BOD Incubator BIBD-103

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

BOD incubator series is intelligently designed to efficiently maintain low temperatures. Easy to clean stainless steel design and duct circulation system ensures temperature uniformity in working area. An ideal choice for BOD analysis of industrial effluents and sewage water.

- Microcomputer intelligent PID control

- LED display with touch keys for setting the parameters

- Stainless steel inner chamber with easy to clean semicircular corners

- Large observation window with magnetic door seal

Specification

Features

Applications

| Capacity | 150 L |

| Temperature Range | 0-60°C |

| Temperature Accuracy | ±0.5°C |

| Temperature Fluctuation | ±1°C |

| Temperature Uniformity | ±1°C |

| Temperature Resolution | ±0.5°C |

| Timer Range | 0-999 min |

| Internal Dimension | 800wx500Dx380H mm |

| Exterior Dimension | 1350Wx640Dx660H mm |

| Package Size | 1470x720x740 mm |

| Shelves | 2 |

| Weight | 102/112 kg |

| Power | 450 W |

| Power Supply | 220V, 60Hz |

- Microcomputer intelligent PID control

- LED display with touch keys for setting the parameters

- Stainless steel inner chamber with easy to clean semicircular corners

- Large observation window with magnetic door seal

- Adjustable shelves with built-in BOD socket

- Duct circulation system ensures uniform temperature in the working room

- Cooling system with high quality compressor

- Refrigerant: Fluorine-free R134a

- Built-in lighting device

- Over temperature alarm function

Fermentation Studies, Bacterial Culturing, Research center, Hospitals and Pharmaceutical lab, Plant, Insect Studies

Operating Manual for BIBD-103

1. Application

2. Product Structure

3. Features

4. Working principle

5. Technical parameter

6. Installation

7.Control panel

8.Operation

10. Maintenances

11. Troubleshooting

1. Application

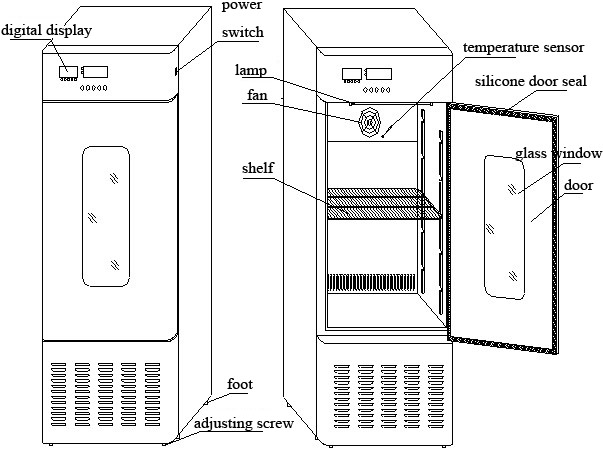

100 series BOD Incubator is thermostatic equipment with cooling function, highly precise and advanced. Widely used in biological genetic engineering, medical treatment, health and epidemic prevention, medical test, agriculture and animal husbandry, aquaculture and other scientific research institutions for plant cultivation, breeding test, bacteria, mould, microbial cultivation & preservation, BOD determination, etc.2. Product Structure

3. Features

The incubator body is made of high quality steel sheet with attractive appearance. Equip with large observation window and built in lighting lamp, which you can observe inside samples clearly. The inner chamber is made of mirror stainless steel, adjustable shelf. Easy to clean and durable.4. Working principle

Biological incubators transfer actual temperature detected from temperature sensor into signal, through microcomputer control to heater and compressor towards required temperature.5. Technical parameter

1.volume:70L、100L、150L、250L;2.temp. range:0~65℃;

3.temp. fluctuation:±1℃(70L、100L、150L) ±1.5℃(250L);

4.temp. uniformity:±1.5℃(70L、100L、150L) ±2℃(250L);

5.power voltage:AC 220V/50Hz;

6.input power:400W(70L、100L)600W(150L) 700W(250L);

7.working ambient temp.10~30℃ relative humidity below 70%

8.refrigeration:R134a;

9.equipment classify: class I type B

6. Installation

1.The equipment should be installed in ventilated place and avoid direct sunlight. The distance between equipment and wall have to be much than 10 CM2.Keep the incubator balance via adjusting screw.(refer to technical drawing)

3.AC 220V/50HZ power supply, in order to be safe, please connect protective conductor thermal

4.Please install this equipment in the place where is far away from fire source

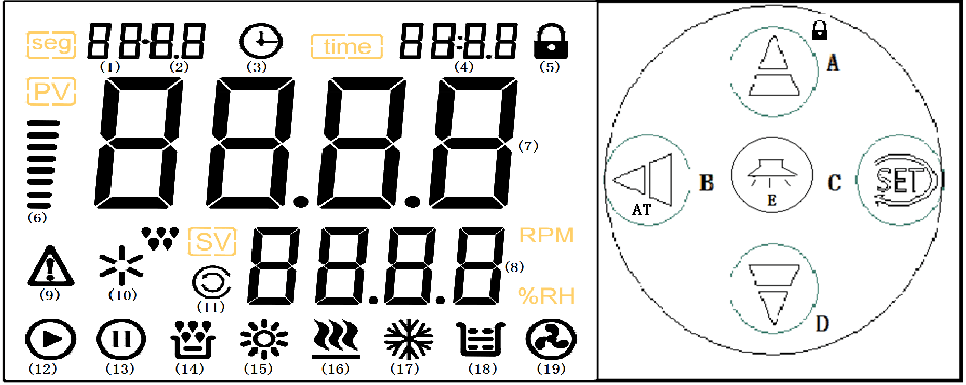

7.Control panel

Indicator and key instruction

(1)Cycle Times: If it is a program segment, the cycle times will be displayed; (2) Number of program segments: the number of segments is displayed when it is in program mode; (3) Appointment time indicator light: it will be on when the machine is turned on; (4) Time: program period time or fixed time; (5) key lock; (6) temperature rise and fall tips; (7) measuring the temperature;(8) setting the temperature; (9) Alarm indicator: it flashes when the machine is stopped or abnormal; (10) standby; (11) spare lamp; (12) Fan operation indicator light: it will light up when it starts running; (13) Stop indicator light: it will light when stopping; (14) standby; (15) Ultraviolet or illuminating lamp indicator: always on for illumination, flashing for ultraviolet disinfection; (16) Heating indicator light: it will light up when there is heating; (17) The cooling indicator lights up when there is cooling output, and flashes when there is cooling delay;(18) standby; (19) Fan indicator light: it will light when the fan outputs; The symbol of℃: it is bright when degree-day is centigrade, and the symbol of ℉ is bright when it is Fahrenheit;Press the keyboard instructions.

A: press ∧: modify the parameter value; (Long press 5S can modify the existing running time, which is available with the program). Click Lock or Unlock.

B: Shift key: shift and modify the parameter value. Press and hold to start/stop the temperature self-setting, and click to query the ambient temperature.

C:SET key: enter parameter setting or press for more than 5 seconds to enter LK or exit parameter setting.

D: Keyless ∨: Modify the parameter value, and press for 5S to enter manual ultraviolet disinfection.

E: Lighting key: Click to start or stop lighting.

8.Operation

1. User parameter SETting: In the standard state, long press the SET key, LK will be displayed on the LCD screen, and LK = 8 will be adjusted. Click the set key to enter.| character | Nominal name | Set range | Say clearly | initial value |

| KS | Power-on operation selection | 0~2 | 0: Stop state when power is on; 1: Run from the first section when power is on; 2: Start running from the place where the power was cut off last time after power on. | 0 |

| md | program schema | 0~1 | 0: customized control; 1. Multi-stage programming control | 0 |

| tn | Timing mode | 0~1 | 0- Start running timing, 1- Temperature stable timing (fixed value only) | 1 |

| Hn | Timing unit | 0~1 | 0- minute, 1- hour | 0 |

| Fn | High and low fan switching | 0~100 | Start the low-speed fan when the temperature is between (set value+fn) and (set value -Fn); Start the high-speed fan at a temperature other than (set value+fn) ~ (set value -Fn) | 1 |

| Ly | illuminate | 0~9999 | When the lighting is turned on, it will automatically turn off after the delay time is not 0. "When the delay time is 0", the delay is invalid and the lighting must be turned off manually. | 0~9999M/h (0) |

| srt | disinfect | 0~9999 | When the disinfection lamp is turned on, the delay time is not 0, and it will be automatically turned off when the time is up. "When the delay time is 0", the delay is invalid and the lighting must be turned off manually. | 0~9999M/h (0) |

| mon | Scheduled boot time setting/scheduled boot month setting | 0~9999 | Function one; The instrument without Beijing time will automatically start after mon minutes; Function 2; The meter with Beijing time will be turned on after the Beijing time reaches the set time (day,Hr,mTn). When Mon is greater than 12, it has the same function. | 0 |

2.Temperature control parameter SETting: In the standard state, press and hold the SET key, LK will be displayed on the LCD screen, and LK = 3 will be adjusted. Click the set key to enter the temperature setting.

| character | Nominal name | Set range | Say clearly | initial value |

| AL | Lower deviation alarm setting value | -50.0~100.0℃ | 0, alarm 1 if there is no alarm, and alarm for lower deviation. When the temperature is less than (temperature set value -AL)℃, turn off the refrigeration. The abnormal indicator lights up and the buzzer rings. | 6.0℃ |

| AH | Upper deviation alarm setting value | -50.0~100.0℃ | On the deviation alarm, when the temperature exceeds (temperature set value+Al)℃, turn off the heating. When the temperature is less than (temperature set value -AL)℃, turn off the refrigeration. The abnormal indicator lights up and the buzzer rings. | 6.0℃ |

| AP | Allow the highest temperature protection of the equipment. | Maximum measured temperature | When the temperature exceeds AP, cut off the heating. When the temperature exceeds AP parameters for 2 minutes, the buzzer will keep ringing and turn off all outputs. It must be powered off before it can be restored. | 120.0℃ |

| P | Heating ratio | 1.0~60.0℃ | The smaller the Pu, the faster the response speed. | 6.5℃ |

| I | Heating integration time | 1~3600秒 | The smaller the integral action time constant, Iu, the stronger the ability to correct static error. | 240 |

| d | Heating differential time | 0~3600S | Differential action time constant, the greater du, the stronger the ability to prevent overheating. | 180 |

| Ar | Heating overshoot suppression | 0~100% | Which is used for restraining temperature overshoot, | 80% |

| t | Heating control period | 1~99 S | Control heating output cycle | 5S |

| ct | Compressor protection delay | (0~9999)s | Delay protection time of compressor, and twice startup time ≥CT seconds; Note that there is no cooling function when CT = 0. | 120S |

| CL | Turn off refrigeration | (0~10.0) ℃ | When switching, the measured temperature < (set temperature+Cl) turns off the refrigeration. Used to initialize parameters. Note: Manual mode is effective when CL = 0. | 0 |

| CH | Turn on refrigeration | (0~10.0) ℃ | When switching, the measured temperature > (set temperature+ch) turns on the refrigeration. Used to initialize parameters. Note: Manual mode is effective when ch = 0. | 0 |

| pb | Zero adjustment of temperature | (-199~999) | Correction near zero degree can be used to correct the error caused by temperature sensor measurement. Pb = reading value of mercury thermometer-current measured value | 0 |

| pk | Full adjustment of temperature (slope) | (-199~2000) | In case of temperature deviation near the set temperature, the value PK = 4000× [Mercury reading value-current measured value] ÷ current measured value can be adjusted. | 0 |

| cb | Environmental temperature correction | -60.0~100.0 | CB = actual ambient temperature-currently measured ambient temperature. | 0 |

| rl | Lower temperature setting | -60.0~100.0 | Set the lower limit of measuring temperature. | -40.0 |

| rh | Upper temperature limit setting | -60.0~100.0 | Set the upper limit of measuring temperature | 100.0 |

3. Temperature and refrigeration control parameter SETting: In the standard state, press and hold the SET key for a long time, then LK will be displayed on the LCD screen, and LK12 will be adjusted. Click the set key to enter the temperature and refrigeration parameter setting.

| character | Nominal name | Set range | Say clearly | initial value |

| tm | Constant temperature selection after the program is finished. | 0~1 | 0: Turn off the temperature control after the program ends. 1: Continue the constant temperature after the program ends, and switch to the fixed value control without timing. | 0 |

| cm | Refrigeration selection | 0~4 | 0: refrigeration start-stop type; 1: refrigeration balance type. It is generally set to 1 during program control; 2: Start-stop mode when the set value is less than Eu, and do not start the compressor when the set value is greater than Eu; 3: When the set value is less than Eu, the compressor is normally turned on, and when the set value is greater than Eu, the compressor is not started; 4: When the set value is less than Eu, the compressor is normally on, and when the set value is greater than Eu, the compressor is in start-stop mode. | 0 |

| Eu | Refrigeration balanced selection | 0~100 | When the parameter is cm = 1: 0: The equilibrium type is judged according to the ambient temperature. If it is higher than the ambient temperature+10 degrees, it will not be cooled, and if it is lower than the ambient temperature+10 degrees, it will always be cooled. 1: Always cooling. | |

| CF | Celsius Fahrenheit selection | 0~1 | 0:℃ 1:℉ | 0 |

| dr | Gated input selection | 0~2 | 0: No door control input; 1: External input closes the door 2: External input opens the door. | 0 |

| dp | Temperature decimal point selection | 0~1 | 0: No decimal point 1: With one decimal point. | 0 |

| wt | Water level detection | 0~1 | 0- no water level, 1- effective water level closure, 2- effective water level disconnection. | 0 |

| LCt | Locking delay | 0-300S | Key lock delay time | 0 |

| FLt | Filter coefficient | 0~9 | Filter coefficient | 4 |

| Hd1 | Defrosting interval 1 | 0-9999 min | After the controller runs Hd1 for minutes, it begins to defrost; Set to 0, no defrosting function (set temperature < 5 degrees) | 0/m |

| Ht1 | Defrosting interval 1 | 0-9999S | When the defrosting time interval is up, start defrosting output Ht1 seconds and then stop defrosting (set temperature < 5 degrees). | 0/s |

| Hd2 | Defrosting interval 2 | 0-9999 min | After the controller runs Hd2 for minutes, it begins to defrost; Set to 0, no defrosting function (5 degrees < set temperature < 20 degrees) | 0 |

| Ht2 | Defrosting interval 2 | 0-9999s | When the defrosting time interval is up, start defrosting output Ht2 seconds and then stop (5 degrees < set temperature < 20 degrees). | 0 |

| Hd3 | Defrosting interval 3 | 0-9999min | After the controller runs Hd3 minutes, it begins to defrost; Set to 0, no defrosting function (set temperature > 20 degrees) | 0 |

| Ht3 | Defrosting interval 3 | 0-9999s | When the defrosting time interval is up, stop defrosting (set temperature > 20 degrees) after starting defrosting output Ht3 seconds. | 0 |

9. View and set intrinsic parameters

In the standard state: in the first stage of program parameter setting, press the setting key to display (1) digital flashing to set the number of cycles by adding, subtracting, shifting and reducing keys. When the number of cycles is not 0, the controller will stop and display end when the number of cycles is 0, and the controller will keep cycling when it is 0; 1-N segments are set in the same way. When the number of cycles reaches the point where it needs to be restarted, press the increase and decrease keys for 5S at the same time, and the controller will restart the control. ; Click the set key display again.(2) The flicker can be increased or decreased, and the shift and decrease keys can set the number of segments; Press the setting key again, and the display (8) will blink to increase or decrease, and shift and decrease the key to set the required temperature; Press the setting key, and the number of the display (4) flashes to set the time by adding, subtracting, shifting and reducing keys; The second paragraph is set in the same way as the first paragraph; If it is set to the end of the required segment, set the time of the segment to 0, and the number of subsequent segments will be hidden, as shown in the following figure:

| character | Nominal name | Set range | Say clearly | initial value |

| Seg(1) | The first cycle number setting | 0~99 | Cycle times = the system ends running when the cycle times are set. | 0 |

| Seg(2) | Number of the first segment | 0~99 | systems operation Number of segments | 0 |

| (8) | End temperature of the first stage | 0 ~ full scale℃ | End temperature of the first stage | 0 |

| Time(4) | End temperature of the first period of operation time | 0~9999min | Time taken for the first period of operation; If st01 = 0, this section is a pause section, which is constant value control. | 0 |

| Seg(1) | The second cycle number setting | 0~99 | Cycle times = the system ends running when the cycle times are set. | 0 |

| Seg(2) | Number of the second paragraph | 0~99 | systems operation Number of segments | 0.0 |

| time | Section n running time | 0~9999min | Time taken for the operation of the n section. | 0 |

| Seg(1) | cycle of operation | 0~99 | When (1) = 0, it runs all the time; (1) = n when running to the end of n times. | 0 |

Further explanation about the operation:

0: set point modification: press the function key, and the setting area of the corresponding time and temperature flashes, and then modify the set temperature and set time in turn. The first period of time is set to 0, and only the first period is run, and there is no timing. For multi-segment programs, if only three segments are run, the time of the fourth segment can be set to 0, and so on; The fixed value control only needs to set the target temperature SP and the timing time ST.

1. Pre-scheduled boot: If it is necessary to automatically boot after a period of time, please start the pre-scheduled boot function. First, stop the control machine, enter the user parameter menu, and set the reserved startup time for parameter mon by increasing or decreasing the key; After the countdown to the scheduled boot is 0, it will automatically boot.

2. Self-tuning function (the timing time St needs to be set to 0 for setting valuecontrol): If the temperature control is not ideal, please start the temperature self-tuning (with refrigeration, it needs to be in the compressor normally open and balanced mode). In the standard state, press the shift key for 5 seconds to start the temperature self-tuning, at which time the indicator light flashes, and the indicator light is always on after the self-tuning, and a new set of PID temperature control parameters is obtained; The temperature control effect is greatly improved. If you want to cancel the temperature self-setting, press and hold the shift key for 2 seconds.

3. Timing and key locking function: If the timing time is set, the instrument will stop running when the timing time is set, and press the increase and decrease keys for 5 seconds at the same time, and the instrument will start running again; Press the lock key in standard mode, and the instrument will lock all the keys. Press it again to unlock it.

4. Two modes can be selected for cooling (through cm parameter setting):

Balance mode: ① When the set value is less than the current ambient temperature+10 degrees, the compressor is turned on and the required set temperature is balanced by heating; (2) The compressor is always on, regardless of the ambient temperature, and the required set temperature is balanced by heating; (through Eu parameter setting) B. Switching mode: refrigeration is self-adaptive, and is not affected by the ambient temperature or the set temperature, so as to ensure that the minimum temperature after refrigeration is turned off meets the technical requirements.

5: Defrosting function (with refrigeration function, and auxiliary function is selected as 0):

Because the humidity of the air may be high and it is easy to frost, it can be output by defrosting; When the controller works for Hd minutes, the defrosting function relay will automatically output Hd seconds (the parameter is set in password 12). This function can prevent frosting after long-term operation.

6. Maximum allowable temperature protection of the equipment: When the temperature is higher than the maximum allowable temperature AP of the equipment, turn off the heating, and when it exceeds the maximum allowable temperature for 2 minutes, the buzzer will keep ringing. If the auxiliary function is selected as 1, the auxiliary function relay output is turned on. 7. Rich peripheral functions: Through RS485 interface, it can be connected with a USB flash drive controller, a micro printer control panel, a mobile phone APP or a PC software to output data.

Note: Only when the compressor works in a balanced mode can it defrost, and other modes have no defrosting function.

Note: The values of the internal parameter table have been debugged and confirmed in the factory, and users do not need to adjust them by themselves.

10. Maintenances

1.Keep upright when moving this biochemical incubator2.In order to prolong the lifetime of equipment, don’t change setting value frequently

3.This equipment is equipped with two fuses, if there is something wrong with this equipment when running, please disconnect power supply first, check the fuse whether is undamaged then check other parts

4.In order to maintain the appearance of equipment, don’t clean the equipment appearance with corrosive solution and clean inner chamber with dry cloth and alcohol

5.If set this equipment aside , please keep inner chamber dry and disconnect power supply

6.In order to make sure uniform temperature , frequently check fan whether works normally. The samples should not be crowded in the inner chamber.

7.In order to make sure good temperature effect, don’t touch or collide the temperature sensor

8. This equipment is equipped with cooling relief function, which is intermittent cooling mode. When cooling stops, it is normal that if there is pull-in of magnet valve or refrigerant backflow sound

11. Troubleshooting

| Troubleshooting | Handing |

| Screen displays (----) | ·There is something wrong with temperature sensor , check the temperature sensor , model : PT100 |

| Temperature can’t reach setting value | ·Setting temperature is lower than display temperature Check whether the heater is damaged Check the controller board and other connections |

| Temperature rises slowly | Check whether the fan stops working fan is broken something wrong with relative connections |

| Screen displays nothing | check whether power switch is on check whether the plug cord is 220V check failures according to wiring layout |