Ultrasonic Homogenizer BLIH-304

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Ultrasonic homogenizers are powerful tools to mix and homogenize solid-liquid and liquid-liquid suspensions. Homogenizers are used in mixing dispersing and emulsifying the solution. also used in disrupting cells/subcellular structures in suspension, and for creating emulsions.

- 7 inch large screen LCD touch screen display. Microcomputer control, which can store 20 sets of work data. Ultrasonic time, ultrasonic power can be set.

- Automatic detection of ultrasonic power to prevent the change of ultrasonic power as the

- temperature of the sample is changed.

- Integrated temperature control to prevent sample overheating. Automatic frequency tracking, automatic fault alarm.

Specification

Features

Applications

| Ultrasonic Frequency | 20-25 (KHZ) |

| Optional probe | 2,3,6,8,10,12 Φ mm |

| Crusher Capacity | 0.1-500 ml |

| Sample temperature monitor | Yes |

| Maximum Power | 0-650 W |

- 7 inch large screen LCD touch screen display. Microcomputer control, which can store 20 sets of work data. Ultrasonic time, ultrasonic power can be set.

- Automatic detection of ultrasonic power to prevent the change of ultrasonic power as the

- temperature of the sample is changed.

- Integrated temperature control to prevent sample overheating. Automatic frequency tracking, automatic fault alarm.

- Single ultrasound time: 0.1-99.9S

- Single interval time: 0.1-99.9S

- Total working time: 1S-99H59M59S(touch type to 99hours)

- Mode of work: clearance or continuity

- frequency: 19.5-20.5KHz

- Can select computer online function

Biology, Research, Pharmaceutical, Chemical, Industries

Operating Manual for BLIH-304

1. General Description

2. Functions and composition

3. Precautions before use

4. Scope of application

5. Function and main parameters

6. Main technical parameters of the instrument

7. Instructions

8. Removal and installation horn

9. Examples of experimental data

1. General Description

4.3 inch TFT touch screen series ultrasonic homogenizer sonicator is our company’s new developed product. With full functions, beautiful appearance, reliable performance. Instrument using large LCD display screen, using the central computer centralized control system, ultrasonic output, gap time, ultrasonic power, duty cycle, temperature can be arbitrarily set, sample detection temperature display, frequency automatic tracking, automatic fault alarm.2. Functions and composition

2.1 Our ultrasonic homogenizer sonicator is a multi-function and multi-purpose instrument that utilizes ultrasonic cavitation in liquid. It can be used for breaking many kinds of cells, bacteria, viruses, animal and plant tissues, also for emulsification and separation , homogenization, extraction, defoaming, cleaning, preparation of nanomaterials, dispersion and accelerated chemical reactions. Widely used in biology, medicine, agriculture, chemistry, materials science, pharmaceutical and other fields of teaching, research, production.2.2 This machine consists of ultrasonic generator (power), transducer components and sound proof box, middle part connected by the cable

3. Precautions before use

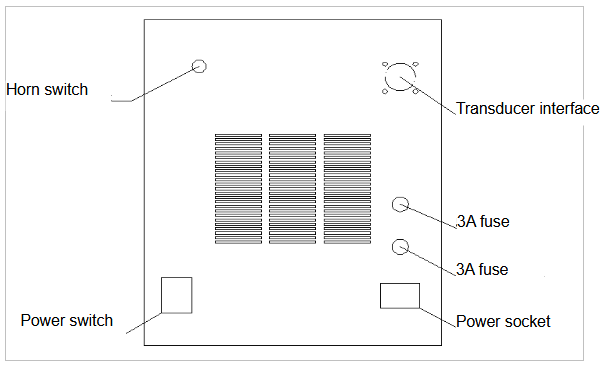

3.1. Check power supply: This machine is powered by 220V ± 5% AC voltage (frequency 50Hz), the power socket is located in the lower left of the instrument rear panel. Please pay attention to the color of the power supply are fitted at the left lower sections of the backboard.Warning: Please kindly use grounded AC power supply to avoid lightning and for safe using, and remove the plug when replacing the fuse

3.2 Working environment

The instrument should be placed in a well ventilated place to work, the normal working room temperature range is 0 ℃ to 40 ℃.

In order to ensure that the instrument can work normally, please kindly note: Anti-corrosion, moisture-proof, sun protection, dust prevention

3.3 Installation

- Connect the power cord, transducer and temperature probe according to each socket

- Insert the transducer into the soundproof box and select suitable container according to the sample size, pour the sample and put it on the lifting platform of the sound proof box. adjust the lift height, the end of the horn inserted into the sample surface is generally 10-20mm and make it in the center of the container.

The horn can not touch the wall of the container, the end part of horn and the bottom of the container should be more than 4cm(or will case no load when with bigger power), to ensure the good break effect

Recommended for use elongated containers.when process small capacity samples, using small ultrasonic power, the horn never can contact with the bottom of the container.

4. Scope of application

Scope of application for various specifications of horns and the best power ratio for new instrument as follows:| Horns (mm) | ★Φ2 | ★Φ3 | ★ Φ6 | Φ8 |

| Process capacity (ml) | 0.2-5 | 3-10 | 10-100 | 20-150 |

| Power ratio (1-100%) | 1-40% | 1-50% | 1-70% | 1-90% |

5. Function and main parameters

1. For the first time use, add water in a 50ml beaker, then put it on the lifting table of the sound proof box, place the transducer on the top hole of the sound proof box,adjust the lift to make the liquid surface immersion horn end face 1-2cm2. Connect the power supply, temperature, transducer interface of the ultrasonic generator, turn on the power switch on the back of the instrument.

3.Click the password box after turn on the machine, then type "123456" to enter the

factory standby state(usually remove the password before leaving the factory),

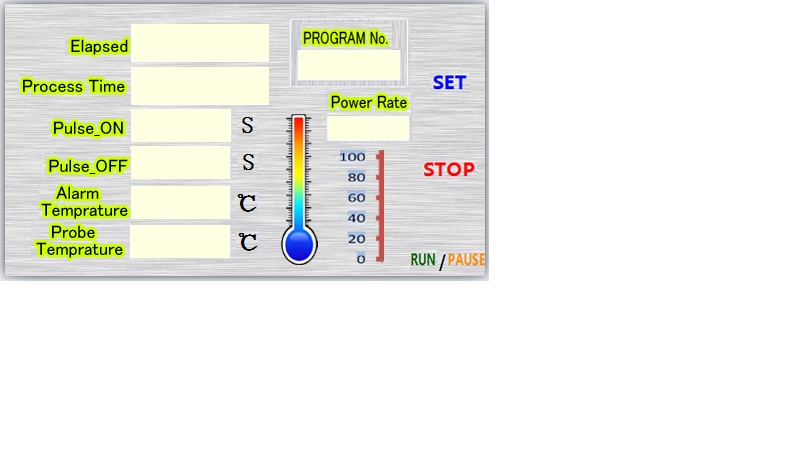

Please see below diagram “standby interface A "

“Standby interface A ”

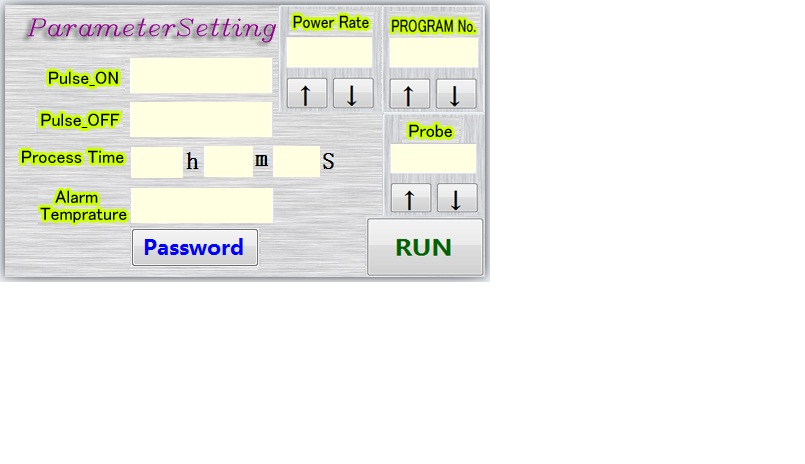

4. Check if the the horn size on the screen consistent with the actual one, if need to reset, please click "SET" button, enter the setting state, as shown in the following figure "Setting interface B", at this time can modify the parameters according to your requirement, click on the box to set your needed parameters, modify it when the numeric keypad jump out, usually can not set “0”

"Setting interface B"(The choice of horn should consistent with the actual installation horn’s size)

5. After setting the parameters and click the "RUN" button, the interface into standby state, then click the "RUN" button again, the instrument begin to work, if need to stop the ultrasound can click the "PAUSE" button, If one cycle of work finished, you need to continue to work, please click "STOP" button, then click "RUN" button, in order to ensure user's experimental data preservation, this instrument has 20 sets of parameters stored (0-19) and call function, adjust above “settings interface B " PROGRAM No.” is ok

6. If the "RESET" key box becomes yellow when the instrument on the working process, it’s for over-temperature alarm, please check whether the set temperature is too low, It’s for overload or fault alarm if turn into red color, then click the "reset" key box cancel the alarm

6. Main technical parameters of the instrument

| Output power | 5-650W (adjustable) |

| Working frequency | 20-25KHz frequency automatic tracking |

| Process capacity | 0.2-500ml (need to match corresponding probe) |

| Timing | 0-99H59M59S (can be set) |

| Working mode | Pulsed |

| Pulse | 0.1-99.9s adjustable(interval/working) |

| Temperature control | Control samples’ temperature(0℃-100℃) |

| Alarm | Fault, temperature, time |

| Input method | touch screen control, |

| Display method | touch screen control, 4.3 inch TFT |

| Display content | Temperature, power, time, etc. |

| Protective device | Program automatic error correction, overload, over temperature protection display |

| Storing data | 20 groups |

| password | Have user password protection |

| Standard configuration | Ultrasonic generator (host) one set Sealed transducers + 6MM horn one set Φ6mm(process capacity 10ml-100ml) |

| Optional horn | Φ2,Φ3,Φ8 |

Instrument interface description(Rear panel)

7. Instructions

5.1 Cautions1.Temperature protection set point should be 1-3℃ higher than the room temperature or the sample temperature. machine will stop in case of over-temperature.

2. Don’t start the machine when the horn is not inserted into the liquid (no load), otherwise it will damage the instrument

3. Process capacity, ultrasonic time&power, waiting for user explore according to a variety of different cells and select the best value

4. After using a long time, the end of the horn will be cavitation corrosion and hairy, can use oil stone or file make it flat, otherwise will affect the work effect

5. In the working process, due to ultrasonic cavitation in the liquid effect, the liquid temperature will rise rapidly, the user should pay more attention to the temperature of various cells, recommended to use short ultrasonic time (less than 5 seconds each time) while also can connect cooling bath for cooling (ultrasonic time 1-4 seconds and gap time 2-8 seconds)

Warning : Turn off the power supply when you change the horn. Please re-select correct horn specification on the interface after restart; otherwise it may cause horn to be damaged

KIND REMIND:

★ Practices prove that instrument will have a better performance at working1~3 seconds and interval 2~6 seconds. you may set a longer gap time to avoid liquid temperature increase. In addition, continuous working may cause empty load, will shorten the life of the instrument

Φ2orΦ3horn’s maximum output power should not exceed 50% for new instrument

Φ6 horn’s maximum output power should not exceed 80% for new instrument

★ Horn selection switch at the back of the machine( must be same as theactual installation of horn for new machine) ★

★NOTE: Please select correct horn (size), for example interface displaysφ6, then you must select φ6 horn. And the switch at the back panel for horn shall be also φ6.

★After the horn is used for a long time, when appear honeycomb, make it flat with file. if the ultrasonic wave can not be generated normally, you can change the horn switch on the back board until the ultrasonic wave is normal.

if the ultrasonic wave can not be generated normally when open the machine (voltage instability or external interference,can change the horn switch on the back board until the ultrasonic wave is normal

8. Removal and installation horn

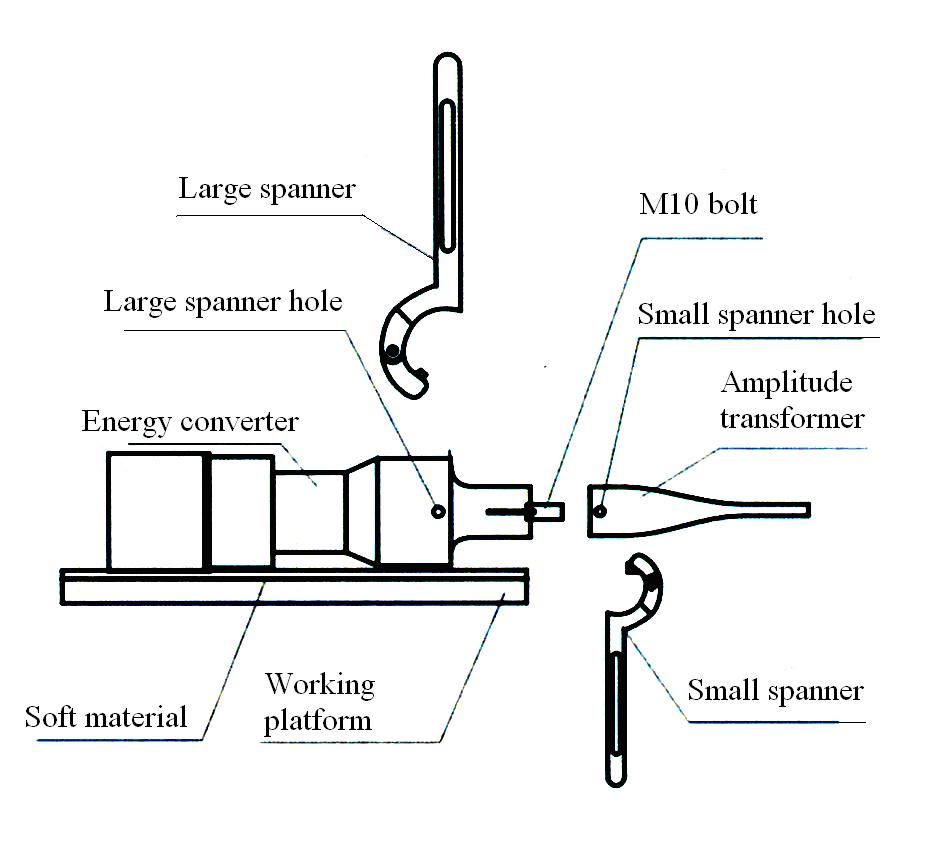

Diagram 3

Diagram 3 Removal and installation horn

- Push the energy converter on the chair with soft materials (such as towel). Put the small spanner into the horn spanner hole and the large spanner into the transducer spanner hole. the large and small spanners shall be oriented to the left and right.

- You stand facing the horn, and hold the large spanner with left hand and small spanner with right hand. Tighten downward with both hands(must be tightened)

- When changing the horn, such as the M10 screw on the horn, remove the bolt out by hand, and then fasten the bolts on the transducer, and must be tightened. If the bolts on the horn, Hex wrench can not be twisted, you can knock the bolts on the wood materials for a few times then can twist

9. Examples of experimental data

for some samples(please refer to Φ6mm horn)| Experimental content | Ultrasonic time (S) | interval time (S) | Total working time(Minute) | Power(%) | container(ml) | Broken rate(﹪) |

| Treponema pallidum | 1.5 | 2 | 10—20 | 35 | 20 | Above 90 |

| staphylococcus | 1.5 | 2 | 10—25 | 35 | 20 | Above 90 |

| Mouse sciatic nerve | 2 | 3 | 10—15 | 35 | 20 | Above 92 |

| Mouse liver | 2 | 3 | 5—15 | 45 | 30 | Above 95 |

| Liver cell enzyme extraction | 2 | 3 | 5—10 | 50 | 30 | Above 95 |

| Escherichia coli | 2 | 3 | 10—15 | 50 | 50 | Above 93 |

| Pseudomonas aeruginosa | 2 | 3 | 5—10 | 60 | 50 | Above 92 |

10. Packing list

1.Ultrasonic generator 1 set

2.transducer (Energy conversion unit+6MM): 1 pc

3.Sound-proof box 1 set

4. Lifting platform(inside sound-proof box)1pc

5. Amplitude pole(2mm+3mm) 1pc

6. power line 1pc

7.Special wrench(for amplitude pole removing) 1 set

8.Fuses : 2 pcs

9.Temperature probe 1pc

10、Centrifuge tube fixture 1 set