Rotary Microtome BHTP-203

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Microtome cuts embedded tissues into thin slices for applications in histology or pathology. Depending upon the type of specimen and desired thickness it uses blades of diamond, steel or glass for further analysis by light microscopy or transmitted electron microscopy (TEM).

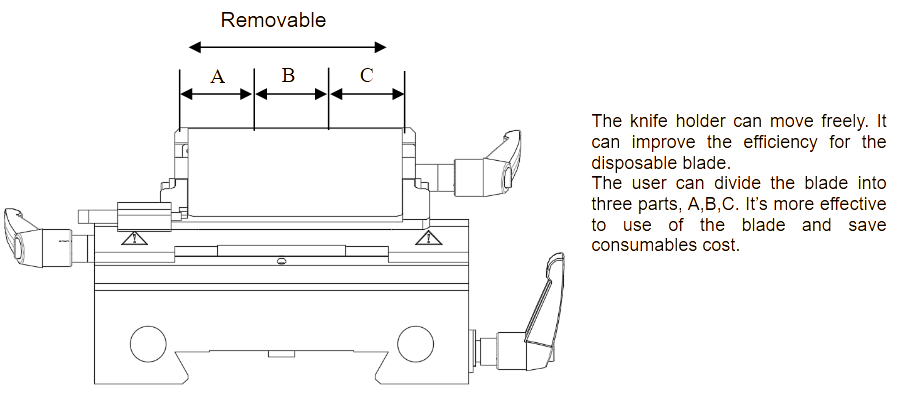

- It have clipper –built case , the user can put blade , wax block ,or other consumable one the top of case. It do not need to lubricate and maintain the microtome frequently. The handwheel in the right can be locked in any position, and the handle can be locked in highest

- position, it is double safe for changing blade or tissue block. The specimen Orienting system axes X and Y 8°, axis 180°. It adopt the special blade holder , it is more safe and convenient to use the disposable blade

- Directly. It also can to longer the user life of disposable blade.

Specification

Features

Applications

| Slice thickness range | 0 μm~60 μm |

| Section thickness setting | 20-60 um in 5 um – increments |

| Horizontal specimen stroke | 20 mm |

| Vertical specimen stroke | 50 mm |

| Slip precision | ± 5 % |

| Maximal slice section | 50×45 mm |

| Specimen adjustment direction | Horizontal 8°, Vertical 8°, Rotating 360° |

| Movement range of blade holder base | Front and Back ± 25 mm, Left and Right ± 25 mm |

| Blade holder angle | 0~10 ° |

- It have clipper –built case , the user can put blade , wax block ,or other consumable one the top of case. It do not need to lubricate and maintain the microtome frequently. The handwheel in the right can be locked in any position, and the handle can be locked in highest

- position, it is double safe for changing blade or tissue block. The specimen Orienting system axes X and Y 8°, axis 180°. It adopt the special blade holder , it is more safe and convenient to use the disposable blade

- Directly. It also can to longer the user life of disposable blade.

Histopathology, Traditional Histology Technique, Cryosectioning Technique, Microscopy

Operating Manual for BHTP-203

1. Information

1.1 Symbol and Meaning

1.2 Instrument Use

2. Instrument Components and Specifications

2.1 Basic Information

2.2 General overview:

3. Technical Parameters

4. Installation

5. Operation

6. Parts adjustment

6.1 Specimen holder and orientation system

6.3 Knife holder

7. Normal Troubles Solving Methods

8. Cleaning and Maintenance.

8.1 Cleaning up the instruments

9.Storage and transportation

10. Notices

11.Packing list

1. Information

1.1 Symbol and Meaning

Danger:

Danger:Indicating an urgent dangerous situation that, if not avoided, will result in death or serious injury.

Warning:

Warning:If you do not avoid this danger, it may result in death or serious injury.

Caution:

Caution:Indicating a potentially hazardous situation that, if not avoided, may result in death or serious injury.

Note:

Note:Indicating information that is not related to risk but is very important. Follow this User Manual.

Note that see the User Manual for relevant warning information.

Note that see the User Manual for relevant warning information. IVD medical device

IVD medical device Waste electrical and electronic equipment should be collected separately.

Waste electrical and electronic equipment should be collected separately. Power on

Power on  Power off

Power off Biohazard warning (black line on yellow background)

Biohazard warning (black line on yellow background) Sign indicator of using flammable solvents and reagents (black line on yellow background)

Sign indicator of using flammable solvents and reagents (black line on yellow background) This warning symbol indicates the instrument surface that will be hot during operation.

This warning symbol indicates the instrument surface that will be hot during operation. Avoid direct contact to prevent burns.

Avoid direct contact to prevent burns. Environmental protection sign of RoHS Directive. The figure in the symbol refers to the product’s number of years of “environment-friendly use” . Use this symbol if the use of a restricted substance exceeds the maximum allowable limit.

Environmental protection sign of RoHS Directive. The figure in the symbol refers to the product’s number of years of “environment-friendly use” . Use this symbol if the use of a restricted substance exceeds the maximum allowable limit. Serial number

Serial number Manufacturing date

Manufacturing date Manufacturer

Manufacturer No stacking

No stacking Limited height of 2 floors (accessory cases only)

Limited height of 2 floors (accessory cases only) Indicating the correct vertical position of the packing container.

Indicating the correct vertical position of the packing container. Goods are fragile and must be handled with care.

Goods are fragile and must be handled with care. The package must be stored in a dry environment.

The package must be stored in a dry environment. Recycle in accordance with local laws and regulations.

Recycle in accordance with local laws and regulations. It meets the requirements of EU Directive 98/79/EC for IVD medical devices. Item

It meets the requirements of EU Directive 98/79/EC for IVD medical devices. Item indication number in the illustration.

indication number in the illustration.1.2 Instrument Use

- The user should read this user manual carefully before installation and operating the machine.- Check your power socket is well grounded.

- Blade is sharp, beware when you change it.

- Do not place blade anywhere with the cutting edge facing upwards.

- Before changing specimens always lock the hand wheel and cover the knife edge with the knife guard.

- Do not put instrument under extreme temperature and high air humidity environment. Failure to follow this will cause instrument severe damage.

- Please keep instrument far away from fire.

- In case of malfunction, contact our company. Don’t try to solve it by your own risk.

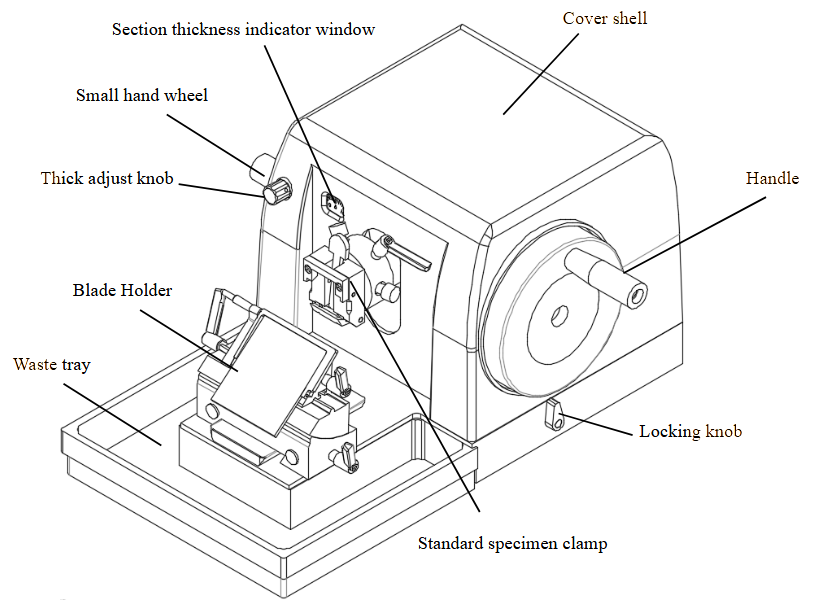

2. Instrument Components and Specifications

2.1 Basic Information

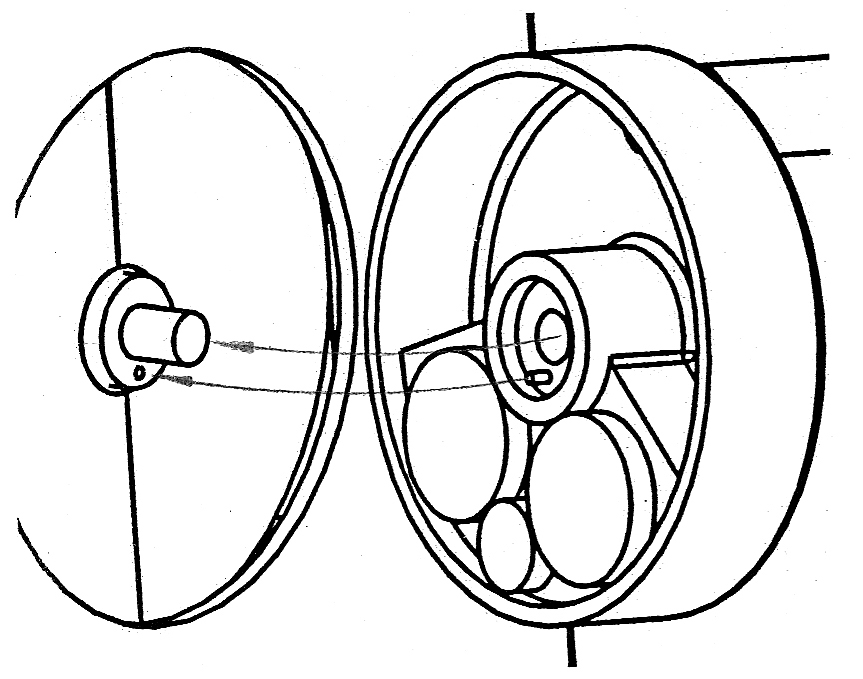

Model BHTP-203 is a manually operated microtome by wheel-turning. The guiding-lines for the vertical and horizontal movement of the specimens are seamless and free from maintenance. Specimen is fed by the turning the handwheel. And all the parts of the instrument are covered into the encloser. The handwheel can be smoothly turned for slice cutting. Selection of the slice thickness can be adjusted by a knob.All the above-mentioned appurtenances and other parts ordered will be packed into the wooden crate for the instrument.

Please check when unpacking the crate. Contact immediately with our company or the seller if any error found.

2.2 General overview:

3. Technical Parameters

3.1 Slice thickness range: 0μm~60μm3.2 Section thickness setting : 0-2 um in 0.5 um –increments

a) 2-10um in 1 um-increments

b) 10-20 um in 2 um-increments

c) 20-60um in 5 um-increments

3.3 Horizontal specimen stroke :20 mm

3.4 Vertical specimen stroke : 50mm

3.5 Slip precision: ± 5%

3.6 Maximal slice section: 50 × 45mm

3.7 Specimen adjustment direction: horizontal 8°, vertical 8°, rotating 360°

3.8 Movement range of blade holder base: front and back ±25mm, left and right ±25mm

3.9 Blade holder angle 0~10°

4. Installation

4.1 This instrument is a movable desk top type which can be placed on the experiment stable working table to prevent it receiving quakes from the ground, and don’t install other vibrating equipments round it.4.2 Place the instrument with appropriate space around it to ventilate and smoothly rotate the handle.

4.3 After confirming power with grounding wire (three holes socket), connect the instrument and power socket by attaching wires. Turn on the switch on the back of instrument and it is under state of working.

4.4 This instrument uses single-phase voltage 220V±10% and 50Hz AC power supply. If does not meet requirement, it needs to externally connect AC voltage stabilizer.

4.5 The instrument should be used at ambient temperature +10℃~+40℃.

4.6 Environmental relative humidity shall not be more than 80%.

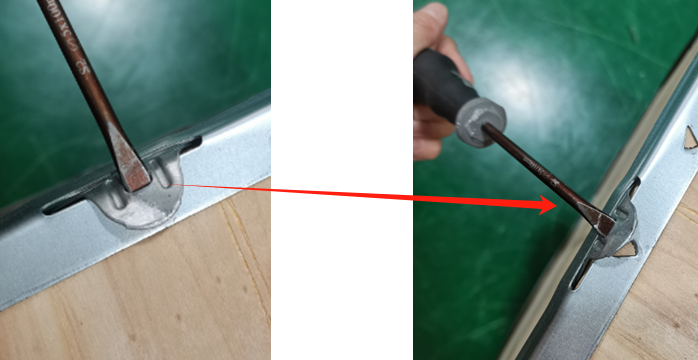

4.7 Unpacking

4.7.1 Please check if there are any damages, water immersion, or other phenomena that may cause equipment damage in the packaging box, Check if the arrow on the box is facing upwards,

Please prepare a flat screwdriver for unboxing;

4.7.2 Please use a "straight" screwdriver to open the buckle of the outer box

4.7.3 Remove the cover plate

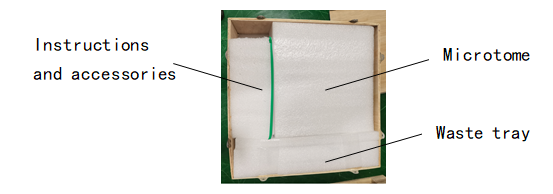

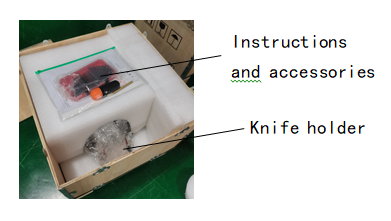

4.7.4 Remove the internal filling material

4.7.5 Remove the machine according to the diagram below

When moving the instrument, do not exert force on the cover, knife holder, and wax block pliers. It is better to support the base area.

When moving the instrument, do not exert force on the cover, knife holder, and wax block pliers. It is better to support the base area.4.8 Installing the instrument:

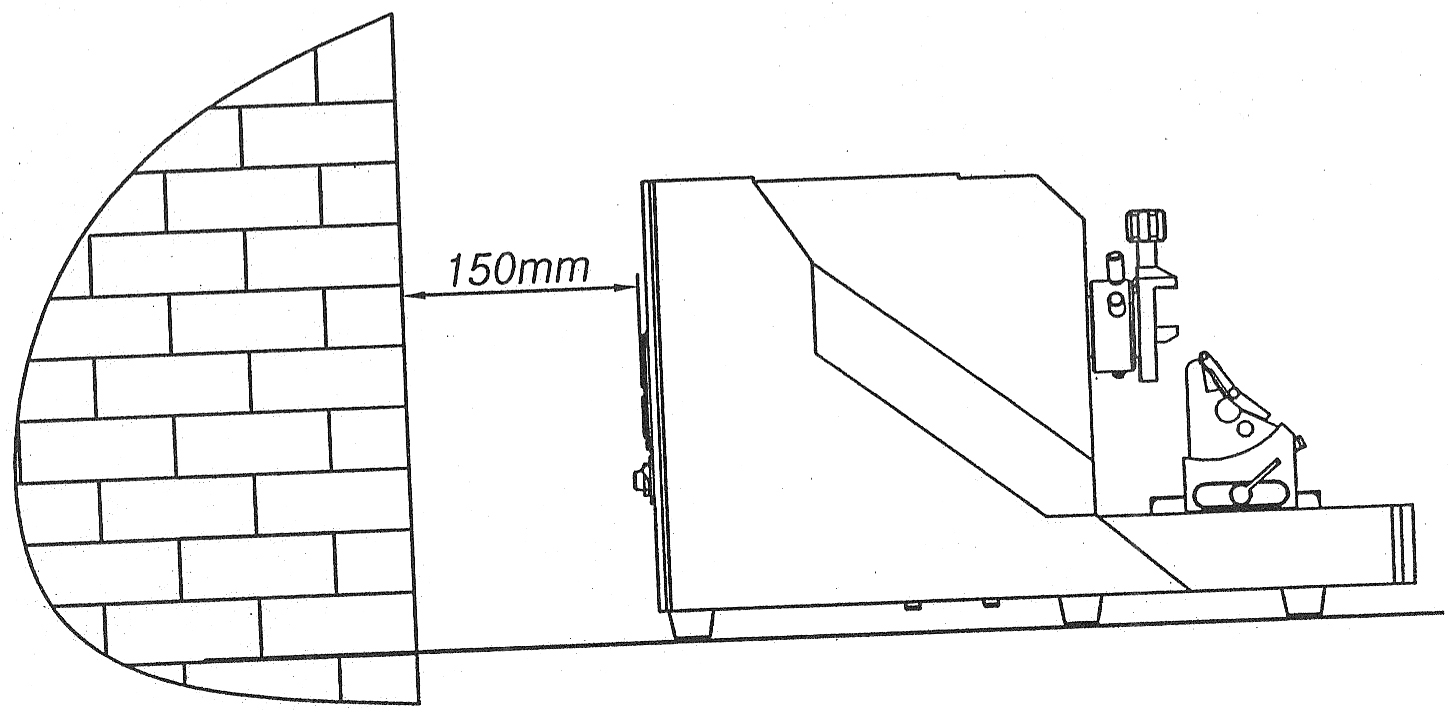

Place the instrument on a stable laboratory table, with back away from the wall about 150mm.

4.9 Site requirement:

The installation site must meet the following requirements:

-Stable, vibration-free laboratory table

-Vibration-free floor

-room temperature always between+10℃~+40℃.

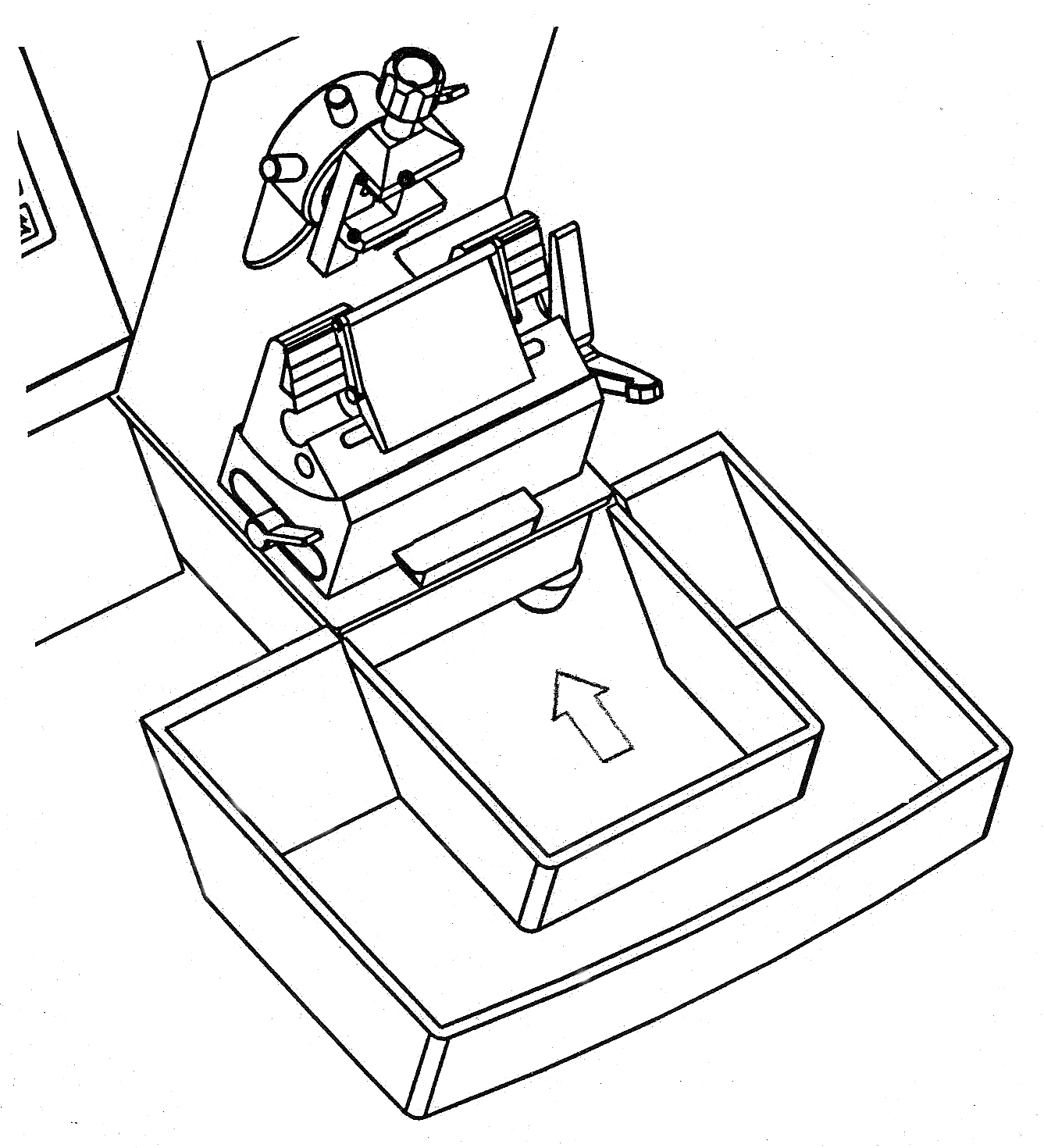

Section waste tray:

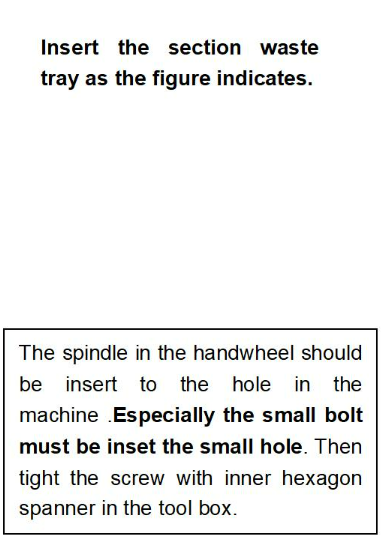

4.10 Installment of the hand wheel

4.10 Installment of the hand wheelMake sure the axis of hand wheel is in the axis hole of the hand wheel . then fix the screw with the inner hexagon spanner .

4.11 Safety instruction for operating the instrument:

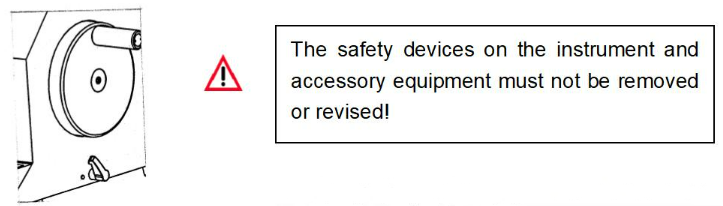

4.11 Safety instruction for operating the instrument:Safety devices

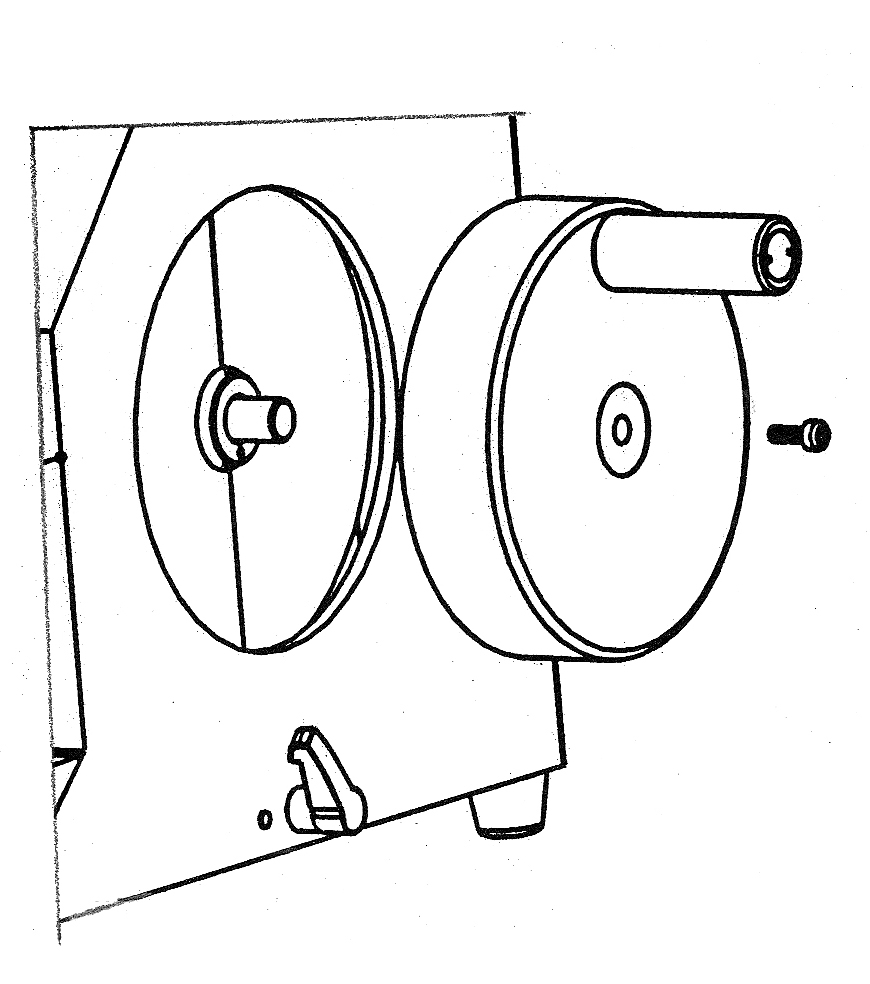

The handwheel can be locked in any direction with the locking spanner . The locking spanner can be set on the locked or released position on the right side of the base.

Inspection:Push the locking spanner backside until the handwheel be locked and can’t rotate.

Release action:Push the locking spanner to the front side, and the handwheel can rotate again.

5. Operation

Instruction to the procedure of paraffin slice-cuttingAttention:Be sure to lock the handwheel and cover the edge of the blade with the blade protecting fitting in the course of operating of the blade and specimen or before changing the specimen.

5.1 Lock the handwheel

Attention:Firmly clamp the specimen before installing the blade.

Put the pre-frozen paraffin onto the specimen clamp.

Be sure to be careful enough to avoid misoperation which will cause serious hurt in the course of using the blade and disposable blade, because the edge of the blade is very sharp.

Be sure to be careful enough to avoid misoperation which will cause serious hurt in the course of using the blade and disposable blade, because the edge of the blade is very sharp.5.2 Turn the handwheel to move the specimen to the backward utmost position.

5.3 Insert the blade into the blade holder and firmly clamp it.

5.4 Adjust the cutting angle (try once from 0°to 3°)

5.5 Try to move the blade holder approaching the specimen.

5.6 Adjust the surface position of the specimen to make it parallel to the edge of the blade.

5.7 Loosen the handwheel.

Be sure to turn the handwheel evenly in the course of the slice-cutting. The harder, the slower.5.8 Turn the handwheel to start the slice-trimming for the ideal surface of the specimen.5.9 Select the ideal thickness of the slice or take the former ones as reference.5.10 Evenly turn the handwheel clockwise to cut slice.5.11 Change the specimen or stop the operation.

Be sure to turn the handwheel evenly in the course of the slice-cutting. The harder, the slower.5.8 Turn the handwheel to start the slice-trimming for the ideal surface of the specimen.5.9 Select the ideal thickness of the slice or take the former ones as reference.5.10 Evenly turn the handwheel clockwise to cut slice.5.11 Change the specimen or stop the operation.  Be sure to lock the handwheel and cover the edge of the blade with the blade protecting fitting in the course of operating of the blade and specimen or before changing the specimen or during the break.5.12 Lock the handwheel.5.13 Cover the edge of the blade with the blade protecting fitting.5.14 Take out the specimen from the specimen-clamp for another operation.

Be sure to lock the handwheel and cover the edge of the blade with the blade protecting fitting in the course of operating of the blade and specimen or before changing the specimen or during the break.5.12 Lock the handwheel.5.13 Cover the edge of the blade with the blade protecting fitting.5.14 Take out the specimen from the specimen-clamp for another operation.End the operation

● Lock the handwheel.

● Take out the blade from the holder and put it into the blade-case.

● Take out the specimen from the specimen-clamp.

● Scrub away the wastes and clean up the instrument.

specimen tissue and fix it.

6. Parts adjustment

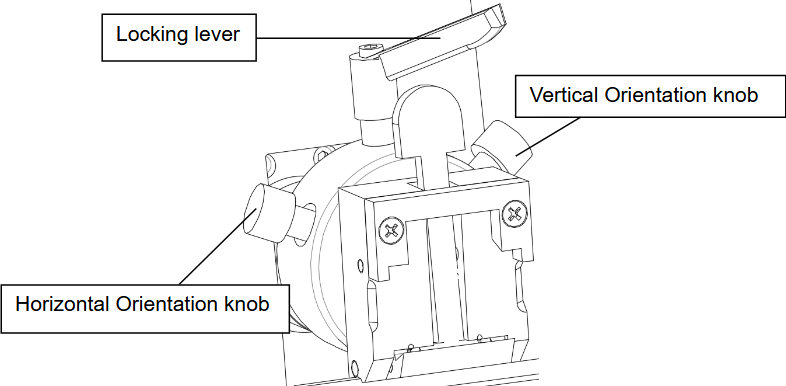

6.1 Specimen holder and orientation system

- Turning the locking lever to set the specimen holder to the adjustable release condition and section lock status.

- Turning the two orientation knobs under release condition make specimen holder clamp plane defluxion by pass horizontal axis and vertical axis for ensuring required tangent plane location to decide the required plane cutting location.

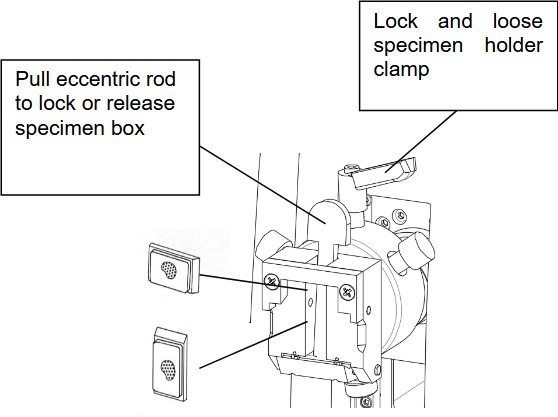

- Turning the adjustable lever to lock and loose specimen holder clamp

6.2 Box shaped specimen clamp.

- Turning the spanner on the specimen clamp can make the jaw in the state of braced and locked.

- The specimen can be put in or take off in the state of braced.

- Specimen box may be placed horizontally or vertically.

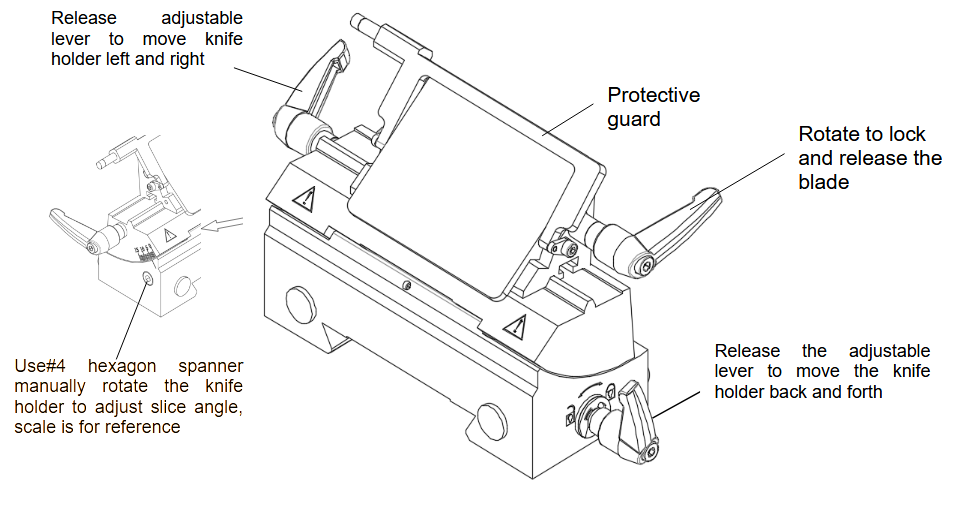

6.3 Knife holder

- To turn the adjustable lever under knife holder to release and lock knife holder base.

- In release conditions you can make the knife holder base do the back and forth movement by hand to choose latched position needed. There is a scale under knife holder for reference by location.

- Use hexagon spanner to turn the eccentric rod in the hole on the left side of the knife holder to release and lock the rotator of the knife holder.

- In release condition you can move the rotator by hand to choose locked cutting angle needed. There is a scale on the right side for reference by location.

- Turn adjustable lever on the rotator to release and lock knife clamp.

- In release condition you can make the knife clamp do the left-and-right movement by hand to choose latched position needed.

- Turn adjustable lever on the knife clamp to release and lock knife flat. Protective guard Release adjustable lever to move knife holder left and right Rotate to lock and release the blade Use#4 hexagon spanner manually rotate the knife holder to adjust slice angle, scale is for reference Release the adjustable lever to move the knife holder back and forth

- You can put in or take off the knife in release conditions. Take off the knife after finish the work.

- The protecting plate shall be on the installed position when the knife is on the knife clamp.

7. Normal Troubles Solving Methods

There are normal problems in the following table which are likely to happen when the instrument is used. Besides, there are some possible causes that lead to these problems happened and solving methods.| Trouble | Reason | Solving Methods |

| Uneven slices produced and sometimes no slice can be cut | Inappropriate angle of the blade, the angle of cutting is too small Not firmly locked the specimen clamp or/and the blade holder. Blunt of the blade | Adjust the angle of cutting until the appropriate angle acquired. Check and firmly locked the screw of the specimen locking and the blade holder. Use the other section of the blade or change for a new one. |

| Slices are compressed or corrugated or extruded | Blunt of the blade. The specimen is too hot. The angle of cutting is too big. The cutting is too fast. | Use the other section of the blade or change for a new one. Freeze the specimen on the freezing platform. Adjust the cutting angle. Turn the handwheel slowly. |

| When cutting hard specimen, the blade holders nicks or vibrant marks are left on the slice | The cutting is too fast. The angle of cutting is too big. Not firmly locked the specimen clamp or/and the blade holder. | Turn the handwheel slowly. Adjust the cutting angle. Check and firmly locked the screw of the specimen locking and the blade holder or the locking handle. |

8. Cleaning and Maintenance.

8.1 Cleaning up the instruments

8.1.1 Conduct the following steps before cleaning each time:- Turn up the specimen grip to the top and lock the hand wheel.

- Release the specimen grip and pull it out.

- Pick off the knife from the knife holder and put it back to the knife box.

- Dismount the knife holder and its seat to clean up.

- Take down the specimen from the specimen nip. Clear away the section waste with dry brush.

- Take down the specimen grip to clear up separately.

8.1.2 Instruments and external surface:

If necessary, the external painted surface can be cleaned with light-duty commercial housework cleaner or suds. And then use wet cloth rub it until dry.

You may use the substitute of xylene, paraffin oil, paraffin scavenger to erase residual.

The instruments must be dry when use again.

8.1.3 Knife holder

Please according to following steps to clean up the knife holder if it had been dismounted.

- Downwardly turn over the cutting edge cover sheet.

- Turn the eccentric rod handle in the lateral of the body of revolution and draw it out from sideward.

- Push the knife clamp back which have knife clip and shift it out from the rotary unit.

- Turn the eccentric rod handle in the lateral of the knife clap and draw it out from sideward.

- Dismount the knife clamp.

- Clean up all parts of the knife holder.

Don’t use xylene or alcoholic liquid (e.g.: glass cleaner) when clean up paraffin.

Don’t use xylene or alcoholic liquid (e.g.: glass cleaner) when clean up paraffin.- Make the knife holder dry and assemble it together.

- Apply to thin layer of lubrication after clean up the parts which had been taken off.

- When fix the knife clip, make sure that its upper part is parallel with the back edge of the knife

clamp seat.

8.1.4 Box shaped specimen grip

- Dismount the box shaped specimen grip to clear away the residual paraffin.

- Don’t use xylene or alcoholic liquid to clean up. Use the substitute of xylene or paraffin scavenger.

- You can put the box shaped specimen grip into oven to heat it to 65℃ until lipid paraffin bleeding off.

- Wipe off paraffin with dry cloth.

- Apply oil to the axis grasping joystick after using oven heating method.

8.2 Lubricate instruments.

Do oil lubrication for the following parts monthly. (1~2 drop is well enough Instruments and specimen holder)

- Grip draw in the clamp.

- Lock in iron at the “T” knife clap back of the microtome bedplate.

- The knife holder slide way on the microtome bedplate.

Knife holder

- Lock in iron at the “T” body of the rotary units on the knife clamp seat.

- The knife control grip is shift to the eccentric rod handle.

- The iron locking head on the knife clamp of the ”T” body of rotary unit and the knife holder with slide way.

- The grasping joystick of the knife.

Box shaped specimen grip

- The bearing of the grasping joystick.

9.Storage and transportation

9.1 Storage: After packaging, the product can be stored for half a year under the temperature of 0-40℃, no acid, no alkali and no corrosion gas.9.2 Transportation: The packaged products can be applied to various modes of transportation under the condition of avoiding direct rain and snow.

10. Notices

- Must grasp the specimen before positioning the knife. During the operation locking hand wheel and cover the knife edge with its cover sheet.l Be most careful when you take the section knife. It is possible to lead to bad hurt because of the sharp cutting edge.

- You should turn the hand wheel with the same speed during the cutting process. The hand wheel turning speed must suit with the hardness of the specimen. Harder specimen use slow speed.

- Locking hand wheel and covering the knife edge with its cover sheet when changing specimen piece.

- The instrument should be positioned on the experiment work table level and stable. Preventing it from quake from the ground, and don’t put other equipments which may produce vibration near the instrument.

- Holding the fore and end trough of the back when moving it and don’t hold the other parts like hand wheel handle.

- Periodically cleaning the instrument.

- Locking the hand wheel before cleaning.

- Don’t use acetone or xylene liquid to clean up the instrument.

- Make sure that no paraffin comes into the inside of machine during the cleaning.

- Please follow the safety warnings of the manufacture when using cleaning solvent.

- Put the hand wheel on the locking position when turn down the instrument.

- Electronic parts be repaired by professionals and other people do not touch them.

11.Packing list

| order number | name | quantity |

| 1 | Main unit | 1 |

| 2 | Blade holder | 1 |

| 3 | Power supply cord | 1 |

| 4 | Brush | 1 |

| 5 | User's manual | 1 |

| 6 | Inner hexagon spanner | 1 |