Climatic Chamber BCCL-203

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Our chambers provide excellent temperature and lighting control for regulated growth of plants and other products. Its responsive humidification sensor and energy efficient design make it a preferred choice for a wide range of applications.

- Forced convection mode

- 30 Stages programmable Micocomputer PID

- Imported environmental protection insulation materials

- Excellent Imported temperature and humidity Sensor

Specification

Features

Applications

| Capacity | 400 L |

| Temperature Range | 10°C~65°C(Light on)/0°C~60°C(Light off) |

| Temperature Uniformity | ±1.5 (10-40°C) |

| Temperature Fluctuation | ±1°C |

| Temperature Resolution | 0.1°C |

| Using Environment Temperature | Ambient temp.10~30°C |

| Using Environment Humidity | <70% |

| Illumination Range | 0-15000 (5 stages adjustable) |

| Timer Range | 0-99h/0-9999mins |

| Shelves | 4 |

| Inner Dimension | 1148 x 554 x 610 mm |

| Overall Dimension | 1828 x 783 x 905 mm |

| Weight (Net/Gross) | 194 kg |

| Power | 1550 W |

- Forced convection mode

- 30 Stages programmable Micocomputer PID

- Imported environmental protection insulation materials

- Excellent Imported temperature and humidity Sensor

- SUS304 stainless steel interior material

- ALLCOLDTM: Refrigeration Technology

- ALLIGENTTM: Humidification System

- ALLFLOWTM: Perfect Air Current Cycling

Supports plant and insect growth, tissue cultivation, antibiotic cultivation and preservation and other controlled temperature experiments.

Operating Manual for BCCL-203

1. Safety and warning signs , label explication

2.Safety operation and Preventive action

3.Safety operation and Preventive measure

4.Safety operation and Preventive measure

4.1 Instruction(application ,performance, technical parameters )

5.Operation

5.1 Display Operation and usage

6. Alarm and safety functions

7.Optional using

8. Trouble shooting

Notices

- In order to ensure safety to use this equipment, please read this manual carefully

- Make sure put this manual in convenient place for later use

- Our company doesn’t provide a safe guarantee if use not according to the instruction manual

- This manual only for user and authorized technician, should be kept properly

- No notice if any changes because of product improvement

- No right to copy this manual in without our company authorization.

1. Safety and warning signs , label explication

This manual has important use information , user should comply with it . Make sure put this manual in convenient place for later use. The symbols appear to the equipment and the manual, ensure you can safely and correctly operate this equipment , and avoid the possible harma. Warning symbol

warning

warningIt will cause serious harm or fatal accident if not comply with warning.

b. Attention symbol

attention

attentionIt will cause injury ,equipment damage and the loss of relative

property if not comply with attention.

c. The meaning of symbols:

prohibiting

prohibiting must follow

must followd. Symbols on equipment

AC

AC protective conductor thermal

protective conductor thermal power is connected

power is connected power is disconnected

power is disconnected warning, attention, caution and danger

warning, attention, caution and danger2.Safety operation and Preventive action

warning

warning | Do not place this equipment outdoors. if it is exposed in the rain, it may cause creepage and electric shock. |

| Only professional person have the qualification to install this equipment. If not, it may cause electric shock or fire. |

| Should place this equipment on firm ground in case of tumble. If not, it may cause injury because it capsizes. |

| Do not place equipment in a humid environment or a place with dripping water. Otherwise it may cause creepage or electric shock |

| Do not place equipment near flammable materials and volatile substances. Otherwise it may cause an explosion or fire. |

| Do not place equipment in the area where surrounded by acidic or corrosive gas, Otherwise it may cause creepage or electric shock |

| Please use a power supply socket with a protective conductor terminal in case of electric shock. If the power socket is without a protective conductor terminal, it is necessary to install it by licensed technician. |

| Do not connect protective conductor terminals through gas, water pipe, telephone line or lighting arrester which will cause electric shock. |

| Please use the specified power supply. If not, it may cause electric shock or fire. |

| Do not put volatile and inflammable substances in the inner chamber of equipment if it cannot be sealed, or it may cause an explosion or fire. |

| Do not insert nail or wire and similar metal objects into any inlet or outlet of equipment, or it may cause electric shock or injury |

| Please operate this equipment in a safe area if it stores any toxic ,harmful and radioactive substances, or it may do harm to humans and the environment. |

| Make sure to cut off power supply before maintaining equipment in case it causes electric shock or injury . |

3.Safety operation and Preventive measure

warning

warning | Do not touch any electric components or switch with wet hand, or it may cause electric shock |

| Make sure to wear a mask when maintaining the equipment to prevent any harmful drug substance and airborne particles. |

| Do not splash water onto the equipment, or it may cause electric shock or short circuit . |

| Do not place a container which is filled with water on the top of equipment, or it may cause creepage or electric shock. |

| Do not drag, twine or bind power cord. Do not damage the power plug, or it may cause electric shock or fire hazard. |

| Do not use loose power plug, or it may cause fire or electric shock |

| Do not dismantle, repair or refit equipment without authorization and guidance from our company.It may cause fire or injury due to the improper handling. |

| Please unplug the power if equipment is malfunctioning. It may cause fire or electric shock if it continues. |

| Press the power plug instead of pulling the power cord when you want to unplug the power from the power socket, or it may cause an electric shock or fire hazard because of a short circuit. |

| Should unplug the power before moving equipment. Do not damage the power cord. Damaged cord may cause electric shock or fire. |

| Should unplug the power plug if it’s not used for a long period, or it may lead to electric shock, leakage or fire because of wear and tear of the insulator. |

| Keep out of reach of children and the door unsealed if the equipment is not supervised or not used for a long period. |

| Should inform authorized technicians when you dispose of the equipment. Should dismount the equipment door to prevent suffocation and such accidents. |

| Keep out of reach of children with the wrapping plastic. |

4.Safety operation and Preventive measure

Attention

Attention | Please clean the dust on the power plug and then insert it into power socket properly, or it may cause over-heating or strike sparks |

| Check temperature, humidity, segment and timing and other setting value when reboot the equipment after been short circuited or cut off by power supply. Otherwise may cause damage lost of products stored inside. |

| Please place equipment in ventilative and dry place if not used for long period after purchase, or it may lead to equipment malfunctioning when use. |

| Should arrange proper carrying-tools or qualified person when moving equipments. Prevent tumbling when moving equipment, it may cause damage of equipment or human injury. |

| Ensure enough space when moving equipment. If you need to carry it to the second or higher floors, make sure the elevator has enough space for the equipment and working personal. |

| Do not put acidic, alkaline or corrosive substance in the inner chamber if the container is not sealed. Otherwise it will cause corrosion or damage to the components of equipment. |

4.1 Instruction(application ,performance, technical parameters )

Application

LC series Lighting Incubator is a thermostatic equipment with heating, cooling and lighting function, highly precise and advanced.

Widely used in medical and health service, biological pharmaceutical industry, agriculture, forestry, environmental science, animal husbandry, aquaculture etc. mainly for the plant germination, seedling, microbe culture, drug, lumber and building materials aging test, insects and small animal breeding etc.

Performance

Lighting incubator transfers actual temperature detected from temperature sensor into signal, Through microcomputer control to heater towards required temperature

Technical parameters

1. Volume - 250L, 300L, 400L

2. Temp range - 0~65C , with lighting10~50C、without lighting5~50C

3. Temp fluctuation range - ±0.5C(10C~40C)

4. Temp uniform range - ±1C(10C~40C )

5. Lighting - 15000IX,

6. Power voltage - 220V/50Hz,

7. Input power - 1350W(250L) , 1350W(300L) 1550W(400L) ,

8. Working ambient - ambient temp 10~30C relative humidity70% below ,

9. Refrigeration - R134,

10. Equipment class - class I

Notice - this equipment has low temperature auto-defrost function, it is normal if

there is fluctuation when low temperature auto-defrost.

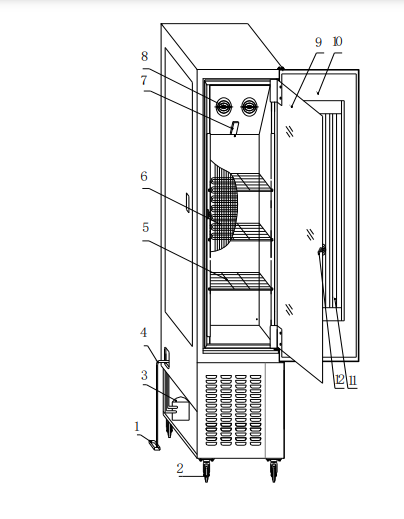

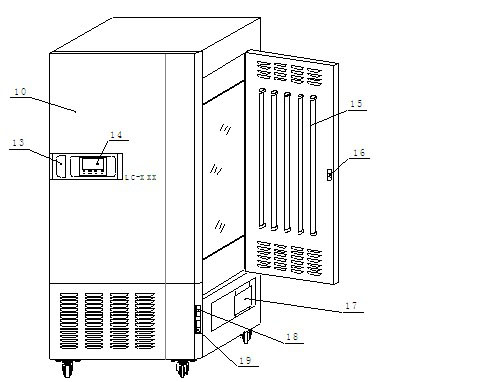

Structure

Components

1.storage water tank 2. wheel 3.compressor part 4.outlet pipe 5.mesh board 6.

evaporator 7.temp. sensor 8.axial fan 9.glass door 10. outer door 11.outer door

lamp 12. internal door key 13. door handle 14. controller 15. side door lamp

16. side door key 17. control panel 18.power supply switch 19.cool switch

Structure

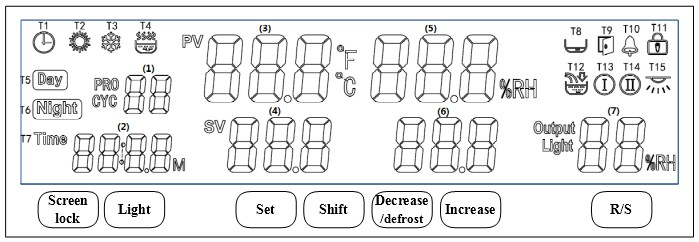

Control panel

Symbol definition

T1 - appointment: its twinkling means the controller enter into appointment mode, meanwhile, the (2) area displays appointment time (count down).

T2 - heat: its lightening means heater working.

T3 - refrigeration: its lightening means air compressor working.

T4 - humidity: its lightening means humidifier working.

T5 - daytime: its lightening means the machine is in daytime mode.

T6 - night: its lightening means the machine is in night mode.

T7 - timer: its twinkling means the timer working, meanwhile, the (2) area displays setting time(count down).

T8 - lack of water: its lightening means lack of water, its twinkling means low-level water alarm. T9 - door open: its lightening means the door is open

T10 - alarm: its lightening means temperature or humidity alarm; its twinkling means low-temperature or high-temperature protection.

T11 - screen lock: its lightening means screen is locked, one can not change any setting value before unlock it.

T12 - watering: its lightening means lamp working, its twinkling means

Display window

1. Area - cycle/segment

2. Area - timer or setting time

3. Area - current temperature value

4. Area - temperature setting value

5. Area - current humidity value

6. Area - humidity setting value

7. Area - illumination or heating output power

Button definition Screen lock - in normal mode, one can press on this button for 2 seconds to lock or unlock the screen. Light: in normal mode, one can click on this button to switch on/off the lamp. Set - in normal mode, one can click on this button to set value of temperature, humidity, illumination and others , or press on this button for 3 seconds to enter into inner parameters. Shift: in setting mode, one can click on this button to shift digit position , in normal mode, one can click on this button to shift daytime or night mode; in programmable mode, one can click on this button to inquire cycles and segments. Decrease/defrost: in setting mode, one can click on this button to decrease setting value , in normal mode, one can press on this button for several seconds to activate defrosting function. Increase: in setting mode, one can click on this button to increase setting value R/S: in normal mode , one can click or press on this button to start or stop the controller running.

Equipment installation

Attention

AttentionAmbient temperature 10~30℃ ;relative humidity less than 70%

Avoid exposure to the sunlight.

Avoid exposure to the sunlight.Do not place it in direct sunlight, or it won’t reach predicted performance

An efficient ventilative place If you operate this equipment in a narrow and concealed room, it may lead to overheating and malfunctioning. Minimum safe distance between equipment and wall is 10CM

An efficient ventilative place If you operate this equipment in a narrow and concealed room, it may lead to overheating and malfunctioning. Minimum safe distance between equipment and wall is 10CM11. Keep away from heat source Don’t install the equipment near heating source. External excess heat will affect performance of the equipment and may cause malfunctioning

12. Flat and firm ground Make sure to install it in flat and firm ground. Uneven surface or leaning installation may damage equipment or injure people. Proper installation can avoid shaking and noise

13. Avoid humid place Install the equipment in a place where humidity is less than 70%. Otherwise it may cause creepage or electric shock.

Warning

WarningDo not place this equipment outdoors. If it exposed in the rain, it may cause creepage and electric shock. Do not place equipment in humid environment or a place with dripping water. Otherwise it may cause creepage or electric shock

Avoid place with flammable or corrosive gas. Do not place equipment near flammable materials and volatile substance. Otherwise it may cause explosion or fire. Do not place equipment in the place where has acidic and corrosive gas, or corrosion will cause creepage, electric shock or equipment damage.

Installation

1. Unpacking Remove packing materials ,open the door for ventilation . Please use neutral detergent to clean if the shell and panel is dirty. then wipe with wet cloth and at last with dry and clean cloth

2. level equipment Fix equipment with the front brake-wheel after installation in case equipment moves

3 Earthing

warning

warningPlease use power socket that has protective conductor terminal in case of electric shock. If it is not connected, has to install protective conductor terminal by licensed technician. Do not connect protective conductor terminal through gas, water pipe, telephone line or lighting arrester which will cause electric shock.

4. Idle equipment Before setting equipment aside , empty water in the humidifier and remove internal, moisture thoroughly. Be sure the inner chamber is dry and cool before closing the door . 5. Move equipment Before moving equipment ,empty water in the humidifier .or it will cause creepage or electric shock because of overflow water or splashed water.

Preparation before operation

1. When equipment running in the first time, please operate as belows: 1.Take out the shelves or other accessories

2.Clean the inner wall with gauze which is soaked by alcohol and then use dry cloth to wipe-dry

3.Put the shelves into inner chamber according to your experiment of requirement

Notice :

Notice :Don’t use NaCl or other Halide solution to clean equipment ,or it will cause rust

5.Operation

5.1 Display Operation and usage

1. After power on, (3) area displays “PS”, (5) area displays “V01”, the buzzer beeps, and then ,after 2 seconds, the controller will enter into normal mode.

2. Setting values: after clicking on set button in normal mode, symbols “TIME”and“SV” twinkle, one can modify the setting value (digit position twinkling), by shift, decrease, increase buttons, and one can shift to next group value by another clicking on set button. After modification, one can press on set button for 1 seconds to quit setting mode, the setting value will be saved automatically.

In programmable mode, segment value position twinkles after clicking on the set button. In this time, one can modify the segment number by decrease or increase button, and inquire setting value of time, humidity, temperature, and illumination in every segment.

In day/night mode, after clicking on set button, “DAY”symbol will twinkle, then, one can choose daytime or night mode by decrease or increase button, after another click on set button, one can inquire and modify every value of current

mode, by increase and decrease buttons.

3. Setting of cycles and segments: in programmable mode or day/night mode, when the controller is in stop situation, after pressing on “set” button for 3 seconds, the

1. area displays “Lc”, the

2. area displays “0”, users can adjust the password to 3 by increase/decrease buttons, so that the controller enters cycle and segment setting mode. PRO----total program number, CYC----total cycle number.

4. fault reminder: Temperature alarm:symbol“℃”flashes quickly when upper deviation occurs,symbol“℃”flashes slowly when lower deviation occurs; Humidity alarm: symbol“%RH”flashes quickly when upper deviation occurs,symbol“%RH”flashes slowly when lower deviation occurs; If the (3) area displays “---”,user should check the sensor and controller.

Inner technical parameters In normal mode, press on set button for 3 seconds, the (1) area will display Lc users can input right code and click on the set button one more time to enter different inner parameters. After adjusting the value of parameters, please do remember to press on the set button for another 3 seconds to quit setting mode.the value adjusted will be saved automatically.

Parameter-1

| symbol | name | function | (range) factory value |

| Lc | password | when“Lc=9”,this parameter group can be inquired and adjusted. | 0 |

| U1 | Running mode | 0:constant value mode; 1:day/night mode, 99 cycles; 2:program mode, 1~30 se gments,0~99 cycles | (0~2) 0 |

| U2 | Power down protection | 0:no operation; 1:begin with the first segment; 2: restart from the power down time | (0~2) 0 |

| U3 | Timer adjust | Modification value=【display value(s)-real value(秒)】*10 ÷ real value(m)。 | (-999~999) 0 |

| U4 | Timing unit | 1:minute 0~9999; 2:hour 0~9999 | (1~2) 1 |

| U5 | Timing temperature point | When U5= display temperature-setting temperature, timer starts to work | (0~10.0℃) 0 |

| U6 | Timing humidity point | When U6= display temperature-setting temperature, timer starts to work | (0~50.0%) 0 |

| U7 | 【R/S】time | Press on the【R/S】for U7 time to run/stop | (0~10s) 0 |

| U8 | Lock screen time | Lock screen time, 0 means unlock | (0~300s) 0 |

| U9 | Reminder time (stop) | The buzzer beeps for U9 seconds when running stop. 0 means buzzer beeps continuously | (0~300s) 0 |

| UA | Illumination time | Illumination time, 0 means manual operation | (0~9999min) 0 |

| Ub | address | Communication address | (1~16) 1 |

parameter -2

| symbol | name | function | (range) factory value |

| Lc | password | when“Lc=103”,this parameter group can be inquired and adjusted. | 0 |

| TH | Temperature upper deviation alarm | when“display value>set value+TH”,upper alarm occurs, heating and humidity cut down User can click on any button to stop buzzer | (0~20.0℃) 5.0 |

| TL | Temperature lower deviation alarm | when“display value<set value+TH”,lower alarm occurs, heating and humidity cut down User can click on any button to stop buzzer | (-50.0~0℃) 0 |

| Tb | Zero adjust(low temperature) | Tb = real temperature - display temperature | (-99.9~99.9℃) 0 |

| TA | Full adjust(high temperature) | TA = 1000 *( real temperature - display temperature)÷display temperature | (-999~999) 0 |

| TP | Proportional band | Adjustment of proportional function. | (0.1~50.0) 8.0 |

| TI | Integration time | Adjustment of integration function | (1~2000s) 500 |

| TD | Differential time | Adjustment of differential function. | (0~2000s) 200 |

| TT | Heat period | Heating control period | (1~60s) 5 |

| Tc | Low temperature cutoff | Heating cutoff point. | (-2.0~0℃) -0.5 |

| To | Heat power | Heating max power percentage | (0~100%) 100 |

parameter -3

| symbol | name | function | (range) factory value |

| Lc | password | when“Lc=203”,this parameter group can be inquired and adjusted. | 0 |

| HH | Humidity upper deviation alarm | when“display value>set value+TH”,upper alarm occurs, heating and humidity cut down User can click on any button to stop buzzer | (0~50.0%) 20.0 |

| HL | Humidity lower deviation alarm | when“display value<set value+TH”,lower alarm occurs, heating and humidity cut down User can click on any button to stop buzzer | (-50.0~0%) 0 |

| Hb | Zero adjust(low humidity) | Tb = real humidity - display humidity | (-99.9~99.9%) 0 |

| HA | Full adjust(high humidity) | TA = 1000 *( real humidity - display humidity)÷display humidity | (-999~999) 0 |

| HP | Proportional band | Adjustment of proportional function. | (0.0~90.0) 10.0 |

| HI | Integration time | Adjustment of integration function | (1~999s) 200 |

| Hd | Differential time | Adjustment of differential function. | (0~999s) 30 |

| HT | Heat period | Heating control period | (0~60s) 5 |

| Hc | Low temperature cutoff | humidity cutoff point. | (-50.0~50.0%) 0.0 |

| Ho | humidity power | Humidity max power percentage | (0~100%) 100 |

parameter -4

| symbol | name | function | (range) factory value |

| Lc | password | when“Lc=72”,this parameter group can be inquired and adjusted. | 0 |

| Sr | Sterilizing | 0:off; 1:on | (0~1) 0 |

| ST | Sterilizing time | sterilizing time, 0 means manual operation | (0~9999min) 0 |

6. Alarm and safety functions

Temperature sensor failure alarm: screen displays: compressor stops working and heating stops. The alarm will stop beeping after 10 times beepsTemperature limit alarm:Measured temperature exceeds the set temperature of 4 degrees, heating stops, The alarm will stop beeping after 10 times beeps

Routine using and maintenance

please keep upright when moving this equipment

please keep upright when moving this equipment Do not frequently modify the set values during process, to avoid overload because compressor starts frequently , or it will affect life of use

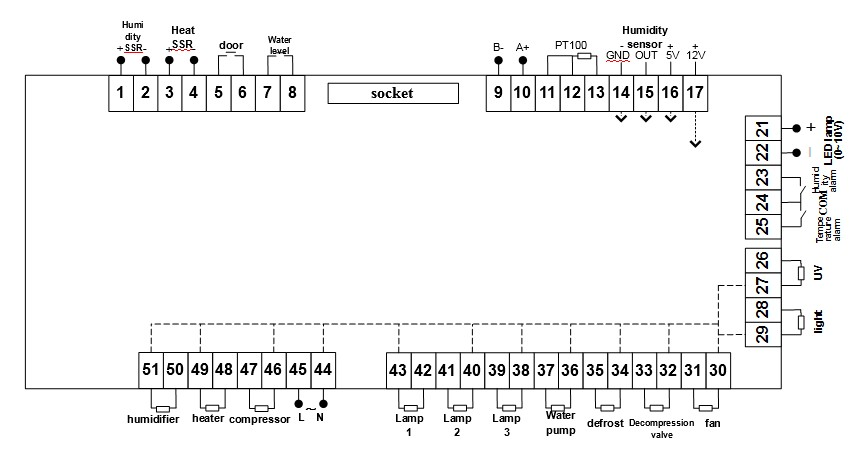

Do not frequently modify the set values during process, to avoid overload because compressor starts frequently , or it will affect life of use The equipment is equipped with power switch and circuit breaker ,if there is something wrong with this equipment during process, please cut off the power and check the control circuit , and then check the other parts. (See wiring diagram)

The equipment is equipped with power switch and circuit breaker ,if there is something wrong with this equipment during process, please cut off the power and check the control circuit , and then check the other parts. (See wiring diagram) Be sure to shut the inner door, and then close the outer door. If the inner door is not fully closed, even if the outer door is closed, the device may not be able to reach maximum performance. Please close the door carefully to avoid damaging silicone door seal

Be sure to shut the inner door, and then close the outer door. If the inner door is not fully closed, even if the outer door is closed, the device may not be able to reach maximum performance. Please close the door carefully to avoid damaging silicone door seal Do not use corrosive solution to wipe the exterior surfaces in order to maintain the appearance of the equipment, keep the chamber clean, use a dry cloth or alcohol to wipe

Do not use corrosive solution to wipe the exterior surfaces in order to maintain the appearance of the equipment, keep the chamber clean, use a dry cloth or alcohol to wipe If set the equipment aside, keep the chamber dry, and cut off the power supply.

If set the equipment aside, keep the chamber dry, and cut off the power supply. In order to ensure uniform temperature, you should often check the axial fan

In order to ensure uniform temperature, you should often check the axial fanDuring experiment, for good circulation, samples should not be crowded

Do not touch temperature probe, in case of temperature is out of control.

Make sure the shelf is fixed, or it could damage the cultures.

Make sure the shelf is fixed, or it could damage the cultures. Do not lean against or press the glass in case injury person.

Do not lean against or press the glass in case injury person. Do not lean against the doors, in case injury person or damage door or damage equipment.

Do not lean against the doors, in case injury person or damage door or damage equipment. When equipment fails to work, please ask professional technician or the factory sales department for help. Please don’t do anything by yourself.

When equipment fails to work, please ask professional technician or the factory sales department for help. Please don’t do anything by yourself.7.Optional using

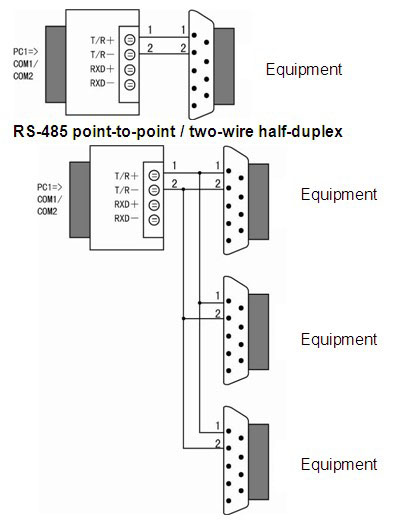

232/RS-485 instructions for use of the converter- In order to proceed with data communication between the different standard serial interface to the computer, an external device or smart instrument, must provide conversion of standard serial interface.

The converter is compatible with RS-232, RS-485 standard, capable of converting single-ended RS-232 signal to a balanced differential RS-485 signals.(it can connect 16 controller of this series together at the same time)

RS-485 point-to-point / two-wire half-duplex

8. Trouble shooting

1. Check if RS-232 port inside connection is correct.2. Check if RS-485 port inside connection is correct.

3.Check if port is connected.

- Data is missing or incorrect

Please check if data communication equipment rate and format is accordance.

1. Trouble shooting

2. Trouble shooting

1. When temp sensor is abnormally, it displays Temp abnormal PLS replace temp Sensor

Specification

Note: Kenton may change product design and specification without notice.

Note: Kenton may change product design and specification without notice.| No. | Name | Quantity | Note |

| 1 | Finish product | 1 | |

| 2 | instruction manual | 1 | |

| 3 | shelf | 4(250L) 4(300L) 4(400L) | |

| 4 | storage water tank | 1 | |

| 5 | water tank | 1 | |

| 6 | Inlet pipe | 1 | |

| 7 | outlet pipe | 1 |

Wiring layout

Packing List

| No. | Name | Quantity | Note |

| 1 | Finish product | 1 | |

| 2 | instruction manual | 1 | |

| 3 | shelf | 4(250L) 4(300L) 4(400L) | |

| 4 | storage water tank | 1 | |

| 5 | water tank | 1 | |

| 6 | Inlet pipe | 1 | |

| 7 | outlet pipe | 1 |