Gradient Thermal Cycler BTHC-102

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Engineered by finest quality and leading edge technology according to the advance technology and market norms under the direction of competent experts. Simple, intuitive programming, cost-efficient, fast setup and convenient to use makes it an ideal choice.

- Optimized to very low energy consumption

- Low noise, low energy consumption, long application life

- Specially designed lids reduce the evaporation during PCR

- Hinge utilized in labtop industry makes lode open more flexible

Specification

Features

ApplicationsAccessories Optional Accessories

| Temperature Range | 0°C~99.9°C |

| Max.Heating Ramp Rate | 4.5°C/s |

| Max.Cooling Ramp Rate | 4°C/s |

| Block Formats | 96x0.2 ml (A) / 54x0.5 ml (B) / 96x0.2 ml+77x05 ml (C) / 384well (D) |

| Display Interface | 5.7'LCD |

| Heating/Cooling adjustable rate | 0.1°C/s~4.0°C/s |

| Uniformity | ≤±0.2°C |

| Accuracy | ≤±0.1°C |

| Gradient Temp Range | 30~99°C |

| Thermal Gradient Span | 1~30°C |

| Gradient Uniformity | ≤0.2°C(single row) |

| Hot Lid Temperature | 20~110°C |

| Max.No.of Cycle | 999 |

| Communication | USB2.0 / RS 232 / RJ45 |

| Temp Control Mode | Block, tube* |

| Memory Capacity | 1000** |

| Note | *10~100µl Optional **Unlimited with use of USB memory stick |

| Intelligent Diagnosis | 108 |

| Dimension (WxDxH) | 380x270x250 mm |

| Weight | 7.8 kg |

- Optimized to very low energy consumption

- Low noise, low energy consumption, long application life

- Specially designed lids reduce the evaporation during PCR

- Hinge utilized in labtop industry makes lode open more flexible

- Infinitely adjustable lid knob, suitable for various types of the tube

- Versatile configuration options

- Gold-plated or silver-plated module improves the efficiency of heat conduction

- Portable desgin is easy for sample blocks interchange without maintenance

- 2000 protocols on board, unlimited with use of USB memeory stick

- ARM Platform, Windows CE operating system

- Large size and color super-high-definition LCD screen

- Intuitive and user-friendly interface, makes programming quick and easy

- Make a reservation and alarm for daily lab work

- Support the function of TM value calculation

- Portability: Transfers method between Genemate systems via USB ports

- Backup: Store your most important methods on a USB memory stick

- Storage: Store an unlimited number of methods by using a USB memory stick

- Uploads: Update firmware when enhancements become available

Analytical Laboratories, Molecular biology, Gene amplification, Gene Expression, Research, Development, Food Science, Pharmaceutical, Life Science, Animal Diagnostics

| Accessory Code | Name | Capacity |

| 5200606009 | Block C | 96x0.2 ml+77x0.5 ml |

| Accessory Code | Name | Capacity |

| 5200606006 | Block A | 96x0.2 ml |

| 5200606007 | Block B | 54x0.5 ml |

| 5200606008 | Block D | 384 well |

Operating Manual for BTHC-102

1. Important Note

1.1 Unpacking check

1.2 Security Warning:

2. Instrument Introduction

2.1 PCR technique brief intro

2.2 Features

3. Menu operations

3.1 File operations

3.2 parameter setting

3.3 Information inquiry

3.4 Others

4. maintenance and problems solving

4.1 instrument maintenance

4.2 common problems analysis and corresponding solving method

5. Question&Answering

1. Important Note

1.1 Unpacking check

When you received the BTHC-102 Thermal Cycler, please open the package and check whether the items comply with the packing list:If you find the components in the box are not consistent with the list, please contact us as soon as possible, and our company will try our best to solve the problem.

Note : When you receive the BTHC-102 and find the package seriously impaired or the instrument impaired, please keep the package and contact us immediately, we will replace the product and find out the reason.

1.2 Security Warning:

Please carefully read the manual before operating the instrument, otherwise the improper operations may cause damage to the instrument or harm your personal safety1.2.1 Operating safety

A.C. power’s grounding should be reliable for fear of an electric shock. The 3-pin plug with this instrument’ s power line is a safety device that should be matched with a grounded socket. Before turn on the power, always check if the mains voltage is consistent with the instrument required. Ensure the rated load of socket is not lower than required.

A.C. power’s grounding should be reliable for fear of an electric shock. The 3-pin plug with this instrument’ s power line is a safety device that should be matched with a grounded socket. Before turn on the power, always check if the mains voltage is consistent with the instrument required. Ensure the rated load of socket is not lower than required. If the A.C. power line is damaged, it must be replaced with a new one. The power line should be free of heavy objects during the instrument’s operation. Keep the power line away from the place where people gather regularly. While connect or disconnect the power line, you should hold the 3-pin plug with your hand. Insert the plug thoroughly to ensure good contact between the plug and socket. Pull the plug, not the line, when you need to disconnect to the mains.

If the A.C. power line is damaged, it must be replaced with a new one. The power line should be free of heavy objects during the instrument’s operation. Keep the power line away from the place where people gather regularly. While connect or disconnect the power line, you should hold the 3-pin plug with your hand. Insert the plug thoroughly to ensure good contact between the plug and socket. Pull the plug, not the line, when you need to disconnect to the mains. During instrument operation, the metal part and the hotlid can reach hightemperature, may cause burns and liquid boil over,is not allowed to be touchedby any part of the body for fear of the body burn, during the whole operation.

During instrument operation, the metal part and the hotlid can reach hightemperature, may cause burns and liquid boil over,is not allowed to be touchedby any part of the body for fear of the body burn, during the whole operation.Don’t put anything around the instrument closer than 30 cm when it is working to ensure the heat dispersion.

1.2.2 Maintenance safety

The instrument need timely clean the block and the heat lid to keep the experiment precise. It is advised that you take out the temperature changing block before you clean. Use a piece of clean soft cloth with some absolute alcohol to swap lightly. Corrosive scour is not allowed, and you should never drop the scour into the heat lid. Put back the block after cleaning.Once one of the following events occurs, you are suggested to disconnect the power line with mains, and contact the distributor or ask a certificated maintenance worker for help:

- Reagent, rain, or other liquid into the device;

- The device malfunctioning, giving off abnormal sound or odor, or the screen displays Error!

- The device falling from high place onto the floor or its shell damaged;

- Significant changes in the device’s performance, such as can’t power on or operate normally.

Note : For your safety and the normal operating of the instrument, don’t open the instrument. Otherwise your safety is not guaranteed and you will lost the right to warranty.

2. Instrument Introduction

2.1 PCR technique brief intro

Polymerase Chain Reaction (PCR) is a technique which is used to amplify the number of copies of a specific region of DNA developed in middle of 80s. There are many distinct merits in the PCR technology, such as specialization, sensitivity, high productivity, celerity, convenience, good reproductively, automatization and so on. In a reaction tube, target gene or segment of DNA, in a matter of hours, will be amplified a million fold, and can be seen by naked eyes; from a hair, a drop of blood, even a cell can be amplified to enough number of DNA for analyzing and identifying. In the past, the procedure may take days and weeks, but now it only take a few hours. PCR is a revolutionary innovation and landmark in the field of biological medicine.PCR has been widely applied in immunology, human genome project, forensics, oncology, population biology, paleontology,zoology,botany research field and clinical diagnosis of virus, tumor, hereditary disease, etc. , by PCR detection.

2.2 Features

2.2.1 Power on intro

After connecting to the electricity, turn on the power, the instrument will beep, that means the power have been supplied, and the LCD will display starting windows(see fig.1), and the device will have self-testing, after the self-testing is passed, the device is ready for operation(see figure 2).This demonstrate the instrument is normal and we can begin the experiment. If the LCD don’t light on or something abnormal happens, please cut of the power supply and connect the producer or get it repaired according to chapter 5 in this manual.

2.2.2 Software intro

This system provides us with a customer selection programming platform. It can held the temperature at constant degree, it can also realize quick temperature adjusting between different temperature set point. The block is designed to be substitutable, which enable the customers to select different blocks according to their own demand, such as 96*0.2mL,54*0.5 mL、96*0.2mL+77*0.5 mL、384well, providing sufficient experiment sample.Running in a low temperature is the basic feature of the advanced gene amplification instrument. Its ability to deal with the sample in low temperature,together with the PCR

itself, make it possible that all procedure can be done automatically. This system uses a advanced and reliable semi-conductor refrigeration scheme, providing an efficient temperature adjusting speed and super wide temperature controlling scale.

Referring to the software designing , the 320*240 super big LCD display can display complete information simultaneously. All buttons are labeled by numbers, making the programming quick and easy. This system slam the door of the link method in the tradition programming method, making use of the specified nature programming method. Link method is hard to learn and command, and the saved programming segment is easy to be damaged.

2.2.3 Structure intro

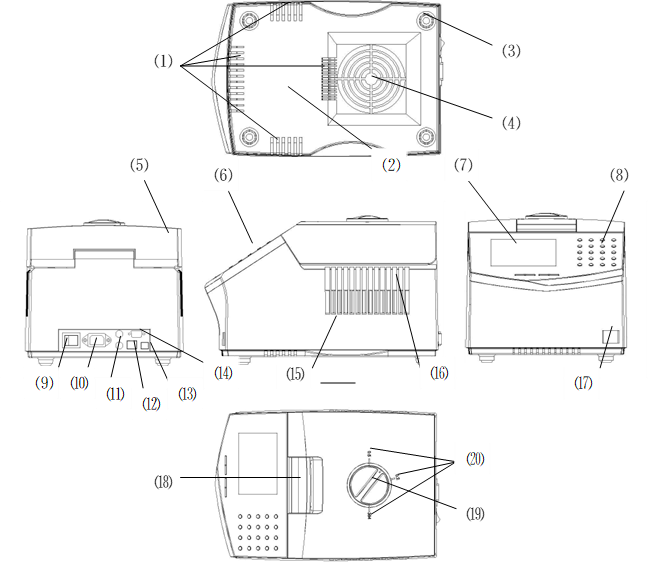

2.2.3.1 appearance view

1. heat dispersion hole

2. bottom

3. eet cushion

4. air in hole

5. upper cover

6. button panel

7. Display

8. button

9. switch

10. power supply socket

11. Fuse socket

12. network interface

13. USB interface

14. 232 interface

15. shell

16. air out hole

17.LOGO

18. heat lid spanner

19. grade knob

20. grade calibration

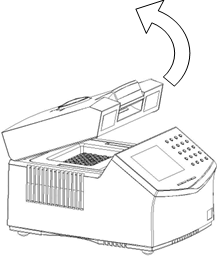

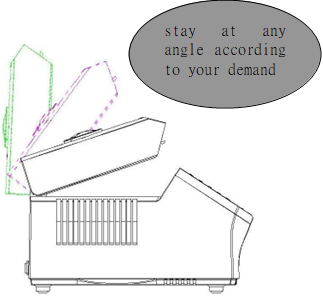

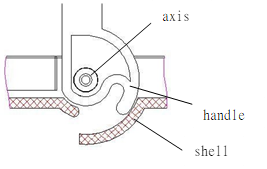

2.2.3.2 free adjusting angle between the upper cover and the shell

This instrument uses the gemel connecting technique and enables the upper cover to stay at any angle, solving the problem brought by the traditional spring connecting structure such as unreliable, instability and short using time.

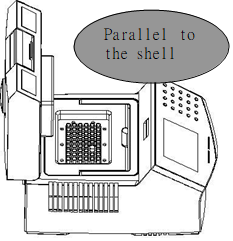

Text BoxAs the above figure shows, when you draw the spanner, the upper cover come away from the shell and could be fixed at any angle. The personalize structure makes the product more beautiful and more convenient to use for the operator.

Note : The angle between the upper cover and the shell range from 0 to 90, please don’t push it more than the upper limit 90 so as not to break the instrument.

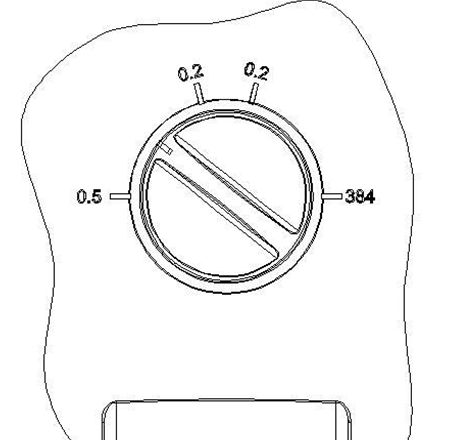

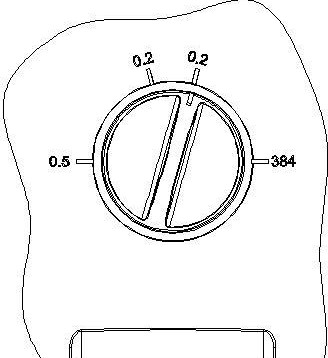

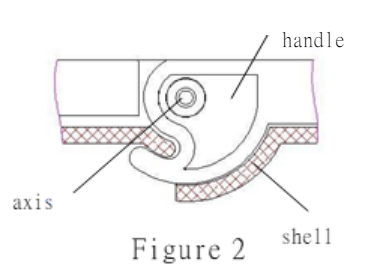

2.2.3.3 selectable heat lid calibration Due to the demand of the experiment, we need to use different test tubes, so we need different instrument suit the tests. This instrument has a design, with which the operator can meet the need of different test tubes on the same instrument simply by changing different block assembly.

As the above figures show, the calibrations 0.5,0.2,0.2and384 on the panel correspondingly suits the 0.5ml,0.2ml(dome),0.2ml(flat) and 384well test tube. Suppose you have to use the 0.2ml(flat) test tube, you just need to take on the block assembly with the 0.2ml groove( see details in 3.4 substitutable block assembly), then revolve the knob to the calibration of 0.2(flat). We use a rational and practical design, slam the door of traditional idea of changing heat lid or even change the instrument.

Note : The calibration knob circles clockwise, namely from 0.5 to 384. Please don’t circle it anti-clockwise so as not to break it.

2.2.3.4 Substitutable block assembly

In order to do different experiments with different test tubes on the same instrument, and to make it easier to change the block assembly, this instrument uses a design of portable and self-lock. This personalized design enables the instrument can meet different demands by changing the least assembly.

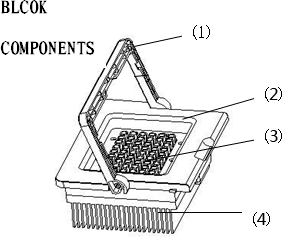

1. handle

2. press frame

3. block

4. Radiator

As the above figure shows, the consolidated design of the block assembly makes it convenient to install and replace, all blocks are made of the same exterior size, the same assemble method and the same installment method(different block assembly corresponds to different test tubes). this kind of design assures the operator can quickly and efficiently replace the block assembly according to their demand.

Figure 1

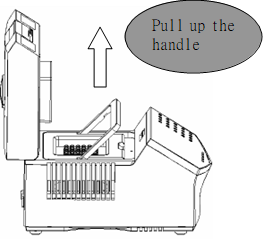

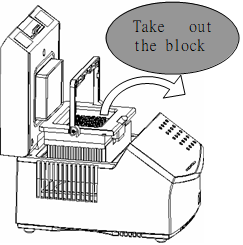

Figure 1shows the state of replacing the block assembly. When the operator is replacing the block, pull the holder upward, when the holder become vertical the block automatically unlock from the holder, operator can easily take out the block assembly.

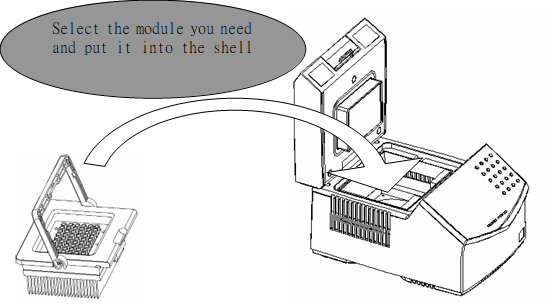

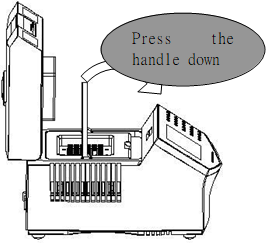

Figure 2 shows the state of installment. When operator has chosen the suitable block, he only needs to hold the holder, put the block into the crust, and put down the holder.

The alnico will attract the block and the holder will self-lock it to the shell.

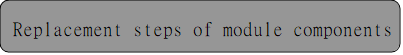

First step: open the free handle by your hand, the open degree is 90°, the block and the shell will release from self-lock.

Second step: lift up the block assembly softly, put it away at safe place after it completely departs from the shell.

Third step: select the block you need and put it vertically into the shell.

Forth step: after the complete contact of the block and the shell, press the handle down, let the alnico on the handle and the shell attract each other.

Fifth step: when the alnico attracts closely, the handle will be parallel to the shell, and the block will be self-locked to the shell. The replacement is completed.

The portable consolidated designed together with the intellectual block self-lock structure enables the operator to replace the block more convenient and more safely. Note : All the wirings in the instrument is connected using the plug,please lightly take out or install the block. You can shake the block softly but never strongly so as not to break the instrument.

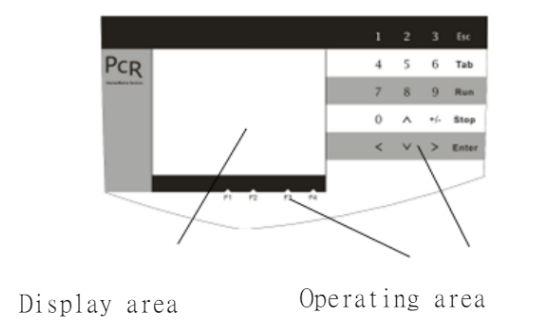

2.2.4 button intro

The operating panel is on the right, and the super big LCD display is on the left. The touching type switches makes operations more easy and convenient.

| Name of button | Using method | ||||

| 0-9 | Numbers, used to set date and time or adjust. | ||||

| ∧、∨、<、> | Cursor shift button, used to move the cursor or turn page | ||||

| Tab | Switching button, used to lowercase and capitalization | switch | between | different | windows, |

| Run | Running button,when select and open a file ,press to run the file. | ||||

| +/- | Switch between minus and plus when programming. | ||||

| F1、F2、F3、F4 | Function button, have different function in different menu windows, such as back, create, delete, save, etc. you can operate it according to the tips. | ||||

| Esc | Cancel button, used to escape from submenus, clear the dialog box and cancel the input. | ||||

| Stop | Stop button, when the file is running, press this button if you want to eliminate the running. | ||||

| Enter | Affirm button, used to affirm various contents in dialog box, selection option and information input. | ||||

2.2.5 instrument working condition and performance indicator

2.2.5.1 instrument working condition Ambient temperature : 10℃~30℃ Relative humidity : ≤ 70%Power supply : AC220V±22V 250VA 50Hz±1Hz

2.2.5.2 instrument storage conditions Ambient temperature : -20℃~+55℃ Relative humidity : ≤80%

Note : In order to assure the normal working and the precision of the experiment result, please operate and store the instrument in the stipulated condition. Otherwise there may be damage to the instrument and harm the operator’s safety and life.

2.2.5.3 instrument performance indicator

Model: BTHC-102-A;BTHC-102-B;BTHC-102-C;BTHC-102-D

Sample size: 96*0.2mL(A);54*0.5mL(B);96*0.2mL+77*0.5mL(C);384well(D)

Temperature range: 0℃—99.9℃(Rt≤30℃)

Temperature ascending speed: ≥3℃/s (45℃—99℃)

Temperature descending speed: ≥2.8℃/s (45℃—99℃)

Temperature uniformity: ≤±0.4℃(45℃≥T≥95℃)

Temperature accuracy:≤±0.1℃ (45℃≥T≥95℃)heat lid

temperature: (Rt +2℃)—110℃

Style of temperature control:block;calculated

Maximum number of program units: 200

Maximum number of cycles: 99

Graphical interfaces:5.7inch,320*240pels LCD Communication interface: USB2.0

Text BoxExterior size: 380mm(L)*270mm(W)*250mm(H)

Net weight: 7.2kg

3. Menu operations

3.1 File operations

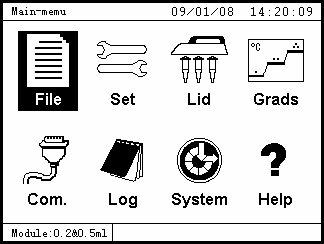

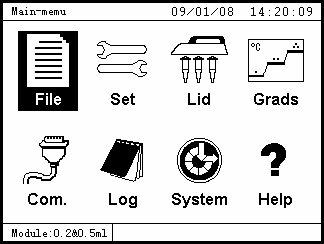

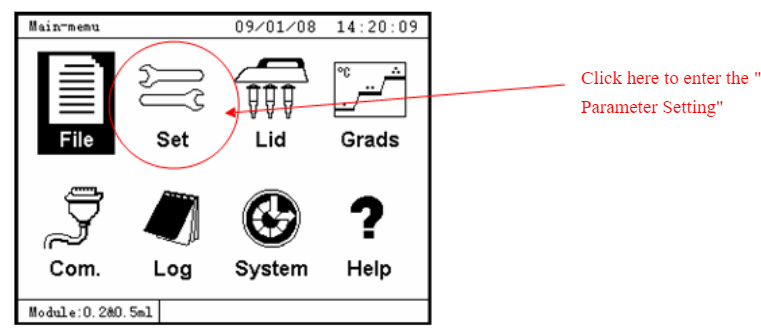

After power on, you will see the main menu window, this window is divided into the information box, main display section and multi-functional key column. The cursor will be displayed in the main display section in a contrast type.

3.1.1 new

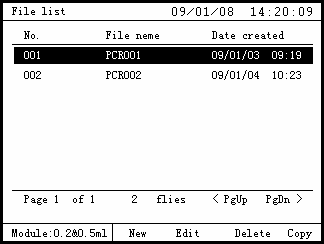

move the cursor ( or press number 1) in the “main menu window” to select the “file” submenu, press ENTER to enter the “files list” window

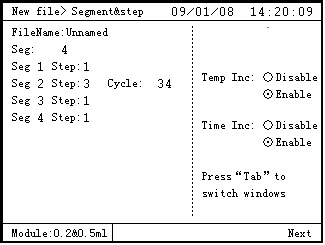

3.1.1.2 press F1, get into the window of “unit segment number setting”. Press SHIFT button to set the units of the file, number of segment units and the times of cycle. After selecting the item, please ENTER to enter the value using the number buttons. If you want to set the extended functions, please press “Tab” to move the cursor to the extended function section, press “∧” and “∨” to move the cursor to select the enable or disable of increment of temperature and increment of time, and press ENTER to affirm. System will get into the “segment &step”.

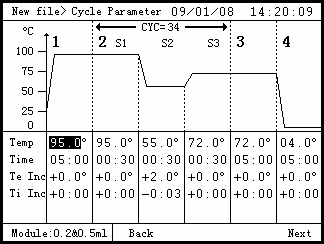

3.1.1.3 the “cycle parameter” window, press F1 to turn to the previous page, press F4 to turn to the next page. Press the SHIFT button to select the temperature point, the time range option, enter the value using the number buttons. Press F4 after completing the setting, the system get into the windows of “file name setting”.

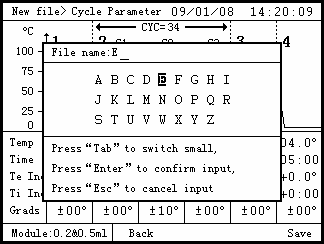

3.1.1.4 the file name could only be composed of by numbers and characters. It can be entirely numbers, entirely characters and combinations of numbers and characters. You can set the file name by input the numbers or characters in the file name display section. Press “Tab” to change between the capitalization and the lowercase, press SHIFT button to select the required character, and press ENTERr to input. Press the number buttons can directly input the numbers into the display section. You can press ESC to cancel you wrong input, and then re-input. Press F4 to save after setting.

3.1.2 Edit

3.1.2.1 move the cursor ( or press number 1) in the “main menu window” to select the “file” submenu, press ENTER to enter the “program files list” window3.1.2.2 in the “program files list” windows, press “<”and “>” to turn pages, press ”∧” and ”∨” to move the cursor to select the file you want to edit .

3.1.2.3 Press F2 after selecting the file, get in to the “unit segment number setting” window, and the following operations are the same as 3.1.1.1 to 3.1.14.

3.1.3 copy

3.1.3.1 move the cursor ( or press number 1) in the “main menu window” to select the “file” submenu, press ENTER to enter the “program files list” window.3.1.3.2 in the “program files list” windows, press “<”and “>” to turn pages, press ”∧” and ”∨” to move the cursor to select the file you want to copy .

3.1.3.3 press F4 after selecting, the system will display a confirm box, press ENTER to affirm the copy and press ESC to cancel. The system will get into the window of “file name setting” window, and press F4 to save after setting the copied file name.

3.1.4 delete

3.1.4.1 move the cursor ( or press number 1) in the “main menu window” to select the “file” submenu, press ENTER to enter the “program files list” window.3.1.4.2 in the “program files list” windows, press “<”and “>” to turn pages, press ”∧” and ”∨” to move the cursor to select the file you want to delete.

3.1.4.3 press F3 after selecting, the system will display a confirm box, press ENTER to affirm the delete and press ESC to cancel.

3.2 parameter setting

3.2.1 Running parameter setting

3.2.1.1 move the cursor ( or press number 2) in the “main menu window” to select the “setting” submenu, press ENTER to enter the “parameter setting” window.

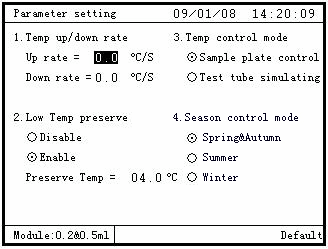

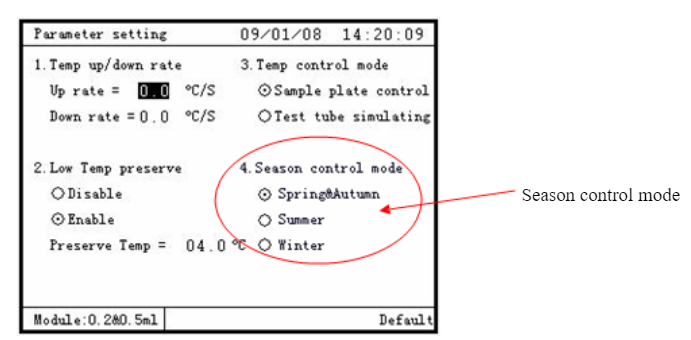

3.2.1.2 In the window of “parameter setting”, press ”∧” and ”∨” to select the options such as speed of ascending or descending temperature, temperature control mode, enable or disable low temperature storage, and the Season control mode. Press ENTER to confirm the option, and input the value by the number buttons. The speed of ascending or descending temperature range: 0.0℃/S~3.0℃/S. Temperature of low temperature storage range: 0℃~40℃.

Note : Recommendation: Temperature lower than 15℃ is winter mode, 15℃~25℃ is spring/autumn mode, higher than 25℃ is summer mode. The mode setting above just for reference only. Specific season mode should be setting based on the actual situation of your area in order to improve the accuracy of experimental results.

3.2.1.3 Press ESC to exit, and the system will show a “to save or not “dialogue box, press ENTER to affirm and ESC otherwise.

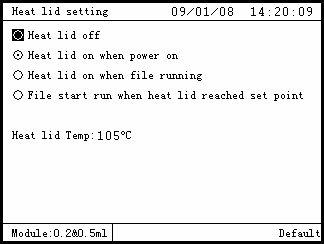

3.2.2 Heat lid setting

3.2.2.1 Move the cursor (or press number 3) in the “main menu window” to select the “heat lid” submenu, press ENTER to enter the “heat lid function setting” window.

3.2.2.2 In the window of “heat lid function setting” press ”∧” and ”∨” to select options such as heat lid shut, startup heat lid when power on, heat lid and program start simultaneously and start program after the heat lid arriving at the setting point, press ENTER to enter the option, input value using the number buttons. The heat lid temperature range: 20℃~110℃

3.2.2.3 press ESC to exit, and the system will show a “ to save or not “ dialogue box, press ENTER to affirm and ESC otherwise.

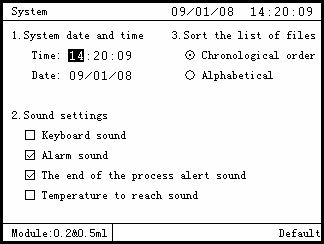

3.2.3 system setting

3.2.3.1 move the cursor ( or press number 7) in the “main menu window” to select the “system” submenu, press ENTER to enter the “system parameter setting” window.

3.2.3.2 In the “system parameter setting” window, press SHIFT button to select options such as system date and time, hint beep, the taxis manner of file list, press ENTER to enter the option and input value using the number buttons.

3.2.3.3 press ESC to exit, and the system will show a “ to save or not “ dialogue box, press ENTERto affirm and ESC otherwise.

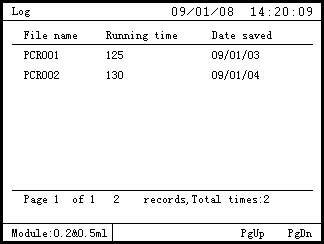

3.3 Information inquiry

3.3.1 log inquiry

3.3.1.1 move the cursor ( or press number 6) in the “main menu window” to select the “log” submenu, press ENTER to enter the “log view” window. If the numbers of all currently created files is below 200, all the files’ information will be displayed in this window. If the number of files is above 200, the most recently created 200 files’ information will be displayed. These information include the file names, run time, and create date, etc.

3.3.1.2 Press “<”and “>” to turn pages

3.3.2 Help information

move the cursor ( or press number 8) in the “main menu window” to select the “help” submenu, press ENTER to enter the “help” window. You can see connecting information of our company.3.4 Others

3.4.1 When the operator enters value out of the permitted scale, the system will value it with default value and the input value will not be adopted.3.4.2 The communication submenu in the main menu window is obligated for update, and is not valid in this version.

4. maintenance and problems solving

4.1 instrument maintenance

The instrument should be stored in dry and ventilated condition, avoid direct exposed to sunlight and dark humid circumstance.Clean the prick hole of the block, for fear the residual affect the accuracy of the experiment. Corrosive impregnant is prohibited. It is advised to use cotton stick dipped with absolute alcohol, and use an air gun to clean each hole.

The dust and waste on the shell should be cleaned with cloth dipped with some clean water, never use impregnant, alcohol, strong acid or strong alkaline in order not to damage the exterior.

After completing the experiment, check the instrument, turn off all the switches, clean the residual the experiment left, including water, the reaction liquid and impurity. Keep the instrument clean and dry. If don’t use it for a long time, cover the instrument to protect it.

4.2 common problems analysis and corresponding solving method

4.2.1 Bad experiment results

If get bad experiment results using this instrument, there may be following problems:(only for reference):- Reaction component is not right or low-quality or small amount of single-strand area is incorrect.

- Melting temperature too high or too low,refer to reaction volumes,increase or decrease time.

- Annealing temperature too high or too low.

- Reaction component concerntration too high or too low.

- The preparation haven't disposed especially.

- Program contains a wrong value.

- Temperature of the sample or sample electrode is low,while block temperature is high.

- Check the recation tube have been placed correctly,overlaid the reaction with mineral oil to enhance heat exchange.

- After a long time usage, the temperature may loss accuracy, and this could be adjusted by the producer, customers should never do it by themselves.

4.2.2 problem reason analysis and corresponding solving method

| No. | Phenomenon | Possible cause | Processing Procedure |

| 1 | No display and the beep missed when power on | Disconnected power supply | Check power supply for correct connection |

| Bad fuse | Replace it(250V 2.5A Φ5×20) | ||

| Switch failure | Replace it | ||

| Other | Contact distributor or manufacture | ||

| 2 | Display of Error! Flicker and beep alarm | Possibly reasons Open circuit in cooling block sensor Short circuit in cooling block sensor Open circuit in hotlid Short circuit in hotlid Open circuit in radiator sensor Short circuit in radiator sensor | Contact distributor or manufacture |

| 3 | Cooling speed slows down obviously or cannot cooling | Ventilation jam | Clear the jam |

| Cooling block failure | Contact distributor or manufacture | ||

| Fan failed or stopped | |||

| 4 | Heating speed slows down obviously or cannot heating | Cooling block failure | |

| 5 | Heating and cooling terminated | Bad sensor | Contact distributor or manufacture |

| Malfunction of all cooling blocks | |||

| 6 | Lid cannot be heated | Lid heater failure | Contact distributor or manufacture |

| Lid sensor failure | |||

| Bad contact between connectors | |||

| 7 | Abnormal characters displayed | Bad contact between chip and its socked | Contact distributor or manufacture |

| Chip malfunctioning | |||

| 8 | Inactive keys | Film panel malfunctioning | Contact distributor or manufacture |

5. Question&Answering

5.1 Q: Is the “Season control mode” should be setting before programming?A: Before programming, select the “Set” on the main menu interface to get into the “Parameter setting” interface, select the corresponding mode of the current area season on the “Season control mode” option.

NOTE : System will default the last operation season mode.

5.2 Q:Why can’t we enter the Communication function?

A:This function is still under updating. You can only use it when the updating process has been finished.

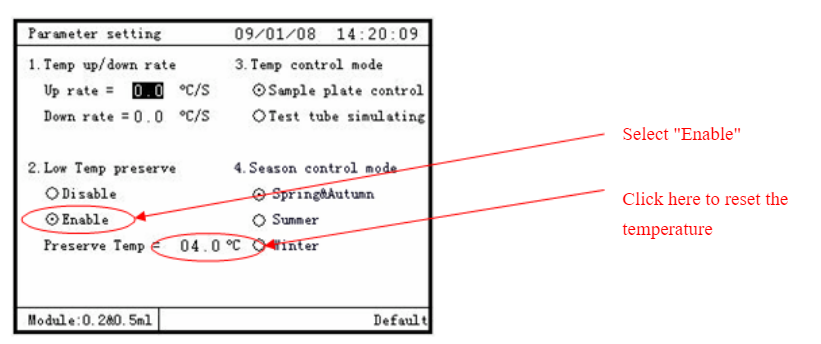

5.3 Q:How to set the 4℃ store function? Should we add a section of program at the end of the program.

A:It’s totally the wrong way to add a section of program at the end of the program. If you do it this way, an unwanted result may be produced.

The right operation is: Start the machine then enter the menu,click the “set” and enter the “parameter setting” interface. After select “enable” you can set the temperature of low temperature store in this interface.

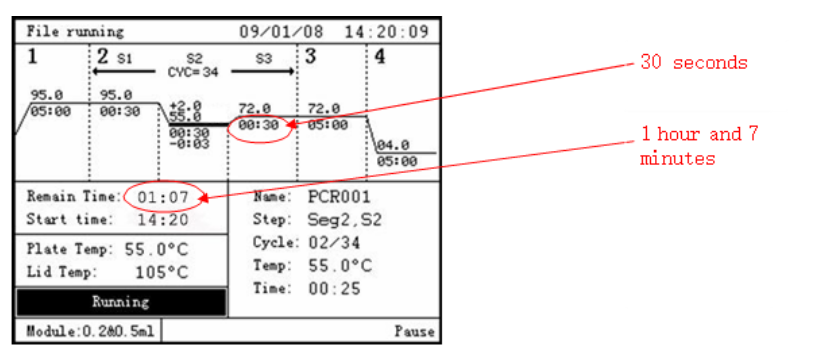

6.4 Q:How to understand time unit in PCR?

The 00:00 in PCR can be presented in two part. In the running interface, the first 00 in the remaining time represents hour, and the latter 00 represents min. Such as 01:07 means 1 hour and 7 minutes. While you are writing program, the first 00 represents minutes and the latter means 30 seconds.

6.5 Q:Can we fix the test tube when we turn the holid button to the correspondinglocation?

A:for most universal test tubes, we only have to turn the button to the location marked on the panel. But for some particular or nonstandard test tube, we have to turn the button to the extent that we feel some resistance. (Note: to force the button roll may cause damage to the test tube and speed up the aging of the instrument.)