Concentrator BET1B2

Vacuum Centrifugal Concentrator- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Specifications

| Model | BET1B2 |

| RPM | 2,000r/min |

| Max power | 2.4kW |

| Max current | 11A |

| Ambient temperature | 0°C ~ +35°C |

| Temperature control range | Room temperature ~ +60°C (+70°C, +80°C) |

| Timer range | 1min~23h59min59s |

| Door opening/closing | Auto |

| Preheating | Available |

| One button linkage | Available |

| Final vacuum | 0.1mbar |

| Auto pressure release | Available |

| Vacuum level display | Available |

| Vacuum interface | Φ10mm |

| Vacuum pump (recommended) | Domestic diaphragm pump/oil pump, imported oil pump/diaphragm pump |

| Cold trap (recommended) | CT-6/CT-40/CT-50 |

| Noise | ≤50dB (A) |

| Power supply | AC220V/50Hz |

| Weight | 42kg |

| Dimensions (LxWxH) | 400x540x350 |

Description

Methods & Principles:Common methods for sample evaporation, drying, concentration and purification include:

• Distillation and rotary evaporation methods at high temperatures and under nearly atmospheric pressure, which can only process a single sample;

• The freeze-drying method under low temperature and high vacuum conditions, which is time-consuming, although sublimation can keep the sample activity;

• Fast evaporation at low temperature by means of termovap sample concentrator, which can process only a small amount of samples, with high use cost and complicated operation;

• Evaporation under vacuum conditions at room temperature by means of vacuum centrifugation concentration, where the evaporation rate of the sample solvent is higher;

•The phenomenon of evaporation is an endothermic process. When the water in a sample evaporates, it will take away the heat of the product, so that the temperature of the product will be lowered, thus maintaining the properties and activity of the sample. However, to speed up the evaporation process, the equipment used needs to provide the heat (generally through cavity heating or infrared heating) to be absorbed in the evaporation. The method is especially suitable for concentrating and purifying heat-sensitive biological samples or clinical medicines.

•The vacuum centrifugal concentrator revolves at speeds of 1500~2000r/min, which generates centrifugal force that prevents sample dispersion and flash boiling during the preparation of high-concentration samples. This can prevent cross-contamination, sample loss, denaturation, activity reduction, oxidation and other problems. The product is particularly suitable for preparing sensitive biological samples, such as nucleic acids and proteins.

Features

• The new EX UI3.0 operating system features microcomputer control, programmable operations, and direct drive by a DC variable-frequency motor for precise speed control.• A 7" wide-angle LCD touch screen is available for digital input and easy to operate. It can display set and run parameters, as well as system data (mbar) in real time. The all-steel housing has corrosion-resistant orange peel fine grain wrinkles showing full lines, featuring an industrial human-machine design that is safe while being visually appealing and allowing for a high recognition rate.

• One-button preheating: The product is fitted with the precise temperature control technology for fast heating and accurate temperature control, thus being capable of heating the chamber temperature to 60°C, quickly reaching and maintaining the set temperature.

• Vacuum setting: Vacuuming starts at the set speed value, and the vacuum level can be controlled during operation within the set precision to enhance sublimation efficiency and provide safe and efficient concentration without oil explosion, foam or sample damage.

• Automatic vacuum release: When the instrument stops running or in case of power outage/shutdown, vacuum release will be automatic to ventilate with the external environment, and slow to protect samples from excessive positive and negative pressure. After complete release, the instrument will automatically open the cover.

• The built-in organic solvent vapor pressure curve charts display the detailed vapor pressure data of different organic solvents at different temperatures, helping users understand the evaporation characteristics of organic solvents, and preventing wrong operations or safety accidents due to lack of understanding.

• The 304 stainless steel seamlessly molded centrifuge chamber has undergone Teflon heat treatment for corrosion resistance, and thus can ensure the purity of sample solvents.

• A variety of rotors are available to meet different experimental throughput needs and suitable for the centrifugal concentration to preheat samples such as nucleic acids and viruses.

• Split design: Independent accessories, free compatibility, flexibility in use.

• One-button linkage function for simpler and more convenient instrument operation.

• The polymethyl methacrylate cover plate is transparent and easy for observation, with an automatic door opening/closing design that is convenient and can prevent wrong operations caused by manual door opening/closing; in case of power outage, it can be powered by a battery to automatically open the cover plate.

• The products have built-in operation guide and early warning modules for over temperature, low pressure and emergency stop, which can help users improve efficiency, reduce the risk of wrong operations, and meet strict requirements for reliability of concentration effects.

• The products are supported by certifications including ISO9001 (2015); ISO13485 (2016); ISO14001 (2015); ISO45001 (2018); and CFDA registration and production qualification.

Economical, Efficient Vacuum Centrifugal Concentrator:

• No foaming of samples and minimal sample loss

• Simultaneous drying of multiple samples

• Sample all concentrated at the bottom of the centrifuge tube

• Suitable for drying samples of 1ml to 3,000ml

• Repeatable drying by controlling process parameters such as rotor chamber temperature (providing evaporation energy) and

vacuum (auto setting of optimal pressure)

• Safe and simple solvent recovery

More Info

| Optional rotors | Optional rotors | Optional rotors |

| 62x0.2mL | 24x5mL | 8x50mL+8x10mL |

| 102x1.5mL | 18x10mL | 10x50mL |

| 204x1.5mL | 20x15mL | 24x8x0.2mL (8-tube strips) |

| 12x5mL | 45x15mL | 2x96 holes |

Applications

Our vacuum centrifugal concentrators are able to quickly and safely evaporate water and organic solvent in samples. The processed samples can be conveniently used for various qualitative and quantitative analyses in areas such as chemicals, biochemicals, biological analysis, immune screening, food safety, residue analysis, etc. These devices are suitable for concentration of immunoglobulins, concentration of drug metabolites, solid phase extraction (SPE), pre- and post-processing of liquid chromatography, ADMET/toxicology, polymer chemistry, DNA/RNA purification and concentration, oligomerization, forensics/drug of abuse, testing, and general lab concentration.• DNA/RNA (the solvents are primarily water, ethanol, and methanol)

• Oligomers or peptides

• PCR products

• High-performance liquid chromatography (HPLC) products

• Synthesis and separation of organic substrates

• Storage and handling of substrates

• Concentration of protein

• Chemical composition

• High throughput screening (HTS)

• Analysis of food and environmental samples

• Toxicological identification and forensic identification

• General laboratory evaporation

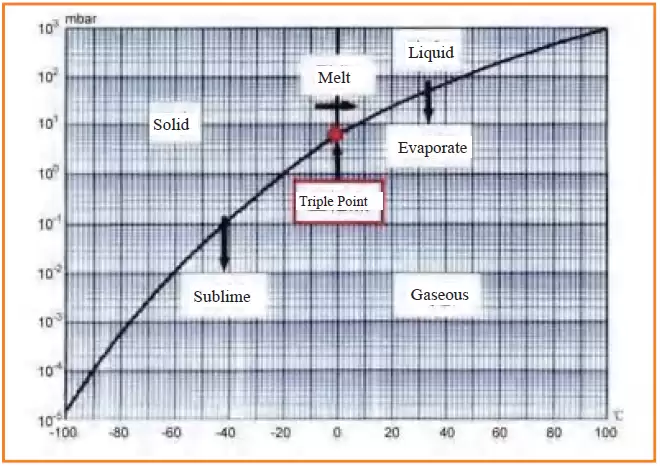

Vapor Pressure Curve

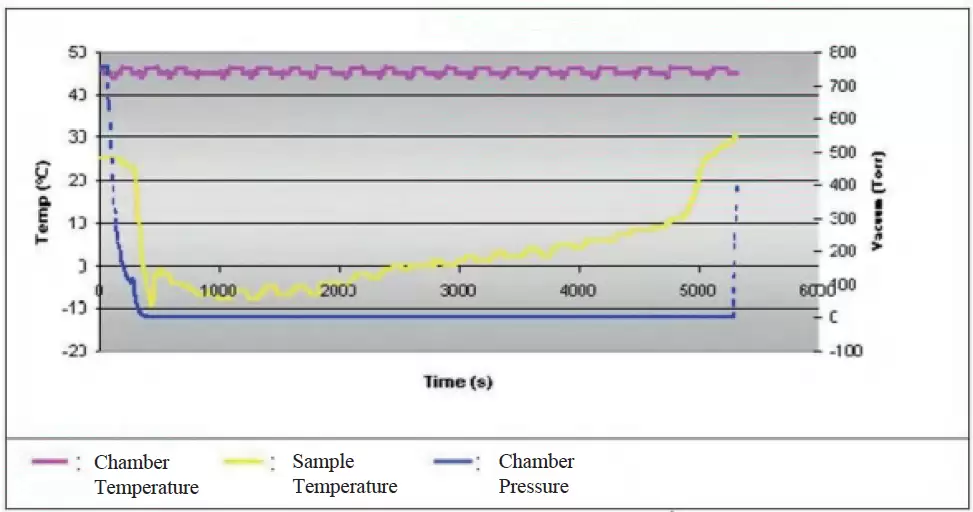

Temperature Change Diagram of Centrifuge Chamber and Samples

Accessories For Purchase

| images | name | description |

| Fixed-angle Rotor 62x1.5mL | Max RPM: 1,500r/min |

| images | name | description |

| Fixed-angle Rotor 12x10mL | Max RPM: 2,000r/min |