Automatic ESR Analyzer BANA-1400

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

In order to precisely determine the standard curve and scan the comprehensive red blood cell sedimentation process within 30 minutes for the sample of the vacuum blood collection tube, the Automatic ESR Analyzer uses modern infrared light colour difference interpretation technology.

- 7-inch color touch LCD screen, easy to operate, high resolution

- 80 samples/hour, rapid detection

- Randomly insert sample positions for testing at any time

- Built-in thermal printer for easy data printing

Specification

Features

Applications

| Measurement Method | Infrared detection |

| Analysis Result | Westergren ESR value (mm/hour) |

| Throughput | Maximum 80 tests/hour |

| Analysis Channels | 40 (load up to 40 samples for analysis at the same time) |

| Loading Type | Load samples at any time, measure at any time |

| Analysis Time | 30 minutes or 60 minutes selectable |

| Sampling Interval | 3 min |

| Measurement Range | 0~120 mm/h |

| Temperature Compensation | The result is automatically corrected to the result at 18°C |

| Result Resolution | 1 mm/1h and 1 mm/2h |

| Blood Level Range | 50 mm~64 mm |

| Result Accuracy | ±2mm/h (ESR≤30mm/h) ±3mm/h (30mm/h<ESR≤80mm/h) ±5mm/h (ESR>80mm/h) |

| Result Precision | CV ≤ 2% |

| Channel Error | ≤ ±4 mm/h |

| Reading Accuracy | 0.2 mm |

| Net Weight (kg) | 90 |

| Display | 7-inch color LCD touch screen |

| Communication Interface | RS232 serial interface |

| Printer | Built-in thermal printer |

| Power Supply | AC220V 50/60Hz |

| External Size (W x D x H) | 360 x 300 x 180 mm |

| Net Weight | 7.3 kg |

| Package Size (WxDxH) | 395x335x375 mm |

| Gross Weight | 10 kg |

- 7-inch color touch LCD screen, easy to operate, high resolution

- 80 samples/hour, rapid detection

- Randomly insert sample positions for testing at any time

- Built-in thermal printer for easy data printing

- Results are automatically temperature compensated

- Advanced optical testing principles to overcome reading errors in manual methods

- Power-off save function, automatically save the test results

Forensic Lab, Protein Analysis, Hospitals, Medical, Laboratory, Research, Industry, Pharmaceutical

Operating Manual for BANA-1400

Chapter 1 Overview

1.1 Main Parameters and Features

1.2 Product Structure

Chapter 2 Measurement Principle

2.1 Principle

2.2 Method

2.3 Formula

2.4 Result Correction

Chapter 3 Installation

3.1 Installation Requirements

3.2 Unpacking

3.3 Installation Acceptance

Chapter 4 Software Operation

4.1 Power On

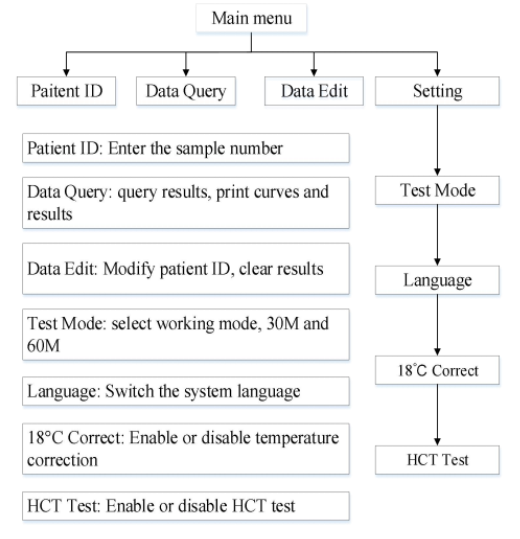

4.2 Main Menu

4.3 Patient ID

4.4 Data Query

4.5 Data Edit

4.6 Setting

Chapter 5 Instrument Operation

5.1 Principle of reading

5.2 Sample Preparation

5.3 Sample Mixing

5.4 Sample Loading

5.5 Sample removal

5.6 SOP

5.7 ESR Curve

5.8 Print

Chapter 6 Maintenance

6.1 Daily Maintenance

6.2 Common Faults

6.3 Fuse replacement

Chapter 7 Safety Protection and Handling

Chapter 1 Overview

BANA-1400 Automatic ESR Analyzer adopts indirect measurement method to realize fast measurement of ESR. Its measurement results have good correlation with the values measured by Westergren method. The whole measurement process is completely controlled by microcomputer, and the operation is extremely simple. This instrument can not only measure the curve of the entire sedimentation process, but also realize the automatic correction of the temperature of the ESR value, as well as the storage, display and printing of the ESR sedimentation process curve and the ESR value.

Figure 1- 1 Automatic ESR Analyzer

1.1 Main Parameters and Features

| Scope of application | Blood erythrocyte sedimentation rate determination (measurement range: 0- 120mm/h) |

| Analysis time | 30 minutes and 60 minutes optional (sampling interval: 3min) |

| Analysis capacity | Maximum 80 tests/hour |

| Analysis channels | 40 (load up to 40 samples for analysis at the same time) |

| Loading type | Load samples at any time, measure at any time |

| Analysis results | ESR value measured by Westergren method (mm/h) |

| Temperature correction | The result is automatically corrected to the result at 18°C |

| Measurement methods | Infrared detection |

| Result resolution | 1mm/ 1h and 1mm/2h |

| Height range of anticoagulated blood | 50mm~64mm |

| Accuracy | ±2mm/h (ESR≤30mm/h) ±3mm/h (30mm/h<ESR≤ 80mm/h) ±5mm/h (ESR>80mm/h) |

| Precision | CV≤2% |

| Channel error: | ≤±4mm/h |

| Reading accuracy | 0.2mm |

| Display | 7-inch color LCD touch screen |

| Communication Interface | RS232 serial interface |

| Printing | Built-in thermal printer |

| Instrument size (W x H x D) | 340mm×440mm×180mm |

| Instrument weight | < 10kg |

| Voltage | AC220V 50Hz |

| Rated power | 60VA |

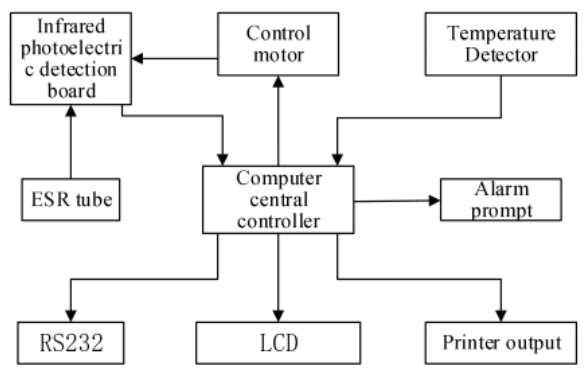

1.2 Product Structure

Figure 1-2 System structure Figure

( 1) Computer central controller: by controlling the actions of each component of the instrument, and processing and calculating the ESR value collected by the detection board, to complete the work procedure set by the instrument.

(2) Switching power supply: Convert the input 220V AC voltage into various DC voltages and send them to each working part.

(3) LCD: Display output measurement results, display instrument operation prompts, and confirm user instructions.

(4) RS232 transmission: transmit sample data to computer.

(5) Printer output: print out the test results.

(6) ESR Tube: Place the blood sample.

(7) Infrared photoelectric detection board: The detection board equipped with infrared transmitting and receiving tubes (TX-RX) moves up and down to measure the interface height of red blood cells and transparent plasma.

(8) Control motor: precisely drive the infrared photoelectric detection board to move up and down.

(9) Temperature Detector: Detects the internal temperature of the instrument in order to perform temperature correction on the measurement results.

( 10) Alarm: Alarm prompts for misoperation of the instrument, etc.

Chapter 2 Measurement Principle

2.1 Principle

Collect blood samples into ESR tubes containing anticoagulant, and place them vertically on the sample holder after mixing. Under the action of gravity, the blood cells will gradually settle, leaving a clear section of plasma in the upper part of the ESR tube. This instrument measures the interface between blood cells and transparent plasma by moving up and down the infrared sending and receiving tubes (TX-RX) on the detection board, and can measure the dynamic sedimentation changes of red blood cells within a certain period of time.

2.2 Method

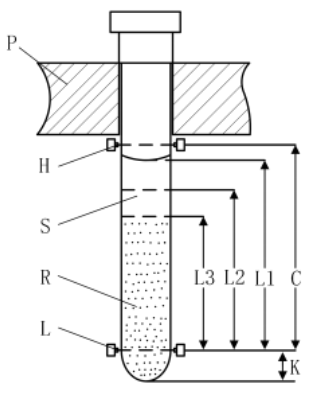

The reading principle of the ESR analyzer is described as shown in Figure 2- 1. The moving range of the infrared transmitting and receiving tubes (TX-RX) is C, and the reading terminals of the ESR tubes are: L is the bottom end, and H is the highest end.

During the movement of the infrared sending and receiving tubes from the bottom end (L) to the highest end (H), if the infrared light cannot reach the receiving tube, it means that the infrared light is blocked by the high density of red blood cells. If the infrared light can pass through the ESR tube to the receiver tube, the signal from the receiver tube tells the computer to start calculating the distance required to reach the mobile terminal.

L1: The height of the blood in the ESR tube at time zero (blood sample initial height). L2: The erythrocyte sedimentation surface in the ESR tube is at the height of 30 minutes. L3: The height of the erythrocyte sedimentation surface in the ESR tube at 60 minutes. K: The height of blood in the ESR tube when the infrared sending and receiving tubes are moved to the bottom. K is determined by the ESR analyzer itself and can be set in the software.

Even if 1.6 mL of anticoagulated whole blood is constantly placed in the ESR tube, the blood height in the ESR tube may vary slightly from sample tube to sample. In order to compensate for this change, the ESR analyzer takes into account the initial height value within a certain height range, and uses the principle of percentage settlement to correct for these changes.

Figure 2- 1 Reading Principle Figure

In the Figure 2- 1:

P: ESR tube sample holder.

H: The highest position of the infrared transmit and receive tubes (TX-RX).

L: The bottom position of the infrared transmit and receive tubes (TX-RX).

R: Red blood cells.

S: Clear plasma.

C: Detection range.

K: The distance from the bottom of the ESR tube to the bottom of the infrared sending and

receiving tubes.

L1: Initial height (at time zero).

L2: The altitude position of the RBC at 30 minutes.

2.3 Formula

The formula for calculating the percentage of sedimentation in 30 minutes is as formula ( 1): %S30= 100(L1-L2)/(L1+K) ( 1)

The formula for calculating the percentage of sedimentation in 60 minutes is as formula ( 1): %S60= 100(L1-L3)/(L1+K) (2)

After summarizing a large number of experimental data from several hospitals and laboratories, the sedimentation percentage corresponding to 30 minutes in the ESR tube was converted to the ESR value of the Westergren method in 1 hour and the calculation formula for converting the sedimentation percentage corresponding to 60 minutes to the ESR value of the Westergren method in 2 hours is the formula (3):

Y=ax+b (3)

In the formula: Y is the ESR result of the Westergren method, x is the sedimentation percentage, and a and b are constants. That is, selecting (a1, b 1) and %S30 values can calculate the ESR value of the Westergren method at 1 hour, and selecting (a2, b2) and %60 values can calculate the ESR value of the Westergren method at 2 hours.

Hematocrit =RBC height after centrifugation / (L1- 11.32) × 100%

Notice: 11.32 means the height occupied by 0.32mL of anticoagulant in the ESR tube.

2.4 Result Correction

The ESR value at different temperatures can be obtained from the formula (3), and the ESR value of the standard Westergren method at 18°C can be obtained by temperature correction. The temperature result correction adopts interpolation correction, which is automatically carried out by the instrument, and the method is as shown in Table 2- 1 (manual correction reference table). If the temperature correction is not set during measurement, manual correction can also be performed. For manual correction, please refer to the following table:Table 2- 1 Manual Correction Reference Table

| 18℃ Correction value | ≤ 16℃ Measurements | 17- 19℃ Measurements | 20-23℃ Measurements | 24-26℃ Measurements | 27-32℃ Measurements |

| Note 1 | 1-7/+20% | No correction | 1-7/-5% | 2-9/- 16% | 1- 12/-37% |

| 18℃ Correction value | ≤ 16℃ Measurements | 17- 19℃ Measurements | 20-23℃ Measurements | 24-26℃ Measurements | 27-32℃ Measurements |

| 8- 13/+12% | required | 8- 15/-5% | 10- 18/- 16% | 13-22/-37% | |

| 14-22/+11% | 16-26/-5% | 19-31/-20% | 23-36/-35% | ||

| 23-31/+11% | 27-36/-4% | 32-43/- 19% | 37-50/-33% | ||

| 32-40/+11% | 37-47/-4% | 44-58/- 18% | 51-64/-31% | ||

| 41-50/+9% | 48-57/-4% | 59-64/- 17% | 65-74/-29% | ||

| 51-59/+9% | 58-67/-3.5% | 65-72/- 16% | 75-87/-26% | ||

| 60-67/+11% | 68-77/-3% | 73-84/- 15% | 88-98/-24% | ||

| 68-76/+11% | 78-87/-2.5% | 85-98/- 14% | 99- 109/-23% | ||

| 77-85/+11% | 88-98/-3% | 99- 108/- 13% | 110- 119/-21% | ||

| 86↑/+11% | 99↑/-3% | 109↑/- 13% | 120↑/-20% |

The BANA-1400 ESR analyzer has a result correction range of 15°C to 32°C. When the temperature is lower than 15°C, please manually correct it below 16°C, and when it is higher than 32°C, please perform manual correction at 27-32°C.

It is recommended that the temperature working range of the ESR analyzer is 15℃-30℃ .

Note 1: The value in the table is the range of the measured value, followed by / is the data to be corrected a%, the correction value at 18°C is the measured value at the measured temperature of the instrument plus or minus the measured value × a% (recommended to be rounded to an integer ).

Chapter 3 Installation

3.1 Installation Requirements

The installation of the BANA-1400 Automatic ESR Analyzer is very convenient, but the following points must be paid attention to during installation:

1. The power cord of the BANA-1400 Automatic ESR Analyzer is a three-core power cord, and the socket must be well grounded to ensure safety and reliable operation.

2. The BANA-1400 Automatic ESR Analyzer should be placed horizontally to ensure that the ESR tube can remain vertical after being inserted into the sample holder, and the instrument should be placed stably, reliably, and to prevent vibration.

After completing the above preparations, the instrument can be powered on for self-checking and system initialization. Instrument settings include date, time, working mode, initial measurement number, temperature correction, and volumetric measurement. we suggest:

( 1) Please read the operating instructions carefully before setting up the instrument.

(2) The working mode of the instrument is usually set to 30 min.

(3) Select 18℃ correct mode for measurement results.

(4) Enable the HCT TEST function of the instrument.

Use environment requirements:

a)Indoor use only.

b)Power supply voltage: AC220V 50Hz.

c)The altitude does not exceed 2000m.

d)Ambient temperature:0℃~+40℃ .

e)Relative humidity: ≤93%.

3.2 Unpacking

After the instrument arrives, please check the packaging carefully to see if there is any physical damage. If the outer package is damaged, please contact our company or local agent. After confirming that there is no damage to the package, unpack as follows:

- Make sure the arrow on the box is upright.

- Open the accessory box and check whether the accessories are complete against the packing list. If there is any missing, please contact the company or local agent in time.

- Check the appearance of the instrument carefully to see if there is any damage to the parts caused by improper transportation. If there is any damage during transportation, please contact the company or local agent immediately.

Carry method

- Make sure that the appearance of the instrument is undamaged and all parts are in good condition before carrying.

- During all moving and transportation, the instrument must be kept upright, not inclined or sideways.

- When carrying, try to avoid vibration. After carrying, you should check and debug it first, and then use the instrument after it is normal.

3.3 Installation Acceptance

1. Connect the power supply and earth wire, after the power switch is turned on, the instrument passes through initialization and then enters the standby state.

2. Operate each function menu according to the user manual, if each function operates normally, it is judged that the instrument is operating normally.

3. Take the QC product for the actual test, if the test result meets the requirements and can be printed correctly, the performance of the instrument is judged to be qualified.

Chapter 4 Software Operation

After the instrument is turned on, it will automatically perform a system self-check. Make sure the instrument is warmed up for 15 minutes to keep the instrument in optimal working condition.4.1 Power On

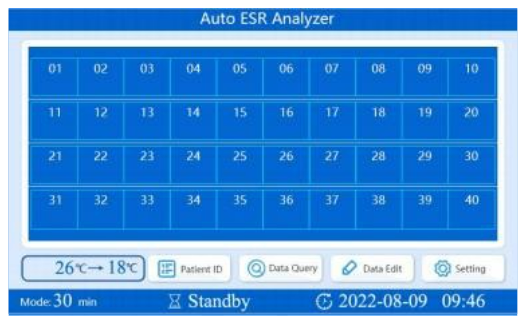

Turn on the power switch, put it in the "I" position, the screen will light up as Figure 4- 1.

Figure 4- 1

The system starts to perform self-check inside the instrument, and the interface displays the real-time temperature. At this time, the system checks the connection of the power supply, memory, and printer, and makes the internal circuit reach a thermally stable state.

4.2 Main Menu

After the instrument self-test is completed, it will enter the main interface, and the screen will display the working mode, temperature, time, working status and other information of the instrument. The working mode can be modified from the SETTING menu. In the lower left corner is the temperature correction indicator box, which displays the current temperature of the tested sample corrected to 18℃ . In the middle is the status mark, the waiting status as shown in the figure means that the detection board is not running, and the status mark shows the working status during the running process. The lower right corner is the time and date, you can click the time position to enter the time and date setting page.

Figure 4-2

The following figure shows the function display box of the main interface, you can directly click the screen to select the function. The numbers on the screen represent the instrument channels.

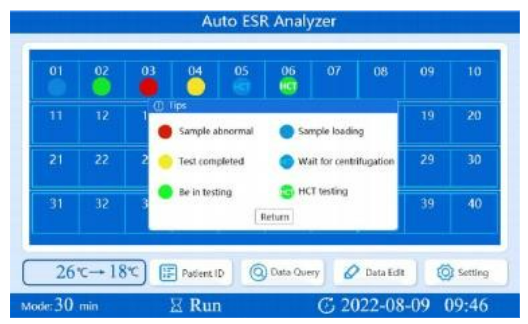

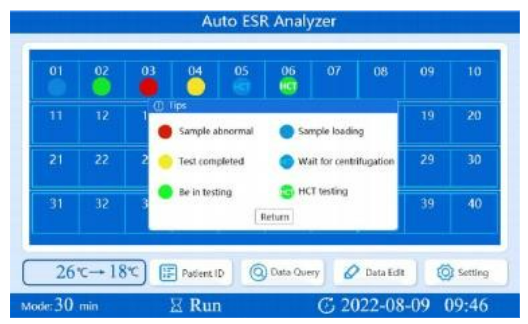

Before the ESR tube is placed, there is no sign below the numbers. The color of the flag indicates the state of the channel during the test. As shown in Figure 4-3 below:

Figure 4-3

Figure 4-4

Blue: Indicates that an ESR tube has just been inserted in this channel, and the instrument detects the sample.

Green: Indicates that the channel sample is being tested, please do not remove the ESR tube during the test.

Red: Indicates that the channel test is abnormal and the blood height is out of range, please remove the ESR tube.

Yellow: Indicates that the channel sample test is completed and the ESR tube can be removed. Marked with HCT blue: This channel can be used for HCT test, please centrifuge the sample and put it back.

Marked with HCT green: Indicates that the channel is undergoing a volumetric measurement, please do not remove the ESR tube.

Notice:

( 1) The ESR tube cannot be pulled out at will during the test.

(2) The ESR tube cannot be detected when the instrument is in the standby state.

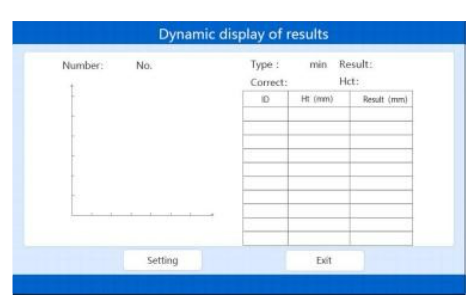

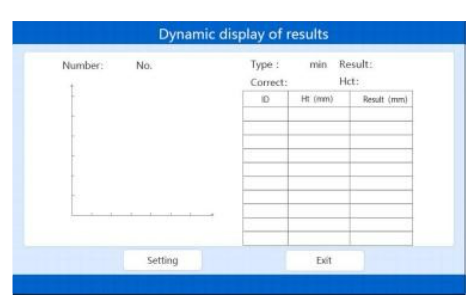

Click the area of the channel on the main interface to enter the single-channel test interface, which is displayed as follows:

Figure 4-5

In this interface, you can view the test mode, result, test curve, channel number, sample placement number and other basic settings. If the relevant settings are incorrect, you can click [Setting] on this interface to change. Before the sample test is completed, the test mode, temperature correction and HCT settings can be modified in this interface. After the test is completed, the data will be printed automatically. The details are shown in Figure 4-6 below:

Figure 4-6

4.3 Patient ID

Press the Patient ID key in the main menu, the analyzer enters the Data Edit interface, and the setting interface is as follows:

As shown in Figure 4-6 , the sample No. is displayed on the left, the channel position number isdisplayed in the middle, and the patient number is entered in the ID column on the right, and the patient number is entered in this interface after the sample is placed. The function keys at the bottom of the interface can be used for the previous page, the next page and the exit operation.

4.4 Data Query

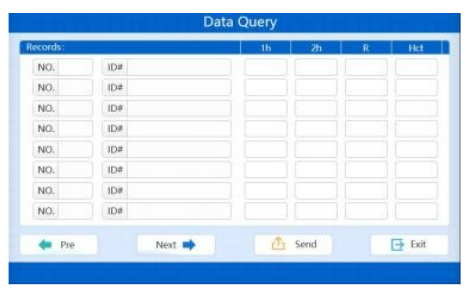

[Next] and [Pre] in the function button of Data Query can query the results by time. The "NO." column is the sample serial number, and the "ID#" column is the patient number. "1h" means the corresponding westergren method measurement result for 1 hour in 30M working mode (mm/ 1h), and "2h" means the corresponding westergren method measurement result for 2 hours in 60M working mode (mm/2h).

"R" indicates that the 18°C correction was initiated for the results during the testing process for this sample. "N" means not to enable 18°C correction. The specific data below "Hct" is the calculated value of the pressure measurement.

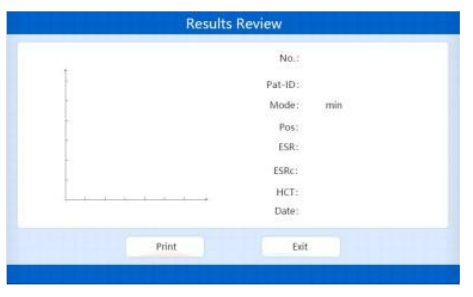

In the data query interface, you can click the test result you want to query, and enter the “Result Review” interface to view the sample test curve and other detailed information, as shown in Figure 4-7 below:

Sample Number: The serial number of test result storage and result printing.

Patient Number: Entered patient ID.

Test Mode: 30min/ 60min

Analysis Channel: The test channel where the ESR tube is placed.

Test Result: The uncorrected temperature corresponds to the results of the Westergren method.

Calibration Result: 18°C after calibration corresponds to the result of the Westergren method.

HCT results: The results of the test for hematocrit.

Time: The length of time the sample was placed.

Print: print the result information of this interface.

Exit: Return to Data Query.

Figure 4-7

4.5 Data Edit

Select "Data Edit" on the main menu to enter this page, edit or modify the sample number with the result in the ID column of this interface, other information is the same as the data query, as shown in Figure 4- 7:

Clear All: Clear all data results with one click. Note: Results cannot be recovered after clearing them.

Clear records: Clear results one by one starting from the last data.

Exit: Return to the main interface.

4.6 Setting

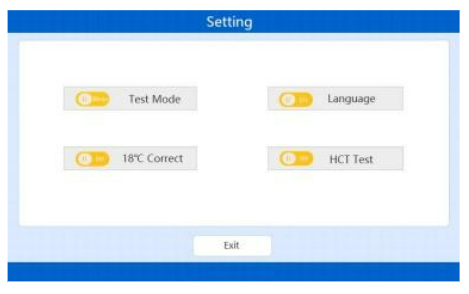

Select "Setting" in the main menu to enter the following interface.

Figure 4-8

The instrument has 30 min (corresponding to 1 hour under the Westergren method) or 60 min (corresponding to 2 hours under the Westergren method) two working modes to choose from. 18℃ Correct can choose to enable or disable the temperature correction function (the test curve will display the corrected curve when enabled, and the uncorrected test curve will be displayed when disabled).

The Language function can switch between Chinese and English languages.

HCT Test can choose to enable or disable this function, and customers can choose to disable the function when HCT test is not needed to save testing time.

Chapter 5 Instrument Operation

5.1 Principle of reading

We use the method of vertical movement of the detection board with infrared photocells to monitor 40 ESR tubes synchronously. The detection board collects one data every 0. 16mm movement (ie the instrument resolution), and the detection period is 3 minutes.

When the ESR tube is inserted into the sample holder of the instrument, the instrument automatically detects the ESR tube and starts timing, and monitors the blood level in the ESR tube.

The acceptable range of blood height set by the instrument is 50mm-64mm (calculated from the bottom of the ESR tube), and the recommended height is 55mm (the corresponding volume is 1.6ml, that is, 0.32mL of anticoagulant, 1.28mLof whole blood). If the blood level in the ESR tube exceeds the acceptance range of the instrument, the instrument will alarm.

If the blood height of the ESR tube is within the acceptable range, the instrument will perform height detection. The whole process will be detected 10 times in the working mode of 30 min, and 20 times in the working mode of 60 min. The specific working principle is detailed in Chapter 2.

5.2 Sample Preparation

The BANA-1400 auto ESR analyzer only needs a sample volume of 1.28mLto complete the measurement. In order to ensure the measured blood level in the ESR tubes, 0.32mLof anticoagulant has been injected into each ESR tube in advance. Observe the marking line on the ESR tube, the blood of the test sample can be directly injected into the ESR tube until the total height of the anticoagulant and blood reaches the marking line. Plug the rubber ESR cap, and slowly invert the ESR tube upside down 4-6 times to mix the anticoagulant and blood thoroughly. Be careful not to have air bubbles in the anticoagulation.

5.3 Sample Mixing

The sample can be thoroughly mixed before testing by the following methods: shake the ESR tube upside down at least 5 times, or use a rotary laboratory mixer or a special mixer.

5.4 Sample Loading

The sample needs to be loaded into the sample holder of the BANA-1400 Automatic ESR Analyzer as soon as possible after mixing, so we recommend mixing the sample near the instrument. Loading of samples can be performed when the instrument is in the working state or in the standby state.

After inserting the sample, please pay attention to the monitoring window corresponding to the sample insertion position on the main menu of the instrument. The insertion position should display a blue icon and have a sound prompt, indicating that a new sample has been inserted at that position.

CAUTION: Inserting a sample in a working state requires waiting for the current run of the assay plate to complete before the sample can be recognized.

5.5 Sample removal

It is strictly forbidden to pull out the ESR tube during the BANA-1400 Automatic ESR Analyzer testing the sample (that is, when the green mark is displayed on the sample position in the monitoring window). If the ESR tube is pulled out at this time, the corresponding green mark disappears. Remix.

After the test is over (that is, the position corresponding to the monitoring window displays a yellow mark), the sample can be removed.

At this time, the yellow mark at the corresponding position of the monitoring window disappears, indicating that the position is open, and a new sample can be reinserted for testing. As long as the sample testing is over, the printer will automatically print out the sample serial number, patient number, ESR value, ESR curve and testing time of the tested sample.

If the user needs to perform HCT test, the sample can be removed and centrifuged after the blue Hct mark appears. A green Hct mark will appear during the compaction test. After the measurement is completed, the position will be displayed as a yellow mark, indicating that the HCT test of the sample has been completed.

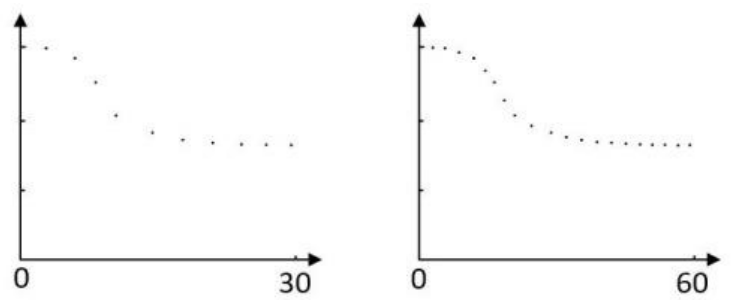

The ESR curve of the BANA-1400 auto ESR analyzer is a curve drawn according to the sedimentation percentage value obtained by detecting the ESR tube every 3 minutes, so the ESR curve is divided into 30 min and 60 min working modes.

5.6 SOP

1. Power on the Automatic ESR Analyzer.

2. Check the setting in main menu: 30min working mode. The results were corrected to the ESR measured at 18°C using the Westergren method for 1 hour. If the main menu settings are incorrect, enter the [Setting].

NOTICE: Do not change the working mode of the instrument while the instrument is running.

3. Load the sample into the sample holder and pay attention to the display of the corresponding position of the monitoring window.

4. Click Patient ID to enter the interface and enter the Patient ID of the corresponding location (maximum 9 digits).

5. Storage of sample ESR value: After 30 minutes, the sample measurement ends, the instrument automatically stores and prints the ESR value and curve. If a yellow mark is displayed in the monitoring window, it means that the sample at this position has been tested and the sample can be removed. A new sample test can be performed again after the yellow mark disappears at this position.

NOTICE: With the HCT Test feature enabled, the sample can be removed and centrifuged after the blue Hct mark appears. The centrifuged sample needs to be placed in the original position for measurement (the green Hct mark is displayed at this tim

5.7 ESR Curve

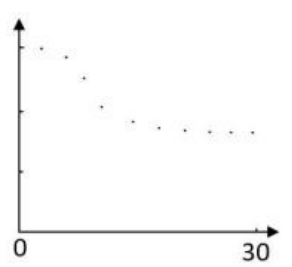

The ESR curve of the BANA-1400 Automatic ESR Analyzer is directly drawn according to the detection of the ESR tube every 3 minutes, so the ESR curve has two working modes: 30 min and 60 min. The ESR curve is shown in the figure below: 5.7 ESR Curve

5.8 Print

After the sample detection is completed, the printer automatically prints the ESR value (mm/h) and ESR curve of the tested sample, as well as the date, time, serial number and patient ID. The format of the result printed by the printer is as follows:

>>> <<<

NO. : 50 (The test result is numbered 50.)

Pat-ID : 123 (Patient ID is 123.)

Pos : 01 (The test channel is No. 1.)

Mode : 30 min (Work mode is 30min.)

ESR : 23mm/h (The test result is that the settlement in one hour 23mm.)

ESRC : 10mm/h (Correct the test results to the results at 18°C.)

HCT : 0.63 (Results of HCT test.)

Date: 2022-07-01 08:30 (The test time is 8:30 on July 1, 2022)

Chapter 6 Maintenance

6.1 Daily Maintenance

The BANA-1400 Automatic ESR Analyzer does not require special maintenance and maintenance, but it needs to keep the working environment dry and clean to prevent dust from falling into the ESR tube loading hole and causing unreliable measurement results of the infrared transmitting and receiving tubes (TX-RX).

Be careful when inserting and removing the ESR tube to prevent the ESR tube from breaking and causing blood to flow inside the instrument. It is recommended that the instrument be turned off when not in use and covered with an instrument cover to avoid direct sunlight.

It is not allowed to wipe the upper surface of the instrument with a damp cloth or corrosive liquid to prevent the liquid from flowing into the instrument from the insertion hole of the ESR tube and causing damage to the instrument.

Surface cleaning of the instrument: Use a dry cloth or medical alcohol cotton to clean the surface of the instrument.

6.2 Common Faults

| Fault description | Troubleshooting |

| Results are not printed after the instrument test is over. | Check if the printer is jammed or out of paper. |

| When the ESR tube is put into the test instrument, the buzzer continuously alarms. | The blood level is beyond the measuring range of the instrument. |

| During the test, the motor vibrates and hits. | ( 1) The limit detector of the detection board is faulty, it is recommended to notify our service center for repair. (2) The left and right limit rods of the detection board are stuck, and it is recommended to notify our service center for repair. |

| Fault description | Troubleshooting |

| No display when power on. | ( 1) Plug and unplug the power socket and restart. (2) Check whether the power connection of the user is normal. (3) It is recommended to notify our service center for repair. |

6.3 Fuse replacement

A burnt fuse will prevent the instrument from turning on.

Purpose

Replace the fuse.

Time for Maintenance

Perform this maintenance when the instrument's power plug is in good contact, but does not respond when turned on.

Maintenance Tool

Flat-blade screwdriver.

Instrument Status

Make sure the instrument is turned off when performing this maintenance operation.

Precautions

WARNING: It cannot be replaced with a fuse of a different specification.

Steps

1. Make sure the instrument is turned off and unplug the power cord.

2. Prepare a new fuse.

3. Use a flat-blade screwdriver to lift out the fuse socket at the power male head on the right side of the instrument, and take out the fuse.

4. Observe whether the fuse is blown, burnt black and other abnormal phenomena.

5. If it is blown or burnt black, replace the new fuse to the current position.

6. Install and tighten in the reverse order of removal.

CAUTION:

CAUTION:This analyzer is valid for 5 years in normal use, please read this user manual carefully, and must operate according to the operation method specified in the manual and use the original electrodes and reagents, otherwise the adverse consequences will be borne by the user!

Chapter 7 Safety Protection and Handling

1. The instrument must be connected to a ground wire, and the ground wire must be grounded reliably.2. It is not allowed to touch the external plug of the instrument with conductive metal objects.

3. Non-professionals are not allowed to open the instrument back cover and instrument shell.

4. When checking the fuse of the instrument, the power plug of the instrument must be unplugged.

5. Pay attention to the marks set on the instrument, and do not remove various marks artificially. Marks include:

A. Product name, model.

B. The name and trademark of the manufacturer.

C. The rated working voltage, rated working frequency and rated input power of the product.

6. Identify the on-off state of the power switch.

The “I” of the power switch is marked as the power-on state, and the “O” is marked as the power-off state.

7. If you find that the instrument has abnormal operation procedures and faults, please cut off the power immediately and contact our service center.

8. Before communicating with the external computer, it must be confirmed that the external computer meets the IEC 60950- 1:2005 national information technology equipment safety requirements or has a safety certification mark, and the external computer is reliably grounded.

9. Because the used ESR tube waste liquid may contain harmful substances to human health, the ESR tube waste liquid should be treated in accordance with the hospital's requirements for the treatment of hazardous substances.

10. Because the ESR tube is a glass product, it must be kept properly, and the used ESR tube must be disposed of in accordance with the hospital's requirements for the disposal of hazardous materials.

Appendix A Function Menu