Tissue Embedding System BHTP-601

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Embedding is a fixation process during which tissues or the specimens of interest are entrapped in the embedding media. The choice of the media depends on type of tissue, type of microtome and types of microscope to examine the tissue.

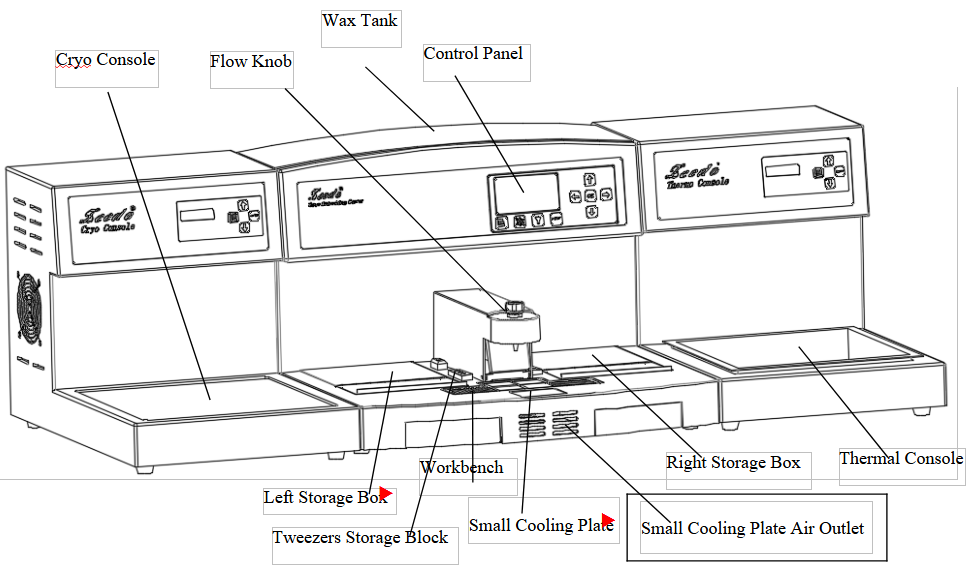

- The Embedding system is composed of three modules, main console and Cryo Console and Thermo Console. It is independent design, can put the position left-to-right or right-to-left, to meet Different habits of customers. The large working surface allows user processing many samples at the same time. The temperature and work start time can be settable through the control panel.

Specification

Features

Applications

| Main Console Nominal supply voltage | 220 V / 50 Hz |

| Main Console Maximum power draw | 800-1000 W |

| Main Console Working temperature | From ambient to 99 ℃ increments 1 ℃ |

| Main Console Capacity Paraffin reservoir | 6.0 Lt |

| Main Console Capacity Cassette/mold tray | 1.6 Lt |

| Main Console Dimensions | 600mmx650mmx460mm (WidthxDepthxHeight) |

| Main Console Weight | 25 kg |

| Cryo Console Nominal supply voltage | 220 V / 50 Hz |

| Cryo Console Maximum power draw | 180 W |

| Cryo Console Working temperature | 0 ℃ to - 20 ℃, increments 1 ℃ |

| Cryo Console Dimensions | 410mmx660mmx450mm (WidthxDepthxHeight) |

| Cryo Console Weight | 25 kg |

| Thermal Console Nominal supply voltage | 220 V / 50 Hz |

| Thermal Console Maximum power draw | 500 W |

| Thermal Console Working temperature | 30 – 90 ℃ |

| Thermal Console Capacity Paraffin tray | 5 Lt |

| Thermal Console Dimensions | 410mmx620mmx440mm (WidthxDepthxHeight) |

| Thermal Console Weight | 14 kg |

- The Embedding system is composed of three modules, main console and Cryo Console and Thermo Console. It is independent design, can put the position left-to-right or right-to-left, to meet Different habits of customers. The large working surface allows user processing many samples at the same time. The temperature and work start time can be settable through the control panel.

Pathology, Histology

Operating Manual for BHTP-601

1. Important note

2. Symbol and meaning

3. Security

4. Summarize

5. Structural feature

6. Main technical specification

7. Instrument installation

7.1 Installation site requirements

7.2 Install the instrument

7.3 Instrument connections

8. Operation method

9. Common faults and troubleshooting methods (for reference only)

10. Maintenance and cleaning

11. Taboos and precautions

12. Packing list

13. Warranty and maintenance

14. Transportation and storage

15. Scrapping and disposal

1. Important note

Please ensure that you have read and understood the following safety statement before using this product.• Please read the instruction manual carefully before installation and use.

• Check that the power cables are properly connected.

• Melted paraffin wax is very hot and may cause serious burns.

• When handling more than one sample at a time, ensure that appropriate measures are taken to avoid mixing.

• Ensure that appropriate measures are taken when handling hazardous materials.

• Do not use paraffin with a melting point above 70 ° C (167°F) as it may not melt.

• The area of the embedded work table is very hot, please take care to prevent burns.

• Do not use this product in the presence of flammable chemicals as this may cause a fire or explosion hazard.

• Do not place the machine in an environment of too high or too low temperature and too wet. The extreme environment can easily cause damage to the machine.

• Please keep the machine away from fire.

• In case of trouble, please contact the company, do not handle without authorization

The model number,factory serial number and year of manufacture are indicated on the nameplate on the back of the instrument.

The service life of this instrument is 6 years.

2. Symbol and meaning

| DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. |

| WARNING: If this hazard is not avoided, death or serious injury may result. |

| CAUTION: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. |

| NOTE: Indicates information that is not related to risk but is important. |

| Instructions require the user to consult the instruction manual for important cautionary information such as warnings and precautions. |

| Indicates the correct vertical position of the box. |

| Items are fragile and must be handled with care. |

| Packaging must be stored in a dry environment. |

| Recycle in accordance with local laws and regulations. |

| Power on |

| Power disconnected |

| Environmental protection mark of RoHS directive. The number in the symbol refers to the "environmentally friendly use" years of the product. This symbol should be used if the use of a restricted substance exceeds the maximum permitted limit. |

| This product complies with the requirements of EU Directive 98/79/EC for in vitro diagnostic (IVD) medical devices. |

| The WEEE (Waste Electrical and Electronic Equipment) symbol is a crossed-out roller bin, indicating the separate collection of electrical and electronic equipment (§ 7 ElektroG Environmental Protection Act). |

Table 1

3. Security

1. Specified purposeThis product is an IVD (In Vitro Diagnostic) instrument and a laboratory paraffin embedding machine, used for sample embedding processing before pathological analysis. It freezes and fixes tissue samples in wax blocks so that they can be separated from the mold.

WARNING

WARNINGThis instrument may only be used for its intended purpose and only when all safety features are in correct working order. Malfunctions that impair safety must be corrected immediately.

2. User group

• Only trained laboratory personnel should operate this equipment.

• All laboratory personnel assigned to operate this equipment must read this instruction manual carefully and must be familiar with all technical features of the instrument before operating it. This instrument is for professional use only.

NOTE

NOTETo avoid damage to the instrument and samples, only accessories and spare parts authorized by Hisure can be installed or used on the instrument.

3. General safety precautions

WARNING

WARNING• The safety and precautions described in this chapter must be followed at all times. Even if you are already familiar with the operation and use of other Hisure products, please be sure to read these instructions.

• It is strictly prohibited to disassemble or modify the protective devices on the instrument and accessories.

• Only qualified service personnel certified by Hisure can repair the instrument and dispose of the internal components of the instrument.

Other risks:

• This instrument is manufactured and tested in accordance with the safety requirements for electrical equipment for measurement, control and laboratory use. Improper operation or handling of the instrument can result in injury or death to the user or other personnel, or damage to the instrument or property.

• This instrument may only be used for its intended purpose and only when all safety features are in correct working order.

• To maintain this condition and ensure safe operation, the user must comply with all safety precautions and warnings in this instruction manual.

• If a safety-threatening failure occurs, the instrument must be stopped immediately and the Hisure technician responsible for instrument service must be notified.

• Only original spare parts and permitted Hisure original accessories can be used.

4.Safety Instructions—Transportation and Installation

WARNING

WARNING• After unpacking the instrument, the instrument can only be transported in an upright position.

• Before connecting the device to the power supply, make sure that the voltage marked on the nameplate matches the voltage available at the installation location.

• The equipment may only be connected via the power cord provided and only to a grounded electrical outlet. Do not use extension cords.

• The power socket to which the instrument is connected should be placed near the instrument and easily accessible.

WARNING

WARNING• A stable power supply that meets the instrument specifications is necessary for proper operation. Before installing the device, make sure that the electrical installation complies with the above prerequisites. Failure to meet the above conditions may result in damage to the instrument.

• Before each maintenance, repair or cleaning, please turn off the instrument and unplug the power plug.

• If the instrument is used in a manner not specified by the manufacturer, the protection provided by the instrument may be impaired.

4. Summarize

The BHTP-601 embedding machine is a commonly used instrument for embedding pathological tissues. The system is equipped with a 6-channel heating control system, which independently controls the wax cylinder, left and right storage boxes, tweezers storage block, worktable, and wax nozzle. It uses high-precision temperature sensors and efficient and fast PID algorithms to achieve a temperature control accuracy of up to 0.1℃; Unique intelligent wax melting mode reduces wax melting time and improves usage efficiency; The constant temperature tweezers storage block keeps the medical tweezers at a certain temperature during the embedding process, improving the quality of tissue embedding; The semiconductor rapid cooling module integrated in front of the workbench can quickly fix the embedded tissue. The temperature control system of this product is more calibrated, more intelligent, and more suitable for use in hospitals and pathology departments of universities;The model number, factory serial number and year of manufacture are indicated on the nameplate on the back of the instrument.

The service life of this instrument is 6 years.

1. Main features:

• Rational layout and easy operation.

• Adopting a 7-inch touch screen display, the temperature display of each functional module is clear, and both Chinese and English languages are optional.

• Using PID constant temperature algorithm, precise temperature control with a control accuracy of 0.1℃.

• Real time temperature curve display, making temperature control more intuitive.

• Fast heating, uniform heating, superior performance, independent temperature control for each branch, dual overheating protection for the temperature control system, safer and more reliable.

• Intelligent wax melting mode, more efficient and intelligent.

• Fully automatic program control, 7*24-hour automatic running time setting, more convenient; Equipped with memory and automatic recovery functions, it automatically retains the preset temperature after operation.

• Large capacity wax melting cylinder, capable of accommodating 600 wax blocks for embedding at once.

• Manual and pedal dual waxing method.

• The wax production time and flow rate can be adjusted.

• Automatic shadowless lighting, adjustable brightness and lighting time.

• Split design, the embedding machine and cryo console can be combined freely.

• The left and right boxes, as well as the inner and outer boxes, are designed to be separated for easy removal, wax replacement, and maintenance.

• A spacious workbench with wax block repair device and flow channel design to prevent paraffin overflow.

• Equipped with a universal metal hose magnifying glass, suitable for handling extremely small specimen tissues; Configure a semiconductor small cooling platform for instant cooling, facilitating rapid positioning and embedding of specimens.

• Lifetime free software upgrade.

2. Use environmental conditions:

• Working power supply: 220V±10%, 50Hz

• Ambient temperature: 0-40℃

• Relative temperature: ≤85%

• Atmospheric pressure: 86-106kpa

3. Security type:

• Common type I, type B.

5. Structural feature

The external structure of the BHTP-601 embedding machine host consists of a control system, a wax melting system, and a cooling system

Figure 1

Outline structure diagram

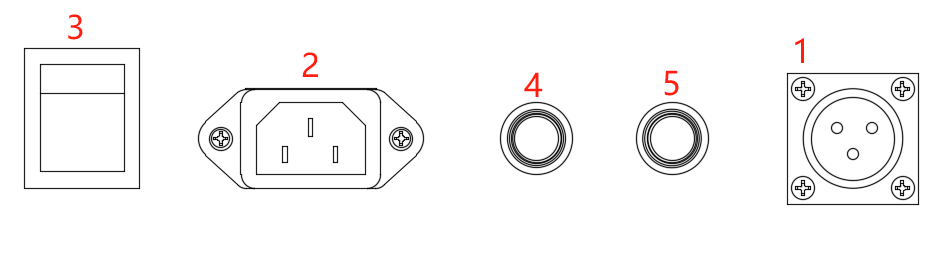

1. Rear panel description:

Figure 2

Rear panel view

1 Power switch: Press “|”, the green light is on, indicating that the power is on, press the“○”end, the green light is off, and the power is off.

2 Three-wire power socket: AC200V power inlet socket.

3 Aviation socket: Connect the foot switch to activate the solenoid valve.

4 Power fuses. This machine is equipped with 2 BGDP-10A (Ф5×20) fuses.

6. Main technical specification

| Dimensions (width*depth*height) | Main Console(750*610*450mm) Cryo Console(410*660*450mm) Thermal Console(410*660*450mm) |

| Weight | Main Console(30kg) Cryo Console(25kg) Thermal Console(14kg) |

| Voltage | 220V±10% |

| Frequency | 50Hz±10% |

| Power | 1500W |

| Fuse | 10A 220V |

| A-weighted noise level (measured at 1 m distance) | <75 dB(A) |

| Performance parameters | |

| Main Console: | |

| Temperature setting range | 0-99℃ |

| Temperature tolerance | ±3℃ |

| Main wax tank volume | 570*125*85mm |

| Storage box capacity | 235*160*50mm,2 in total |

| workbench size | 273*103mm |

| Heating time to reach set temperature | ≤60 minutes |

| Automatic operation timing setting range | Any day, any hour, any minute of the week |

| Cryo Console: | |

| Refrigeration temperature range | Room temperature ~ -20℃ |

| Work area size | 350*350mm |

| Thermal Console: | |

| Temperature setting range | 30-99℃ |

| Tank volume | 310*315*55mm |

| Environmental conditions | |

| Operating temperature | +15~+35℃ |

| Working relative humidity | 20%~80%,No condensation |

| Working altitude | Up to 2000m above sea level |

| Storage temperature | 0~+50℃ |

| Storage relative humidity | 10%~85%,No condensation |

| Transport temperature | -29~+50℃ |

| Transport relative humidity | 20%~80%,No condensation |

Table 1

7. Instrument installation

7.1 Installation site requirements

• Stable and vibration-free experimental bench, the table top is flat and smooth, and the ground is as vibration-free as possible.• Avoid sunlight or drastic temperature changes. The room temperature is kept constant between +20°C and +30°C.

• Relative air humidity max. 80 %, non-condensing.

• The instrument should be installed in such a way that air circulation is not affected.

• When installing, please install the instrument in a location where the power can be disconnected at any time. The power cord serving as the mains disconnect device must always be accessible.

WARNING

WARNING• When the room temperature exceeds +30℃, it may not be guaranteed that all locations reach the operating temperature of the instrument.

• To ensure correct operation and facilitate disconnection from the instrument, a clearance of at least 15 cm is required at the back of the instrument. Failure to allow this distance may result in severe damage to the instrument's freezing stage. Do not operate the instrument in hazardous locations.

• There is a cooling vent on the left side of the cryo console. Please ensure that the safe and effective distance between the left side of the equipment and other equipment is more than 20 cm and maintain ventilation. Otherwise, the hot air blown from the cooling vent will bounce through obstacles and bounce to the surface of the cryo console, which will cause serious damage. Affect the cooling effect.

• When the cryo console reaches the preset temperature, the compressor will be • turned off, and there is a thermal protection mechanism inside. It takes about 3 minutes to restart the compressor, which may cause the temperature of the cryo console to rise. It is recommended to set the temperature lower when using it;

• The cooling and heating areas of the embedding machine may be affected by the wind speed of the external environment, resulting in abnormal heating or cooling;

7.2 Install the instrument

WARNING

WARNINGImproper handling and transportation of the instrument.

PERSONAL INJURY AND/OR PROPERTY DAMAGE

• The number of persons carrying the instrument shall not be less than 2.

• Grasp the corners of the frame and lift the instrument steadily.

1. Have at least 2 people hold the corners of the instrument and lift the instrument steadily.

2. Place the instrument on the workbench.

3. Check against the order to see if all attachments have been delivered.

7.3 Instrument connections

WARNING

WARNING• Before connecting the device to power, be sure to compare the connection parameters on the nameplate with the local power supply.

• The instrument must be connected to a grounded electrical outlet. Only use the power cord supplied with the local power supply.

How to turn on:

1. Plug the power plug into the electrical outlet.

2. Press the instrument switch to the“|”state (on).

3. When the instrument is not in use, please set the switch to the“○”state (stop).

8. Operation method

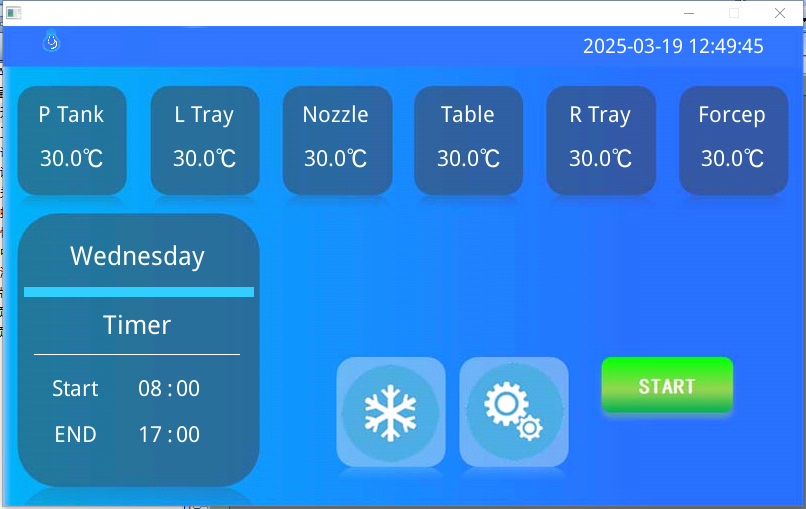

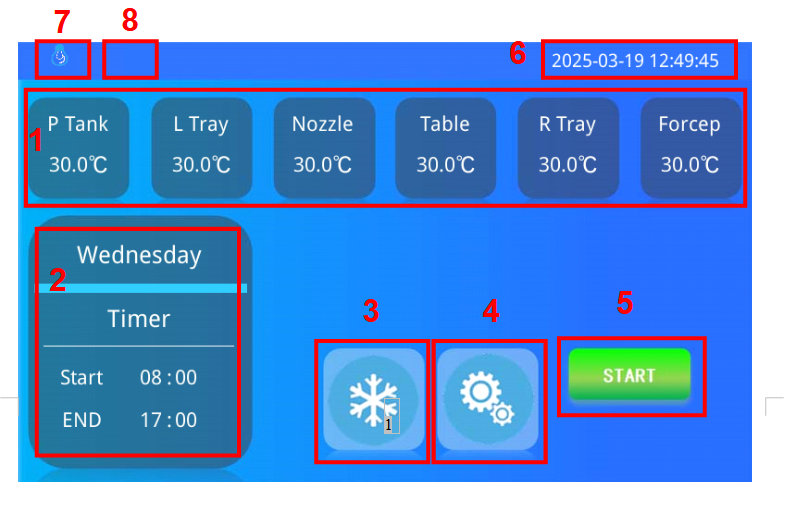

1. Power on: Connect the power supply, press the instrument switch to the "|" state, and the embedding machine system will display the company logo animation when turned on;2. After waiting for the self-test to complete, enter work interface as shown in.

Figure 3

Boot interface diagram

The work interface can realize system startup, small cold table startup, temperature display in various functional areas, access to temperature curve window, access to settings window, display and setting of lighting status, wax removal status, time, and daily power on/off time; Each functional block is shown in Figure 4.

| 1 | Temperature display in each district Click to enter the temperature curve display area | 5 | Turn on heating After opening, it turns red |

| 2 | Automatic power on/off time of the day | 6 | Date and time display Long press to set date and time |

| 3 | Cooling point activated | 7 | Lighting indicator on |

| 4 | Enter Settings | 8 | Wax release switch on indicator |

Table 2

Figure 4

Indicator diagram of each area on the work interface

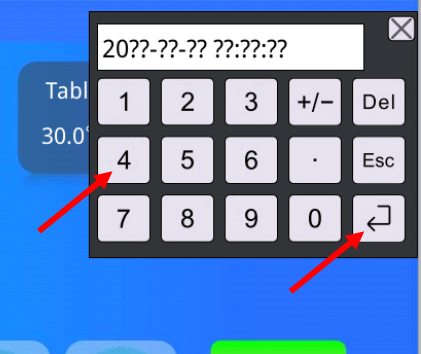

3. Setting of 3 times: Press and hold the time display area for 3 seconds to set the time. Enter the year, month, day, hour, minute, and second in sequence, and press Enter to complete. The display interface is shown in Figure 5

Figure 5

Time Setting Interface

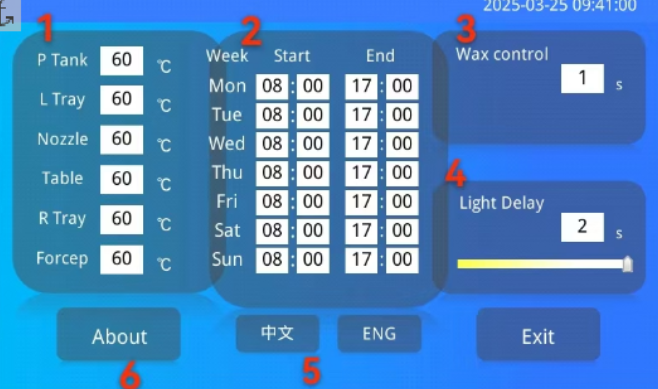

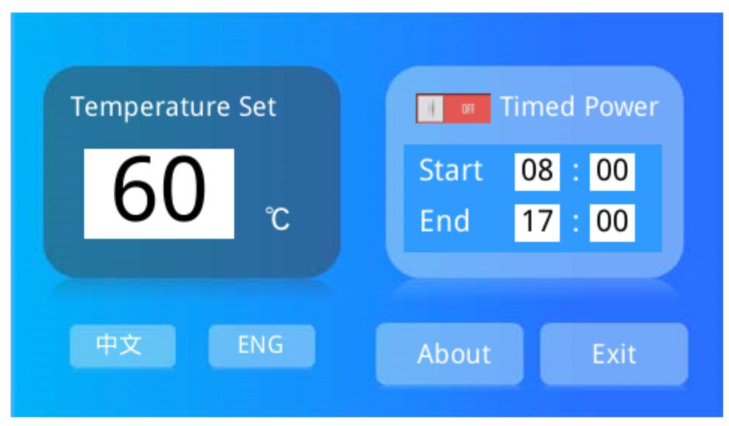

4. Settings. Click on the settings icon to enter the settings interface, which is divided into 5 areas: 1. temperature setting, 2. 7*24-hour timer, 3. wax output control, 4. lighting delay, 5. Chinese and English, and 6. About. The settings interface is shown in Figure 6

Figure 6

4.1 Temperature settings, click on the numeric area behind each functional area and enter the temperature you need;

NOTE:

NOTE:To ensure complete melting of paraffin, the temperature of the wax cylinder should be 5-10 ℃ higher than the melting point temperature of paraffin.

4.2 7*24 hours refers to the time setting for turning on and off within a week. When the time setting is the same, it means that automatic operation will not be turned on for that day;

4.3 Wax dispensing control: When the wax dispensing time of a single press of the wax dispensing switch is set to 0, it indicates the jog mode (wax dispensing when pressed and closing when released);

4.4 Lighting Delay: Similar to the basic function of wax dispensing control, when set to 0, it indicates jog mode; The adjustment board can be used to adjust the brightness;

4.5 Switching between Chinese and English: The five-star red flag is in Chinese, and the rice flag is in English;

4.6 About: Click this button to enter the About interface (as shown in Figure 4-5), where you can view manufacturer information, product information, and other content;

4.7 After setting, press the exit button to return to the work interface;

5. Running

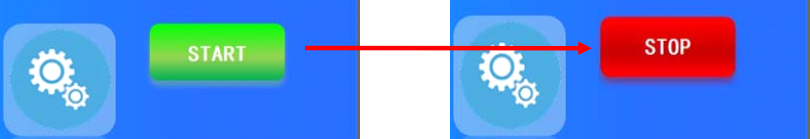

5.1 Click the green START button, and the green "START" button will turn into a red "STOP" button. The system will automatically run according to the temperature set by the parameters;

Figure 7

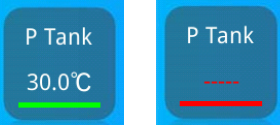

5.1.1 In the heating process, a green line will appear below each functional module, and the length of the line represents the current heating power, as shown in the left figure below;

5.1.2 When the line below turns red and the temperature display changes to "----", it indicates that the temperature sensor in that area is incorrect and needs to be checked, as shown in the figure on the right below;

Figure 8

NOTE:

NOTE:When a sensor error occurs, please try turning off the power first and then restarting the device. After restarting the device, the temperature display will be normal and it can operate normally; This state is mainly caused by line interference, please check the grounding wire;

After restarting the device, it still shows abnormalities. Please check if the temperature sensor and corresponding circuit plug are secure.

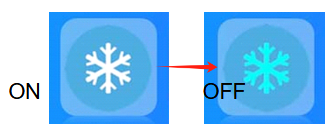

5.2 Click the cooling point button to activate the cooling point.

Figure 9

NOTE:

NOTE:During the heating process, the temperature display area of the wax cylinder will show intelligent wax melting. After all the wax melting is completed, the temperature of the wax cylinder will be displayed in this area;

The time for complete wax melting may vary depending on the amount of wax

added to the wax cylinder and the ambient temperature. Generally, the wax melting time takes more than 90 minutes;

Before the wax melting is completed (temperature is not displayed), in order to prevent errors from occurring, the wax dispensing switch will not be able to be turned on;

Click on the temperature display area to display the heating temperature curve, and click again to return to the work interface;

6. Cold and hot tables: The operation of the cryo and thermo console is basically the same as that of the main console, and the working interface is shown in Figure 11;

Figure 10

Working interface of cryo and thermo console

6.1 Click the "START" button to start running;

6.2 Click the settings button to enter the settings interface, as shown in Figure 12.

Figure 11

Working interface of cryo and thermo console

6.3 The cryo and thermo console setting interface is divided into temperature setting, Chinese and English, and timed power on/ off

6.3.1 Click on the number to enter the desired temperature;

6.3.2 The “中文” is in Chinese, and the “English” is in English;

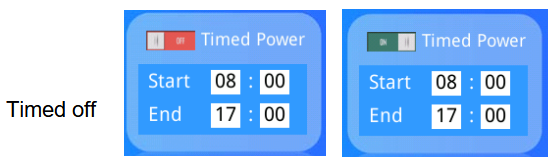

6.3.3 Timing power on/ off: Enter the corresponding time and turn on the timing power on/ off button above to achieve the same automatic power on/ off function as the main console;

Figure 12

7. Embedment

NOTE:

NOTE:Before embedding, please ensure that all the paraffin in the wax cylinder has melted.

7.1 Place the processed tissue box in the storage box, ensuring that the melted paraffin covers the entire part of the tissue box;

7.2 Remove the clean embedding mold and place it on the workbench. Use a foot pedal or manual switch to inject an appropriate amount of paraffin wax;

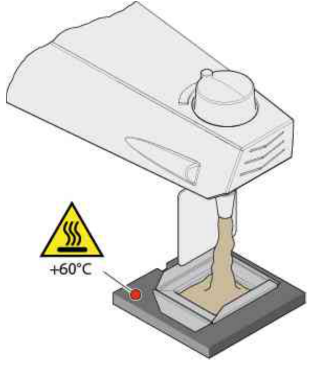

Figure 13

NOTE:

NOTE:Do not let a shell form on the surface of the embedded mold, otherwise it may cause paraffin splitting during the preparation of the microscopic section.

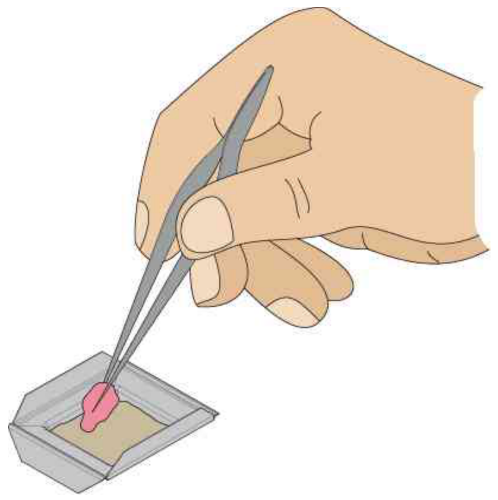

7.3 The sample is removed from the tissue cassette using tweezers and then fixed in the embedded mold as required;

Figure 14

NOTE:

NOTE:• Extra care needs to be taken when handling samples to prevent them from dripping onto the work area.

• Dripping samples may result in cross-contamination of tissues. If transferring tissue diskette to a work surface, make sure to clean it before proceeding.

• If you want to retrieve a new dripped sample from the workspace, take care to ensure that the sample is not damaged.

• Ensure that the tip of the tweezers is kept clean to avoid cross-contamination of the sample.

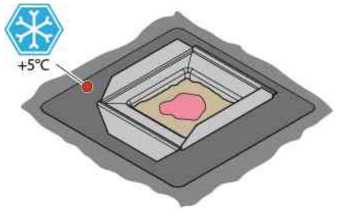

7.4 Move the embedding mold to the cold table, and wait until the paraffin becomes transparent;

Figure 15

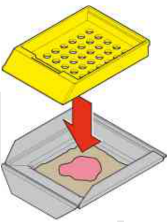

7.5 Move the embedding mold back to the workbench and place the tissue cassette on the embedding mold.

Figure 16

7.6 Fill the tissue cassette with paraffin wax.

Figure 17

NOTE:

NOTE:Use the paraffin flow adjustment knob to adjust the paraffin flow rate to the appropriate setting.

Incorrect flow settings may result in ineffective paraffin formation and/or problems in orienting the sample.

7.7 Transfer the embedding mold and tissue cassette to the cold stage for rapid cooling;

Figure 18

NOTE:

NOTE:It should be placed on the cryo console for more than 1 hour to ensure that the paraffin is completely fixed. Excessive cooling time may cause small cracks in the paraffin shape at the bottom of the investment mold.

7.8 After being completely cooled and fixed, the tissue cassette can be removed from the embedding mold to prepare for slicing;

Figure 19

7.9 Embedding complete

9. Common faults and troubleshooting methods (for reference only)

| Fault phenomenon | Fault cause | Elimination method |

| Unable to boot | Power supply no input | Check the external power supply or replace the power cable |

| The fuse is blown out | Change the fuse | |

| unheated | The temperature setting is too low | Set the temperature to the desired temperature; |

| The work switch is not turned on | Turn ON [ON/OFF] heating switch | |

| No wax | The wax tip temperature does not reach the set value | Wait for the wax tip temperature to reach the set temperature |

| The traffic switch is not turned on | Turn the flow switch counterclockwise | |

| Temperature display ER | Temperature sensor off | Check whether the temperature sensor falls off |

| Temperature sensor failure | Replace the temperature sensor |

Table 3

10. Maintenance and cleaning

WARNING

WARNING• Turn off the instrument and unplug it before each cleaning.

• When handling cleaning materials, comply with the manufacturer's safety regulations and current laboratory regulations in your country.

• During cleaning, no liquid should penetrate into the instrument!

• In order to prevent scratching the surface of the instrument, metal tools with sharp edges should not be used under any circumstances.

Working surface:

• Common laboratory cleaning products suitable for paraffin removal (e.g., PolyGuard or xylene substitutes) are available for cleaning work areas.

• Use dry dust-free paper to clean condensation on the instrument.

Instruments and external surfaces:

• If necessary, clean the outer surface of the spray paint with a mild household cleaner or soapy water and wipe it with a damp cloth.

• Avoid organic solvents from touching the surface of the instrument for a long time. Do not use xylene, acetone or alcohol on painted surfaces!

In order to ensure long-term reliable operation of the instrument, please comply with the following points:

• The instrument should be cleaned carefully after each use.

• Use a brush or vacuum cleaner to regularly remove dust from the ventilation slot behind the instrument.

11. Taboos and precautions

WARNING

WARNING• Must have a good grounding socket before switching on the power.

• This instrument is used for histological and pathological sections only, not for other purposes.

• The back of the instrument should be about 15cm away from the wall to maintain good heat dissipation, otherwise it will affect the life of the instrument.

1. After the instrument arrives, unpack the box to check the appearance and accept the accessories. Please read the instruction manual carefully before starting operation. The operator must hold the operating certificate.

2. In order to ensure personal and equipment safety, the machine must use three-wire power supply, and ensure that the instrument is reliably grounded. Do not use a power supply without ground cables or grounding cables.

3. In order to prevent the heater temperature is too high, the internal installation of overheating protection temperature relay. If the heater temperature is too high, when the dangerous temperature exceeds 95℃, the temperature relay will automatically cut off the heating power supply. When the temperature is lower than this, the heating will automatically resume. Once you find that the temperature protection is out of control, please cut off the power immediately!

4. When the paraffin is not melted, you can not use manual or foot switches to prevent wax leakage.

5. After the work, please unplug the power plug, do a good job of cleaning and maintenance.

12. Packing list

| No. | Name | Quantity |

| 1 | Main console, Cryo console, Thermal console | 1 set |

| 2 | Storage tank | 2 |

| 3 | Lid of storage tank | 2 |

| 4 | Power cord | 1 |

| 5 | Fuse wire | 1 |

| 6 | Foot switch | 1 |

| 7 | Magnifier | 1 |

| 8 | User Manual | 1 |

Table 4

13. Warranty and maintenance

Under the condition that the user complies with the rules of use, the factory or a legitimate dealer is responsible for the warranty within one year from the sale. The maintenance of this product requires a certain professional knowledge, please do not repair yourself. Please inform the factory as soon as possible for products that have exceeded the warranty period. Our factory will carry out maintenance in time according to the regulations.14. Transportation and storage

1. Transportation: The packaged products can be used in various modes of transportation under the condition of avoiding direct rain and snow.2. Storage: After the product packaging, it can be stored for half a year under the condition of 0-40 ℃, no acid, no alkali and no corrosive gas.

15. Scrapping and disposal

CAUTION

CAUTIONInstruments or instrument components must be disposed of in accordance with applicable local regulations in force. All contaminated objects must be immediately disinfected with an appropriate disinfectant to prevent spread to other areas of the laboratory or to laboratory staff.

Instruments can become contaminated when using biohazardous samples. Thorough disinfection (e.g. multiple cleaning steps, disinfection or sterilization) is required before reuse or disposal. Dispose of instruments according to applicable laboratory specifications.

Instrument components, such as computers, monitors, etc. that are marked with the symbol of a dustbin with a fork are governed by EU Directive 2002/96/EC of the European Parliament and of the Council (27 January 2003) on Waste Electrical and Electronic Products (WEEE).

These objects must be disposed of at the collection point in accordance with local regulations.

2023.9.8 Version V1.0

2024.2.22 Version V1.1 Add installation precautions

2025.3.19 Version V1.2 Touch screen version