Home Spectrophotometer

Spectrophotometer

Double Beam UV Visible Spectrophotometer

Double Beam UV Visible Spectrophotometer

Double Beam UV Visible Spectrophotometer BSDBU-201-C

Double Beam UV Visible Spectrophotometer BSDBU-201-C

Spectrophotometer

Spectrophotometer

Double Beam UV Visible Spectrophotometer

Double Beam UV Visible Spectrophotometer

Double Beam UV Visible Spectrophotometer BSDBU-201-C

Double Beam UV Visible Spectrophotometer BSDBU-201-C

Double Beam UV Visible Spectrophotometer BSDBU-201-C

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Designed to conserve benchspace, our product offers the measurement range of 190-1100nm at bandwidth of 1.8nm and 2nm. Engineered for a wide range of applications, our systems provide dependable performance and reliable results. It produces the photometric range of -0.3 to 3 A; 0-200 %T and photometric accuracy of ±0.2%T which makes it suitable for various quantitative assays.

- Dual optical path, dual beam optical system, dual detector, using high performance imported grating, lower stray light, stronger stability, reliability, more accurate analysis

- use 10 " touch screen, built-in 32G memory, support Bluetooth connection network

- powerful data analysis function, internal computer of the host, can input calibration curve, can independently complete photometric measurement, quantitative measurement, spectral scanning, dynamics, DNA/ protein testing, multi-wavelength testing and data printing functions

- Adopt the optical system suspension design, the whole optical path is independently fixed on the 16mm thick aluminum deformation-free base, the deformation of the bottom plate and the vibration of the outside have no impact on the optical system, thus greatly improving the stability and reliability of the instrument

Specification

Features

ApplicationsAccessories

| Wavelength Range | 190-1100 nm |

| Wavelength Accuracy | ±0.1nm(D2 656. 1 nm) |

| Wavelength Repeatability | ≤0.1 nm |

| Spectral Bandwidth | 1.8 nm |

| Photometric Range | 0-200%T, -0.3--3A, 0-9999C |

| Photometric Accuracy | ±0.2T (0-100%T) |

| Photometric Repeatability | ≤0.05 %T(0-100%T) |

| Stability | ±0.004A/h at 500 nm |

| Baseline Flatness | ±0.001A |

| Stray Light | 0.03 %T220 nm, 360nm |

| Light Source | Tungsten and Deuterium Lamp |

| Detector | Silicon Photodiode |

| Software | USB |

| Gross Dimension (W/D/H) | 630x430x210 mm |

| Display | 800x480 touch screen |

| Noise | ±0.0004 A |

| Weight (Net/Gross) | 28 kg |

| Power Supply | 220V/50Hz 110V/60Hz |

- Dual optical path, dual beam optical system, dual detector, using high performance imported grating, lower stray light, stronger stability, reliability, more accurate analysis

- use 10 " touch screen, built-in 32G memory, support Bluetooth connection network

- powerful data analysis function, internal computer of the host, can input calibration curve, can independently complete photometric measurement, quantitative measurement, spectral scanning, dynamics, DNA/ protein testing, multi-wavelength testing and data printing functions

- Adopt the optical system suspension design, the whole optical path is independently fixed on the 16mm thick aluminum deformation-free base, the deformation of the bottom plate and the vibration of the outside have no impact on the optical system, thus greatly improving the stability and reliability of the instrument

- With powerful storage function, the instrument can be directly connected to the printer for A4 format data and graph printing

- With automatic startup verification and system positioning functions, to repair the deviation caused by long-term application

- Data can be exported to U disk

Most suitable for quantitative determination assays and toxicological assays in environmental, industrial, pharmaceutical fields.

| Accessory Code | Name | Unit |

| 3000706027 | 1 cm glass cuvette | 4 pcs |

| 3000706028 | power cord | 1 pcs |

| 3000706029 | dust cover | 1 pcs |

| 3000706030 | 1 cm quartz quvette | 2 pcs |

Operating Manual for BSDBU-201-C

1.Introduction

1.1 Measurement Principle

1.2 Performance and features

1.3 Application

1.4 Technical Specifications

1.5 Packing List

1.6 Symbols and Notices

1.7 Product Design

2 Installation

2.1 Unpacking

2.2 Requirements

2.3 Installation

3. Instrument Operation

3.1 Power On & Self-diagnosis

3.2 Multi- cell Holder Management

3.3 Photometric Measurement

3.4 Quantitative Analysis

3.5 Kinetic Analysis

3.6 Wavelength Scan

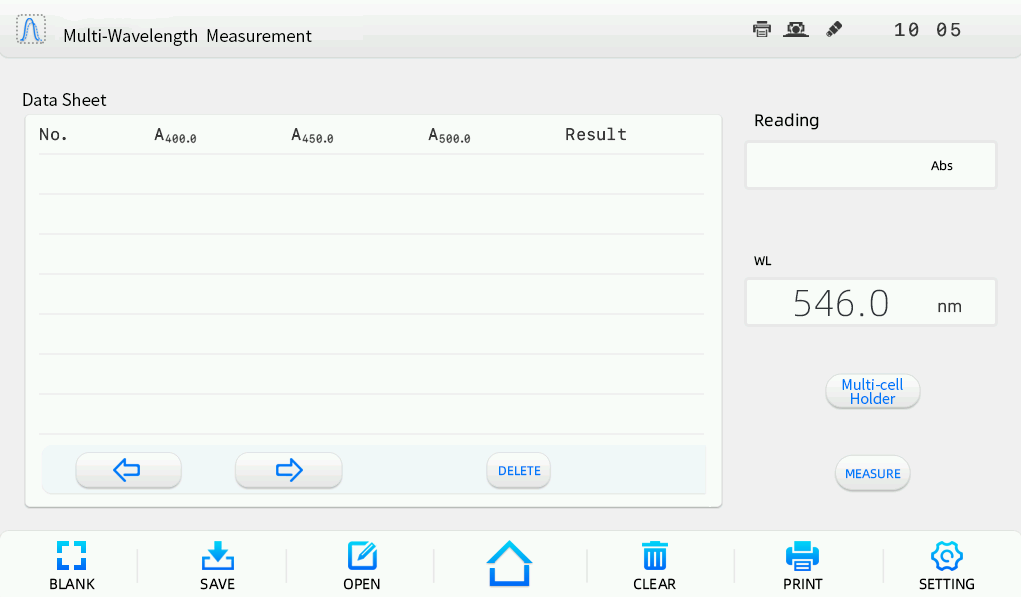

3.7 Multi-wavelength Measurement

3.8 DNA/Protein Measurement

3.9 System Settings

4. Maintenance

5. Troubleshooting

1.Introduction

1.1 Measurement Principle

The measurement principle of spectrophotometer is based on the Lambert-Beer law. When the beam of collimated monochromatic light passes through a certain uniform colored solution, the absorbance of the solution is directly proportional to the concentration of the solution and the optical path. And it supplies basis for the quantitative analysis. The Lambert-Beer law is described as following formula:A=k × b × C

A — Absorbance of the analyte

k — The absorption coefficient

b — The path length in cm

c — The analyte concentration

1.2 Performance and features

The performance and features of BSDBU-201-C series UV/Vis Spectrophotometer are as following:- Low stray light and high resolution optical system enables accurate measurement with good stability and reproducibility.

- Novel technologies organically combine light, machine, electricity and microcomputer, together with scientific design, enables the instrument stability approaching or reaching a high level.

- 10 inches colorful capacitive touch screen, guarantees the touch point more precise, and enables much high sensitivity and excellent stability.

- High resolution with 1024 × 600, with fast running speed and large capacity.

- Interactive human machine interface enables the operation interface much friendly, and the operation is convenient.

- Powerful function of system settings, measurement functions such as photometric measurement, quantitative analysis, kinetic analysis, wavelength scan, multi-wavelength measurement, and DNA/protein measurement are available without on-line operation.

- Available for cell position control with the accessory of automatic cells holder.

- It provides unlimited storage. Data reading and writing are quite conveniently. USB storage is also available.

- Connecting to designated model of inkjet printer is available and with direct output of A4 paper report, enables the print report to be much neat and clear.

1.3 Application

The UV/Vis spectrophotometer is a common analytical instrument in chemistry laboratory, and it is widely used in pharmaceutical, medicine and health, chemical, energy, machinery, metallurgy, environmental protection, geology, food, biology, materials, agriculture, forestry, fisheries and many other industries. It’s also applied in the fields of higher education, metrology, teaching and scientific research, and quality control, raw material and product inspection during production process.BSDBU-201-C series is a double beam UV/Vis spectrophotometer equipped with touch screen, thanks to its stable performance, accurate measurement and powerful functions, it has strong advantages in various fields of scientific research and quality control.

1.4 Technical Specifications

| Model | BSDBU-201-C |

| Wavelength Range | 190nm -1100nm |

| Optical System | Double beam |

| Light Source | Tungsten lamp and Deuterium lamp |

| Display | 10-inch color touch screen |

| Photometric Range | 0 - 200%T,-0.3A - 3A, 0 - 9999C |

| Control Mode | Stand-alone system PC controlled ( PC software is optional) |

| Data Output | USB Port Bluetooth (Optional) |

| Dimensions | 610mm × 410mm × 230mm |

1.5 Packing List

| No. | Item | Unit | Qty | Note |

| 1 | BSDBU-201-C series UV/Vis Spectrophotometer | set | 1 | |

| 2 | Power Cord | pc | 1 | |

| 3 | Quartz Cell | kit | 1 | 2 pcs/kit |

| 4 | Glass Cell | kit | 1 | 4 pcs/kit |

| 5 | Dust Cover | pc | 1 | |

| 6 | User’s Manual | pc | 1 | |

| 7 | Quality Certificate | pc | 1 | |

| 8 | Packing List | pc | 1 |

1.6 Symbols and Notices

:HIGH VOLTAGE.

:HIGH VOLTAGE.Caution the danger of high voltage, and be careful of the risk of electric shock.

: HOT SURFACE

: HOT SURFACECaution the hot surface, and avoid the risk of burn.

: ULTRAVIOLET RADIATION

: ULTRAVIOLET RADIATIONCaution the emission of UV radiation.

: NOTICE.

: NOTICE.Pay attentions to the notice.

: SPECIAL EXPLANATION.

: SPECIAL EXPLANATION.Pay additional attention to the special explanation.

1.7 Product Design

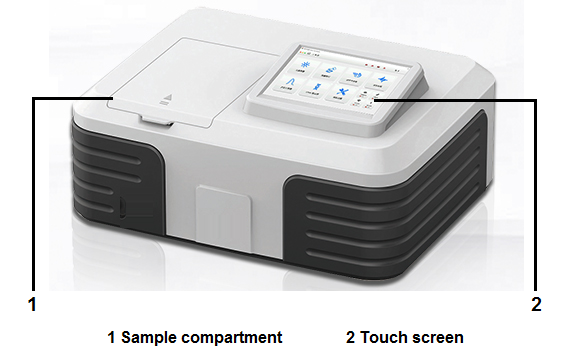

The profile of BSDBU-201-C series UV/Vis Spectrophotometer is shown in Fig. 1-1:

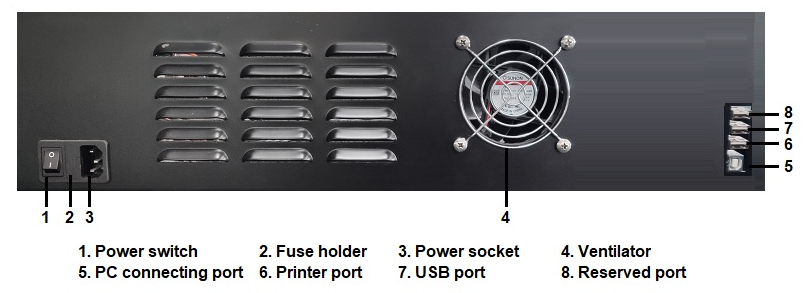

The back side of BSDBU-201-C series UV/Vis Spectrophotometer is shown in Fig. 1-2:

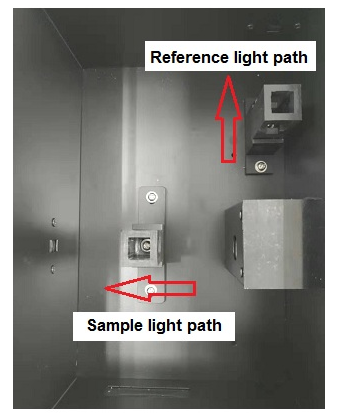

The compartment configuration of BSDBU-201-C series UV/Vis Spectrophotometer is shown in

Fig. 1-3

2 Installation

2.1 Unpacking

Please check the outer packing and make sure it is intact before unpacking. Then, check the instrument and accessories according to packing list and ensure they are completely well. If any questions, or anything lost or damaged, please contact us in time.2.2 Requirements

A laboratory should be prepared, and following requirements should be met:1) The instrument should be placed in a dry room, and the room temperature should be in the range of 5 ℃- 35 ℃. The relative humidity should be no more than 85%.

2) Power supply requirement: The rated voltage should be 220V ± 22V AC (110V ± 11V AC is also optional), the frequency should be 50Hz (60Hz is also optional). Well-grounded is also required. An electronic AC regulator or AC regulator with the power more than 1000W is suggested to enhance the anti-interference performance of the instrument.

3) Other requirements: Be far away from strong or continuous vibration. Neither setting up the instrument near electromagnetic field, nor exposing the instrument to direct sunlight or the radiation of heaters. It should be free of dust, as well as corrosive vapors. The instrument should be placed on a stable workbench. And for well cooling and ventilation, a clearance of at least 15 cm to the wall is suggested.

2.3 Installation

Install the instrument as following steps:Step 1: Place the instrument onto a stable bench after unpacking.

Step 2: Connect the power cord to the instrument. If a printer is equipped, connect the power cord of the printer and connect the instrument to the printer with the communication cable.

3. Instrument Operation

Before switching on the device, make sure all connections working well. The power supply should be well-grounded and meet related requirements, neither sample in the sample compartment nor any other blocks in the light path.3.1 Power On & Self-diagnosis

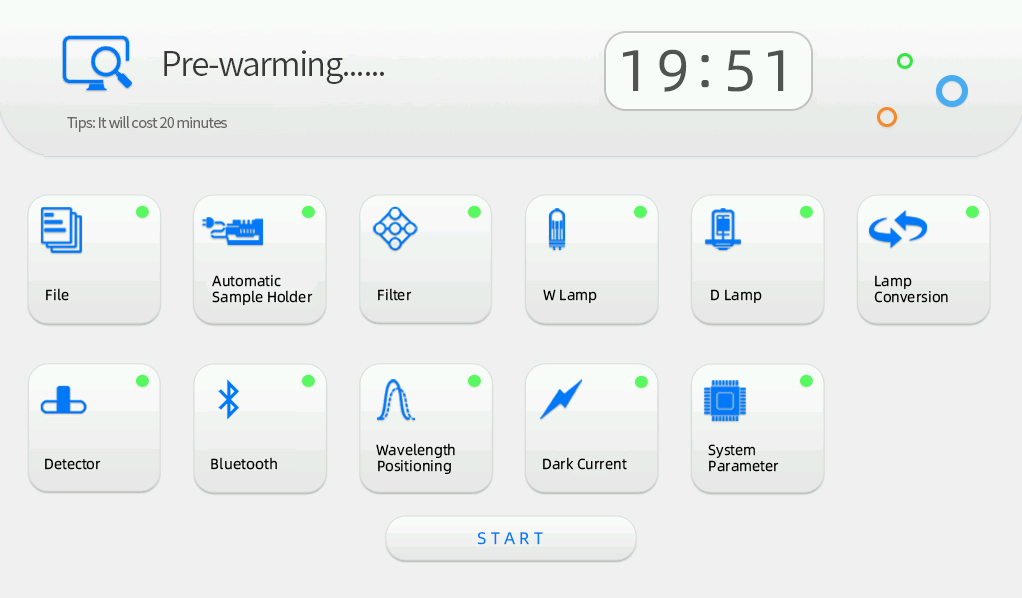

1. Power On & Self-diagnosisSwitch on the device, it will proceed self-diagnosis. (Fig. 3-1). System will automatically diagnose the file, automatic sample holder, filter, tungsten lamp, deuterium lamp, lamp conversion, detector, Bluetooth, wavelength positioning, dark current, system parameters, and so on.

There is a status indicator lamp beside each self-diagnosis item, and it will turn green when the item passes in the self-diagnosis process. If any item is fail, the system will automatically give buzzing alarm, and the status indicator lamp will turn red at the same time. However, it will continue the self-diagnosis process.

There is a status indicator lamp beside each self-diagnosis item, and it will turn green when the item passes in the self-diagnosis process. If any item is fail, the system will automatically give buzzing alarm, and the status indicator lamp will turn red at the same time. However, it will continue the self-diagnosis process. Please don’t open the lid of the sample compartment during the self-diagnosis process. Please contact us in time if any self-diagnosis item fails. Or you can refer to Chapter 5 for troubleshooting.

Please don’t open the lid of the sample compartment during the self-diagnosis process. Please contact us in time if any self-diagnosis item fails. Or you can refer to Chapter 5 for troubleshooting.2. Pre-warming

Pre-warming starts after self-diagnosis finished, it takes around 20mins. The system will give buzzing alarm when pre-warming completed and enter the main operation interface automatically. Users also can click “

” to skip pre-warming.

” to skip pre-warming.3. Ready for operation

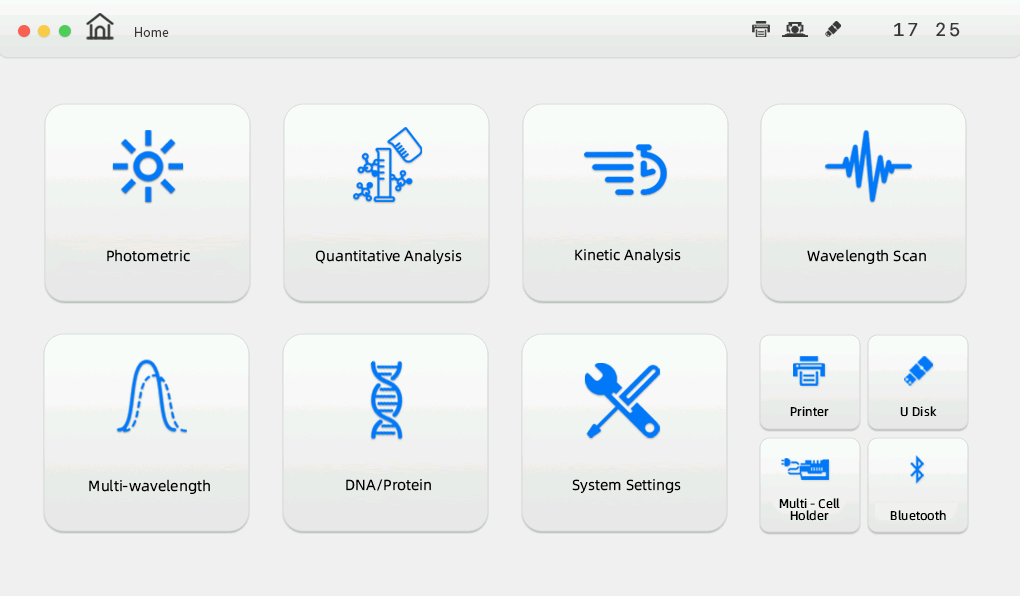

After pre-warming, device is ready for operation. (Fig. 3-2)

Functions such as photometric measurement, quantitative analysis, kinetic analysis, wavelength scan, multi-wavelength measurement, DNA/protein measurement and system settings are available, choose and click the icon accordingly to enter the related mode.

Fig. 3-2

4. Description of touch keys

The common touch keys are shown on the bottom panel after entering each operation interface, followings are the descriptions.

: For blank calibration, adjust to 0.000 Abs or 100.0 %T.

: For blank calibration, adjust to 0.000 Abs or 100.0 %T. : Save the data.

: Save the data. : Open the data.

: Open the data. : Exit the current interface, and return to the main interface.

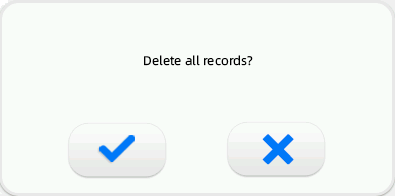

: Exit the current interface, and return to the main interface. : Delete all records displayed in the current measurement interface.

: Delete all records displayed in the current measurement interface. : Print the data.

: Print the data. : For measurement parameters setting.

: For measurement parameters setting. : Measure and record the data.

: Measure and record the data. : Delete the selected measurement data.

: Delete the selected measurement data. : Page up for data browsing or back to previous page.

: Page up for data browsing or back to previous page. : Page down for data browsing or go to next page.

: Page down for data browsing or go to next page.3.2 Multi- cell Holder Management

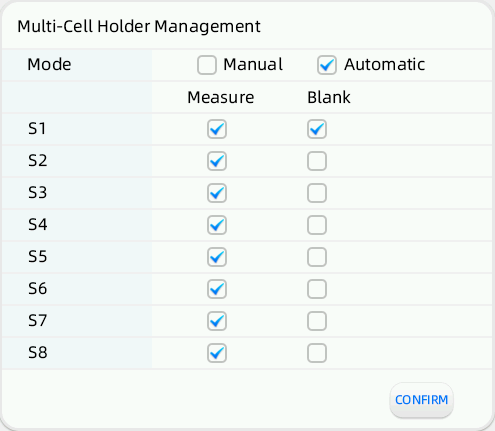

It’s only available for the instrument with the accessory of certain automatic cell holder.

It’s only available for the instrument with the accessory of certain automatic cell holder.With the accessory of certain automatic cell holder, automatic measurement can be performed with the functions of photometric measurement, quantitative analysis, multi-wavelength measurement, and DNA/protein measurement. Click the icon “” on the bottom right corner of the main interface to enter the multi-cell holder management interface (Fig. 3-3).

Fig. 3-3

Select the sample with the relevant cell position and click “

” to return to the main interface.

” to return to the main interface.3.3 Photometric Measurement

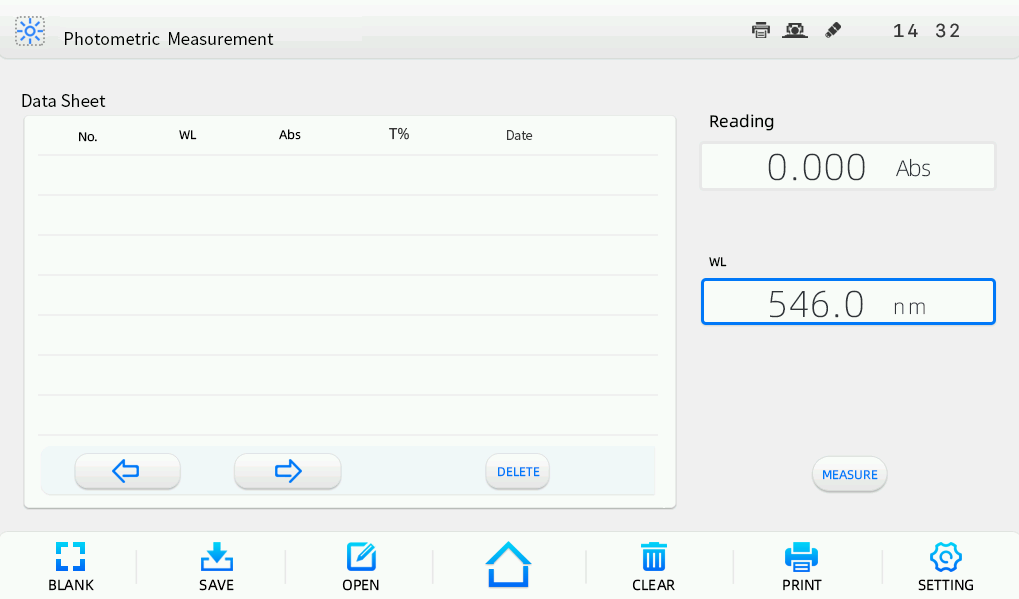

Absorbance, transmittance, and energy measurements under certain wavelength are available with photometric measurement. The measurement result also can be printed out.Click the icon “

” in the main interface to enter the photometric measurement interface (Fig. 3-4).

” in the main interface to enter the photometric measurement interface (Fig. 3-4).

Fig. 3-4

3.3.1 Photometric measurement

Following are the operation steps for photometric measurement.

Step 1 Enter the photometric measurement interface.

Click the icon “

” in the main interface to enter the photometric measurement interface.

” in the main interface to enter the photometric measurement interface.Step 2 Set the measurement wavelength.

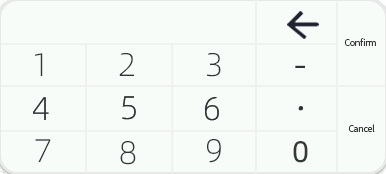

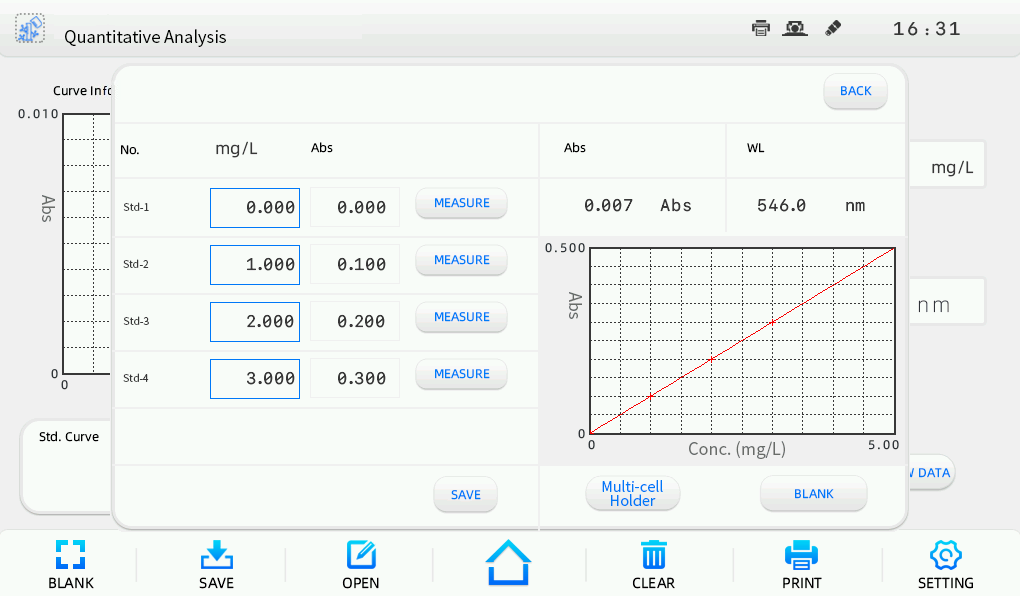

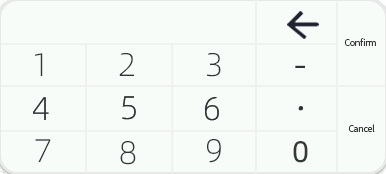

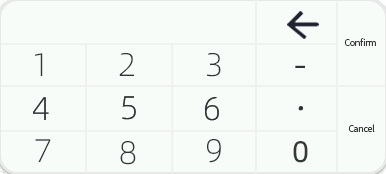

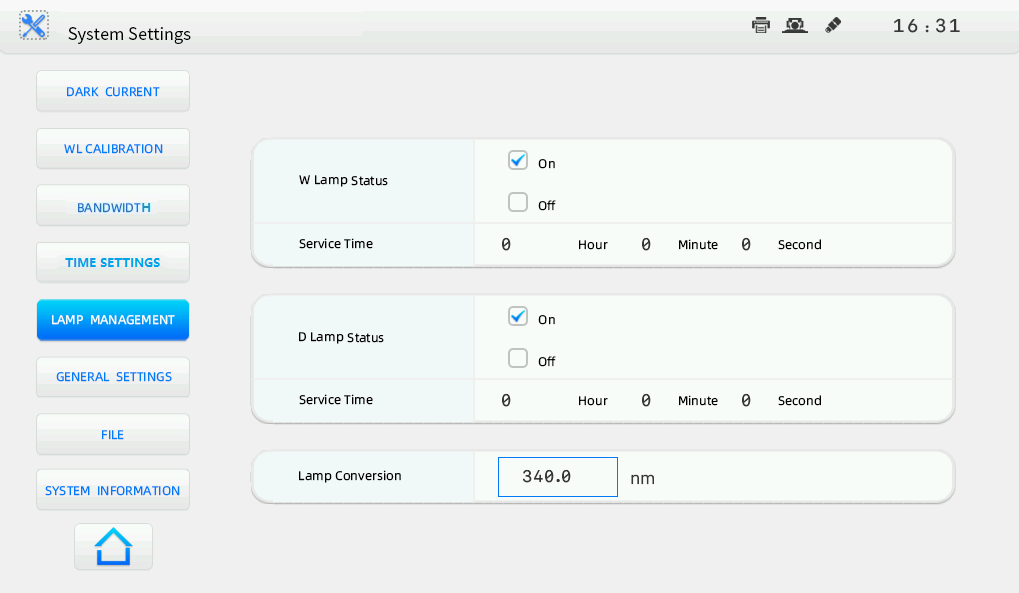

In the photometric measurement interface, click in the current wavelength display bar, a digital input window will pop up (Fig. 3-5). Click “

” after inputting the wavelength value, a prompt “Wavelength moving…” will be shown, and the instrument will move wavelength to the designated spot. User can click “

” after inputting the wavelength value, a prompt “Wavelength moving…” will be shown, and the instrument will move wavelength to the designated spot. User can click “  ” to exit the digital input window if wavelength setting is unnecessary.

” to exit the digital input window if wavelength setting is unnecessary.

Fig. 3-5

The valid wavelength range is between 190 nm and 1100 nm. If the input value is out of range, it is invalid, user needs to input again.

The valid wavelength range is between 190 nm and 1100 nm. If the input value is out of range, it is invalid, user needs to input again. User can click “” to clear the input when an error is found, then input the target value again. The touch key “” also works in the process of digital setting in subsequent operations.

User can click “” to clear the input when an error is found, then input the target value again. The touch key “” also works in the process of digital setting in subsequent operations.Step 3 Sample measurement.

Put the blank solution or reference solution separately into the reference light path and sample light path, and click “

”. The instrument will be adjusted to 0.000 Abs/100.0 %T under the certain wavelength. Then, replace the blank solution or reference solution with the sample solution only in the sample light path, click “

”. The instrument will be adjusted to 0.000 Abs/100.0 %T under the certain wavelength. Then, replace the blank solution or reference solution with the sample solution only in the sample light path, click “  ” and record the measurement result.

” and record the measurement result.3.3.2 Data processing

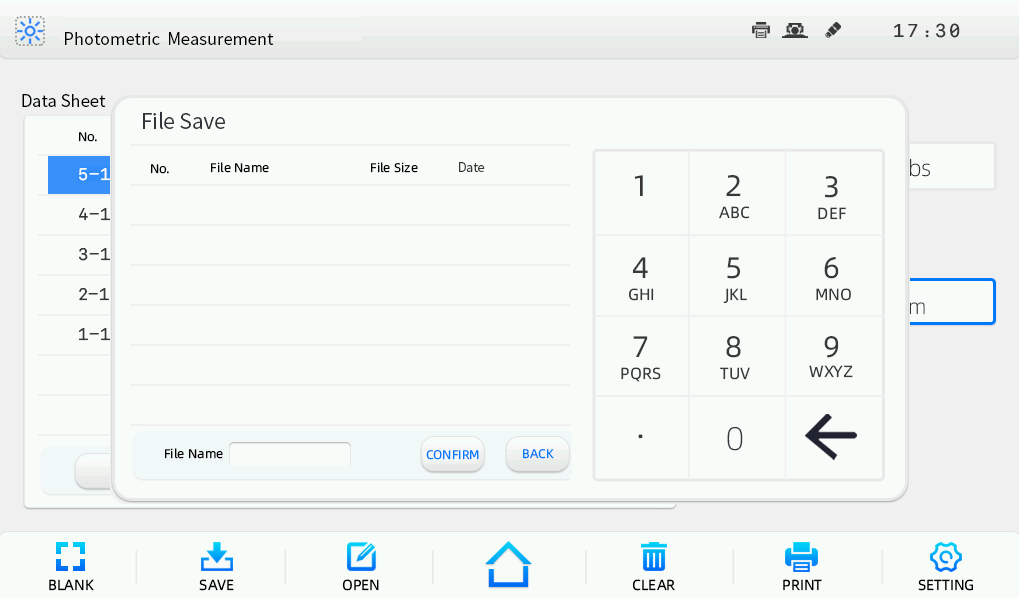

User can do data processing such as data saving, opening, printing and deleting after completing photometric measurements.

Data saving: User can save the data to the instrument memory by clicking “

”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-6), and click “

”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-6), and click “  ”, the file will be saved with the suffix of “.bas”.

”, the file will be saved with the suffix of “.bas”.

Fig. 3-6

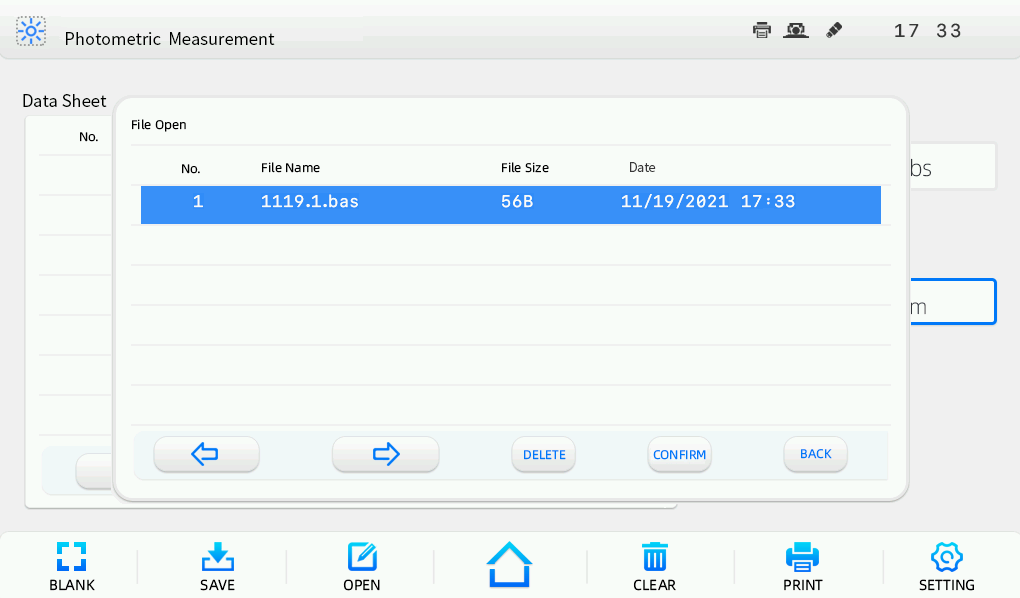

Data opening: Click “

” to enter the data opening interface (Fig. 3-7). User can select the file to be opened, and click “

” to enter the data opening interface (Fig. 3-7). User can select the file to be opened, and click “  ” to open the data.

” to open the data.

Fig. 3-7

Fig. 3-8

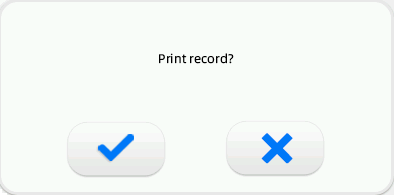

Data printing: User can print the data by clicking “

” if a printer is connected. A dialog box will pop up (Fig. 3-8), click “

” if a printer is connected. A dialog box will pop up (Fig. 3-8), click “  ” to print the data.

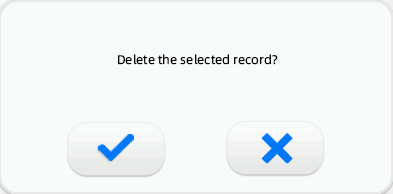

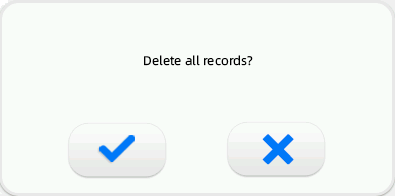

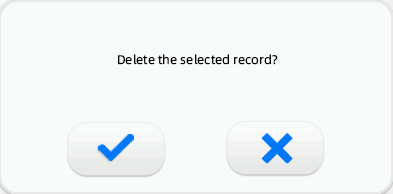

” to print the data.Data deleting: If a few data need to be deleted, user can select the row of the data and click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-9), click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-9), click “  ” to make sure the deleting. User also can click “

” to make sure the deleting. User also can click “  ” on the lower pane of the

” on the lower pane of theoperation interface to clear all the data displayed in the data sheet. A dialog box will pop up (Fig. 3-10), click “

” to make sure the deleting.

” to make sure the deleting.

Fig. 3-9

Fig. 3-10

Fig. 3-11

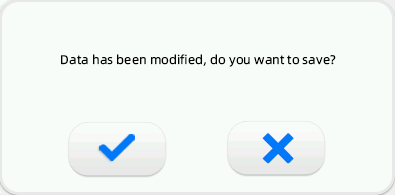

The delete operation only works for current display. The already saved data won’t lost. Before exit the current interface or returning to the main interface, a dialog box will pop up (Fig. 3-11). If the data after delete operation need to be saved, user can click “

The delete operation only works for current display. The already saved data won’t lost. Before exit the current interface or returning to the main interface, a dialog box will pop up (Fig. 3-11). If the data after delete operation need to be saved, user can click “  ” to save the updated data.

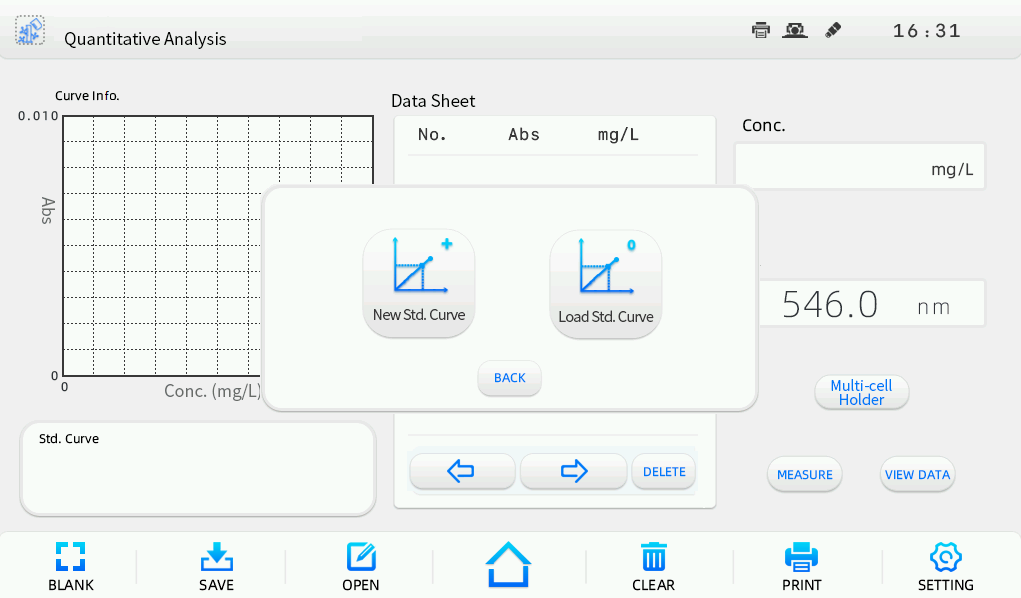

” to save the updated data.3.4 Quantitative Analysis

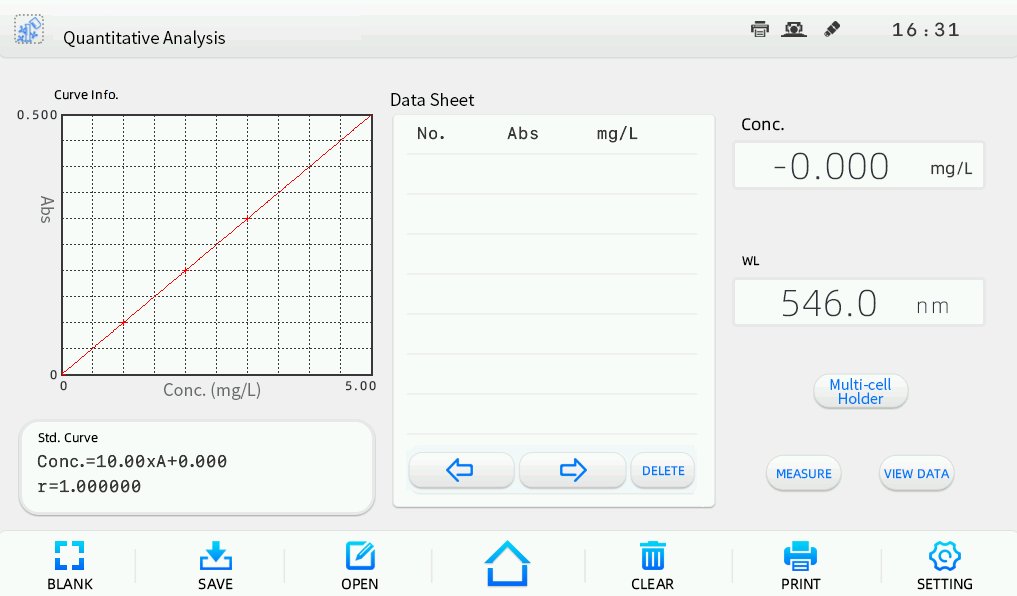

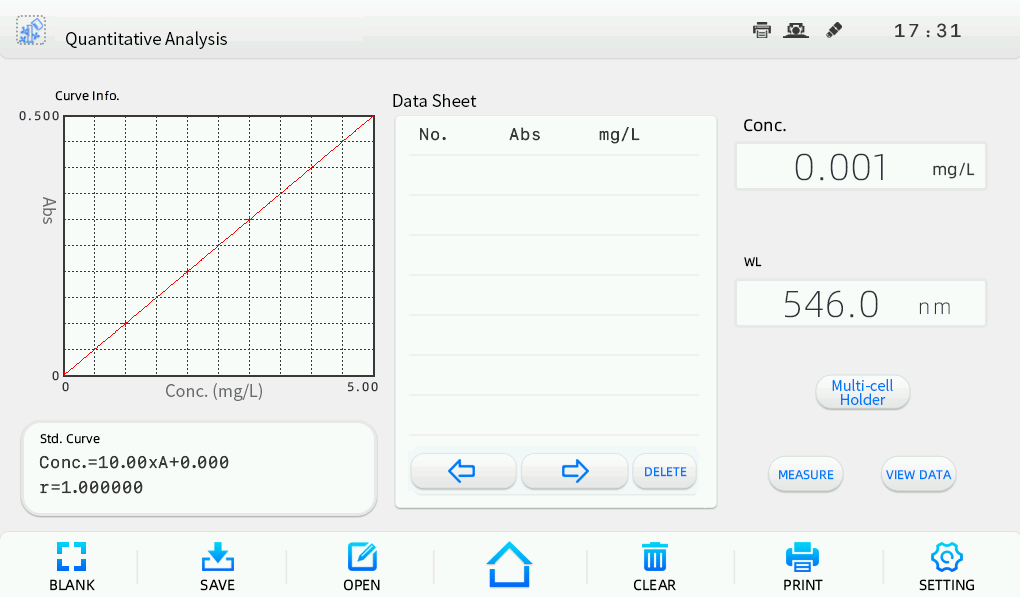

User can do sample measurement based on the method of standard curve in the quantitative analysis interface. User also can utilize coefficient method to do sample measurement.Click the icon “

” in the main interface to enter the quantitative analysis interface (Fig. 3-12).

” in the main interface to enter the quantitative analysis interface (Fig. 3-12).

Fig. 3-12

3.4.1 Standard curve measurement

The method of standard curve means to establish a calibration curve first, then measure the sample based on the calibration curve. The standard curve is also known as the standard calibration curve. Measure the absorbance of the sample and obtain the concentration that calculated according to the standard curve.

Different absorbance linearity range will cause different measurement error. The best absorbance linearity range is between 0.2 and 0.8.

Different absorbance linearity range will cause different measurement error. The best absorbance linearity range is between 0.2 and 0.8.1. Enter the interface of the standard curve method

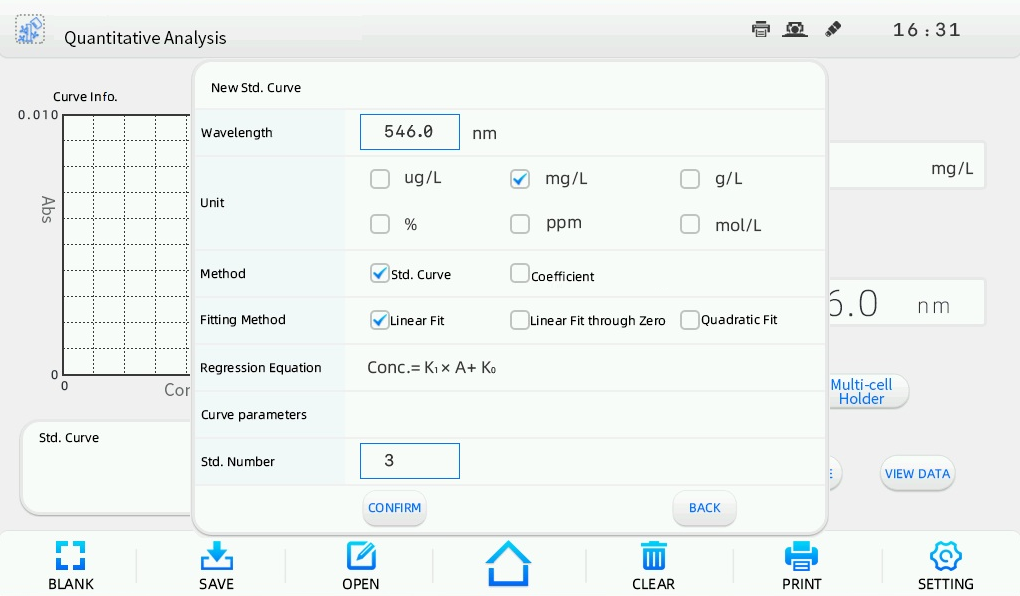

In the main quantitative analysis interface, click “” to enter the interface of the standard curve method (Fig. 3-13).

Fig. 3-13

2. Create standard curve

In the interface of the standard curve method, set the wavelength, select the method “Std. Curve” and certain fitting method, set the std. number, and click “

” to enter the standard curve measurement interface.

” to enter the standard curve measurement interface.Following are detail operation steps for standard curve measurement:

Step 1 Measurement wavelength setting.

Click in the wavelength column in the interface of the standard curve method, and a digital input window will pop up (Fig. 3-14). Click “

” after inputting the wavelength value, a prompt “Wavelength moving…” will be shown, and the instrument will move wavelength to the designated spot.

” after inputting the wavelength value, a prompt “Wavelength moving…” will be shown, and the instrument will move wavelength to the designated spot.

Fig. 3-14

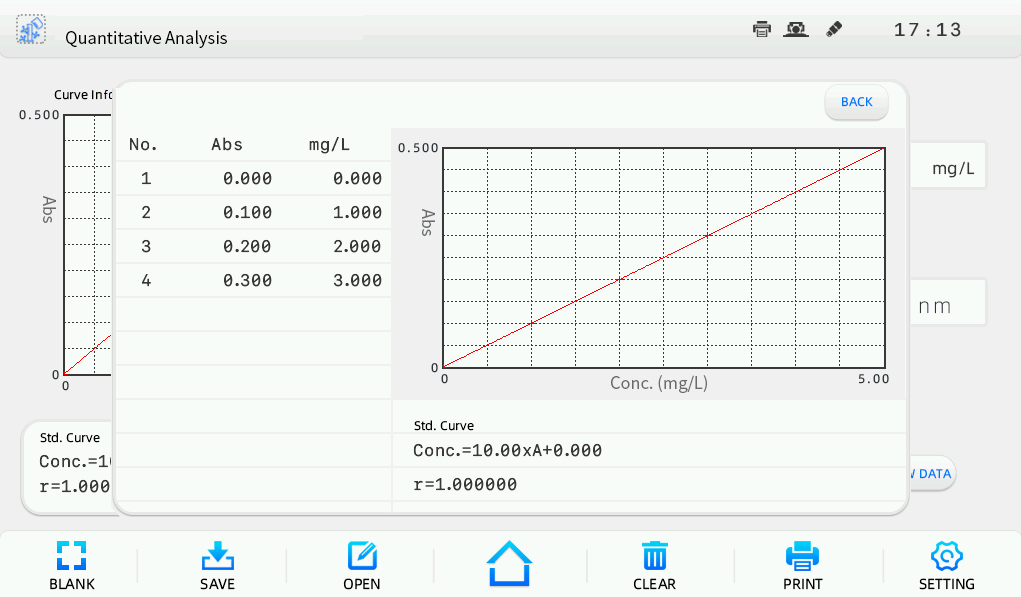

Step 2 Standard samples measurement and standard curve establishing.

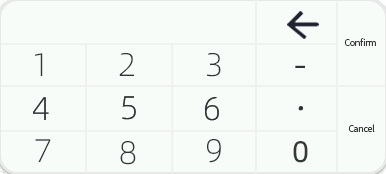

In the interface of the standard curve method, click in std. number column, input the number value and confirm it, then click “

” to enter the standard curve measurement interface (Fig. 3-15)

” to enter the standard curve measurement interface (Fig. 3-15)

Click in the concentration column of std-1, input the concentration value and confirm it. Input other standard concentration value one by one. Put the reference solution of standard samples separately into the reference light path and sample light path, and click “

” to adjust 0.000 Abs. Then, replace the reference solution with the first standard sample solution only in the sample light path, click “

” to adjust 0.000 Abs. Then, replace the reference solution with the first standard sample solution only in the sample light path, click “  ” to record the Abs. value. Measure other standard sample solutions accordingly.

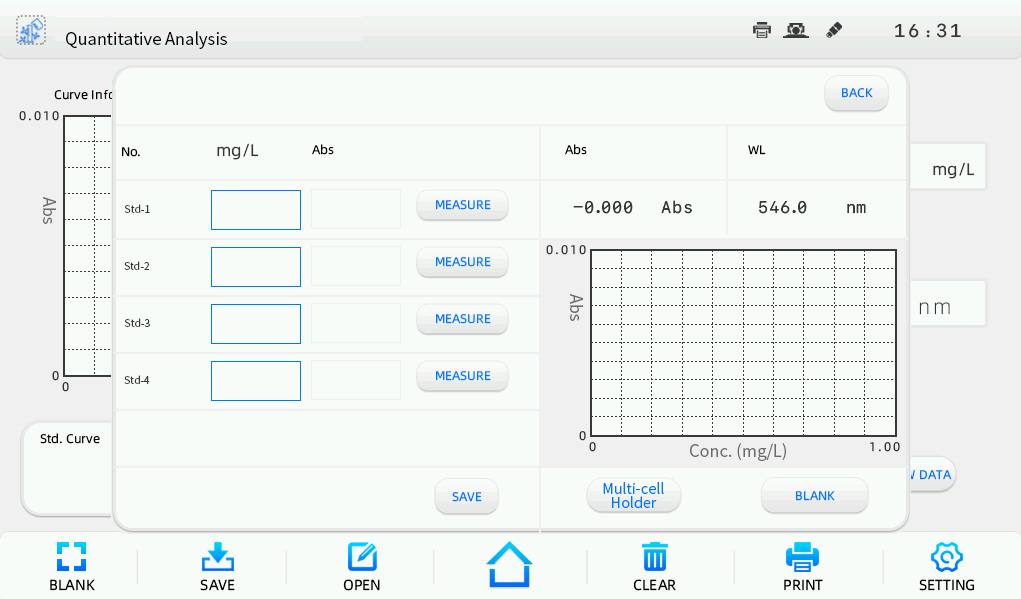

” to record the Abs. value. Measure other standard sample solutions accordingly.At last, the standard curve is obtained (Fig. 3-16). Up to ten standard points can be measured.

Fig. 3-16

Step 3 Sample measurement.

Click “

” in the obtained standard curve interface to enter the sample measurement interface (Fig. 3-17). The curve information including the standard curve, curve equation and the correlation coefficient are shown on the left pane. Put the blank solution separately into the reference light path and sample light path, and click “

” in the obtained standard curve interface to enter the sample measurement interface (Fig. 3-17). The curve information including the standard curve, curve equation and the correlation coefficient are shown on the left pane. Put the blank solution separately into the reference light path and sample light path, and click “  ” to adjust 0.000 Abs. Then, replace the blank solution with the sample solution only in the sample light path, click “

” to adjust 0.000 Abs. Then, replace the blank solution with the sample solution only in the sample light path, click “  ”, the measurement result will be recorded.

”, the measurement result will be recorded.

Fig. 3-17

In the sample measurement interface, user can click “” to retrieve the data record of standard samples (Fig. 3-18).

Fig. 3-18

3. Data processing

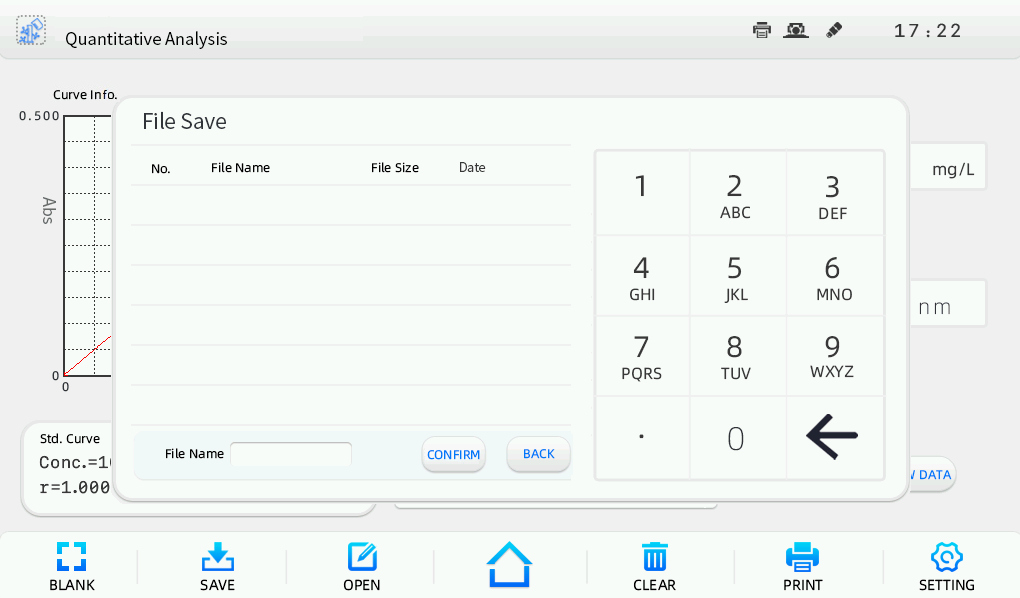

User can do data processing such as data saving, opening, printing and deleting after completing standard curve measurement.

Data saving: User can save the data to the instrument memory by clicking “”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-19), and click “”, the file will be saved with the suffix of “.qua”.

Fig. 3-19

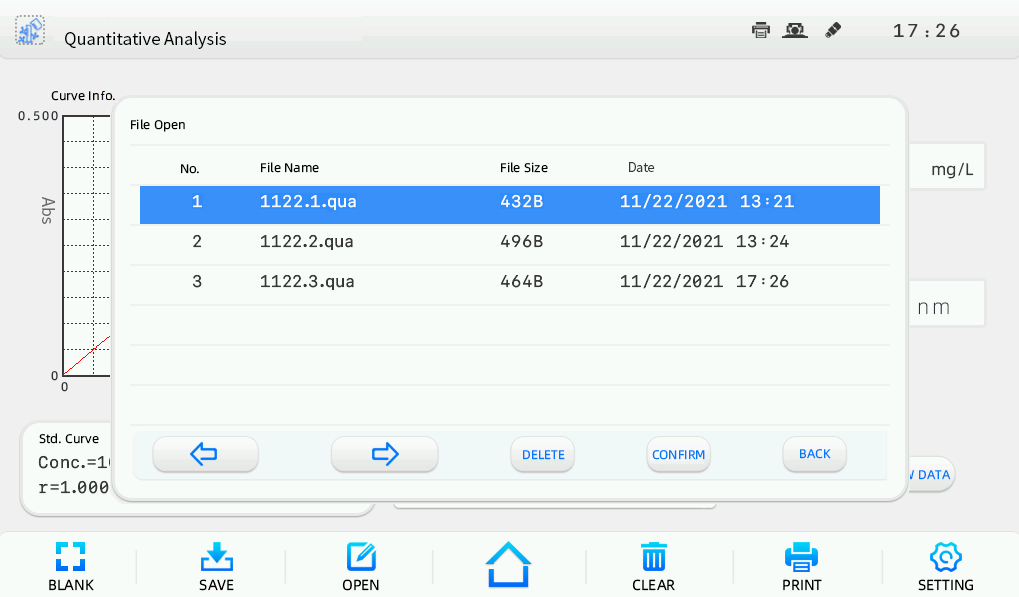

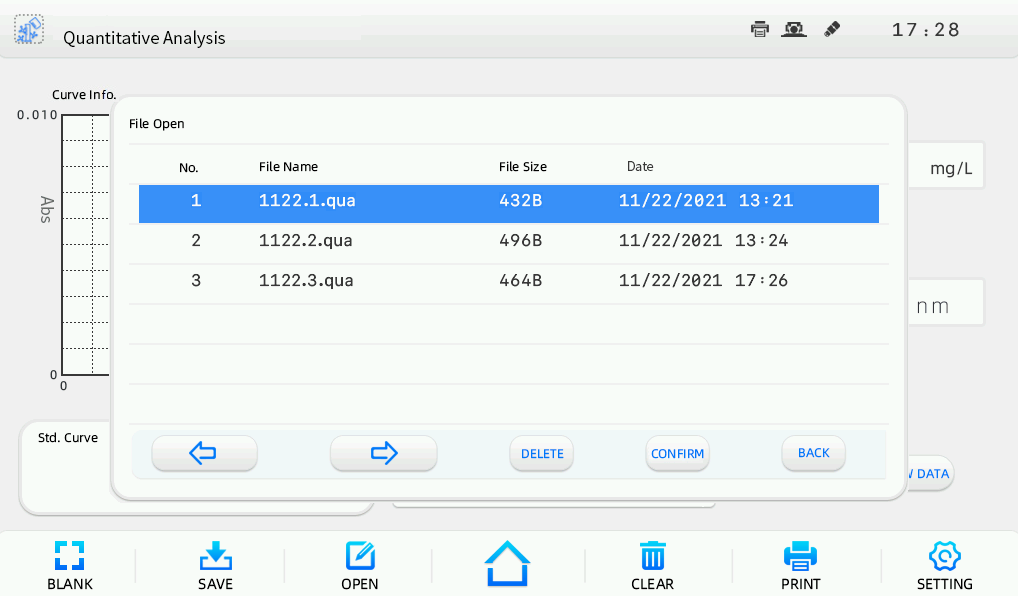

Data opening: Click “

” to enter the data opening interface (Fig. 3-20). User can select the file to be opened, and click “

” to enter the data opening interface (Fig. 3-20). User can select the file to be opened, and click “  ” to open the data.

” to open the data.

Fig. 3-20

Fig. 3-21

Data printing: User can print the data by clicking “

” if a printer is connected. A dialog box will pop up (Fig. 3-21), click “

” if a printer is connected. A dialog box will pop up (Fig. 3-21), click “  ” to print the data.

” to print the data.Data deleting: If a few data need to be deleted, user can select the row of the data and click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-22), click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-22), click “  ” to make sure the deleting. User also can click “

” to make sure the deleting. User also can click “  ” on the lower pane of the operation interface to clear all the data displayed in the data sheet. A dialog box will pop up (Fig. 3-23), click “

” on the lower pane of the operation interface to clear all the data displayed in the data sheet. A dialog box will pop up (Fig. 3-23), click “  ” to make sure the deleting.

” to make sure the deleting.

Fig. 3-22

Fig. 3-23

Fig. 3-24

The delete operation only works for current display. The already saved data won’t lost. Before exit the current interface or returning to the main interface, a dialog box will pop up (Fig. 3-24). If the data after delete operation need to be saved, user can click “” to save the updated data.

The delete operation only works for current display. The already saved data won’t lost. Before exit the current interface or returning to the main interface, a dialog box will pop up (Fig. 3-24). If the data after delete operation need to be saved, user can click “” to save the updated data.4. Load standard curve

User can load the saved standard curve. In the main quantitative analysis interface, click “

” to enter the standard curve loading interface (Fig. 3-25).

” to enter the standard curve loading interface (Fig. 3-25).

Fig. 3-25

User can browse the pages by clicking “

” and “

” and “  ”, and select the file of the standard curve need to be loaded. Then, click “

”, and select the file of the standard curve need to be loaded. Then, click “  ” to enter the sample measurement interface.

” to enter the sample measurement interface. The file are saved in ascending order, and the latest saved file is saved at the bottom. The instrument memory is unlimited, user can save files freely.

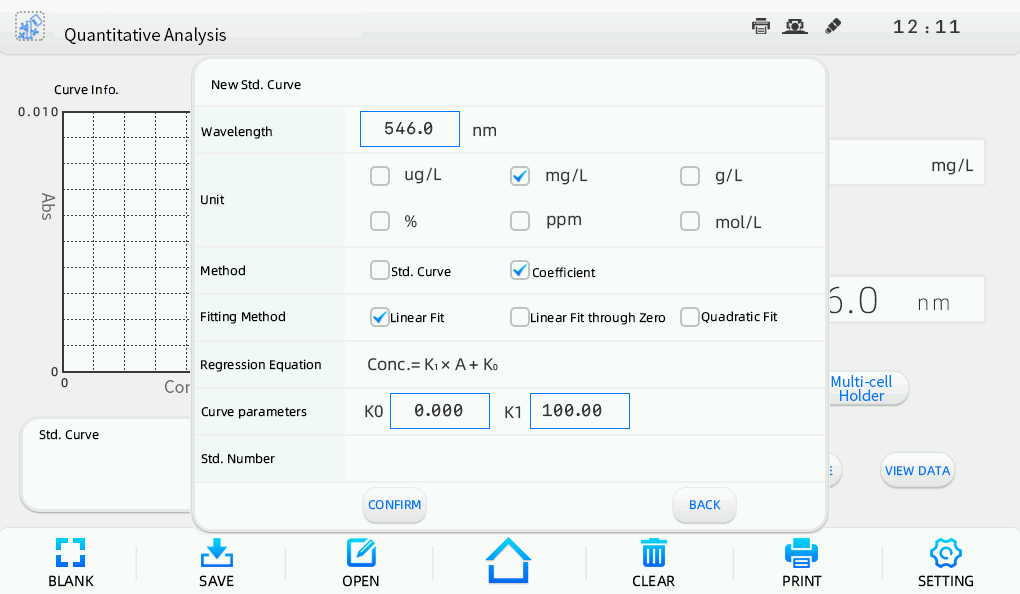

The file are saved in ascending order, and the latest saved file is saved at the bottom. The instrument memory is unlimited, user can save files freely.3.4.2 Coefficient method application

The coefficient method is a simple application of standard curve method. User can input the coefficients of the standard curve, and do the sample measurement further. The calculation formula is based on the fitting method. For linear fit, the calculation formula is C=K1×A+K0.

Following are detail operation steps for coefficient method:

Step 1 Enter the coefficient method interface.

In the main quantitative analysis interface, click “” to enter the interface of the standard curve method, select “Coefficient” as the method (Fig. 3-26).

Fig. 3-26

Step 2 Measurement wavelength setting.

Click in the wavelength column, and a digital input window will pop up (Fig. 3-27). Click “

” after inputting the wavelength value, a prompt “Wavelength moving…” will be shown, and the instrument will move wavelength to the designated spot.

” after inputting the wavelength value, a prompt “Wavelength moving…” will be shown, and the instrument will move wavelength to the designated spot.

Fig. 3-27

Step 3 Coefficients setting.

For linear fit as an example, select the fitting method “Linear Fit”. Click the blank column of K1, input the value in the pop-up digital input window and make sure the setting, input the value of K0 like the same. Then, click “” to enter the sample measurement interface (Fig. 3-28).

Fig. 3-28

Step 4 Sample measurement.

Put the blank solution separately into the reference light path and sample light path, and click “

” to adjust 0.000 Abs. Then, replace the blank solution with the sample solution only in the sample light path, click “

” to adjust 0.000 Abs. Then, replace the blank solution with the sample solution only in the sample light path, click “  ”, the measurement result will be recorded.

”, the measurement result will be recorded.User can do data processing such as data saving, printing and deleting after completing sample measurement. It is omitted here.

3.4.3 Concentration unit setting

Whether utilizing standard curve method or coefficient method to do quantitative analysis, user can set the concentration unit. After clicking “

” to enter the interface of the standard curve method, user can select certain concentration unit. There are six kinds of commonly used concentration unit for chosen, µg/L, mg/L, g/L, %, ppm and mol/L.

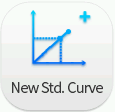

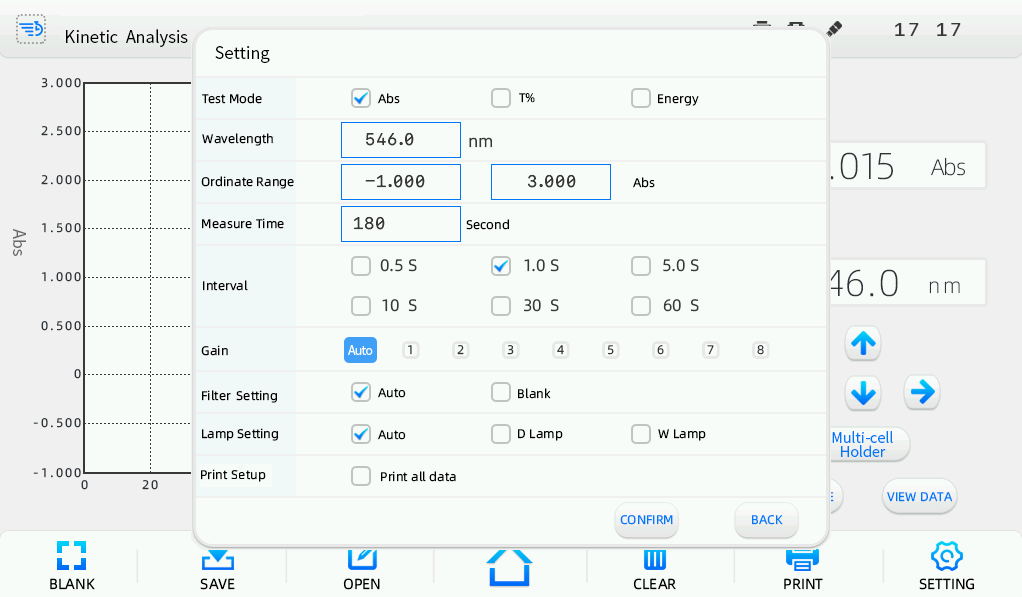

” to enter the interface of the standard curve method, user can select certain concentration unit. There are six kinds of commonly used concentration unit for chosen, µg/L, mg/L, g/L, %, ppm and mol/L.3.5 Kinetic Analysis

A curve of absorbance or transmittance or energy at a specific wavelength in a certain time range is available with kinetic analysis, and the variation tendency of a sample can be analyzed.Click the icon “

” in the main interface to enter the kinetic analysis interface (Fig. 3-29).

” in the main interface to enter the kinetic analysis interface (Fig. 3-29).

Fig. 3-29

3.5.1 Kinetic analysis

Following are the operation steps for kinetic analysis:

Step 1 Enter the kinetic analysis interface.

Click the icon “

” in the main interface to enter the kinetic analysis interface.

” in the main interface to enter the kinetic analysis interface.Step 2 Set the kinetics scan parameters.

Click “

” to enter the kinetics scan setting interface (Fig. 3-30). User can select the test mode, set the measurement wavelength and time, time interval, the ordinate range. Click in the wavelength column, input the wavelength value in the

” to enter the kinetics scan setting interface (Fig. 3-30). User can select the test mode, set the measurement wavelength and time, time interval, the ordinate range. Click in the wavelength column, input the wavelength value in thedigital input window, click “

” to make sure the setting. Then, separately set the ordinate range and time like the same. Click “

” to make sure the setting. Then, separately set the ordinate range and time like the same. Click “  ” to return to the kinetic analysis interface after completing all the settings.

” to return to the kinetic analysis interface after completing all the settings.

Fig. 3-30

The time interval can be selected among 0.5 s,1.0 s, 5.0 s, 10 s, 30 s, and 60 s.

Step 3 Kinetics scan.

Put the blank solution separately into the reference light path and sample light path, and click “

”. The instrument will be adjusted to 0.000 Abs/100.0 %T under certain wavelength. Then, replace the blank solution with the sample solution only in the sample light path, click “

”. The instrument will be adjusted to 0.000 Abs/100.0 %T under certain wavelength. Then, replace the blank solution with the sample solution only in the sample light path, click “  ” to begin the kinetics scan. The scan curve will be shown instantly in the graph display area during the kinetics scan process (Fig. 3-31).

” to begin the kinetics scan. The scan curve will be shown instantly in the graph display area during the kinetics scan process (Fig. 3-31).

Fig. 3-31

3.5.2 Data processing

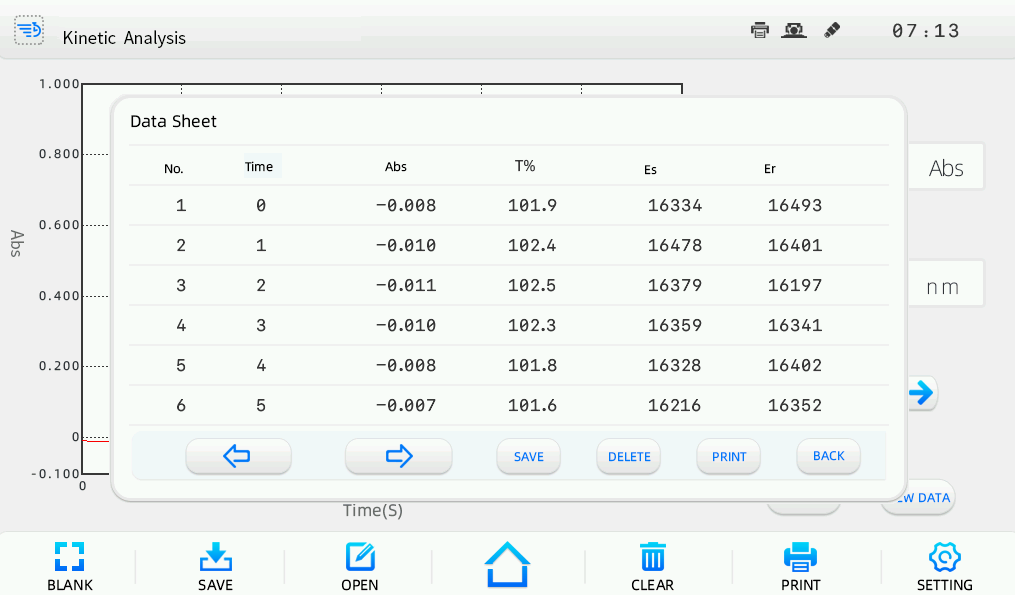

Data retrieval with the graph is available after completing the kinetics scan. User can click “” to enter the data sheet displaying interface (Fig. 3-32) after completing kinetics scan, and do data processing such as data browsing, saving, deleting, and printing.

Fig. 3-32

Data retrieval: After completing the kinetics scan, user can click “

” and “

” and “  ” to search the peaks or valleys. User also can click “

” to search the peaks or valleys. User also can click “  ” and “

” and “  ” to search the data point by point.

” to search the data point by point.Data browsing: In the data sheet displaying interface, user can browse the data pages by clicking “

” and “

” and “  ”.

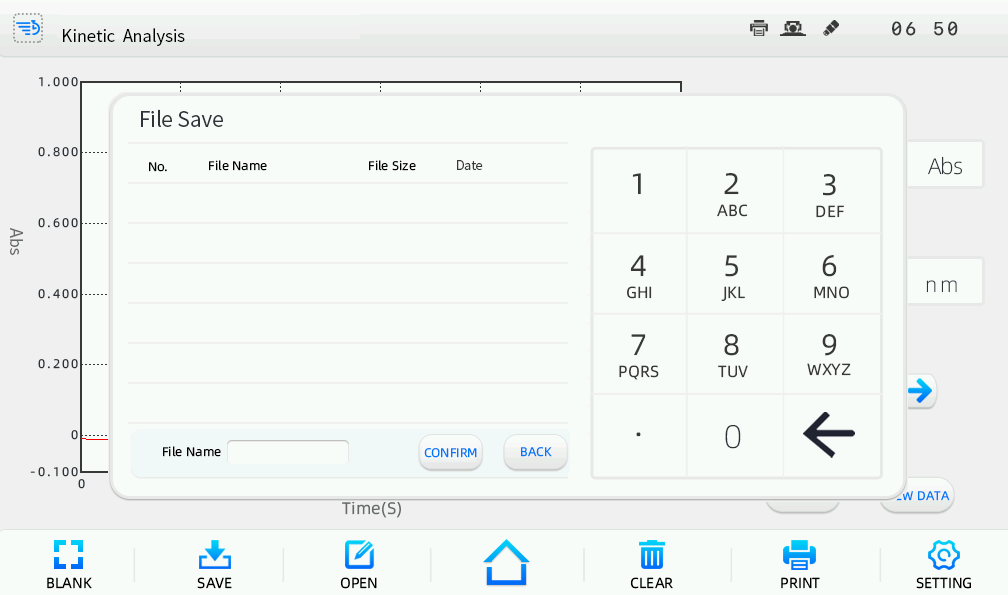

”.Data saving: User can save the data to the instrument memory by clicking “

”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-33), and click “

”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-33), and click “  ”, the file will be saved with the suffix of “.kin”.

”, the file will be saved with the suffix of “.kin”.

Fig. 3-33

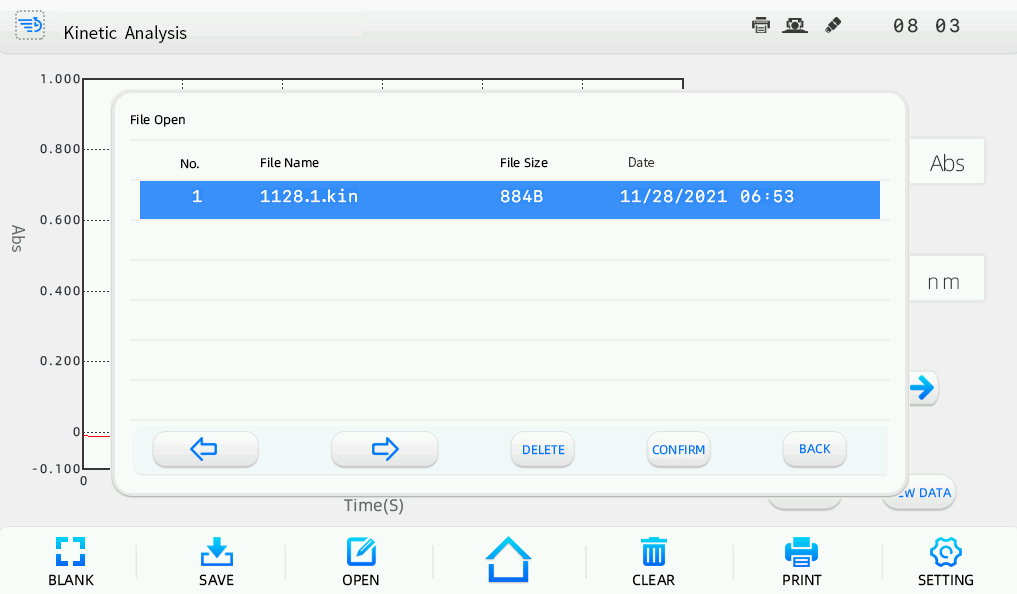

Data opening: Click “

” to enter the data opening interface (Fig. 3-34). User can select the file to be opened, and click “

” to enter the data opening interface (Fig. 3-34). User can select the file to be opened, and click “  ” to open the data.

” to open the data.

Fig. 3-34

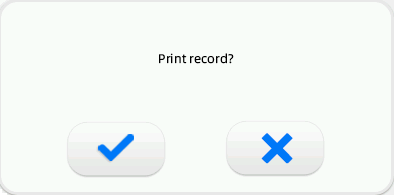

Data printing: User can print the data by clicking “

” if a printer is connected. A dialog box will pop up (Fig. 3-35), click “

” if a printer is connected. A dialog box will pop up (Fig. 3-35), click “  ” to print the data.

” to print the data.

Fig. 3-35 Fig. 3-36

Data deleting: If the data displayed in the data sheet need to be deleted, user can click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-36), click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-36), click “  ” to make sure the deleting. User also can click “

” to make sure the deleting. User also can click “  ” on the lower pane of the operation interface to perform the data deleting.

” on the lower pane of the operation interface to perform the data deleting. It’s not available for deleting a part of the kinetic scan data. Once performing the data deleting, all the data displayed will be deleted.

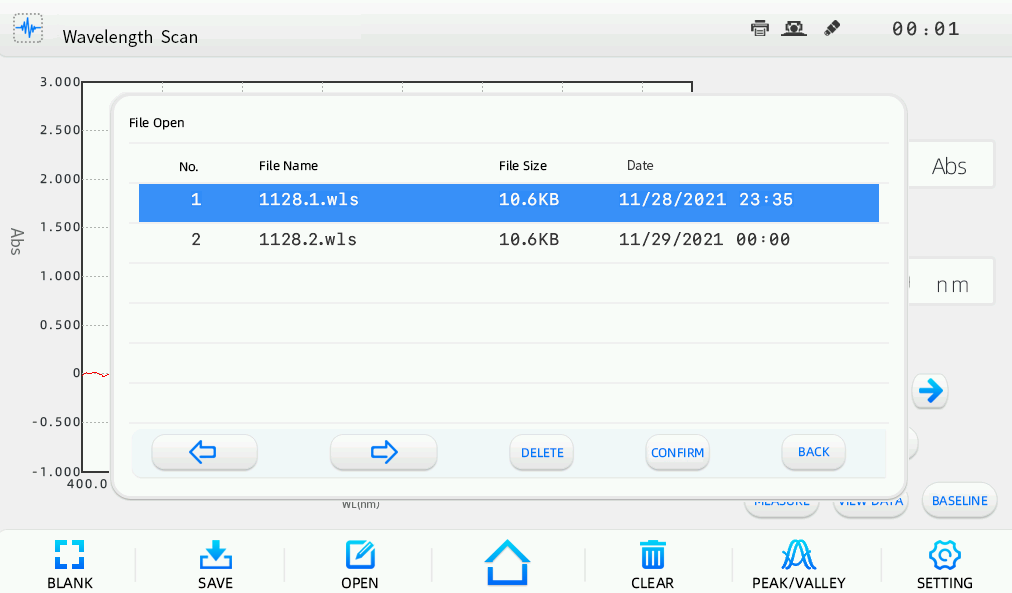

It’s not available for deleting a part of the kinetic scan data. Once performing the data deleting, all the data displayed will be deleted.3.6 Wavelength Scan

A curve of absorbance or transmittance or energy in a certain wavelength range is available with wavelength scan. User can do qualitative analysis such as to determine components of a simple sample by this function.Click the icon “

” in the main interface to enter the wavelength scan interface (Fig. 3-37).

” in the main interface to enter the wavelength scan interface (Fig. 3-37).

Fig. 3-37

3.6.1 Wavelength scan

Following are the operation steps for wavelength scan:

Step 1 Enter the wavelength scan interface.

Click the icon “

” in the main interface to enter the wavelength scan interface.

” in the main interface to enter the wavelength scan interface.Step 2 Set the wavelength scan parameters.

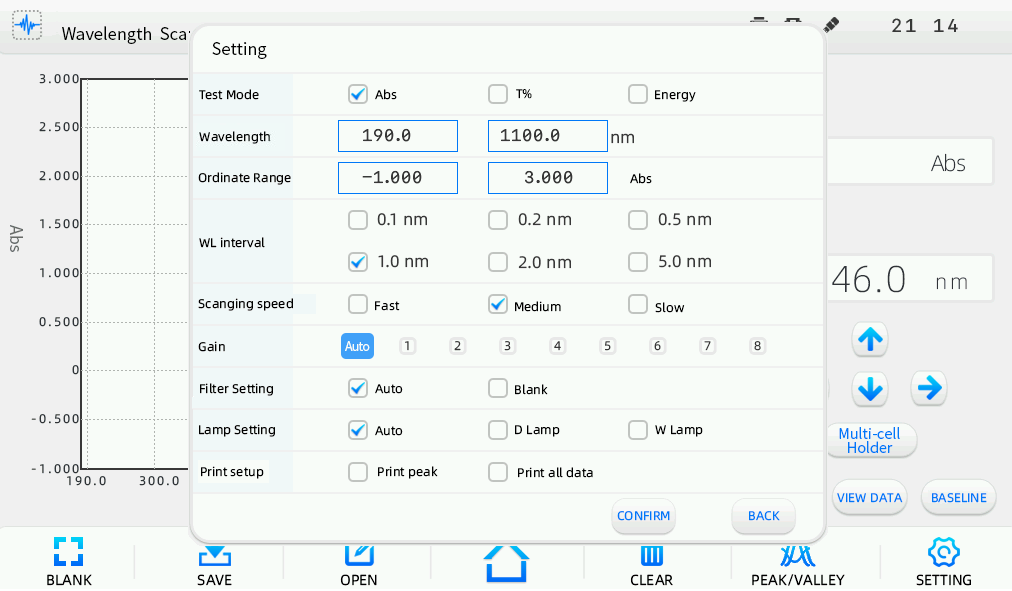

Click “

” to enter the wavelength scan setting interface (Fig. 3-38). User can select the test mode, set the measurement wavelength range and the ordinate range, select the wavelength interval and scanning speed. Click in the wavelength column, successively input the value of wavelength range in the digital input window, click “

” to enter the wavelength scan setting interface (Fig. 3-38). User can select the test mode, set the measurement wavelength range and the ordinate range, select the wavelength interval and scanning speed. Click in the wavelength column, successively input the value of wavelength range in the digital input window, click “  ” to make sure the setting. Set the ordinate range like the same. The wavelength interval can be selected among 0.1 nm, 0.2 nm, 0.5 nm, 1.0 nm, 2.0 nm, and 5.0 nm. There are three kinds of scanning speed for selection, fast, medium, and slow. Just select the right wavelength interval and scanning speed. Then, click “

” to make sure the setting. Set the ordinate range like the same. The wavelength interval can be selected among 0.1 nm, 0.2 nm, 0.5 nm, 1.0 nm, 2.0 nm, and 5.0 nm. There are three kinds of scanning speed for selection, fast, medium, and slow. Just select the right wavelength interval and scanning speed. Then, click “  ” to return to the wavelength scan interface after completing all the settings.

” to return to the wavelength scan interface after completing all the settings.

Fig. 3-38

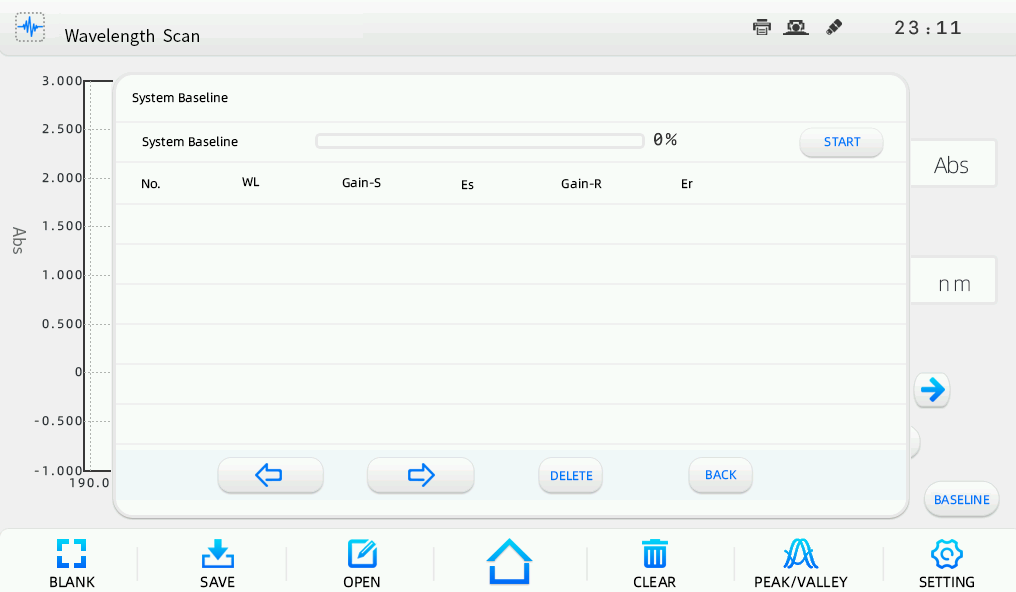

Step 3 System baseline calibration.

System baseline calibration should be done before performing the wavelength scan. Click “

” to enter the system baseline calibration interface (Fig. 3-39). Click “

” to enter the system baseline calibration interface (Fig. 3-39). Click “  ” to perform system baseline calibration. Click “

” to perform system baseline calibration. Click “  ” to return to the wavelength scan interface after completing the calibration.

” to return to the wavelength scan interface after completing the calibration.

Fig. 3-39

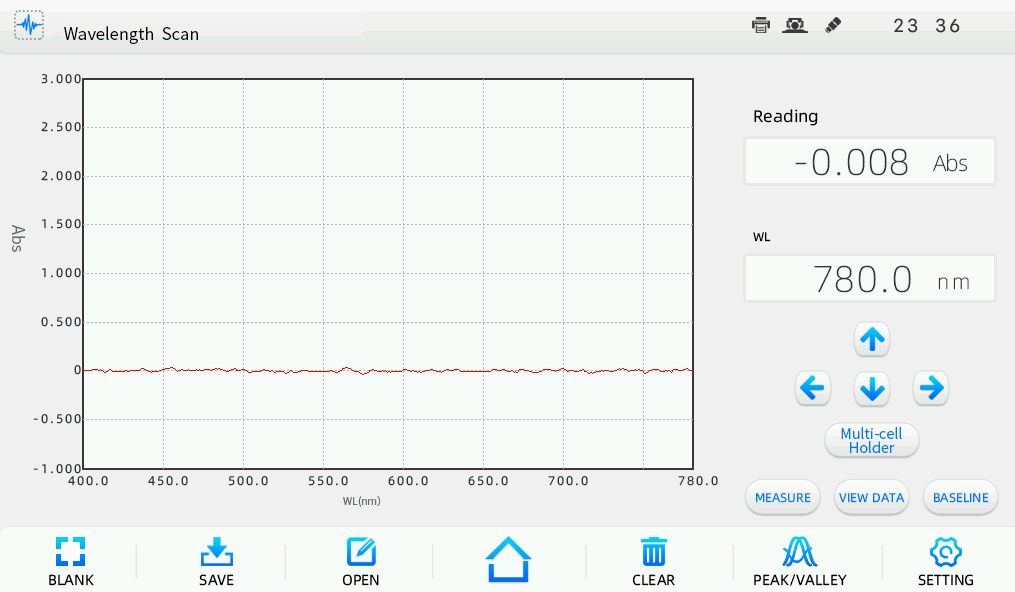

Step 4 Wavelength scan.

Put the blank solution separately into the reference light path and sample light path, and click “

” to perform blank calibration. A prompt “Blanking…” will be shown at the same time. The instrument will be adjusted to 0.000 Abs/100.0 %T under each wavelength. Then, replace the blank solution with the sample solution only in the sample light path, click “

” to perform blank calibration. A prompt “Blanking…” will be shown at the same time. The instrument will be adjusted to 0.000 Abs/100.0 %T under each wavelength. Then, replace the blank solution with the sample solution only in the sample light path, click “  ” to begin the wavelength scan. The scan curve will be shown instantly in the graph display area during the wavelength scan process (Fig. 3-40).

” to begin the wavelength scan. The scan curve will be shown instantly in the graph display area during the wavelength scan process (Fig. 3-40).

Fig. 3-40

The scanning sequence is from the maximum wavelength to the minimum wavelength. The system will automatically give buzzing alarm after completing the baseline calibration and sample scan, and the instrument will return to the maximum wavelength at the same time.

The scanning sequence is from the maximum wavelength to the minimum wavelength. The system will automatically give buzzing alarm after completing the baseline calibration and sample scan, and the instrument will return to the maximum wavelength at the same time.3.6.2 Data processing

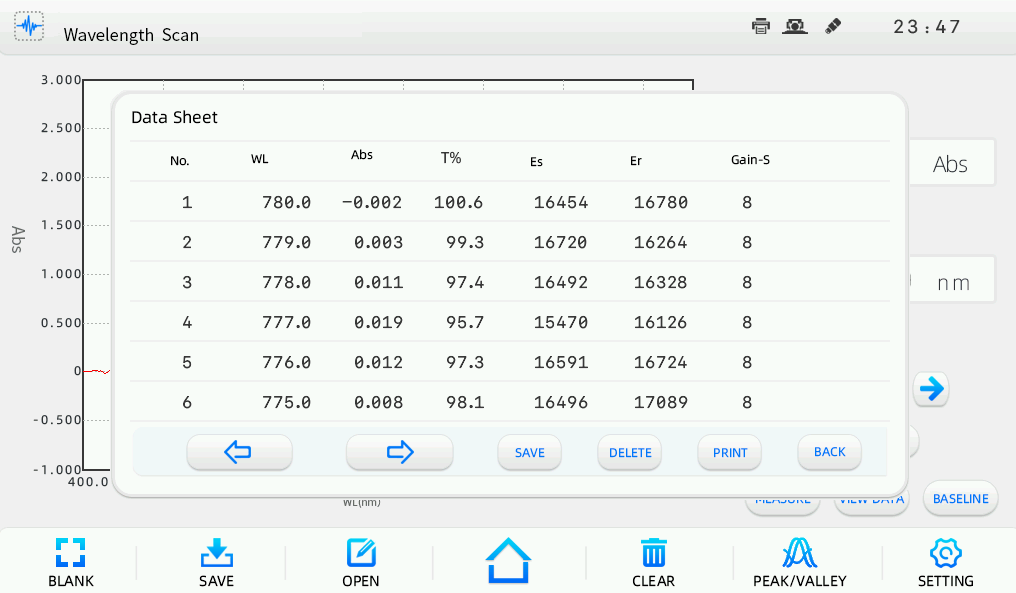

Data retrieval with the graph is available after completing the wavelength scan. User can click “

” to enter the data sheet displaying interface (Fig. 3-41) after completing wavelength scan, and do data processing such as data browsing, saving, deleting, and printing.

” to enter the data sheet displaying interface (Fig. 3-41) after completing wavelength scan, and do data processing such as data browsing, saving, deleting, and printing.

Fig. 3-41

Data retrieval: After completing the wavelength scan, user can click“

” and “

” and “  ” to search the peaks or valleys. User also can click “

” to search the peaks or valleys. User also can click “  ” and “

” and “  ” to search the data point by point.

” to search the data point by point.Data browsing: In the data sheet displaying interface, user can browse the data pages by clicking “

” and “

” and “  ”.

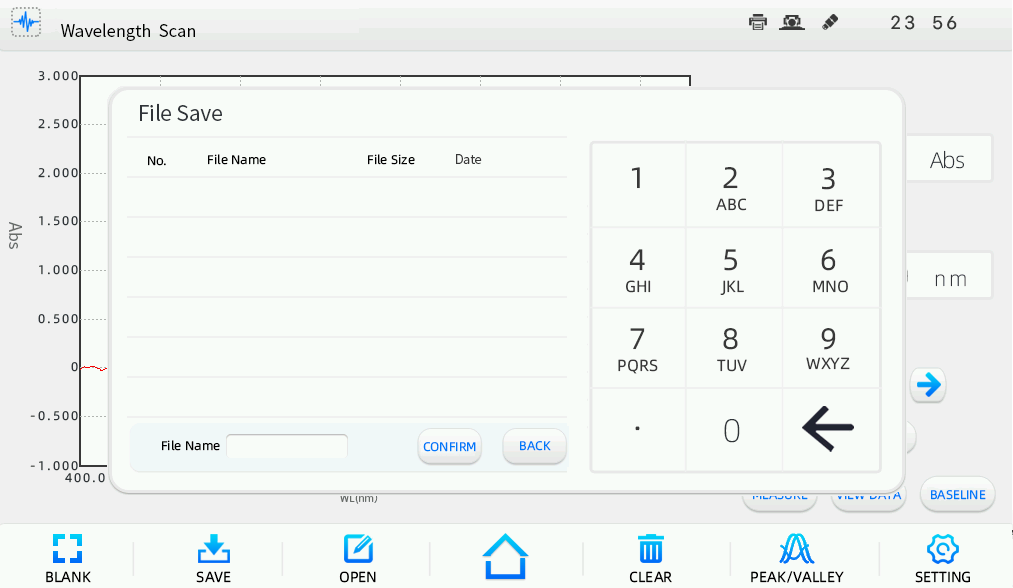

”.Data saving: User can save the data to the instrument memory by clicking “

”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-42), and click “

”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-42), and click “  ”, the file will be saved with the suffix of “.wls”.

”, the file will be saved with the suffix of “.wls”.

Fig. 3-42

Data opening: Click “

” to enter the data opening interface (Fig. 3-43). User can select the file to be opened, and click “

” to enter the data opening interface (Fig. 3-43). User can select the file to be opened, and click “  ” to open the data.

” to open the data.

Fig. 3-43

Data printing: User can print the data by clicking “

” if a printer is connected. A dialog box will pop up (Fig. 3-44), click “

” if a printer is connected. A dialog box will pop up (Fig. 3-44), click “  ” to print the data.

” to print the data.

Fig. 3-44

Fig. 3-45

Data deleting: If the data displayed in the data sheet need to be deleted, user can click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-45), click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-45), click “  ” to make sure the deleting. User also can click “

” to make sure the deleting. User also can click “  ” on the lower pane of the operation interface to perform the data deleting.

” on the lower pane of the operation interface to perform the data deleting. It’s not available for deleting a part of the wavelength scan data. Once performing the data deleting, all the data displayed will be deleted.

It’s not available for deleting a part of the wavelength scan data. Once performing the data deleting, all the data displayed will be deleted.3.7 Multi-wavelength Measurement

User can quickly obtain absorbance values of the sample under several wavelengths with multi-wavelength measurement.Click the icon “

” in the main interface to enter the multi-wavelength measurement interface (Fig. 3-46).

” in the main interface to enter the multi-wavelength measurement interface (Fig. 3-46).

Fig. 3-46

3.7.1 Multi-wavelength measurement

Following are the operation steps for multi-wavelength measurement:

Step 1 Enter the multi-wavelength measurement interface.

Click the icon “

” in the main interface to enter the multi-wavelength measurement interface.

” in the main interface to enter the multi-wavelength measurement interface.Step 2 Set the measurement parameters.

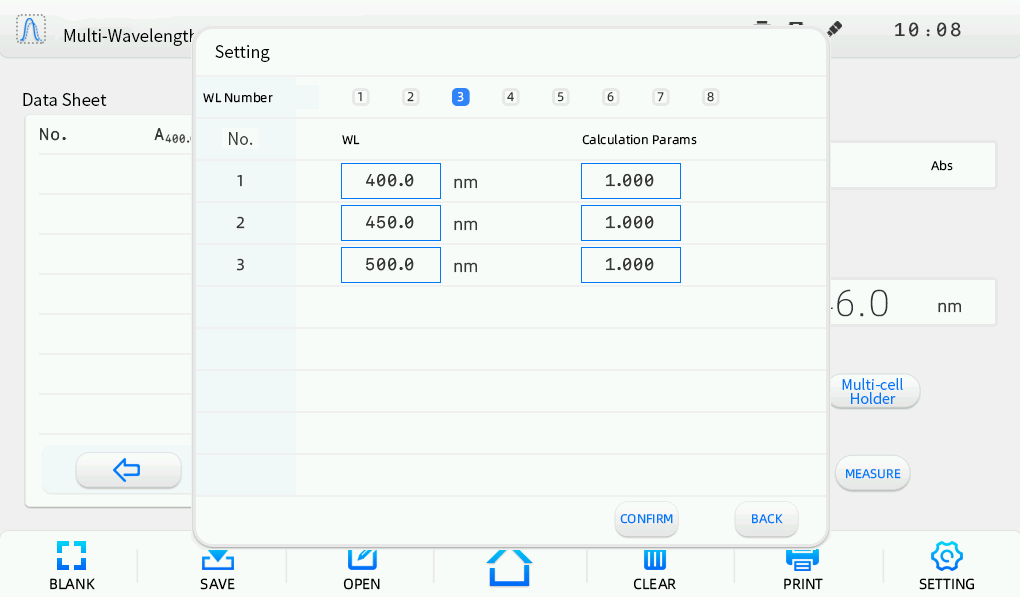

In the multi-wavelength measurement interface, click “

” to enter the parameters setting interface (Fig. 3-47). Up to eight wavelengths can be set. Select the right wavelength number, and click in the first wavelength column, a digital input window will pop up (Fig. 3-48). Click “

” to enter the parameters setting interface (Fig. 3-47). Up to eight wavelengths can be set. Select the right wavelength number, and click in the first wavelength column, a digital input window will pop up (Fig. 3-48). Click “  ” after inputting the wavelength value. Click in the calculation parameter column, user can edit the calculation parameter. Input other wavelengths and calculation parameters successively. Then, click “

” after inputting the wavelength value. Click in the calculation parameter column, user can edit the calculation parameter. Input other wavelengths and calculation parameters successively. Then, click “  ” to return to the multi-wavelength measurement interface after completing all the settings.

” to return to the multi-wavelength measurement interface after completing all the settings.

Fig. 3-47

Fig. 3-48

Step 3 Sample measurement.

Put the blank solution or reference solution separately into the reference light path and sample light path, and click “

”. The instrument will be adjusted to 0.000 Abs/100.0 %T under certain wavelengths. Then, replace the blank solution or reference solution with the sample solution only in the sample light path, click “

”. The instrument will be adjusted to 0.000 Abs/100.0 %T under certain wavelengths. Then, replace the blank solution or reference solution with the sample solution only in the sample light path, click “  ” and record the measurement result.

” and record the measurement result.3.7.2 Data processing

User can do data processing such as data saving, opening, printing and deleting after completing multi-wavelength measurements.

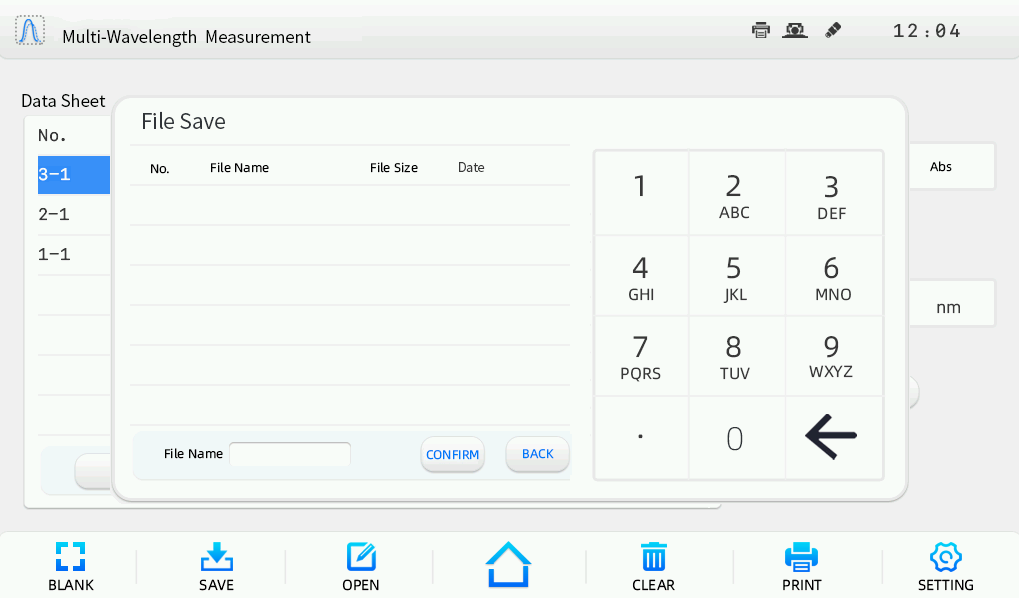

Data saving: User can save the data to the instrument memory by clicking “”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-49), and click “”, the file will be saved with the suffix of “.mul”.

Fig. 3-49

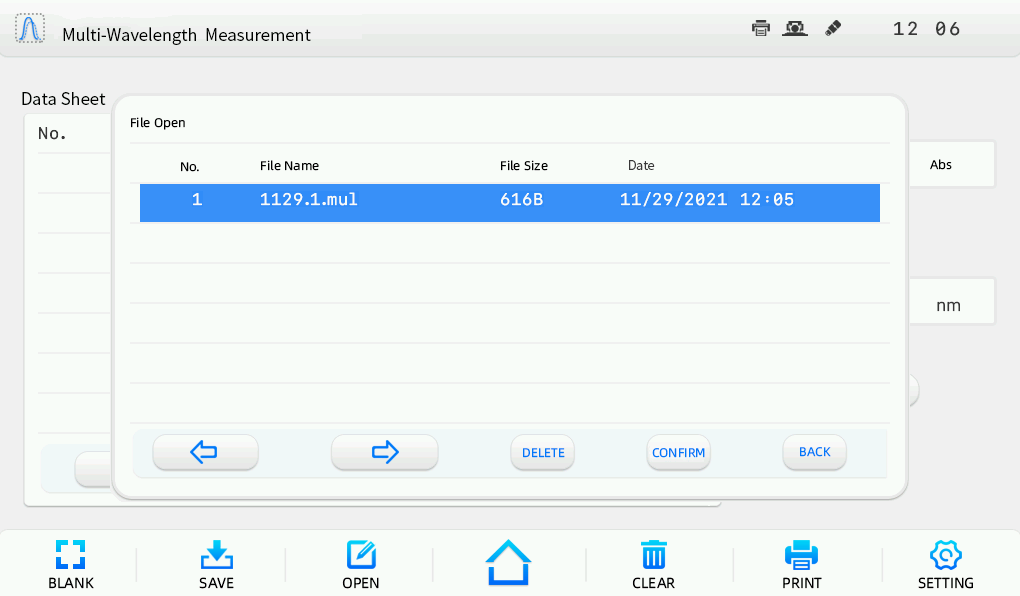

Data opening: Click “

” to enter the data opening interface (Fig. 3-50). User can select the file to be opened, and click “

” to enter the data opening interface (Fig. 3-50). User can select the file to be opened, and click “  ” to open the data.

” to open the data.

Fig. 3-50

Fig. 3-51

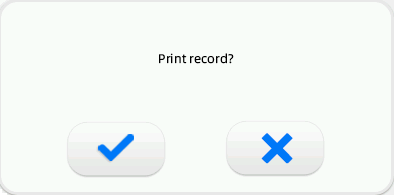

Data printing: User can print the data by clicking “

” if a printer is connected. A dialog box will pop up (Fig. 3-51), click “

” if a printer is connected. A dialog box will pop up (Fig. 3-51), click “  ” to print the data.

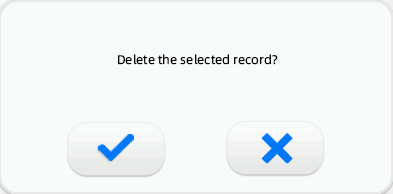

” to print the data.Data deleting: If a few data need to be deleted, user can select the row of the data and click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-52), click “” to make sure the deleting. User also can click

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-52), click “” to make sure the deleting. User also can click  “” on the lower pane of the operation interface to clear all the data displayed in the data sheet. A dialog box will pop up (Fig. 3-53), click “

“” on the lower pane of the operation interface to clear all the data displayed in the data sheet. A dialog box will pop up (Fig. 3-53), click “  ” to make sure the deleting.

” to make sure the deleting.

Fig. 3-52

Fig. 3-53

Fig. 3-54

The delete operation only works for current display. The already saved data won’t lost. Before exit the current interface or returning to the main interface, a dialog box will pop up (Fig. 3-54). If the data after delete operation need to be saved, user can click “” to save the updated data.

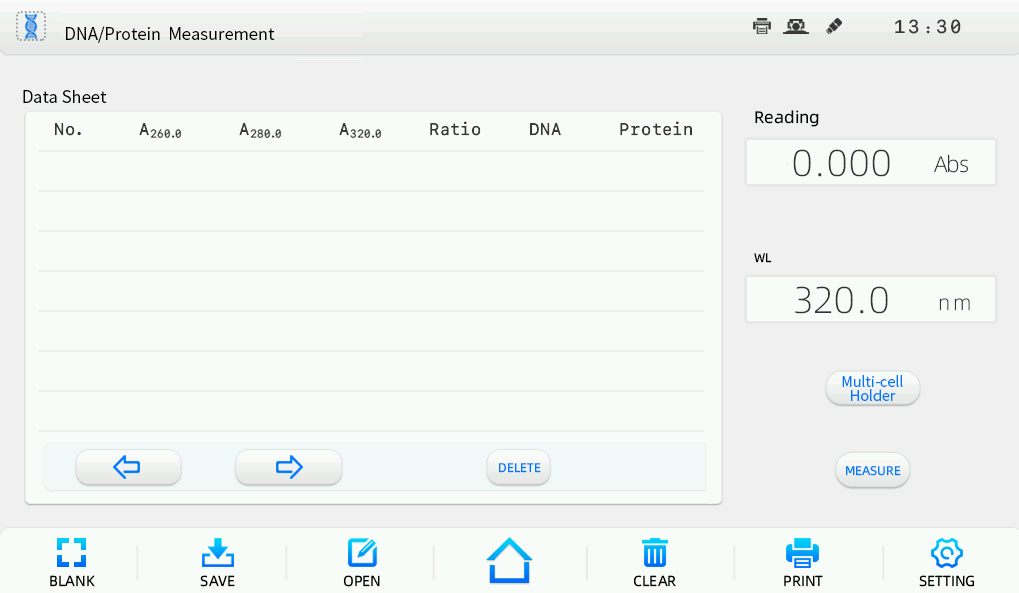

The delete operation only works for current display. The already saved data won’t lost. Before exit the current interface or returning to the main interface, a dialog box will pop up (Fig. 3-54). If the data after delete operation need to be saved, user can click “” to save the updated data.3.8 DNA/Protein Measurement

With the DNA/Protein measurement function, quantitative analysis and purity detection of DNA and protein according to the UV absorption characteristics are available.Click the icon “

” in the main interface to enter the DNA/Protein measurement interface (Fig. 3-55).

” in the main interface to enter the DNA/Protein measurement interface (Fig. 3-55).

Fig. 3-55

3.8.1 DNA/Protein measurement

Following are the operation steps for DNA/Protein measurement:

Step 1 Enter the DNA/Protein measurement interface.

Click the icon “

” in the main interface to enter the DNA/Protein measurement interface.

” in the main interface to enter the DNA/Protein measurement interface.Step 2 Select the test mode.

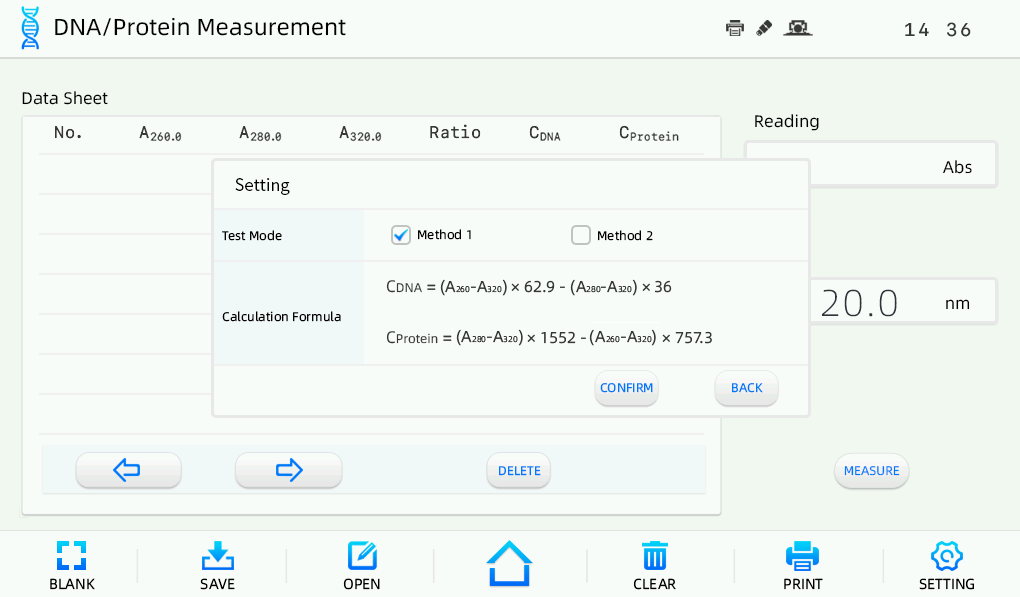

In the DNA/Protein measurement interface, click “

” to enter the measurement setting interface (Fig. 3-56). There are two test modes for selection, method 1 with the calculation formula of CDNA=(A260 - A320)x 62.9 - (A280 - A320)x 36, CProtein=(A280 - A320)x 1552 - (A260 - A320)x 757.3, and method 2 with the calculation formula of CDNA=(A260 - A320)x 49.1 - (A230 - A320)x 3.48, CProtein=(A230 - A320)x 183 - (A260 - A320) x 75.8

” to enter the measurement setting interface (Fig. 3-56). There are two test modes for selection, method 1 with the calculation formula of CDNA=(A260 - A320)x 62.9 - (A280 - A320)x 36, CProtein=(A280 - A320)x 1552 - (A260 - A320)x 757.3, and method 2 with the calculation formula of CDNA=(A260 - A320)x 49.1 - (A230 - A320)x 3.48, CProtein=(A230 - A320)x 183 - (A260 - A320) x 75.8Select the right test mode, and click “

” to return to the DNA/Protein measurement interface.

” to return to the DNA/Protein measurement interface.

Fig. 3-56

Step 3 Sample measurement.

Put the blank solution or reference solution separately into the reference light path and sample light path, and click “

”. The instrument will be adjusted to 0.000 Abs/100.0 %T under certain wavelengths. Then, replace the blank solution or reference solution with the sample solution only in the sample light path, click “

”. The instrument will be adjusted to 0.000 Abs/100.0 %T under certain wavelengths. Then, replace the blank solution or reference solution with the sample solution only in the sample light path, click “  ” and record the measurement result.

” and record the measurement result.3.8.2 Data processing

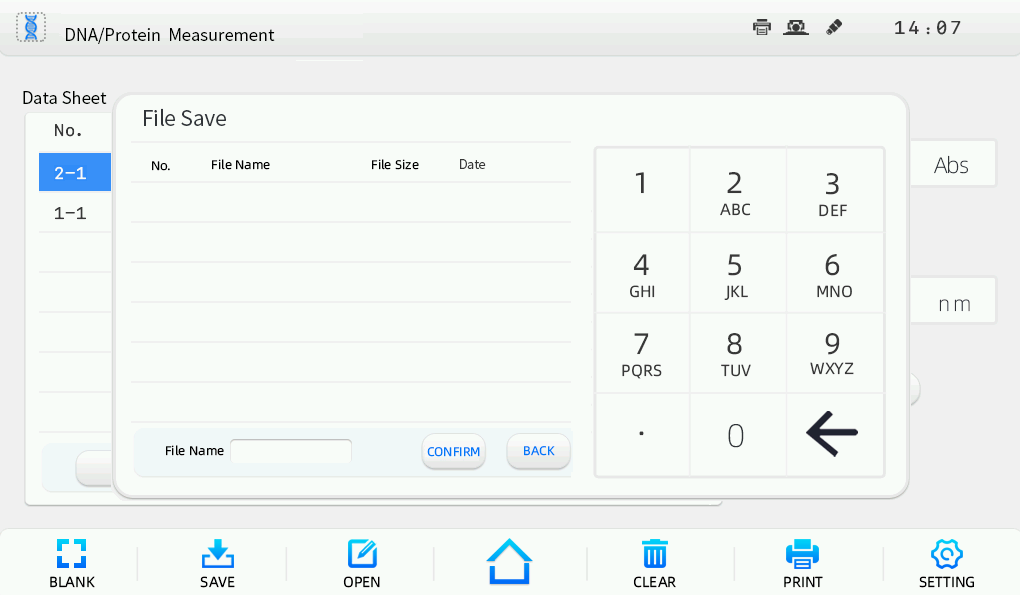

User can do data processing such as data saving, opening, printing and deleting after completing DNA/Protein measurements.

Data saving: User can save the data to the instrument memory by clicking “

”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-57), and click “

”. When a USB storage device is connected, user can select to save the data to the USB storage device. Input the file name in the file save window (Fig. 3-57), and click “  ”, the file will be saved with the suffix of “.dna”.

”, the file will be saved with the suffix of “.dna”.

Fig. 3-57

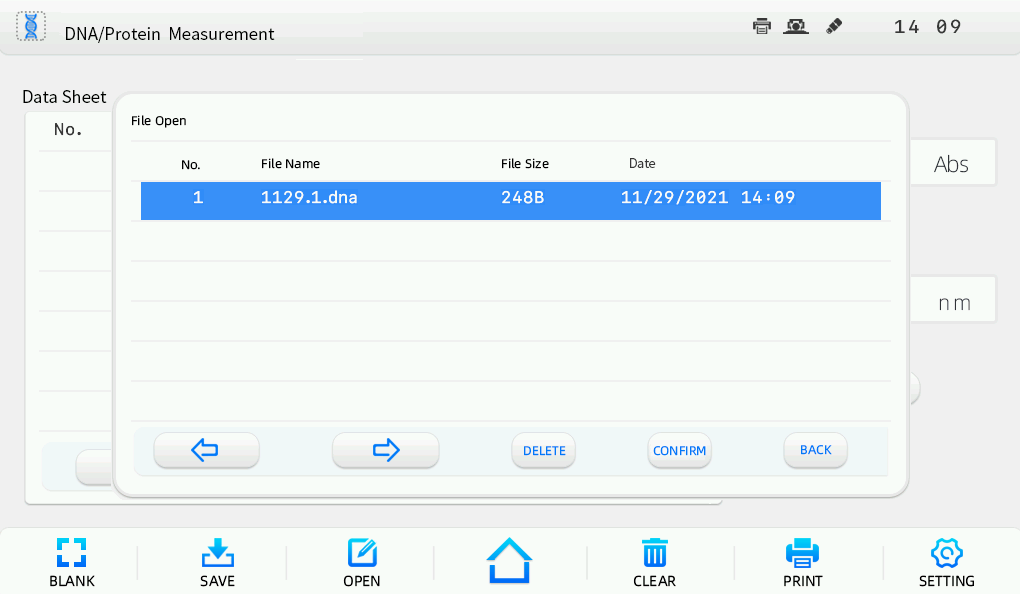

Data opening: Click “

” to enter the data opening interface (Fig. 3-58). User can select the file to be opened, and click “

” to enter the data opening interface (Fig. 3-58). User can select the file to be opened, and click “  ” to open the data.

” to open the data.

Fig. 3-58

Fig. 3-59

Data printing: User can print the data by clicking “

” if a printer is connected. A dialog box will pop up (Fig. 3-59), click “

” if a printer is connected. A dialog box will pop up (Fig. 3-59), click “  ” to print the data.

” to print the data.Data deleting: If a few data need to be deleted, user can select the row of the data and click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-60), click “

” at the bottom of the data sheet, a dialog box will pop up (Fig. 3-60), click “  ” to make sure the deleting. User also can click “

” to make sure the deleting. User also can click “  ” on the lower pane of the

” on the lower pane of theoperation interface to clear all the data displayed in the data sheet. A dialog box will pop up (Fig. 3-61), click “

” to make sure the deleting.

” to make sure the deleting.

Fig. 3-60 Fig. 3-61 Fig. 3-62

The delete operation only works for current display. The already saved data won’t lost. Before exit the current interface or returning to the main interface, a dialog box will pop up (Fig. 3-62). If the data after delete operation need to be saved, user can click “

” to save the updated data.

” to save the updated data.3.9 System Settings

Operations such as dark current calibration, wavelength calibration, bandwidth setting, time settings, lamps management, general settings, and the relevant operation with file system and system information are available in the system settings interface.Click the icon “

” in the main interface to enter the system settings interface (Fig. 3-63).

” in the main interface to enter the system settings interface (Fig. 3-63).

Fig. 3-63

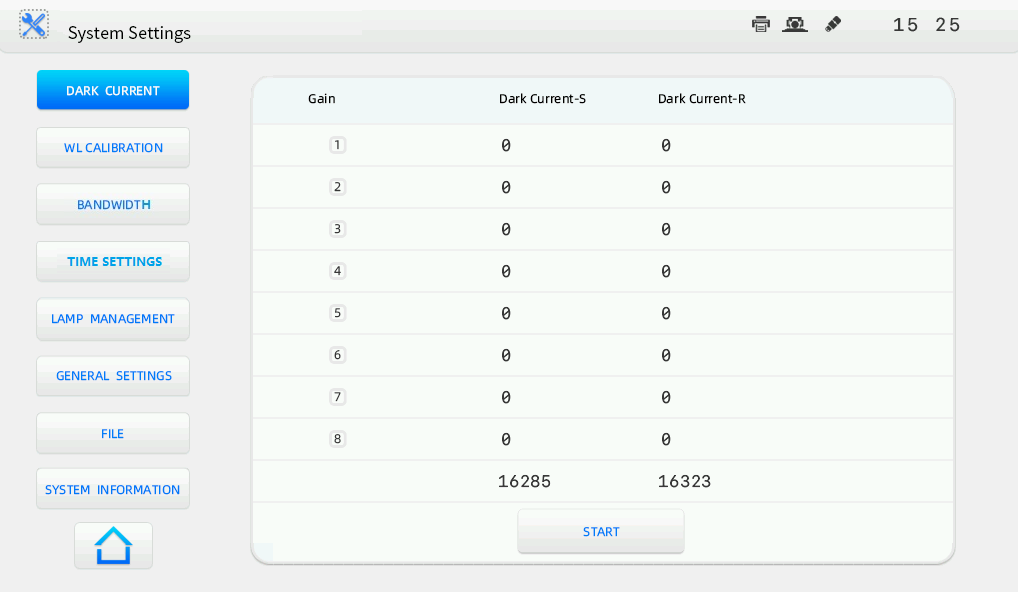

3.9.1 Dark current calibration

The dark current may changes when the instrument runs for a long time, or the wavelength is set again, or any other influences. For measurement accuracy, the dark current calibration is necessary before measurement.

Click “

” in the system settings interface to enter the dark current calibration interface (Fig. 3-64). Click “

” in the system settings interface to enter the dark current calibration interface (Fig. 3-64). Click “  ”, the system will start the calibration and a prompt “Correcting dark current…” will be shown. The dark current data displayed will be refreshed after completing the calibration. Click “

”, the system will start the calibration and a prompt “Correcting dark current…” will be shown. The dark current data displayed will be refreshed after completing the calibration. Click “  ” to return to the main interface.

” to return to the main interface.

Fig. 3-64

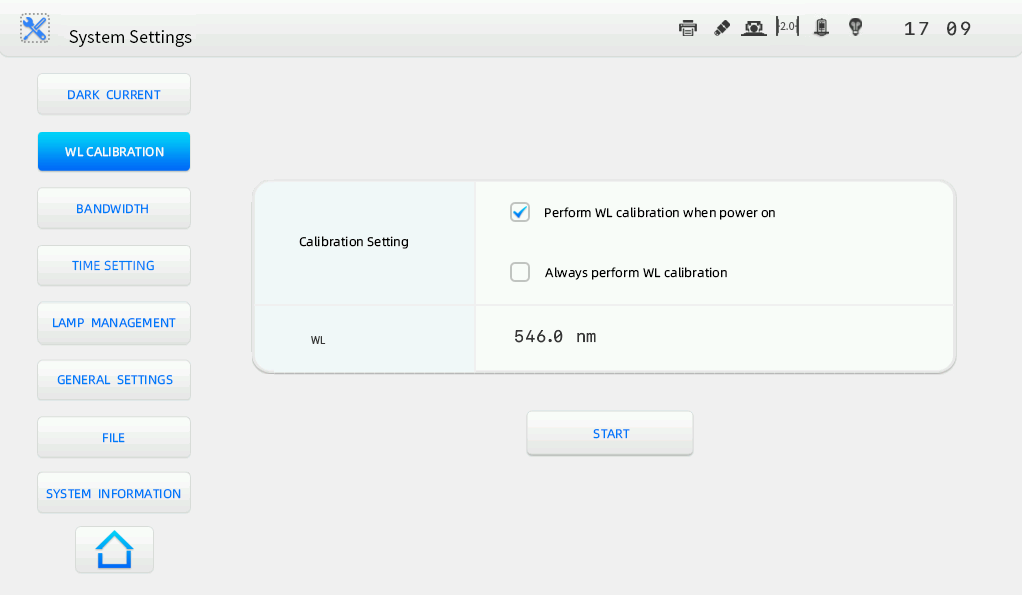

3.9.2 Wavelength calibration

The wavelength calibration is necessary when user doubts that there is a deviation of the wavelength. Click “

” in the system settings interface to enter the wavelength calibration interface (Fig. 3-65). Click “

” in the system settings interface to enter the wavelength calibration interface (Fig. 3-65). Click “  ”, the system will start the calibration of characteristic wavelength 656.1nm with the deuterium lamp in the instrument, and a prompt “Correcting wavelength…” will be shown. The calibration process may cost more than one minute. Click “

”, the system will start the calibration of characteristic wavelength 656.1nm with the deuterium lamp in the instrument, and a prompt “Correcting wavelength…” will be shown. The calibration process may cost more than one minute. Click “  ” to return to the main interface after completing the calibration.

” to return to the main interface after completing the calibration.

Fig. 3-65

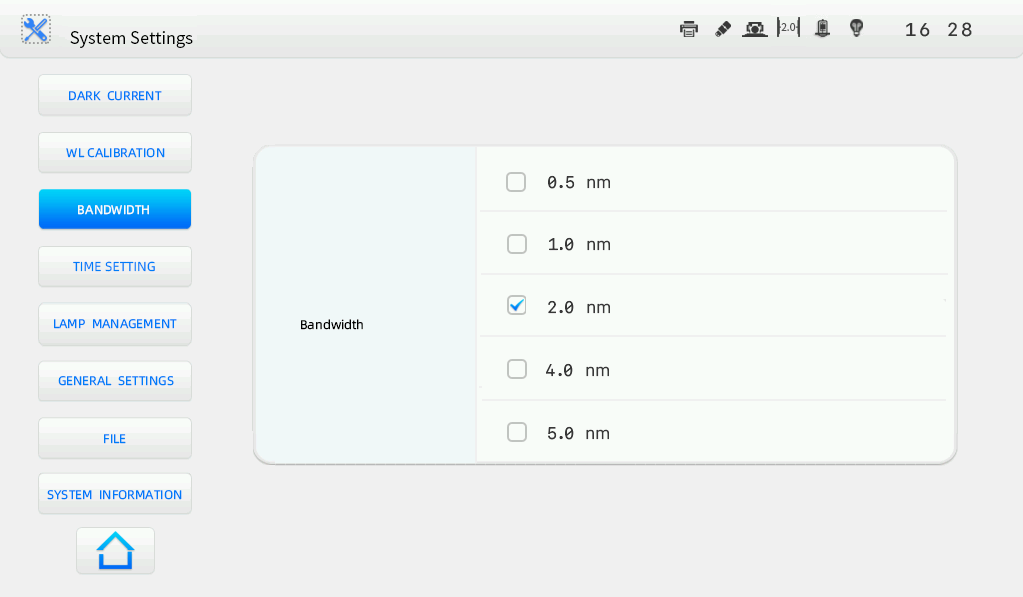

3.9.3 Bandwidth setting

User can set the bandwidth. Click “

” in the system settings interface to enter the bandwidth setting interface (Fig. 3-66). The bandwidth of BSDBU-201-C series UV/Vis Spectrophotometer is adjustable. There are five kinds of bandwidth for selection, 0.5 nm, 1.0 nm, 2.0 nm, 4.0 nm, and 5.0 nm.

” in the system settings interface to enter the bandwidth setting interface (Fig. 3-66). The bandwidth of BSDBU-201-C series UV/Vis Spectrophotometer is adjustable. There are five kinds of bandwidth for selection, 0.5 nm, 1.0 nm, 2.0 nm, 4.0 nm, and 5.0 nm.

Fig. 3-66

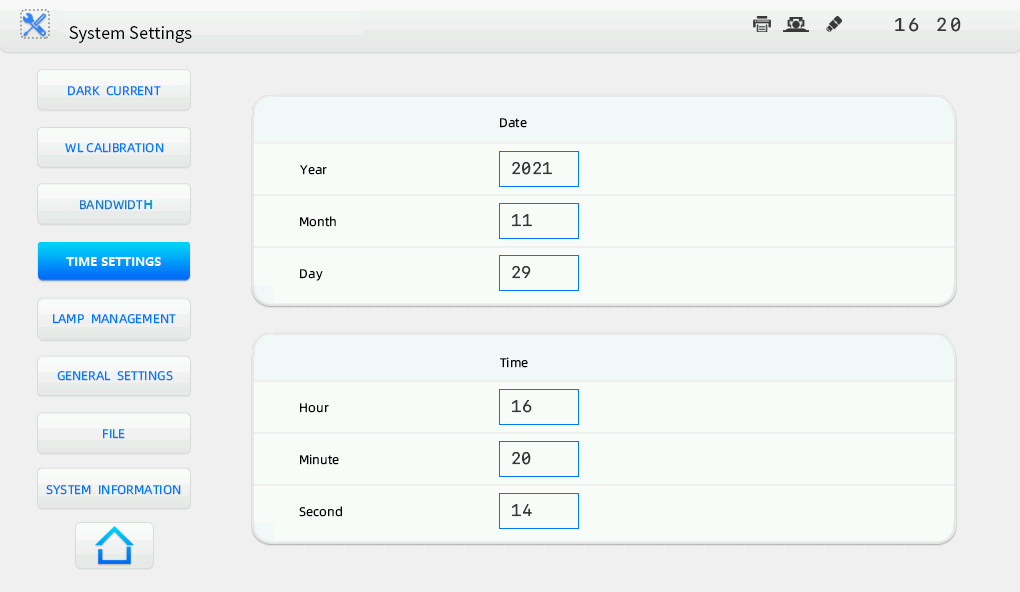

3.9.4 Time settings

User can set the system displaying time. Click “

” in the system settings interface to enter the time setting interface (Fig. 3-67).

” in the system settings interface to enter the time setting interface (Fig. 3-67).

Fig. 3-67 Fig. 3-68

Click in the year column, a digital input window will pop up (Fig. 3-68). Click “

” after inputting the year value. Successively set other time parameters. Click “

” after inputting the year value. Successively set other time parameters. Click “  ” to return to the main interface after completing all the settings.

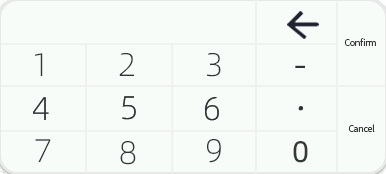

” to return to the main interface after completing all the settings.3.9.5 Lamps management

Click “

” in the system settings interface to enter the lamps management interface (Fig. 3-69).

” in the system settings interface to enter the lamps management interface (Fig. 3-69).

Fig. 3-69

User can switch on or off the lamp as necessary. The service time of the lamp is recorded. User also can set the lamp conversion wavelength. Click in the lamp conversion column, input the conversion wavelength value in the pop-up digital input window and click “

” to confirm the setting.

” to confirm the setting. User maybe only use the UV range or visble range to measure, to prolong the service life of the lamp, switching off the idle lamp after the instrument completing self-diagnosis is suggested.

User maybe only use the UV range or visble range to measure, to prolong the service life of the lamp, switching off the idle lamp after the instrument completing self-diagnosis is suggested. The default lamp conversion wavelength is 340nm, and the valid setting range is between 300nm and 400nm. For measurement accuracy, please don’t measure just under the coeversion wavelength. Please set the conversion wavelength properly before measurement.

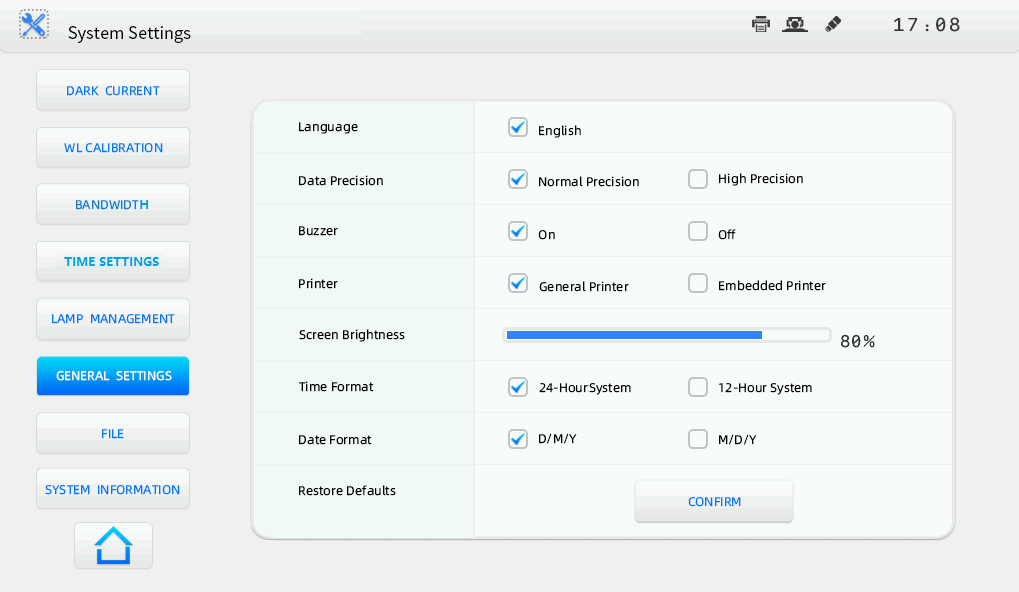

The default lamp conversion wavelength is 340nm, and the valid setting range is between 300nm and 400nm. For measurement accuracy, please don’t measure just under the coeversion wavelength. Please set the conversion wavelength properly before measurement.3.9.6 General settings

Click “

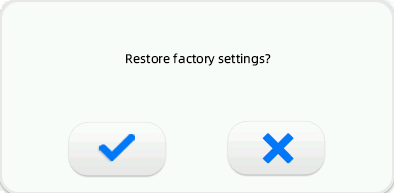

” in the system settings interface to enter the general setting interface (Fig. 3-70). User can select language, data precision, buzzer on or off, printer type, time format, and date format. The screen brightness also can be set. User can click “

” in the system settings interface to enter the general setting interface (Fig. 3-70). User can select language, data precision, buzzer on or off, printer type, time format, and date format. The screen brightness also can be set. User can click “  ” to restore the factory defaults as necessary, and a dialog box will pop up (Fig. 3-71), click “

” to restore the factory defaults as necessary, and a dialog box will pop up (Fig. 3-71), click “  ” to make sure the restoring. And a prompt “Restoring factory settings… ” will be shown.

” to make sure the restoring. And a prompt “Restoring factory settings… ” will be shown.

Fig. 3-70

Fig. 3-71

All the saved data including the test record, parameters setting and standard curves will be cleared by factory defaults restoring. So, please be careful to perform this operation.

All the saved data including the test record, parameters setting and standard curves will be cleared by factory defaults restoring. So, please be careful to perform this operation.3.9.7 File system

Click “

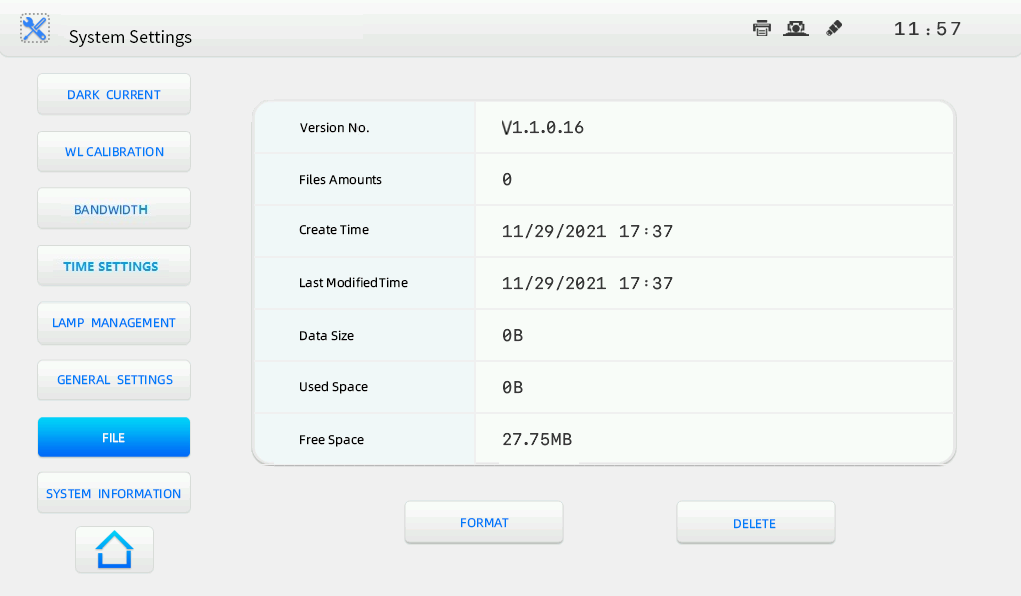

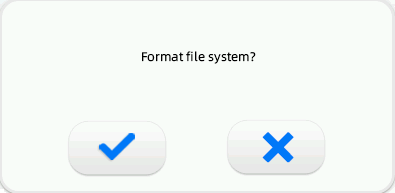

” in the system settings interface to enter the file system operation interface (Fig. 3-72). User can click “

” in the system settings interface to enter the file system operation interface (Fig. 3-72). User can click “  ” to perform file format as necessary, and a dialog box will pop up (Fig. 3-73), click “

” to perform file format as necessary, and a dialog box will pop up (Fig. 3-73), click “  ” to make sure the format, and a prompt “Formatting file system… ” will be shown. Otherwise, click “

” to make sure the format, and a prompt “Formatting file system… ” will be shown. Otherwise, click “  ” to exit the file formatting.

” to exit the file formatting.

Fig. 3-72

Fig. 3-73

Once the file formatting is performed, all the data saved will be cleared. So, please be careful to perform this operation.

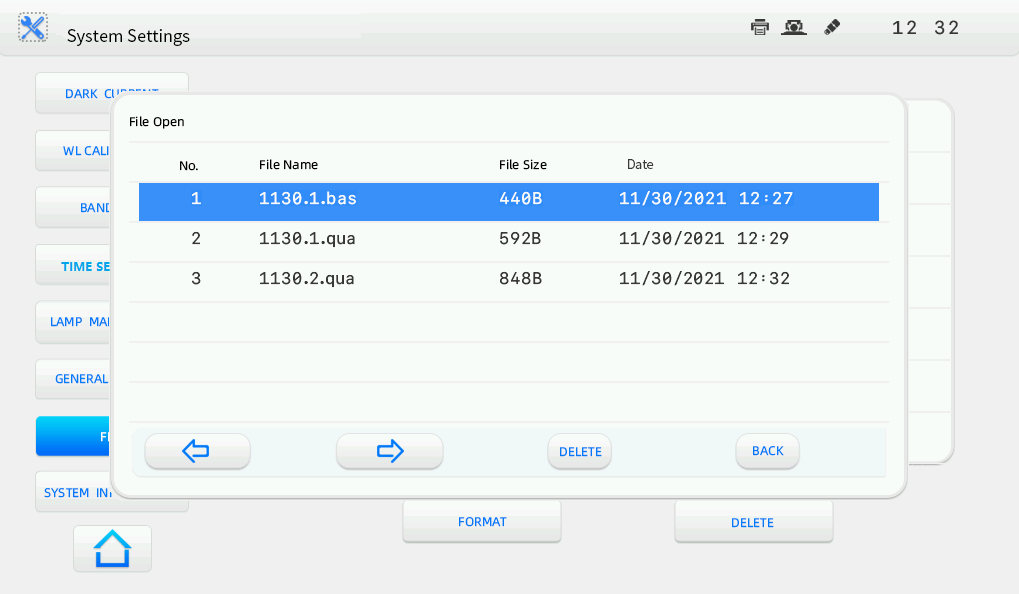

Once the file formatting is performed, all the data saved will be cleared. So, please be careful to perform this operation.User also can delete the file. Click “

” to enter the file opening interface (Fig. 3-74), select the file and click “

” to enter the file opening interface (Fig. 3-74), select the file and click “  ” at the bottom of the file list, a dialog box will pop up (Fig. 3-75), click “

” at the bottom of the file list, a dialog box will pop up (Fig. 3-75), click “  ” to make sure the file deleting. Otherwise, click “

” to make sure the file deleting. Otherwise, click “  ” and “

” and “  ” to exit the deleting.

” to exit the deleting.

Fig. 3-74

Fig. 3-75

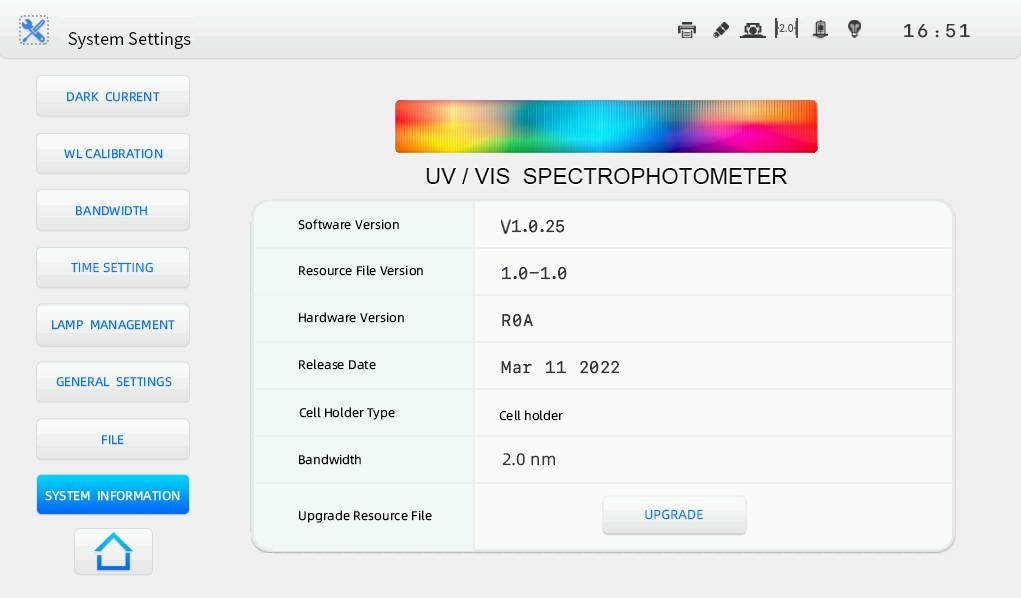

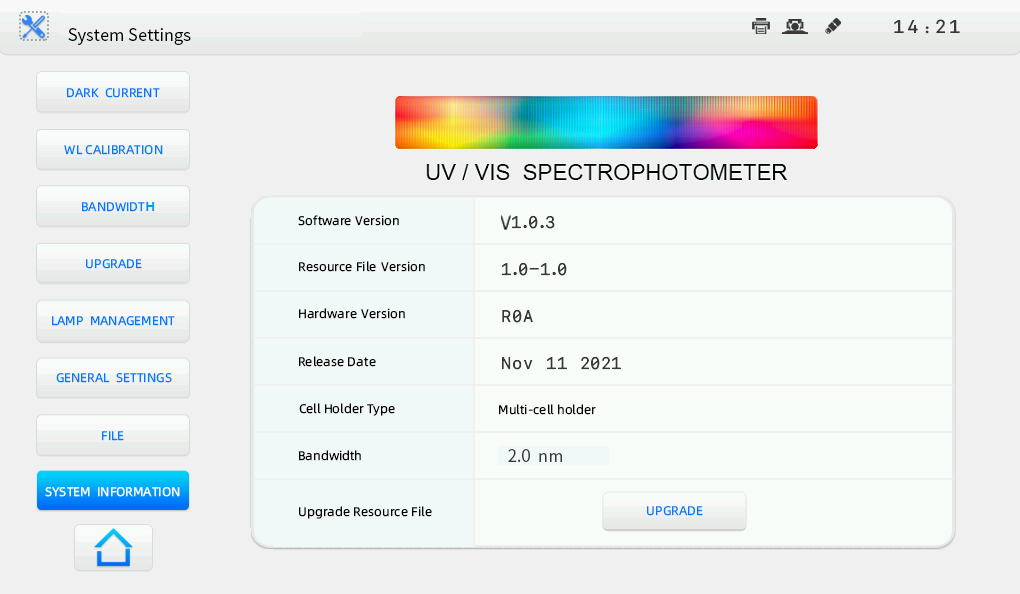

3.9.8 System information

Click “

” in the system settings interface to enter the system information displaying interface (Fig. 3-76). The system information such as software version, resource file version, hardware version, release date, cell-holder type, and bandwidth can be viewed in this interface. User also can click “

” in the system settings interface to enter the system information displaying interface (Fig. 3-76). The system information such as software version, resource file version, hardware version, release date, cell-holder type, and bandwidth can be viewed in this interface. User also can click “  ” to upgrade the resource file as necessary.

” to upgrade the resource file as necessary.

Fig. 3-76

4. Maintenance

BSDBU-201-C series UV/Vis Spectrophotometer is a precise optical instrument. It was assembled and debugged carefully before delivery. However, appropriate maintenance will not only guarantee its reliability and stability, but also prolong its service life. Correct use is the best maintenance. In addition to previously mentioned installation requirements, following tips also should be noticed in daily use.(1) Before switching on the power, make sure that neither sample in the sample compartment nor any other block in the light path, and the cell holder position is all right, to avoid error during the self-diagnosis.

(2) Please carefully load the solution into the cuvette, and the height is better no more than 2/3 of the cuvette. Try to avoid the bubble generation, for the bubble on the inner surface of the cuvette or in the solution will affect the measurement result. Please wipe off the solution that residue on the outer surface of the cuvette in time. To measure volatile samples, using with cuvette cover is suggested. Try to avoid contamination to the cell holder, otherwise, wipe off the residue solution on the cell holder promptly.

(3) Don’t touch both the two optical surfaces of the cuvette with finger, for the finger will absorb the light and furtherly affect the measurement accuracy. Please handle the cuvette gently, for it is frangible. Clean the cuvette properly. Improper cleaning or without enough clean also will affect the measurement accuracy, even cause unstable result.

(4) Whether placing or removing the sample, please close the lid of the sample compartment in time during the measurement. Please remove the sample from the sample compartment promptly after completing the measurement, check that there is no residue in the sample compartment and keep it dry. Any solution sample or residue left in the sample compartment may cause damage to parts of the instrument such as filter turning moldy, some components be corroded. Please open and close the lid gently.

(5) To prolong the service life of the lamp, switching off the idle lamp during the measurement is suggested. Please switch off the instrument and disconnect the plug in time, to prevent possible damage from thunderstorms.

(6) Be careful in the transport. Don’t place heavy object onto the instrument, to prevent the light path shift which will furtherly affect the instrument stability and measurement accuracy.

(7) Don’t disassemble the cover and the inner parts of the instrument without authorization, especially for the optical parts. Don’t loosen the tightening screws and nuts at will. All optical surfaces including the light sources can’t be touched by hand or any other objects. Otherwise, it may affect the normal operation even cause damage.

(8) Keep the instrument surface and the working environment clean. For the surface of the cover deals with painting process, please don’t clean the cover with organic solutions such as alcohol, gasoline and ether. If the instrument is not in use, user can cover the instrument with clean cloth or dust cover to avoid dust accumulation.

(9) A long time not in use should be avoided, and regular boot is suggested to guarantee the normal operation. In the high temperature and humidity area, user should pay more attention to keep away from moisture.

The instrument self-diagnosis is performed for normal diagnosis each time when switching on the power. However, the system error may accumulate after transport, moving, and a period of time’s use. When the measurement data differs greatly from the experienced value, or any above situation occurs, the dark current calibration and wavelength calibration are suggested to be done.

The instrument self-diagnosis is performed for normal diagnosis each time when switching on the power. However, the system error may accumulate after transport, moving, and a period of time’s use. When the measurement data differs greatly from the experienced value, or any above situation occurs, the dark current calibration and wavelength calibration are suggested to be done.5. Troubleshooting

Each BSDBU-201-C series UV/Vis Spectrophotometer is strictly debugged and inspected before delivery. Commonly, it won’t appear problems in normal storage, transport and use. However, wrong operation or extreme states, and problems caused by long-term use still can’t be avoided, such as the damage of electrical and optical units caused by bad storage and working environment, the damage of vulnerable units or the loosen of the fixing parts caused by improper transport, the lamp exceeds its lifetime, the wastage of electrical units, other troubles caused by wrong operation, and so on.Please carefully refer to the related instructions before operating the instrument. Troubles and troubleshooting are introduced in following table (Table 5-1).

Table 5-1

| No. | Trouble | Cause | Troubleshooting | |

| 1 | No response when switching on the power. | 1) Power disconnection. | - Check the power supply and power cord, make sure that the power supply is OK and the power cord is connected well. | |

| 2) The fuse is burned. | - Change the fuse. | |||

| 3) The switching power supply is damaged. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| 2 | No display or unclear display, however the fan of the power supply unit is running when switching on the power. | 1) The control chip or component is damaged. | - Contact the distributor or the factory technical engineer for maintenance. | |

| 2) Bad connection of the display, or the display is damaged. | - Contact the distributor or the factory technical engineer for maintenance or change the display. | |||

| 3 | Self-diagnosis Failure | Lamp conversion fault. | 1) Control motor fault. | - Contact the distributor or the factory technical engineer for maintenance. |

| Filter fault. | 1) Control motor does not work. | - Contact the distributor or the factory technical engineer for maintenance. | ||

| 2) The optocoupler positioning is abnormal. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| No. | Trouble | Cause | Troubleshooting | |

| 3 | Self-diagnosis Failure | Detector fault. | 1) Amplifier circuit fault. | - Contact the distributor or the factory technical engineer for maintenance. |

| 2) Filter position error. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| 3) Bad connection of signal wire between the amplifier and the microcomputer board. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| Wavelength calibration fault. | 1) Some sample in the sample compartment, or the lid of the sample compartment is opened. | - Check the sample compartment, make sure that no sample is in the light path. Don’t open the lid of the sample compartment during self- diagnosis. | ||

| 2) Wrong position of the cell holder causes block to the light path. | - Make sure that the cell holder is in right position. | |||

| 3) Deuterium lamp is not lighted. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| 4) The optical parts turn moldy and cause low energy. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| 5) Wavelength motor fault. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| 6) Filter motor fault. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| Dark current error | 1) The lid of the sample compartment is opened during self- diagnosis. | - Don’t open the lid of the sample compartment during self- diagnosis. | ||

| 2) Amplifier board fault. | - Contact the distributor or the factory technical engineer for maintenance. | |||

| 4 | The reading is not stable when adjusting 100% T or 0.000 Abs. | 1) Wrong position of the cell holder causes block to the light path. | - Make sure that the cell holder is in right position. | |

| 2) The pre-warming time is not enough. | - Pre-warming with enough time, no less than 30 min. | |||

| 3) The tungsten lamp is exhausted or with bad connection. | - Replace the tungsten lamp with a new one. | |||

| No. | Trouble | Cause | Troubleshooting |

| 5 | The reading is not stable when adjusting 100% T or 0.000 Abs. | 4) Deuterium lamp is exhausted. | - Replace the deuterium lamp with a new one. |

| 5) Wavelength error. | - Do dark current calibration and wavelength calibration, then, try again. | ||

| 6) Light path, or the amplifier and its power supply fault. | - Contact the distributor or the factory technical engineer for maintenance. | ||

| 6 | The sample reading is not stable. | 1) Abnormal self- diagnosis. | - Make sure that the instrument can pass through the self- diagnosis successfully. |

| 2) The pre-warming time is not enough. | - Pre-warming with enough time, no less than 30 min. | ||

| 3) Unstable voltage. | - Contact the distributor or the factory technical engineer for maintenance. | ||

| 4) Ambient interference, such as unstable power supply, corrosive gas interference. | - Configure with a steady power supply, keep the instrument from corrosive gas. | ||

| 5) Unstable sample. | - For the sample is unstable, measure it as soon as possible. If there is some bubble in the solution, eliminate the bubble or reload the solution. Measure with a cuvette cover for volatile sample. | ||

| 6) The cuvette is contaminated and it’s too dirty. | - Make sure that the cuvette is clean before measurement. | ||

| 7) The blank value is much higher, or the sample concentration is too high and the absorbance reading is out of the stable range. | - The absorbance value of the blank solution or reference solution is better below 0.1. Dilute the sample solution properly, and the absorbance value is better between 0.2 and 0.8. | ||

| 8) The tungsten lamp or deuterium lamp is exhausted, and the energy is too weak. | - Change the light source. |

| No. | Trouble | Cause | Troubleshooting |

| 6 | The sample reading is not accurate. | 1) Dark current drift. | - Calibrate the dark current, and measure the sample again after blank recalibrating. |

| 2) Cuvette matching error | - Make sure that the cuvettes matching well. | ||

| 7 | The touch screen has no response. | System halted. | - Restart the instrument. |

| 8 | The printer doesn’t work, or printing error. | 1) Loosen connection between the instrument and the printer. | - Make sure the connection between the instrument and the printer is well. |

| 2) The printer model doesn’t match. | - Choose the factory specified printer type. |