreases, the cycle times range from 1 to 99 times. For example, change the number of cycles from 32 times to 20 times. Just let the outer box of the upper right picture display a white box and press the "-" key to change the number 32 to 20.

f) Press “1 ~ 9” keys, on the right site of the displayed number of cycles, the S1 that displayed will change accordingly. the display of S1 will change, preset settings from S1 ~ S9. For example: change the preset setting from S1 to S9, press "1 ~ 9" key to change S1 to S9. (Note: in the operation of the device, press the "+" or "-" can adjust speed, the final value will be saved as the setting speed)

4.2 Stop / Start

a) Press Press the START/STOP button once, can run the current program. After the timing is over, stop running.(Note: When the motor is accelerating or decelerating, the indicator light flashing, to achieve the set speed keep normally on, the indicator light will be off when there is no speed.)

b) At the end of the operation, the instrument waits for the instructions at the end interface. At this time, press MODE or 1 ~ 9 button to reset the speed, time, cycle number or other pre-stored settings; Press the START / STOP button directly to start the program according to the previously set speed and time parameters.

c) When During operation, press the START / STOP button to stop the instrument. Press again to restart operation.

5. Failure Analysis and Trouble Shooting

Failure Analysis and Processing Procedures| No. | Phenomenon | Possible Causes | Processing Procedure |

| 1 | No signal display when power on. | No power | Check the power |

| Broken switch | Exchange the switch | ||

| Others | Contact with the seller | ||

| 2 | Shaking heavily | Samples placed imbalanced | Place the samples evenly |

| 3 | Actual speed and displayed speed are not matching | Broken controller | Contact with the seller |

| 4 | Err displays | Speed out of control | Contact with the seller |

Appendix A:Wiring Diagram of BMGS-104

(Below diagram is just for reference. It is subject to change without prior notice.)