Fungal Growth Incubator BIFG-101

- Sea, Air, Door to Door Shipping

- 1 Year Warranty

- US & European Standards

Designed for energy saving and environmental protection, it has a unique air duct design for temperature uniformity that supports wide range of applications.

- Programmable microcomputer based PID controller

- LCD display

- Unique air duct circulation system ensures temperature uniformity

- Mirror finished stainless steel inner chamber

Specification

Features

Applications

| Capacity | 100 L |

| Temperature Range | 0-60°C |

| Temperature Accuracy | ±1°C |

| Temperature Fluctuation | ±1°C |

| Temperature Uniformity | ±0.1°C |

| Temperature Resolution | 0.1°C |

| Humidity Range | 50-90 %RH |

| Humidity Fluctuation | ±5% |

| Interior volume (cu ft) | 3.5 cubic feet |

| Timer Range | 0-999 min |

| Internal Dimension | 580Wx450Dx380H mm |

| Exterior Dimension | 1100Wx590Dx620H mm |

| Package Size | 1220x670x700 mm |

| Shelves | 2 |

| Weight | 93/100 kg |

| Power | 400 W |

| Power Supply | 220V, 60Hz |

- Programmable microcomputer based PID controller

- LCD display

- Unique air duct circulation system ensures temperature uniformity

- Mirror finished stainless steel inner chamber

- Double door with magnetically sealed outer door

- Inner chamber equipped with a lightning device for easier observation

- Large capacity humidifier enables automatic water intake function

- UV sterilization lamp ensures bacteria-free working chamber

- Built-in socket and adjustable shelf

- Touch-button operation with timer function

- Fluorine-free R134a refrigerant

- Equipped with compressor providing stable and long lasting operation

- Balanced refrigeration, low temperature fluctuation, auto-defrost function

- Multiple safety function, delay protection function

- Over-temperature alarm function

Temperature dependent incubations, Enzymatic reactions, Reagent Storage. Programmable controls, Refrigeration

Operating Manual for BIFG-101

1. Application

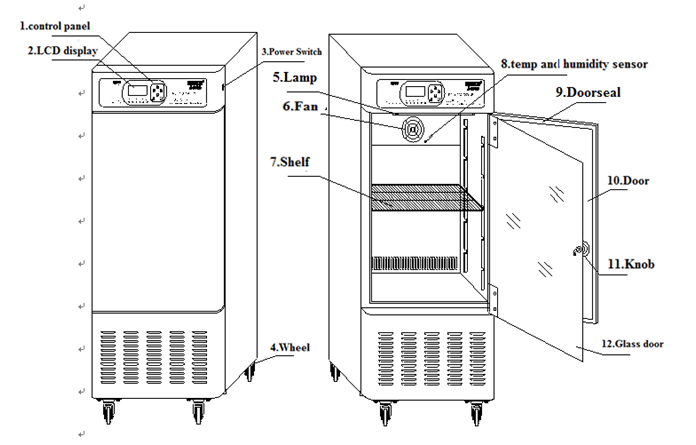

2. Product Drawing

3. Structure

4. Working principle

5. Run Preparation

6. Technical Parameters

7. Equipment installation

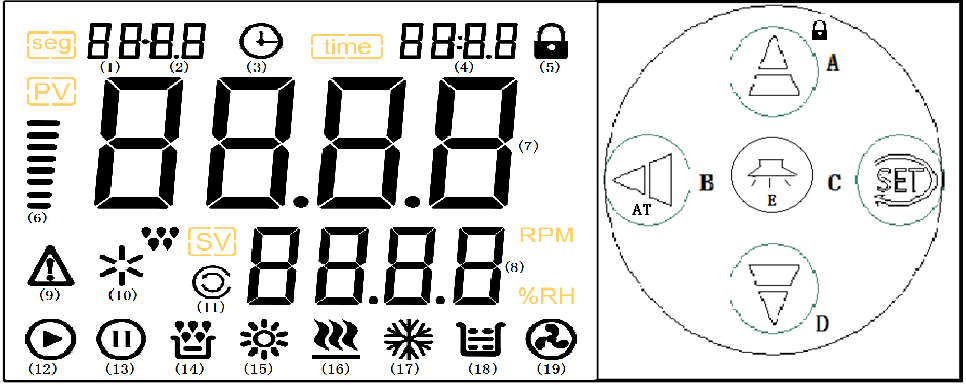

8. Control panel

9. Operation method

9.1. Notice and Maintenance

9.2 Optional Using

9.3 Trouble shooting

10. Wiring layout

1. Application

Fungal Growth Incubator BIFG-101 is a high precision constant temperature equipment with hot and cold control function, can be used for plant cultivation, breeding experiment, bacteria, mold, microbial cultivation and preservation, water analysis in determining BOD test. Is the ideal test equipment for biological engineering, medical, health institution ,drug testing, animal husbandry, fishery and other scientific research units.2. Product Drawing

3. Structure

The machine body is made of high quality sheet processing, surface coating is firm and looks beautiful. built-in interior door glass Windows, and with the lighting in the cabinet, make the test items at a glance. Inner is stainless steel material , match the activity shelf, inside cabinet the temperature uniformity is good, the machine is durable and easily to clean.Temperature control part adopts new intelligent digital display temperature control instrument with single-chip microcomputer technology, users can according to different requirements, by manipulating the touch control panel keys and set temperature, humidity, time for adjustment to reach the purpose of the test.

In both Chinese and English display optional, interface clear, humanized operation.

4. Working principle

Constant temperature and humidity incubator is working by feeling the actual temperature and humidity, then transfer into electrical signals through temperature and humidity sensor , heater or refrigeration compressor working under the microcomputer control ,so as to achieve the required temperature; control the humidifier to reach the humidity as required.5. Run Preparation

Before the first operation of this machine, please do according to the following procedure:1. Remove the shelf and other accessories inside equipment

2. Use alcohol soaked sponge to wipe disinfection cabinet wall, then using a dry gauze with alcohol wipe to clean

3. Put the shelf according to the experimental requirements inside equipment.

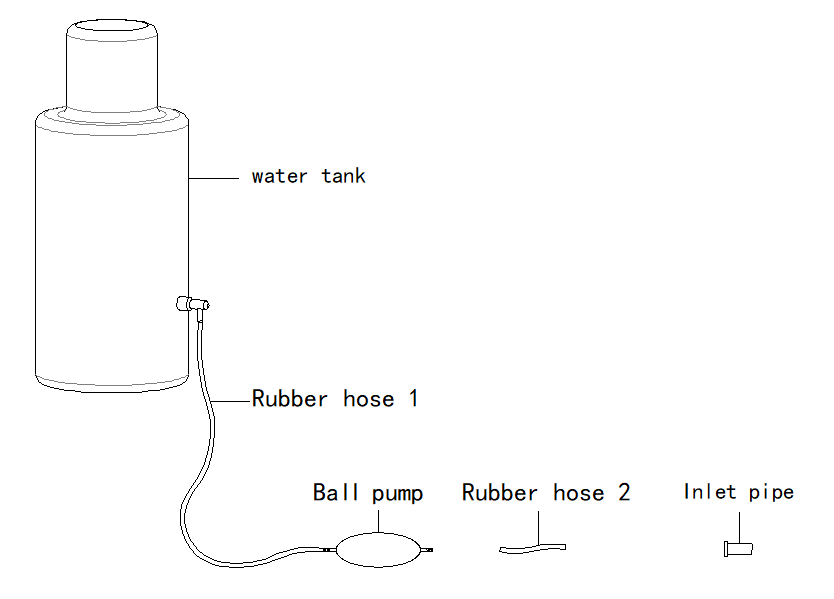

4. Before using ,water tank should be placed on the top of the equipment, then insert pipe to back water inlet and weir (refer to the parts diagram), and placed water basin for use under the overflow pipe outlet.

5. Give enough water into the water tank.

6. Before the equipment is energized, the air in the rubber tube should be discharged first. The steps are as follows: Connect the water tank with the rubber tube 1, the ball pump and the rubber tube 2, and unscrew the water supply switch of the water tank. At this time, the air and water in the pipe will flow out together. If not, squeeze the ball pump until the air and water in the pipe flow out smoothly, and the other port of the rubber tube 2 can be connected to the water inlet interface of the equipment. Note: If the air is not effectively discharged, water may not enter the tank, resulting in abnormal humidification.

6. Technical Parameters

1. Temp. Range:0~65℃;(with humidity 10~50℃)2. Temp. accuracy:±0.1℃;

3. Temp. Fluctuation:±0.5℃(10℃~40℃);

4. Temp. Uniformity:±0.5℃(10℃~40℃);

5. Humidity range:40-95%RH(10℃~40℃);

6. Humidity fluctuation:±3%;

7. Voltage: Single phase 220V/50HZ

8. Power:900W(100L) 1150W(150L) 1350W(250L);

9. Working environment:ambient temperature 10~30℃ humidity below 70%

10.Timer Range: 0-9999 min

11. Refrigeration fluid:R290;

12. Device Class:Class I.

13. Note: this machine has low temperature automation function, temperature and humidity in low temperature automatic defrost there will be some fluctuation is a normal phenomenon.

7. Equipment installation

1. The device should be installed in the ventilated dry room to avoid direct sunlight, and equipment must have at least 10 cm distance to the wall.2. At the bottom of the box is equipped with universal wheel, please lock the front two brake pedal when moving to make the machine place smoothly.

3. This equipment use 220V / 50 hz ac power supply, power supply circuit must be reliable grounding line, ensure use safety.

8. Control panel

Description:

(1) Number of cycles: show the number of cycles when it is a program segment; (2) Number of program segments: Show the number of segments when in program mode;(3) Appointment time indicator light: the appointment is on when the appointment is turned on; (4) Time: Program segment time or fixed timing time;(5) Key lock;(6) Temperature prompt;(7) Measure temperature;(8) Set the temperature;(9) Alarm indicator light: flashing when it is shut down or abnormal; (10) Standby;(11) Standby light;(12) Fan operation indicator light: On when it is started;(13) Stop indicator light: on when shutting down;(14) standby;(15) ultraviolet or lighting indicator light: always on for lighting, flashing for ultraviolet disinfection; (16) heating indicator light: on when there is heating;(17) the refrigeration indicator light is on when there is refrigeration output, and the refrigeration delay flashes;(18) standby;(19) Fan indicator light: turn on when the fan is output;℃Symbol: When the temperature unit is Celsius℃Bright,℉Symbol: Fahrenheit℉Bright; Button instruction

A: Add key ∧ to modify the parameter value; (Long press 2S to modify the existing running time, with the program has this function), tap to lock the screen, and then tap to unlock.

B: Shift key: Shift the parameter value. Hold down to start/stop temperature self-tuning, and tap to query the ambient temperature.

C: SET key: Enter parameter setting or hold down for more than 2 seconds to enter LK or exit parameter setting.

D: decrease key ∨ : Change parameter value, long press 2S to enter manual ultraviolet disinfection and then press to stop disinfection.

E: Lighting key: point according to the clear output. Humidity self-setting: Press the SET C:SET key + B: shift key at the same time. 5 seconds later, the %RH symbol flashes to enter the humidity self-setting.

9. Operation method

Five.Internal parameters Set Operate1. User parameter setting: In the standard state, long press the SET key to display LK on the LCD screen, adjust LK=8, and press the SET key to enter the parameter setting.

| Character | Name | Set the range | Instructions | Initial value |

| KS | Power-on operation selection | 0~2 | 0: Stop when the power is on 1: Run from the first stage when the power is on; 2: Start from the place where the last power was cut off after the power is on. | 0 |

| Md | Program control selection | 0~1 | 0: Fixed value control;1:99Segment program control(Only multisegment program control has a second parameter) | 0 |

| Tn | Time-counting method | 0~1 | 0-Start running the timer, 1-Temperature stable timer (only fixed value) | 1 |

| Hn | Time-based unit | 0~1 | 0-minute, 1-hour | 0 |

| Fn | High and low fan switching | 0~100 | (Set value+Fn)~(Set value-Fn)When the temperature is betweenStart upLow-speed fan;(Set value+Fn)~(Set value-Fn)Go toExteriorAt the temperatureHigh start-upSpeed fan | 0 |

| Ly | Lighting delay | 0~9999Minute | When the lamp is turned on and the delay time is not 0, it will turn off automatically. "When the delay time is 0", the delay is invalid, you must manually turn off the lamp. | 0/M |

| Srt | Disinfection delay | 0~9999Minute | When the disinfection lamp is turned on, the delay time is not 0, and the lamp is automatically turned off when the time is up. "When the delay time is 0", the delay is invalid, you must manually turn off the lamp.. | 0/M |

| Mon | Appointment start-up time setting/appointment start-up month setting | 0~9999 | Function 1; No Beijing time meter mon minutes after automatic boot; Function 2; Instrument with Beijing time, when Beijing time arrives here set time (day,Hr,mTn) after the boot, Mon greater than 12 with the same function. | 0 |

2. Temperature control parameter setting: in the standard state, long press the SET key, the LCD screen will display LK, adjust LK=3, tap the SET key to enter the parameter setting.

| Character | Name | Set the range | Instructions | Initial value |

| AL | Lower deviation alarm setting value | -50.0~Ten0.0℃ | 0, noneCall the police to call the police 1,ForLower deviation alarm, when the temperature is less than (temperature set value-AL)℃Turn off the refrigeration. The abnormal indicator light is on and the buzzer rings. | 6.0℃ |

| AH | UpDeviation alarm setting value | -50.0~Ten0.0℃ | UpDeviation alarm, when the temperature exceeds (temperature set value + AL)℃Turn off the heating. When the temperature is less than (temperature set value-AL)℃Turn off the refrigeration. The abnormal indicator light is on and the buzzer rings. | 6.0℃ |

| AP | Allow equipmentThe highest temperatureProtect | Maximum measured temperature | When the temperature exceeds the AP, cut off the heating. When the temperature exceeds the AP parameter for 2 minutes, the buzzer keeps calling and turns off all outputs. The power must be cut off before it can be restored. | 120.0℃ |

| Parking lot | Heating ratio belt | 1.0~60.0℃ | The proportional effect is adjusted. The smaller the Pu, the faster the response speed. | 6.5℃ |

| I | Heating integral time | 1~3600 seconds | Integral action time constant, the smaller the Iu, the stronger the ability to correct the static difference. | 240 |

| Dimension | Heating differential time | 0~3600Small size | Differential action time constant, the larger the du, the stronger the ability to prevent overtemperature. | 180 |

| AR | Heating and over-rushing inhibition | 0~100% | It is used to suppress excessive temperature. | 80% |

| T | Heating control cycle | 1~99 seconds | Control the heating output cycle | 5Second |

| Tc | Start-stop mode controlScope | 0~10 | Start-stop mode temperature controlScope | 1 |

| Computed tomography | Compressor protection delay | (0~3600) seconds | Compressor delay protection time, two-time start time≥CT seconds | 120 seconds |

| Pb | Zero adjustment of temperature | (-199~999) | Set the upper limit of measurement temperature | 0 |

| Player kill | Fullness adjustment of temperature (Slope) | (-199~2000) | When the temperature deviates near the set temperature, the value can be adjusted.Pk=4000×[Mercury reading value - current measurement value]÷Current measured values | 0 |

| Cb | Ambient temperature correction | -60.0~100.0 | Cb= Actual ambient temperature - currently measured ambient temperature | 0 |

| Rl | Setting the lower temperature limit | -60.0~100.0 | Set the lower limit of measurement temperature | -40.0 |

| Rh | Temperature upper limit setting | -60.0~100.0 | Set the upper limit of measurement temperature | 100.0 |

3. Humidity control parameter setting: In the standard state, long press the SET key, the LCD screen will display LK, adjust LK=5, tap the SET key to enter the parameter setting.

| Character | Name | Set the range | Instructions | Initial value |

| bH | Lower deviation alarm setting value | -50.0~Ten0.0℃ | 0 no alarm is alarm 1 is the lower deviation alarm, when the temperature is less than (temperature set value -AL) ℃, turn off the refrigeration. The abnormal indicator is on and the buzzer sounds. | 15.0℃ |

| HP | Humidification ratio strip | 1.0~60.0℃ | The proportional effect is adjusted. The smaller the Pu, the faster the response speed. | 10.0℃ |

| HI | Humidification integration time | 1~3600 seconds | Integral action time constant, the smaller the Iu, the stronger the ability to correct the static difference. | 240 |

| HD | Humidification differential time | 0~3600Small size | Differential action time constant, the larger the du, the stronger the ability to prevent over temperature. | 180 |

| AR | Humidification overshoot suppression | 0~100% | It is used to suppress excessive temperature. | 80% |

| HT | Humidification control period | 1~99 seconds | Control the heating output cycle | 5Second |

| KT | Start-stop mode control range | 0~10 | Start-stop mode temperature control Scope | 1 |

| HC | Compressor protection delay | (0~3600) seconds | Compressor delay protection time, two-time start time≥CT seconds | 120 seconds |

| HB | Zero humidity adjustment | (-199~999) | Set the upper limit of measurement temperature | 0 |

| HK | Humidity full degree adjustment (Slope) | (-199~2000) | Near the set temperature, when the temperature is deviated, the value Pk=1000 can be adjusted.×[Mercury reading value - current measurement value]÷Current measured values | 0 |

| HL | Humidity lower limit setting | -60.0~100.0 | Set the lower limit of measurement temperature | -40.0 |

| HH | Upper humidity setting | -60.0~100.0 | Set the upper limit of measurement temperature | 100.0 |

4. Temperature refrigeration control parameter setting: in the standard state, long press the SET key, then the LCD screen will display LK, adjust LK12, click the SET key to enter the parameter setting.

| Character | Name | Set the range | Say | Initial value |

| TM | Refrigeration selection | 0~1 | 0: refrigeration start-stop type; 1: refrigeration balanced type. The program control is generally set to 1. 0: Turn off the temperature control after the program 1: Continue the constant temperature after the program, and turn it into no-time fixed value control. | 0 |

| Co | Refrigeration balanced selection | 0~1 | 0: cooling start-stop type; 1: The compressor is normally open; 2: Do not start the compressor; 3: Open when the temperature and humidity set values are less than or equal to the temperature (tnc) and humidity (Hnc) values respectively; Start and stop the compressor when it is greater than; | 0 |

| CF | Choice of Fahrenheit | 0~1 | 0: Celsius 1: Fahrenheit | 0 |

| Dr | Gate control input selection | 0~2 | 0: No door-controlled input; 1: External input closes the door 2: External input disconnects to open the door | 0 |

| Dp | Temperature decimal point selection | 0~1 | 0: No decimal point 1: With a decimal point | 0 |

| WT | Water level | 0~1 | 0-no water level, 1-water level closure is effective, 2-water level disconnection is effective | 0 |

| Tnc | Refrigeration temperature | 0~100.0 | Refer to CO=3Model | 40 |

| HNCentigrade | dehumidification | 0~100.0 | Refer to CO=3Model | 10 |

| FLT | Temperature filter coefficient | 0~20 | Temperature filter coefficient | 1 |

| FLH | Humidity filtering coefficient | 0-50 | Humidity filtering coefficient | 20 |

| A0t | Water refill timeout | 0-9999 seconds | Forcibly turn off the water refill output when the water refill duration is greater than the Aot value | 600Second |

| Adt | Water refill delay | 0-9999 seconds | After filling up the water, + delay time to turn off the water supply output | 0 seconds |

| Cm | Two Compressor mode | 1-9999Hour | CM=0 is the defrosting mode; When CM=1, it is fixed for compressor 1. When CM=2, it is fixed to work for compressor 2; Compressor continuous working time CM≧3 hours, automatically switch to another compressor, switch to each other | Hour |

| HF | Pre-start time for switchover of two compressors | 0-9999 seconds | In the dual-compressor mode, when the first compressor time is about to end, the second compressor starts in advance. | Second |

| HD | Frosting time | 0-300Second | Defrosting time interval, start defrosting output Hd seconds, stop defrosting | 3Second |

| Sd | Refrigerate Type | 0~1 | 0: automatic cooling mode; 1: Manual cooling mode. | 0 |

| CL | CloseRefrigerate | (-10.0~10.0) ℃ | When switching mode, measuring temperature < (set temperature +CL) off refrigeration. | 0 |

| CH | Close Refrigerate | (-10.0~10.0) ℃ | When switching mode, measuring temperature < (set temperature +CH) off refrigeration | 0 |

| HL | Close dehumidification | (-20~20) %RH | When switching mode, measurement: humidity < (set temperature +CL) off refrigeration | 0 |

| HH | Open dehumidification | (-20~20) %RH | When switching mode, measure humidity < (set temperature +CH) off cooling. | 0 |

| Ht | Defrosting time interval | 0-9999Minute | After the controller runs Ht for a few minutes, the frost begins to defrost. Set to 0, no defrosting function | 0 minutes |

4.1 Print control parameter setting: in the standard state, long press the SET key, the LCD screen will display LK, adjust LK=16, click the SET key to enter the parameter setting.

| Ut | Usb flash drive storage interval | 0~9999Minute | Set the interval between the storage time of the U disk (how long to print once); Set 0 to not print. | 0 |

| Pt | Print time interval | 0~9999Minute | Set the printing interval (how often to store once); Set 0 to not store. | 0/M |

| Pn | Printer timing unit | 0~9999 | 0-1: minutes;2:Hour | 1/M |

| Ud | Keep back | |||

| Ptn | Printing Type of machine | 0~1 | 0: RongZhong printer;1: WeihuangPrinter | 1 |

| PtL | Printing Type | 0~1 | 0:Digital printing;1:Curve printing | 0 |

| Pts | Whether to print Settings | 0~1 | 0: No Print the set value;1:Print settings | 0 |

| FO | Printer paper width setting | 0-1 | Set up Paper width | Keep back |

| Yr | A particular year | 0~9999 | Year setting | 0 |

| Mon | Month | 0~9999 | Month setting | 0 |

| Day | Date | 0~9999 | Date setting | 0 |

| Hr | Hour | 0~9999 | Hour setting | 0 |

| mIn | Minute | 0~9999 | Minute setting | 0 |

| On | Update the settings | 0~1 | 0 do not update settings; 1 update settings | 0 |

5. Communication parameter setting: In the standard state, long press the SET key, the LCD screen will display LK, adjust LK=36, click the SET key to enter the parameter setting.

| dId | Equipment Number | 0~9999 | Equipment Number | 0 |

| ADn | Mailing address | 0~99 | Mailing address | 3 |

| BA | Potter filter | 0~5 | 0: 1200;1:2400;2:4800;3:9600; 4:19200;5:38400 | 3 |

| FO | Communication format | 0~2 | 0: No verification;1: Check of singularity;2: even-parity; | 0 |

Note: The value of the internal parameter table has been adjusted and confirmed by the factory, and the user does not need to adjust it by himself.

9.1. Notice and Maintenance

Avoid putting down the Constant temperature and humidity incubator in greater than 45 degrees or inversion when moving it .

Avoid putting down the Constant temperature and humidity incubator in greater than 45 degrees or inversion when moving it .  Do not change frequently of the use value, to cause compressor frequently open and overload , affect the service life of the equipment。

Do not change frequently of the use value, to cause compressor frequently open and overload , affect the service life of the equipment。 the machine have the power switch, in case of failure operation, please cut off power supply, check whether the control circuit is in good condition, then check the other parts.(see diagram)

the machine have the power switch, in case of failure operation, please cut off power supply, check whether the control circuit is in good condition, then check the other parts.(see diagram) Be sure to close the inner door , and then the outdoor .If the inner door didn’t close well, even if close the outdoor, the device may not be able to maximum work., please be careful not to overexert cause damage door gasket When closing.

Be sure to close the inner door , and then the outdoor .If the inner door didn’t close well, even if close the outdoor, the device may not be able to maximum work., please be careful not to overexert cause damage door gasket When closing. Recommend to use the pure water or distilled water to fill in the tank , ensure water is clean.

Recommend to use the pure water or distilled water to fill in the tank , ensure water is clean. In order to maintain the appearance of the equipment, do not use corrosive solution to clean the machine, can use dry cloth or alcohol to wipe, keep box clean.

In order to maintain the appearance of the equipment, do not use corrosive solution to clean the machine, can use dry cloth or alcohol to wipe, keep box clean. should keep in dry, and cut off power supply when the equipment is not using.

should keep in dry, and cut off power supply when the equipment is not using. In order to ensure the cabinet uniformity inside , should often check whether the axial flow fan is running normally .When doing the experiment, should not put too close article to stop the fan outlet, make sure the air circulation in the box is in good condition. Do not touch the thermal probe in the collision to cause temperature abuse

In order to ensure the cabinet uniformity inside , should often check whether the axial flow fan is running normally .When doing the experiment, should not put too close article to stop the fan outlet, make sure the air circulation in the box is in good condition. Do not touch the thermal probe in the collision to cause temperature abuse Make sure shelf is fixed well, otherwise may make cultures damage

Make sure shelf is fixed well, otherwise may make cultures damage Don not lean against the glass or put pressure on the glass, it may cause harm to personnel

Don not lean against the glass or put pressure on the glass, it may cause harm to personnel Staff do not leak again the equipment on the door, to prevent the equipment overturned or door broken making people harm or machine broken. - When equipment fails to work, please ask professional technician or the factory sales department for help. Please don’t do anything by yourself.

Staff do not leak again the equipment on the door, to prevent the equipment overturned or door broken making people harm or machine broken. - When equipment fails to work, please ask professional technician or the factory sales department for help. Please don’t do anything by yourself.9.2 Optional Using

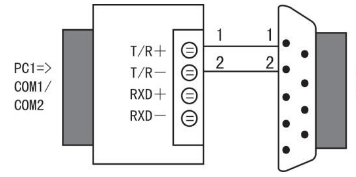

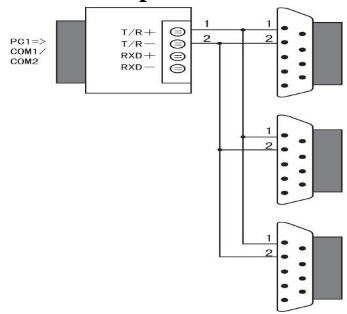

RS-232/RS-485 instructions for use of the converter.- In order to proceed with data communication between the different standard serial interface to the computer, an external device or smart instrument, must provide conversion of standard serial interface. The converter is compatible with RS-232, RS-485 standard, capable of converting single-ended RS-232 signal to a balanced differential RS-485 signals.

- RS-485 point-to-point/two-wire half-duplex

- RS-485 point-to-multipoint/two-wire half-duplex

9.3 Trouble shooting

- Data communication failure

(1)Check if RS-232 port inside connection is correct.

(2)Check if RS-485 port inside connection is correct.

(3)Check if port is connected.

- Data is missing or incorrect

Please check if data communication equipment rate and format is accordance.

(1)Trouble shooting

| Trouble | handling |

| Sensor failure warning | ·Heating sensor abnormal, please check heating sensor (model:PT100) ·Humidity sensor abnormal, please check humidity sensor |

| Temp. can’t reach setting value | ·Please check heating tube |

| Humidity can’t reach setting value | ·Please check water level, water level should cover half of the heating tube. ·Please check humidity heating tube. |

| Screen displays nothing | ·Please check if socket is 220V ·Please check if power is connected ·Please check if power switch, if it is tripping operation, please check wring layout. |

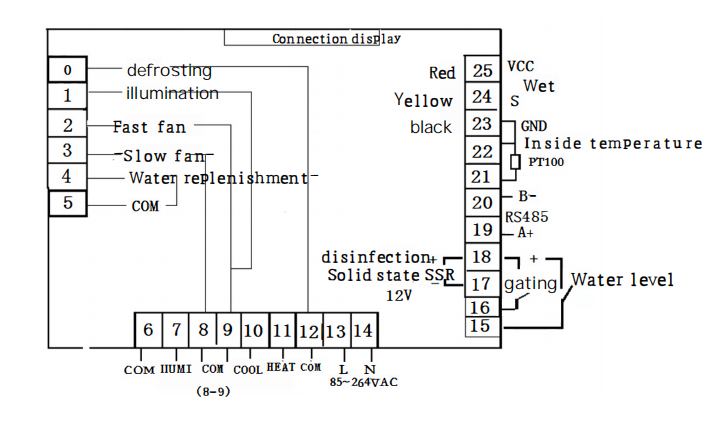

10. Wiring layout

Packing List

| No. | Name | Quantity | Note |

| 1 | product | 1 | |

| 2 | manual | 1 | |

| 3 | shelf | 2(100L) 2(150L) 2(250L) | |

| 4 | Inlet pipe | 1(2.5m) | With a hose hoopφ8-20 |

| 5 | outlet pipe | 1(0.3m) | With a hose hoopφ8-20 |

| 6 | Overflow pipe | 1(0.3m) | With a hose hoopφ8-20 |

| 7 | water tank | 1 |