Low Temperature Circulator BCLT-2103

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

- P.I.D temperature controller provides accurate and reliable temperature control

- Large LCD display screen and interface provides for user-friendly operation

- Preset On/Off function

- Independent circulating pump switch for easy starting/stopping the cycle

Specification

Features

| Capacity | 15.5 L |

| Temperature range | -20 - 20°C |

| Temperature accuracy | ±2°C |

| Cooling capacity at 10°C | 1500 W |

| Refrigerant | R410A |

| Security features | Delay, leakage, overcurrent, overvoltage |

| Total power | 1300 W |

| Power requirements | AC 220 V / 50 HZ |

| Pump power | 60 |

| Pump flow max. | 17 L / min |

| Maximum head | 15 m |

| Inlet/Outlet pipe diameter | Φ12 mm |

| Weight | 60 |

| Liquid storage | 13 |

| Noise level | ≤55 |

| Dimension | 400Wx500Dx739H mm |

- P.I.D temperature controller provides accurate and reliable temperature control

- Large LCD display screen and interface provides for user-friendly operation

- Preset On/Off function

- Independent circulating pump switch for easy starting/stopping the cycle

- Easy to set Adjustable Timer. (1 minute to 5,999 minutes)

- Maintenance-free operation with easy to clean surface

- Both heater and bath chamber are made of corrosion-resistant stainless steel

- No angle in bath chamber, easy to clean.Uniquely designed heating method can up to 80 °C

- Programming setting function with 7 periods and 9 steps for each period, which means. There are 63 programmable steps in total

Operating Manual for BCLT-2103

1. Safety warning

2. Product Introduction

3. Product use

4. Maintenance and Precautions

5. Attachment

6. Packing List

1. Safety warning

! Dangerous (may result in serious loss of property or casualties)1. The instrument must be grounded and away from sources of electromagnetic interference (must not be zero line or middle line for the ground).

2. Before use, please confirm the voltage and frequency of the power supply match the product requirements.

3. The product should use a separate power outlet, and confirm the plug, socket, good grounding.

4. Do not allow products in operation without turning off the power switch and unplug the power plug.

5.Do not allow free access or cut short product power line.

6. Do not repair without authorization, the company commissioned by the professionals must be repaired.

! Warning (may cause property damage or personal injury)

1. Must fully read and understand this product manual before operation.

2. When unplugging the power plug, do not drag the power cord directly.

3. One of the following conditions, you must unplug the product power plug:

3.1 When replacing the fuse tube.

3.2 Product failure to be checked repair.

3.3 Long time to stop using the product.

3.4 When moving the product.

! Note (may affect the service life of the product cause it could not work normally)

1. The product should be placed on a hard and firm surface to keep it level.

2. The product should be left some space around.

3. The product must be used under certain conditions of use. (See Chapter III 1.1 ~ 1.4)

4. The product must be used under the correct settings. (See Chapter III for details)

2. Product Introduction

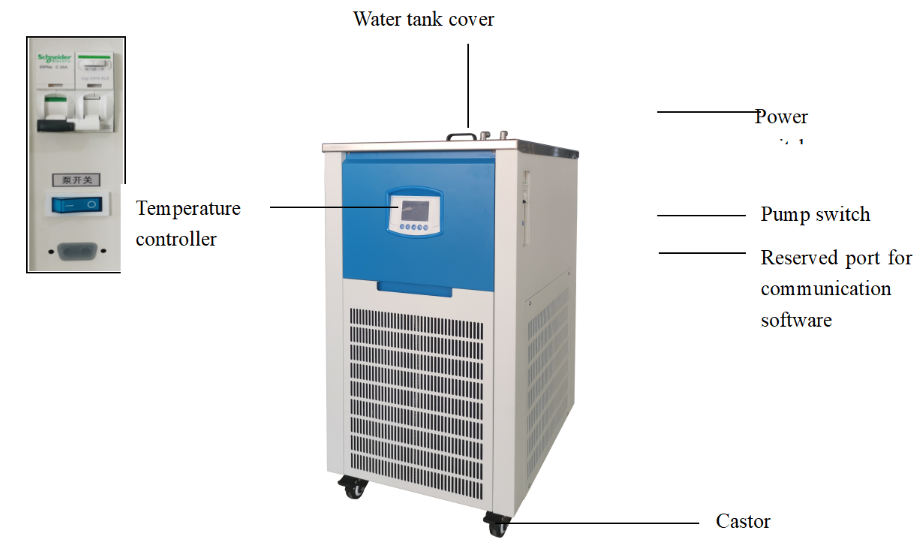

1. Outline

Figure 1

Figure 2

2. Structure Functional Overview

Low temperature circulation tank by the cycle controller, box and refrigeration system composed of three parts. Circulation controller is composed of the temperature controller, temperature sensors, and circulation pump. The box is made of high quality thin steel plate, the surface is sprayed and treated, the liner is made of stainless steel. The refrigeration system is composed of the compressor, condenser, evaporator and other components.

The device relies on the cooling system to rapidly cool down to the desired temperature and the magnetic stirrer system provides good temperature uniformity in the bath. The circulation pump is in addition to meet their own needs of constant temperature control, at the same time for the transfer of heated bath.

Behind the low temperature circulation sink there are inlet and outlet connections. Temperature controller is a CPU processor and peripheral circuits consisting of a double-row four-digit display digital controller, with Pt100 platinum resistance as a temperature sensing element, with high control accuracy, good stability advantages, meanwhile with timing, over-temperature alarm protection and other alarm functions.

3. Product use

1. Preparation before use1.1 The product should work under the following conditions of use.

a. Ambient temperature: 5 ℃ ~ 35 ℃, air relative humidity: ≤ 85%

b. Atmospheric pressure: (86 ~ 106) KPa

c. Altitude not higher than 2000 meters

d. Power: AC220V±10%/50HZ

e. Keep away from heat source, no corrosive gas around, no strong vibration source and strong electromagnetic field.

1.2 The base that place the equipment should be flat and of non-combustible material.

1.3 Keep the equipment around (front and rear ventilation grid) at least 300mm of space, well-ventilated.

1.4 This equipment is equipped with a compressor. After the equipment is transported, do not operate it right away. After standing in the correct position, wait for (1 ~ 2) days to restart to ensure the normal operation of the compressor.

1.5 When pouring into the bath, please be careful not to pour the liquid into the instrument. It is recommended to open the insulation cover to add water or other medium from the sink port, the liquid must cover the evaporator.

1.6 Should be based on different temperature range, filling different bath (non-over-temperature use).

When the operating temperature is below 5 ℃, please pay attention to the danger of icing! Bath recommended: ethanol or ethylene glycol.

2. Power on

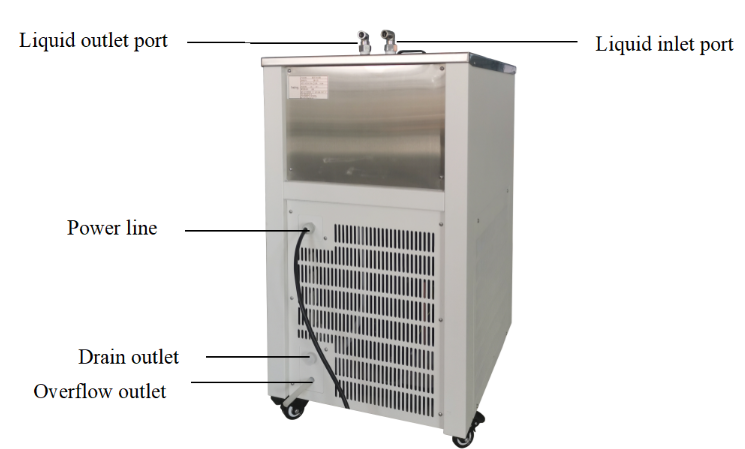

Figure 3

Controller panel

2.1.1 Indicator light description

1)TEMP: Display the measured temperature.

2)SET: Display the setting temperature.

3)Cooling light: Light when the cooling output.

4)TIME area: Display the running time or parameter value.

5)Silencer light: There is an alarm, light when the buzzer has silenced.

6)Alarm light: Light when alarm.

2.1.2 Key Description

① Function key: Used for setting value modification; parameter recall and parameter modification confirmation.

② Shift key: used to set value, shift of internal parameters and view of ambient temperature.

③ Decrease key: In the setting state, click once to decrease 1 digit unit, long press the button, will jump to decrease more digits.

④ Add key: In the setting state, click once to increase 1 digit unit, long press the button, will jump to add more digits.

⑤ Start/stop key: Press and hold this button for more than 4 seconds to control cooling operation / stop.

3. Operating steps

1)Timing function: Press

key once, When the time is set as 0, there is no timing function; when the time setting is not 0, the controller has the timing function. Press

key once, When the time is set as 0, there is no timing function; when the time setting is not 0, the controller has the timing function. Press  key once, the TIME value flashes, indicating that the time can be set as needed, by add, decrease and shift key, set the desired time value. Timing time to, Time window shows "END", buzzer sound, press any key to silence.

key once, the TIME value flashes, indicating that the time can be set as needed, by add, decrease and shift key, set the desired time value. Timing time to, Time window shows "END", buzzer sound, press any key to silence.2)Temperature setting:Press

key again, “TEMP SET” window flashes,indicating that the temperature can be set as desired. Set the desired temperature by add, decrease and shift key. Then press

key again, “TEMP SET” window flashes,indicating that the temperature can be set as desired. Set the desired temperature by add, decrease and shift key. Then press  key again, return to standard display mode.

key again, return to standard display mode.Note:①Every time modify a parameter,,need to press“

” key to confirm the modification is valid.

” key to confirm the modification is valid.②After all the parameters are set,long press “

” key for about 4 seconds to start running.

” key for about 4 seconds to start running.4. Upper deviation alarm setting

The setting of the upper deviation is reasonable, can play the role of system temperature control or out of control protection, the product must be used when working.

Example: If the product is shipped with AL = 3.0, the alarm temperature is: (set temperature + AL value) ℃

5. Check the temperature control accuracy

5.1 With 0.1 ℃ index mercury thermometer (or resolution 0.1 ℃ digital thermometer) into the bath, the mercury end should be immersed in the bath and placed in the geometric center of the bath.

5.2 Choose a point within the range of product control, when the temperature measurement value is equal to the set value, then keep the temperature for about 1 hour. Observe that the difference between the actual measured value of the mercury thermometer and the measured value of the thermometer should be ≤ ± 0.5 ℃.

4. Maintenance and Precautions

1. The device must be connected to a good grounding outlet! To ensure personal safety.2. When the bath is water, please pay attention to the use of temperature, prevent freezing, resulting in temperature control being inaccurate.

3. When replenishing the bath liquid, the type of bath liquid into the bath must be the same. (Note that the liquid medium in the working chamber must be filled with different bath liquid according to different operating temperature)

4. Use of flammable bath! Such as the use of improper bath caused damage, is responsible for the user.

5. Connect the rubber tube, connecting the clamp pressure to prevent fall off.

6. Continuous operation, part of the bath cover and circulation pump junction will become very cold, therefore, in the touch of these places, we must be careful to prevent frostbite.

7. Tank filled with liquid is strictly prohibited to transfer or tilt, so as not to be immersed in liquid immersion into the device causing danger or equipment damage.

8. Please use clean water or medium, strictly prevent sediment and other foreign matter into the cooling system damage circulation pump.

9. After use, turn off the power switch, unplug the power cord plug, drain into the drain plug (note the bath temperature, be careful to avoid frostbite) and dry the cabinet.

5. Attachment

1. Main Specifications| Product Name | Cooling recirculating chiller | ||||

| Model | BCLT-2101 | BCLT-2102 | BCLT-2103 | BCLT-2104 | BCLT-2105 |

| Storage tank maximum capacity (L) | 5 | 8 | 15.5 | 30 | 62 |

| Temperature range | -20~20°C | ||||

| Temperature accuracy | ±2°C | ||||

| Cooling capacity at 10°C (W) | 530 | 800 | 1500 | 2500 | 4000 |

| Refrigerant | R404A | R410A | |||

| Security features | Delay, leakage, overcurrent, overvoltage | ||||

| Total power (W) | 550 | 600 | 1300 | 1600 | 2400 |

| Power requirements | AC220V/50HZ | ||||

| Pump power (W) | 30 | 60 | 550 | ||

| Pump flow max. (L/min) | 6 | 17 | 30 | ||

| Maximum head (m) | 9 | 15 | 25 | ||

| Inlet/Outlet pipe diameter (mm) | φ10 | φ12 | |||

| Weight (kg) | 32 | 41 | 60 | 76 | 126 |

| Liquid storage (L) | 3.5 | 5.2 | 13 | 25 | 52 |

| Noise level (dB) | ≤45 | ≤55 | ≤65 | ≤75 | |

| Dimensions WxDxH (mm) (include caster) | 210x410x511 | 310x445x570 | 400x500x739 | 450x600x821 | 560x845x850 |

Table 1

| Product Name | Cooling / Heating recirculating chiller | ||||

| Model | BCLT-2201 | BCLT-2202 | BCLT-2203 | BCLT-2204 | BCLT-2205 |

| Storage tank maximum capacity (L) | 5 | 8 | 15.5 | 30 | 62 |

| Temperature range | -20~80°C | ||||

| Temperature accuracy | ±0.5°C | ||||

| Cooling capacity at 10°C (W) | 530 | 800 | 1500 | 2500 | 4000 |

| Refrigerant | R404A | R410A | |||

| Security features | Delay, leakage, overcurrent, overvoltage (applies to all models) | ||||

| Total power (W) | 1100 | 1350 | 2500 | 3000 | 4300 |

| Power requirements | AC220V/50HZ | ||||

| Pump power (W) | 30 | 60 | 550 | ||

| Pump flow max. (L/min) | 6 | 17 | 30 | ||

| Maximum head (m) | 9 | 15 | 25 | ||

| Inlet/Outlet pipe diameter (mm) | φ10 | φ12 | |||

| Weight (kg) | 32 | 41 | 60 | 76 | 126 |

| Liquid storage (L) | 3.5 | 5.2 | 13 | 25 | 52 |

| Noise level (dB) | ≤45 | ≤55 | ≤65 | ≤75 | |

| Dimensions WxDxH (mm) | 210x410x511 | 310x445x570 | 400x500x739 | 450x600x821 | 560x845x850 |

Table 2

2. Each function parameter table

Under normal conditions, if you press SET key and SHIFT LEFT key for over 3 seconds simultaneously, LK code will be displayed on the screen and setup of a password will allow entry into the parameter settings. Please do not change any values without further consulting.

1) When the output area on the LCD screen displays LK, press add-subtract key or shift key to let LK=0000 and pressing the SET key may allow you to enter into the setting of the user's parameter hierarchy.

| Prompting character | Name | Setup scope | Description | Initial value |

| dy | Run delay | 00:00-99:59 | 00:00: No delay. Other values- Start of a program will be delayed dy time after pressing the RUN key. |

Table 3

(2)When the output area on LCD screen displays LK, make LK=0003. You can enter into setting of manufacturer’s parameter hierarchy only by pressing SET key.

The menu of manufacturer’s parameter hierarchy is as follows:

| Prompting character | Name | Setup scope | Description | Initial value |

| tM | Maximum Allowable Temperature Setting | Set within the measuring range | Stop heating and alarm when the maximum temperature is exceeded. | |

| PO | Power-up Mode | 0~3 | PO=0000: Controller is in a stopped state after power-on. User must start the operation by pressing the RUN/STOP button for 3 seconds. PO=0001: Controller automatically starts the step operation after power-on. PO=0002: Controller starts running from the last power-off. | |

| AL | Alarming Setting | 0~full range | Alarm illuminates with audible output (and Hold function) when the temperature exceeds the Setpoint + AL value. | |

| Pb | Zero adjustment (intercept) | -100.0~100.0 | When the zero error of the meter is large and the full-scale error is small, adjust this value. Generally, PT100 rarely adjusts this value. | |

| PK | Full Scale Adjustment (Slope) | -1000~1000 S | When the zero error of the meter is small and the full-scale error is large, adjust this value. PK=4000× (Mercury thermometer value - display value)/display value, generally PT100 first adjust this value. | |

| PA | Revision of RT | -80-80 | When the actual RT differs from that shown by the controller, adjust the value accordingly. | |

| 2b | The second zero correction | -100-100 | When the second channel zero error is large and the full scale error is small, adjust this value. Generally, Pt100 rarely adjusts this value. | |

| 2K | Second channel full scale adjustment | -1000~1000 | When the zero error of the second channel is small and the full-scale error is large, adjust the value. PK=4000×(mercury thermometer value-display value)/display value, generally Pt100 adjust this value first. |

Table 4

Products are strictly tested before leaving the factory, when the studio technical indicators meet the requirements, work properly, generally do not be amended.

3.Trouble shooting

| Problems | Causes | Handling methods |

| 1. No power (Light does not shine) | No electrical outlet or poor plug / receptacle contact | Reinsert or repair |

| Power into the line off or the power switch is bad | Replace or repair | |

| Breaker jump | If replaced, still jump., you must check the temperature meter, circulation pump, refrigeration unit and other components, repair before powering on | |

| 2. Instrument no display | Temperature controller bad power or incoming terminal off | Replace the temperature controller or reconnect the cable |

| 3. Instrument PV screen display---- | Pt100 sensor defective or instrument input circuit fault | Replace Pt100 or replace the temperature controller |

| Thermometer full-scale setting error so that the measured value is out of range | Reset | |

| 4. Not cool | Cooling power switch is not on | Turn on |

| Compressor bad, bad protector, boot does not start | Replace the compressor | |

| Overheating causes compressor protector to start | Stop for a few hours, natural recovery | |

| Leakage of refrigerant, insufficient cooling capacity, blocked lines | Drain and add refrigerant. | |

| 5. Large temperature error | Poor contact of Pt100 sensor, big error | Replace Pt100 |

| Correct SC, HL parameters (large error) | Refer to this manual | |

| Adjust parameters such as PID (static difference) | Refer to this manual | |

| Cold, heat power imbalance | Adjust AL | |

| 6.Poor uniformity | Circulating pump flow is not enough, the bath does not cycle, | Adjust or replace |

Table 5

6. Packing List

Product name:Low temperature circulation bath| Serial number | Category | Name | Unit | Quantity | Remark |

| 1 | Document | Operation instruction | 1 | ||

| 2 | Document | Packing list | 1 | ||

| 3 | Spare parts | Power line | 1 | ||

| 4 | Spare parts | Connecting tube | 2 |