General Purpose Incubator BIGP-613

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Biolab Scientific offers a range of high quality, efficient and reliable general purpose incubators that provide superior degree of temperature uniformity. Equipped with microprocessor PID controller, this series of incubators provide exceptional temperature control with added security of over temperature protection. These incubators serve the purpose for most biological analysis, research and general laboratory applications.

- ALLCOLD Refrigeration Technology: Auto defrost, multiple security system, long time running, environmental protection, high efficiency and energy saving, Auto-defrost function, Imported DuPont SUVA R134 a environmental refrigerant.

- ALLIGENT Humidification System: Automatic water intake, automatic water level control, persistent

- ALLFLOW Perfect Air Current Cycling: Perfect forced convection, maximum number of working room, minimum temperature recovery time after the opening, world famous axial fan, perfect air current design.

- ALLSENS Programmable PID Control: Adaptive PID controller precisely controls the temperature and humidity, prevent temperature soaring, keep working room temperature stable and uniformity.

Specification

Features

Applications

| Capacity | 400 L |

| Temperature Range | 0-65°C |

| Ambient Temperature | 10~30°C |

| Temperature Fluctuation | ±0.5 at 10-40°C |

| Temperature Uniformity | ±1.5 |

| Temperature Resolution | 0.1°C |

| Relative Humidity | Below 70% |

| Sterilization Function | No |

| Humidity Range | 40-95 %RH |

| Humidity Fluctuation | ±2 RH |

| Interior | SUS304 Stainless Steel Materials |

| Heat insulator material | Imported environmental protection material |

| Timer Range | 0-99 hrs, 0-9999 min |

| Convection Mode | Forced Convection |

| Internal Dimension | 601Wx639Dx1052H mm |

| Exterior Dimension | 745Wx930Dx1700H mm |

| Package Size | 815x1090x1907 mm |

| Shelves/Trays | 4 |

| Weight | 158.5/188 kg |

| Power | 1350 W |

| Power Supply | Single phase AC220 V/50 Hz |

- ALLCOLD Refrigeration Technology: Auto defrost, multiple security system, long time running, environmental protection, high efficiency and energy saving, Auto-defrost function, Imported DuPont SUVA R134 a environmental refrigerant.

- ALLIGENT Humidification System: Automatic water intake, automatic water level control, persistent

- ALLFLOW Perfect Air Current Cycling: Perfect forced convection, maximum number of working room, minimum temperature recovery time after the opening, world famous axial fan, perfect air current design.

- ALLSENS Programmable PID Control: Adaptive PID controller precisely controls the temperature and humidity, prevent temperature soaring, keep working room temperature stable and uniformity.

- Excellent Imported temperature and humidity Sensor.

- Efficient isolation Design

Quality Control, Medicine Processing Industries, Research, Pharmaceuticals, Microbial Culturing

Operating Manual for BIGP-613

1. Application

2. Performance

3. Technical parameters

4. Components

5. Equipment installation

6. Installation

7. Preparation before Operation

8. Panel instruction

9. Operation and usage

10. Inner technical parameters

Parameter-1

Temperature parameter-2

Humidity parameter -3

Compressor parameter -4

parameter -5

11. Specification

12. Wiring layout

BIGP-613 -Series

1. Application

• BIGP-613 constant temperature and humidity chamber is thermostatic equipment with heating, cooling and humidification function, highly precise and advanced. Widely used in plant cultivation, breeding test, bacteria, mold, microbial cultivation & preservation, BOD determination and so on. Which is also used in biological genetic engineering, medical treatment, health and epidemic prevention, medical test, agriculture and animal husbandry, aquatic and other scientific research institutions.2. Performance

Constant temperature and humidity transfers actual temperature and humidity detected from temp. sensor and humidity sensor into signal. Through microcomputer control to heater towards required temperature and humidity.3. Technical parameters

1. volume:150L.250L.400L2. Temp range :0~65℃;(with humidity5~50℃);

3. Temp fluctuation range :±0.5℃(10℃~40℃);

4. Temp uniform range :±1℃(10℃~40℃);

5. Humidity range :40-95%RH(10℃~40℃ );

6. Humidity fluctuation :±2%;

7. Power voltage : 220V/50Hz;

8. Input power:1080W(150L) 1100W(250L) 1350W(400L);

9. Working ambient :ambient temp 10~30℃ relative humidity70% below ;

0. refrigeration:R134;

1. Equipment class:class I

Notice :this equipment has low temperature auto-defrost function, it is normal that there is fluctuation when low temperature auto-defrost

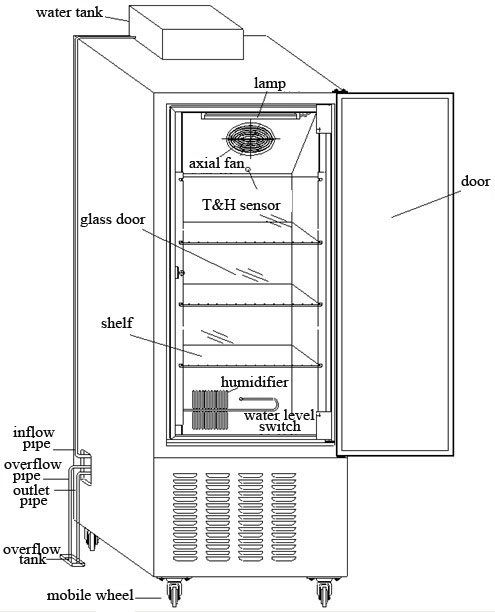

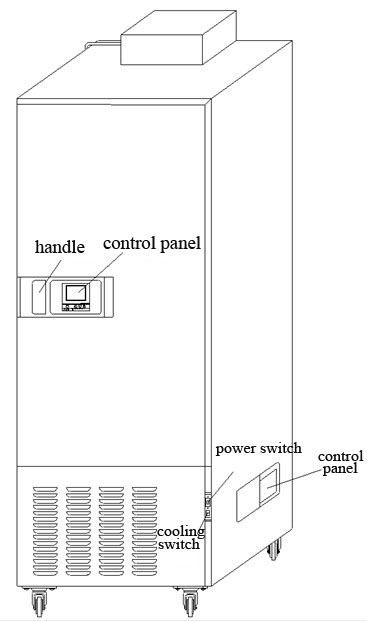

4. Components

Structure

5. Equipment installation

In order to make sure the equipment can run normally, please place equipment as following:Attention: ambient temperature 10~30℃ ;relative humidity less than 70%

1. Avoid exposure to the sunlight.

Do not place it in direct sunlight, or it won’t reach predicted performance

2. An efficient vent place

If you operate this equipment in a narrow and concealed room, it may lead to

over-heating and malfunctioning. Minimum safe distance between equipment and wall is 10CM

d) Keep away from heat source

Don’t install the equipment near heating source. External excess heat will affect performance of the equipment and may cause malfunctioning

e) Flat and firm ground

Make sure to install it in flat and firm ground. Uneven surface or leaning installation may damage equipment or injure people. Proper installation can avoid shaking and noise

f) Avoid humid place

Install the equipment in a place where humidity is less than 70%. Otherwise it may cause short-circuit or electric shock. Warning

Do not place this equipment outdoors. If it exposed in the rain, it may cause short-circuit and electric shock.

Do not place equipment in humid environment or a place with dripping water. Otherwise it may cause short-circuit or electric shock

• Avoid place with flammable or corrosive gas.

Do not place equipment near flammable materials and volatile substance. Otherwise it may cause explosion or fire. Do not place equipment in the place where has acidic and corrosive gas, or corrosion will cause short-circuit, electric shock or equipment damage.

6. Installation

1. UnpackingRemove packing materials ,open the door for ventilation. Please use neutral detergent to clean if the shell and panel is dirty. then wipe with wet cloth and at last with dry and clean cloth

2. level equipment

Fix equipment with the front brake-wheel after installation in case equipment moves

3 Earthing

Warning

Please use power socket that has protective conductor terminal in case of electric shock. If it is not connected, has to install protective conductor terminal by licensed technician.

Do not connect protective conductor terminal through gas, water pipe, telephone line or lighting arrester which will cause electric shock.

4. Idle equipment

Before setting equipment aside , empty water in the humidifier and remove internal, moisture thoroughly. Be sure the inner chamber is dry and cool before closing the door .

5. Move equipment

Before moving equipment ,empty water in the humidifier .or it will cause creepage or electric shock because of overflow water or splashed water

7. Preparation before Operation

When equipment running in the first time, please operate as below:1.Take out the shelves or other accessories

2.Clean the inner wall with gauze which is soaked by alcohol and then use dry cloth to wipe-dry

3.Put the shelves into inner chamber according to your experiment of requirement

4.Put water tank on the top of equipment before using ,please connect water pipe with water inlet and overflow outlet which in the left of equipment (refer to component picture ) ,and put storage water tank under the overflow pipe and water outlet for spare use

5.Pour enough pure water into water tank

Notice :don’t use NaCl or other Halide solution to clean equipment ,or it will cause rust

8. Panel instruction

Symbol definition

T1: appointment: its twinkling means the controller enter into appointment mode, meanwhile, the (2) area displays appointment time (count down).

T2: heat: its lightening means heater working.

T3: refrigeration: its lightening means air compressor working.

T4: humidity: its lightening means humidifier working.

T5: daytime: its lightening means the machine is in daytime mode.

T6: night: its lightening means the machine is in night mode.

T7: timer: its twinkling means the timer working, meanwhile, the (2) area displays setting time(count down).

T8: lack of water: its lightening means lack of water, its twinkling means low-level water alarm.

T9: door open: its lightening means the door is open

T10: alarm: its lightening means temperature or humidity alarm; its twinkling means low-temperature or high-temperature protection.

T11: screen lock: its lightening means screen is locked, one can not change any setting value before unlock it.

T12: watering: its lightening means water pump working.

T13: defrosting: its lightening means the defrosting system working.

T14: valve: its lightening means valve working.

T15: illumination/sterilization: its lightening means lamp working, its twinkling means UV lamp working.

Display window

(1) Area: cycle/segment

(2) Area: timer or setting time

(3) Area: current temperature value

(4) Area: temperature setting value

(5) Area: current humidity value

(6) Area: humidity setting value

(7) Area: illumination or heating output power

Button definition

Screen lock: in normal mode, one can press on this button for 2 seconds to lock or unlock the screen.

Light: in normal mode, one can click on this button to switch on/off the lamp.

Set: in normal mode, one can click on this button to set value of temperature, humidity, illumination and others; or press on this button for 3 seconds to enter into inner parameters.

Shift: in setting mode, one can click on this button to shift digit position; in normal mode, one can click on this button to shift daytime or night mode; in programmable mode, one can click on this button to inquire cycles and segments.

Decrease/defrost: in setting mode, one can click on this button to decrease setting value; in normal mode, one can press on this button for several seconds to activate defrosting function.

Increase: in setting mode, one can click on this button to increase setting value

R/S: in normal mode, one can click or press on this button to start or stop the controller running.

9. Operation and usage

1. After power on, (3) area displays “PS”, (5) area displays “V01”, the buzzer beeps, and then ,after 2 seconds, the controller will enter into normal mode.2. Setting values: after clicking on set button in normal mode, symbols “TIME”and“SV” twinkle, one can modify the setting value (digit position twinkling), by shift, decrease, increase buttons, and one can shift to next group value by another clicking on set button. After modification, one can press on set button for 1 seconds to quit setting mode, the setting value will be saved automatically.

In programmable mode, segment value position twinkles after clicking on the set button. In this time, one can modify the segment number by decrease or increase button, and inquire setting value of time, humidity, temperature, and illumination in every segment.

In day/night mode, after clicking on set button, “DAY”symbol will twinkle, then, one can choose daytime or night mode by decrease or increase button, after another click on set button, one can inquire and modify every value of current mode, by increase and decrease buttons.

3. Setting of cycles and segments: in programmable mode or day/night mode, when the controller is in stop situation, after pressing on “set” button for 3 seconds, the (1) area displays “Lc”, the (2) area displays “0”, users can adjust the password to 3 by increase/decrease buttons, so that the controller enters cycle and segment setting mode. PRO----total program number, CYC----total cycle number.

4. fault reminder:

Temperature alarm:symbol“℃”flashes quickly when upper deviation occurs,symbol“℃”flashes slowly when lower deviation occurs;

Humidity alarm: symbol“%RH”flashes quickly when upper deviation occurs,symbol“%RH”flashes slowly when lower deviation occurs;

If the (3) area displays “---”,user should check the sensor and controller.

10. Inner technical parameters

In normal mode, press on set button for 3 seconds, the (1) area will display “Lc”,users can input right code and click on the set button one more time to enter different inner parameters. After adjusting the value of parameters, please do remember to press on the set button for another 3 seconds to quit setting mode.the value adjusted will be saved automatically.Parameter-1

| symbol | name | function | (range) factory value |

| Lc | password | when“Lc=9”,this parameter group can be inquired and adjusted. | 0 |

| U1 | Running mode | 0:constant value mode; 1:day/night mode, 99 cycles; 2:program mode, 1~30 segments,0~99 cycles | (0~2) 0 |

| U2 | Power down protection | 0:no operation;1:begin with the first segment; 2: restart from the power down time | (0~2) 0 |

| U3 | Timer adjust | Modification value=【display value(s)-real value(S)】*10 real value(m)。 | (-999~999) 0 |

| U4 | Timing unit | 1:minute 0~9999; 2:hour 0~9999 | (1~2) 1 |

| U5 | Timing temperature point | When U5= display temperature-setting temperature, timer starts to work | (0~10.0℃ 0 |

| U6 | Timing humidity point | When U6= display temperature-setting temperature, timer starts to work | (0~50.0%) 0 |

| U7 | 【R/S】time | Press on the【R/S】for U7 time to run/stop | (0~10s) 0 |

| U8 | Lock screen time | Lock screen time, 0 means unlock | (0~300s) 0 |

| U9 | Reminder time (stop) | The buzzer beeps for U9 seconds when running stop. 0 means buzzer beeps continuously | (0~300s) 0 |

| UA | Illumination time | Illumination time, 0 means manual operation | (0~9999min) 0 |

| Ub | address | Communication address | (1~16) 1 |

Temperature parameter-2

| symbol | name | function | (range) factory value |

| Lc | password | when“Lc=103”,this parameter group can be inquired and adjusted. | 0 |

| TH | Temperature upper deviation alarm | when“display value>set value+TH”,upper alarm occurs, heating and humidity cut down User can click on any button to stop buzzer | (0~20.0℃) 5.0 |

| TL | Temperature lower deviation alarm | when“display value<set value+TH”,lower alarm occurs, heating and humidity cut down User can click on any button to stop buzzer | (-50.0~0℃) 0 |

| Tb | Zero adjust(low temperature) | Tb = real temperature -display temperature | (-99.9~99.9 0 |

| TA | Full adjust(high temperature) | TA = 1000 *( real temperature - display temperature)÷display temperature | (-999~999) 0 |

| TP | Proportional band | Adjustment of proportional function. | (0.1~50.0) 8.0 |

| TI | Integration time | Adjustment of integration function | (1~2000s) 500 |

| TD | Differential time | Adjustment of differential function. | (0~2000s) 200 |

| TT | Heat period | Heating control period | (1~60s) 5 |

| Tc | Low temperature cutoff | Heating cutoff point. | (-2.0~0℃) -0.5 |

| To | Heat power | Heating max power percentage | (0~100%) 100 |

Humidity parameter -3

| symbol | name | function | rangefactory value |

| Lc | password | when“Lc=203”,this parameter group can be inquired and adjusted. | 0 |

| HH | Humidity upper deviation alarm | when“display value>set value+TH”,upper alarm occurs, heating and humidity cut down User can click on any button to stop buzzer | (0~50.0%) 20.0 |

| HL | Humidity lower deviation alarm | when“display value<set value+TH”,lower alarm occurs, heating and humidity cut down User can click on any button to stop buzzer | (-50.0~0%) 0 |

| Hb | Zero adjust(low humidity) | Tb = real humidity - display humidity | (-99.9~99.9%) 0 |

| HA | Full adjust(high humidity) | TA = 1000 *( real humidity - display humidity)÷display humidity | (-999~999) 0 |

| HP | Proportional band | Adjustment of proportional function. | (0.0~90.0) 10.0 |

| HI | Integration time | Adjustment of integration function | (1~999s) 200 |

| Hd | Differential time | Adjustment of differential function. | (0~999s) 30 |

| HT | Heat period | Heating control period | (0~60s) 5 |

| Hc | Low temperature cutoff | humidity cutoff point. | (-50.0~50.0%) 0.0 |

| Ho | humidity power | Humidity max power percentage | (0~100%) 100 |

Compressor parameter -4

| symbol | name | function | (range) factory value |

| Lc | password | when“Lc=109”,this parameter group can be inquired and adjusted. | 0 |

| C1 | Forbidden compressor | when“temp.measured value≥C1”, the compressor must not work. | (0~100.0%) 80.0 |

| C2 | Not start compressor | when“temp.setting value≥C2”,Start the compressor only once when the temperature measuredt value is higher than the temperature setting value. | (0~100.0%) 42.0 |

| C3 | Constant temp.open point | when“temp.setting value≤C3”,compressor works in balance mode | (-15~100℃) 0.0 |

| C4 | Costant humi open point | when“humi.setting value≤C4”,compressor works in balance mode. | (0~100%) 10 |

| C5 | Working mode | (0~3) 3 | |

| C6 | Compressor start delay | (0~600s) 180 | |

| C7 | Defrost mode | (0~2) 0 | |

| C8 | Defrost interval 1 | (0~9999min) 0 | |

| C9 | Defrost interval 2 | (0~9999min) 0 | |

| CA | Defrost interval 3 | (0~9999min) 0 | |

| Cb | Defrost time 1 | (0~200s) 0 | |

| Cc | Defrost time 2 | (0~200s) 0 | |

| Cd | Defrost time 3 | (0~200s) 0 | |

| CE | Solenoid valve function | (-2~1) -2 | |

| CF | Solenoid valve start | (0~50.0℃) 0 |

parameter -5

| symbol | name | Function | range) factory value |

| Lc | password | “Lc=209” this parameter group can be inquired and adjusted. | 0 |

| P1 | Illumination control | 0:no illumination 1:3 levels 2:4 levels 3:5 levels 4:6 levels 5:10 levels | (0~5) 4 |

| P2 | Humidity set | 0:no humidity;1:humidity display only;2:humidity can be controlled。 | (0~2) 2 |

appointing set -5

| symbol | name | function | (range) factory value |

| Lc | password | When”Lc=36” this parameter group can be inquired and adjusted. | 0 |

| AP | Appointing set | 0:shut off appointing fuction; 1:start appointing fuction | (0~1) 0 |

| T_ | Appointing time | When AP=1, the timer can be set. | (0~9999min) 0 |

11. Specification

| Name | BIGP-613 series constant climate chamber |

| Model | BIGP-613 |

| Exterior Dimension | 745×930×1700 |

| Interior Dimension | 601×639×1052 |

| Effective volume | 392L |

| Shell | Cold-roll steel sheets with powder coat treatment |

| Inner shell | SUS304 mirror stainless steel |

| Door | With heating preservation design |

| inner door | Tempered glass (5mm) |

| Shelf | Carbon steel with chromeplate |

| Heating preservation system | Polystyrene foam |

| Cooling system | R134a(without fluorine), Green, environmental protection, energy saving |

| Heating system | Use finned high efficient heating tube |

| Fan | Axial flow fan |

| Humidity System | Use electric heating to control humidify stable |

| Temp. sensor | Sumsung Temp. sensor PT100 |

| Humidity sensor | Cybersen humidity sensor |

| Display | LCD(Liquid Crystal Display),China Display |

| Warning system | Temp. & humidity upper limit warning with screen prompt; Temp. & humidity sensor fault warning with screen prompt |

| Weight | 145kg |

| Optional Accessories | Switch port ,Portable printer |

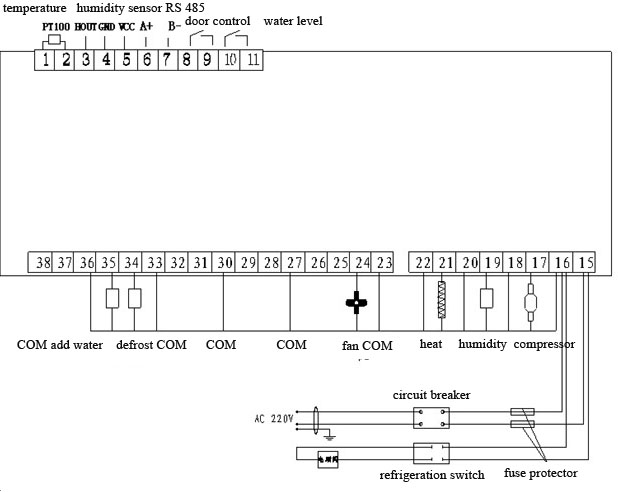

12. Wiring layout

BIGP-613 -Series

constant temperature and humidity chamberPacking List

| No. | Name | Quantity | Note |

| 1 | product | 1 | |

| 2 | manual | 1 | |

| 3 | shelf | 3(150L) 4(250L) 4(400L) | |

| 4 | storage water tank | 1 | |

| 5 | water tank | 1 | |

| 6 | Inlet pipe | 1 | |

| 7 | outlet pipe | 1 |