Benchtop Low Speed Centrifuge BCBL-310

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Designed around your applications to provide you competent sample processing and reliable results. Microcomputer programmable with excellent temperature controls and low noise operation maximize your productivity. Highly efficient with low maintenance requirements, it is an ideal separation tool for multiple research applications.

- Brushless motor with simpler construction, more reliable performance, longer life and quietly running.

- Automatically electric lid lock, super speed, over temperature protection and imbalance protection.

- The centrifuge body is made of high quality steel, safe and reliable.

- Rotor is connected to spindle by specialized taper sleeve, loading simple and quick, no direction, safe and reliable.

Specification

Features

Optional Accessories

| Maximum Capacity (No of tubes x Vol.) | 4x800ml |

| Maximum Speed | 6000 |

| Speed Accuracy | ±20rpm |

| Maximum RCF | 4730xg |

| Time Range | 0~99min |

| RPM/RCF Convert | Yes |

| Noise Level | ≤58 dBA |

| Temperature | Normal |

| Acceleration/ Deceleration | 10 kinds |

| Power Supply | AC 220V/110V 50/60HZ 2A |

| Overall Dimension | 685x500x385mm |

| Net Weight | 67 kg |

- Brushless motor with simpler construction, more reliable performance, longer life and quietly running.

- Automatically electric lid lock, super speed, over temperature protection and imbalance protection.

- The centrifuge body is made of high quality steel, safe and reliable.

- Rotor is connected to spindle by specialized taper sleeve, loading simple and quick, no direction, safe and reliable.

- Microprocessor control, TD6B with digital display which

- indicate the speed, time, RCF in operation, speed raising and reducing quick, operate simply.

- 10 kinds of accelerating and decelerating speed for your choice

| Accessory Code | Name | Volume(ml) | RPM | RCFxg |

| 680616006 | Swing Rotor | 4x800 ml | 4000 | 3450xg |

| 680616007 | Swing Rotor | 4x750 ml | 4000 | 3530xg |

| 680616008 | Swing Rotor | 4x500/600 ml | 4000 | 3380xg |

| 680616009 | Swing Rotor | 4x4x96(well) | 4000 | 2940xg |

| 680616010 | Microplate Rotor | 2x4x96(well) | 4000 | 3210xg |

| 680616011 | Swing Rotor | 4x1x50 ml | 5000 | 4730xg |

| 680616012 | Swing Rotor | 4x1x50 ml | 5000 | 4730xg |

| 680616013 | Swing Rotor | 4x1x100 ml | 5000 | 4730xg |

| 680616014 | Swing Rotor | 4x2x100 ml | 4000 | 3020xg |

| 680616015 | Swing Rotor | 4x2x50 ml | 4000 | 3200xg |

| 680616016 | Swing Rotor | 4x4x15 ml | 4000 | 3200xg |

| 680616017 | Swing Rotor | 4x6x15ml | 4000 | 3200xg |

| 680616018 | Swing Rotor | 4x8x15ml | 4000 | 3200xg |

| 680616019 | Swing Rotor | 4x12x5ml vacuum tube | 4000 | 2480xg |

| 680616020 | Swing Rotor | 4x12x7ml vacuum tube | 4000 | 2760xg |

| 680616021 | Swing Rotor | 4x12x10ml vacuum tube | 4000 | 2880xg |

| 680616022 | Swing Rotor | 4x8x10/7/5ml vacuum tube | 4000 | 2790xg |

| 680616023 | Swing Rotor | 4x6x10/7/5ml vacuum tube | 4000 | 2790xg |

| 680616024 | Swing Rotor | 4x4x10/7/5ml vacuum tube | 4000 | 2790xg |

| 680616025 | Swing Rotor | 4x24x5ml vacuum tube | 4000 | 2480xg |

| 680616026 | Swing Rotor | 4x24x7ml vacuum tube | 4000 | 3140xg |

| 680616027 | Swing Rotor | 4x30x7ml vacuum tube | 4000 | 3140xg |

| 680616028 | Swing Rotor | 4x30x5ml vacuum tube | 4000 | 3140xg |

| 680616029 | Swing Rotor | 4x40x7ml vacuum tube | 4000 | 3270xg |

| 680616030 | Swing Rotor | 4x18x10ml vacuum tube | 4000 | 3140xg |

| 680616031 | Swing Rotor | 4x28x10ml vacuum tube | 4000 | 3140xg |

| 680616032 | Swing Rotor | 4 x babcock flask | 4000 | 3830xg |

| 680616033 | Fixed Rotor | 6x15ml | 6000 | 3660xg |

| 680616034 | Fixed Rotor | 12x15ml | 6000 | 4430xg |

| 680616035 | Fixed Rotor | 24x15ml | 5000 | 3500xg |

| 680616036 | Fixed Rotor | 30x15ml | 5000 | 3830xg |

| 680616037 | Fixed Rotor | 4x50ml | 6000 | 3620xg |

| 680616038 | Fixed Rotor | 6x50ml | 6000 | 4110xg |

| 680616039 | Fixed Rotor | 12x50ml | 5000 | 3860xg |

| 680616040 | Fixed Rotor | 24x50ml | 4000 | 2970xg |

| 680616041 | Fixed Rotor | 4x100ml | 6000 | 3790xg |

| 680616042 | Fixed Rotor | 6x100ml | 6000 | 4510xg |

| 680616043 | Fixed Rotor | 12x100ml | 4000 | 2970xg |

Operating Manual for BCBL-310

1. Model and name

2. Application

3. Major technical parameters

4. Rotor type and parameters

5. Major features

6. Unpacking

7. Installation

8. Operation

9. Warning:

10. Warranty Policy

1. Model and name

Benchtop Low Speed Centrifuge BCBL-3102. Application

Benchtop Low Speed Centrifuge BCBL-310 is widely used in the fields of clinic medicine, biochemistry, genetic engineering and radio immunity, best choice to all labs of science units and hospitals.3. Major technical parameters

| Max. Speed: | 6000r/m |

| Max. RCF: | 4730×g |

| Time Range: | 0-99min |

| Power Supply: | 220/110V 50/60Hz |

| Noise: | ≤65dB (A) |

| Dimension: | 685×500×405mm(L×W×H) |

| Net Weight: | 67kg |

4. Rotor type and parameters

| Order No. | Rotor | Max speed | Max capacity (ml) | Max RCF (*g) |

| NO30671 | Swing rotor(round cup) | 4000 | 4×800ml | 3450 |

| NO30696 | Swing rotor(round cup) | 4000 | 4×500ml | 3380 |

| NO30679 | Swing rotor(Square cup) | 4000 | 4×500ml | 3310 |

| NO31494 | Swing rotor | 4000 | 4×4×96well | 2840 |

| NO31491 | Bucket rotor | 4000 | 2×4×96well | 2490 |

| NO31376 | 4000 | 2×3×48well | 2300 | |

| NO31377 | Swing rotor | 5000 | 4×1×50ml | 4730 |

| 5000 | 4×1×100ml | 4730 | ||

| NO31378 | Swing rotor | 4000 | 4x12x5ml | 3200 |

| 4000 | 4x12x7ml | 3200 | ||

| 4000 | 4x12x10ml | 3200 | ||

| NO30690 | Swing rotor | 4000 | 4×24×5ml Vacuum tube | 2840 |

| 4×24×7ml Vacuum tube | 3140 | |||

| 4×18×10ml Vacuum tube | 3140 | |||

| 4×31×7ml Radiation and immunity tube | 3140 | |||

| 4×31×5ml Radiation and immunity tube | 2840 | |||

| NO31493 | Swing rotor | 4000 | Milk fat | 3830 |

| NO31378 | Fixed rotor | 4000 | 4×8 x 15ml | 3200 |

| NO30607 | Fixed rotor | 6000 | 12×15ml | 4430 |

| NO30639 | Fixed rotor | 5000 | 24×15ml | 3500 |

| NO30627 | Fixed rotor | 5000 | 30×15ml | 3830 |

| NO30640 | Fixed rotor | 6000 | 4×50ml | 3620 |

| NO30611 | Fixed rotor | 6000 | 6×50ml | 4110 |

| NO30641 | Fixed rotor | 5000 | 12×50ml | 3860 |

| NO30642 | Fixed rotor | 5000 | 24×50ml | 4640 |

| NO30613 | Fixed rotor | 6000 | 4×100ml | 3790 |

| NO30614 | Fixed rotor | 6000 | 6×100ml | 4510 |

| NO30643 | Fixed rotor | 5000 | 12×100ml | 4640 |

5. Major features

1. Microprocessor control, LED display, directly driving by brushless frequency conversion electromotor. PWM speed adjustment. (1)Adopt special vibration isolator for ideal effect of vibration damping and automatic balance.2. Accuracy PWM speed adjustment, no carbon dust pollution, low noise and small vibration. It will give a quiet lab.

3. Many rotors are available for this model of centrifuge with convenient operation.

6. Unpacking

Please check whether there are serious damages on the package as soon as you received the centrifuge, if so, please contact us directly, if not, please unpacking the package, take out the instruction manual, checking the components and accessories. If you found something missing, please tell us.7. Installation

1. The centrifuge should be installed on a rigid, even surface.2. Electrical source should be 220V/110V Single phase, with independent earth line, never replace the earth line with the neutral line.

3. No shock wave-generating items, nor corrosive gas in the nearby environment

4. Relative humidity of environment: 85%

5. To guarantee sufficient ventilation, please ensure that the centrifuge has at least 15 cm free space on all sides, including the rear.

6. Use the attached power cord

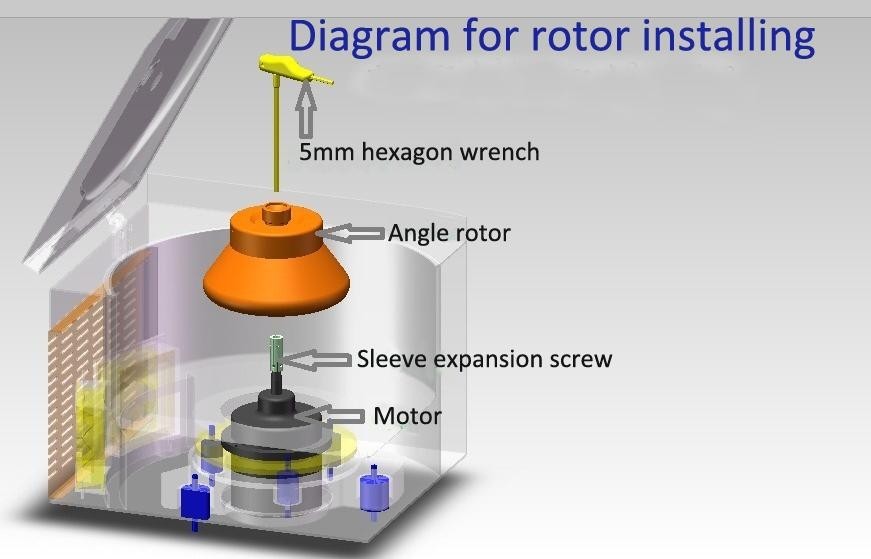

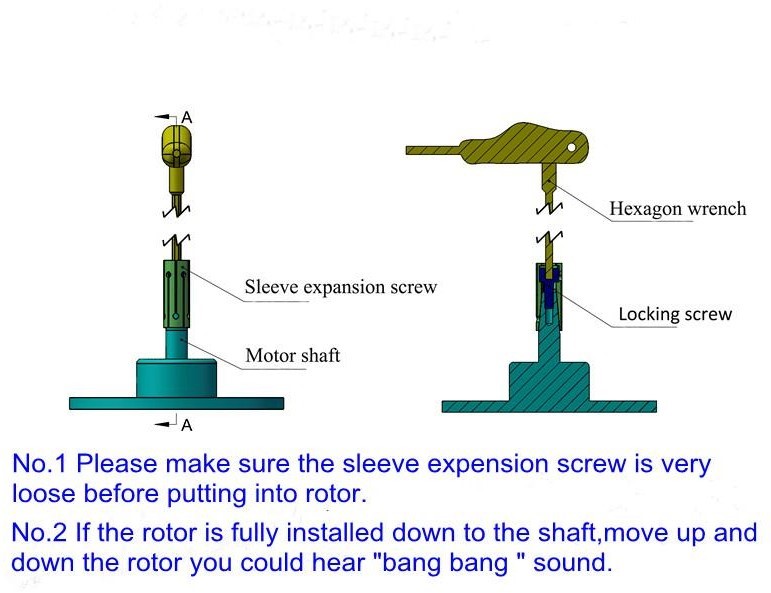

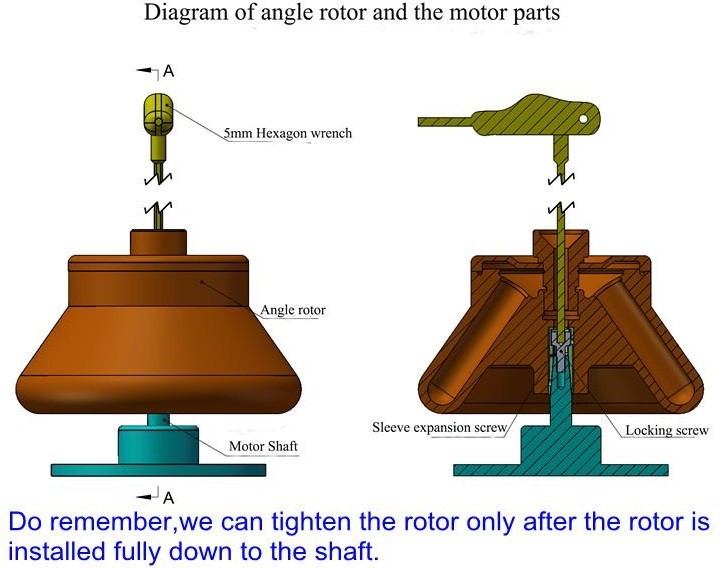

7. Installation of the rotor:(Pay attention to this part carefully)

Rotating sleeve expansion screw with the wrench from clockwise with 1-2 circles, then put the rotor. Check the sleeve expansion screw to make sure it is very loose before putting into rotor. That is because only when the sleeve expansion screw is very loose, the rotor can be fully installed down to the shaft which is correctly installed. If the rotor is installed fully: move the rotor up and down from the shaft, you could hear “bang bang...” sound. If you find the sleeve expansion screw is tight and the rotor can not be installed down fully, rotating with the wrench from anticlockwise 3-4 circles to loose the screw and move the rotor up and down to check, if you can hear sound, it is correct, if not, continue to loose the screw till the rotor can be fully installed down to the shaft. Only after the rotor is fully installed down to the shaft, then you can tighten the rotor.

8. Operation

1. Power onPower switch is located on the right bottom corner of control panel. Turn it to “On” position, the power indicator will turn red.

2. Lid release

Press on “Open” button, the lid will “click” to open, push the lid upward until it open completely. Spring level will help to open the lid.

3. Proper loading of the rotor

Check the rotor before loading. Never use rotors showing signs of cracking or corrosion, never use expired rotors.

Load the rotor to the central adapter located on the axle of electrical motor, and tighten the screw on it.

Fill the tubes equally by eye (about 75% of the total volume), balance the tubes by scale. The difference in weight between the tubes should not exceed 2 grams.

Load the tubes symmetrically.

4. Closing the lid

After the rotor has been properly loaded, close the centrifuge lid. If “E-1” appears on the “Speed screen”, it means the lid is not shut properly.

5. Set the parameters

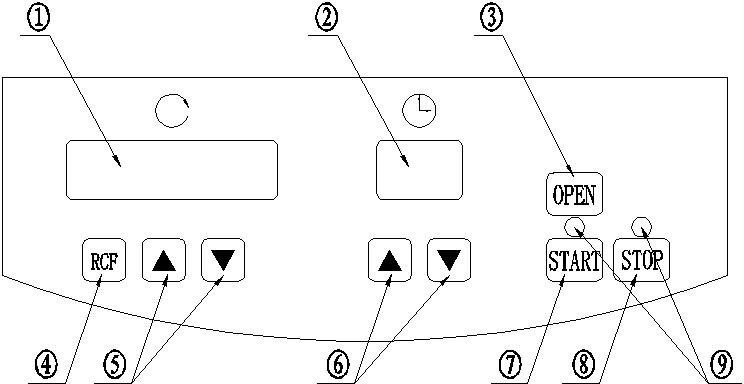

Control panel

1. Speed/RCF/Rotor No. screen

2. Timer screen

3. open the lid

4. RCF

5. +/- key for speed

6. +/- key for run time

7. Start the centrifuge

8. Stop the centrifuge

9. start light and stop light

Plug in and turn on the switch, the time window and speed window in the panel will be brighten.

Pre-selection of the parameters:

1. “ Rotor No./Speed/RCF conversion window

You can circularly press the button RCF will respectively display rotor no., speed and centrifugal force (RCF).

Note: Speed screen: usually “rpm” is shown as a default set in this screen done at factory.

1. Set the speed

As shown in Chart 1, press speed button 5 , speed selection range from 0rpm to maximum 5000rpm , press speed button 5 ,speed will be down, set the speed you prefer, after the digital tube flashes twice, then the setting speed will storage automatically.

2. Set RCF

As shown in Chart 1, Pressing 4 “RCF” button in the display window 1 , it will show the RCF, press button 5 △,the RCF selection range from 0 to maximum RCF. Press button 5 ▽, the RCF will be down. Set the RCF you prefer, after the digital tube flashes twice, then the setting RCF will storage automatically.

3. Select Rotor NO.

It shows the parameters of rotors. It will display the last 2 digits of the rotor no.

For example: 4x800ml swing out rotor no.30671, it was set no.

71. So if you need use this rotor, please select no.71

4. Set the time

As shown in Chart 1, Press time button 6 , the time selection range from 0 minute to 99 minutes, then press time button 6. The time will be down, set the speed and time you prefer, after the digital tube flashes twice, then the setting speed will storage automatically.

5. Set deceleration and acceleration.

It will be done as b4 or b5 default in factory. Different solution test has different requirement for the deceleration and acceleration rate, so we can set the corresponding deceleration and acceleration. When in power off, long time pressing Stop key, instrument has a sound with “di”, time screen display

, press △ , ▽ under time screen to select suitable deceleration and acceleration rate. After setting the parameter, no need to press any key, parameters can be stored automatically. 5seconds later, change to time display automatically. There are 10 grades can be chosen (0-9), the larger of the No, the quicker of the deceleration and acceleration rate.

, press △ , ▽ under time screen to select suitable deceleration and acceleration rate. After setting the parameter, no need to press any key, parameters can be stored automatically. 5seconds later, change to time display automatically. There are 10 grades can be chosen (0-9), the larger of the No, the quicker of the deceleration and acceleration rate.6. Start the centrifuge

Press the start button, the start indicator will be brighten,the centrifuge starts to work,the speed window will show the speed; the time window begin to count down, the speed will be up to what you preselected within1-2minutes.

7. Stop the centrifuge

When the time window count down to 0 ( or press the stop button, stop indicator will be brighten, the speed will be down to 0,then the centrifuge will stop running.

Open the lid; take out the tubes, centrifugation finished.

8. Power off

Press the down side of the switch button, now the panel is cut off, but the whole machine is not power off, if you stop using the machine, you should take out the plug from the power supply socket.

9. Warning:

1. Do not move and open the centrifuge in working status.2. Place the centrifuge on a steady platform. Make four rubber cushions stand in balance to prevent vibration.

3. The liquid added to the centrifuge tube must be even. Large difference may be cause big shaking in running. In this case, the centrifuge should be stopped for checking. The tubes should be placed symmetrically by even number.

4. If the centrifuge tubes break while working, great shaking will occur. The centrifuge should be stopped for checking and further treatment.

5. The centrifuge must be connected with grounded outlet.

10. Warranty Policy

1. We have one –year warranty on our all products2. After the machine fixed, our professional technician will file it and keep track of the usage of the machine.

3. We will pay attention to the feedback of the customers within 24 hours.

4. We won’t charge customers any money for repairing the machine in one-year warranty time.

5. We only charge for the accessories on repairing the machine beyond the one-year warranty time.